Top dosing skid supplier Singapore – Best 2025

Introduction: Why Dosing Skids Matter

In industries where precision, reliability, and efficiency are non-negotiable, dosing skids play a pivotal role. A dosing skid system is a modular and integrated unit used to accurately inject chemicals into a process stream. These skids are essential in water treatment, chemical processing, oil & gas, pharmaceuticals, and food & beverage industries.

In Singapore, where industries demand world-class equipment and turnkey solutions, selecting the top dosing skid supplier Singapore is a strategic decision. It impacts operational safety, chemical usage, regulatory compliance, and ultimately, the bottom line.

If you’re searching for the top dosing skid supplier Singapore, you’re already aware of the importance of high-precision chemical dosing equipment. This article explores the comprehensive features, advantages, design considerations, and why selecting the top dosing skid supplier Singapore is vital for long-term industrial success.

What Is a Dosing Skid?

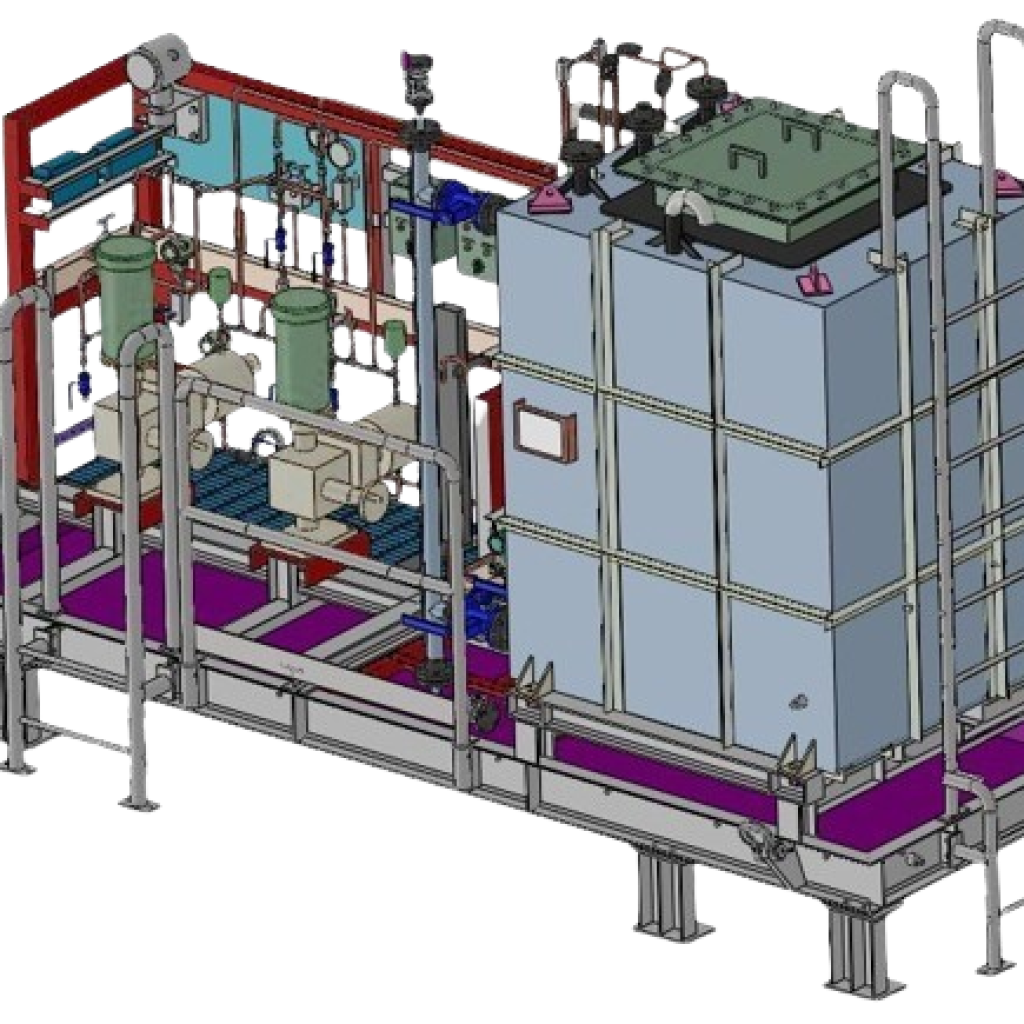

A dosing skid is a pre-engineered and fabricated modular system that includes:

- Dosing pumps (diaphragm or plunger)

- Chemical storage tanks

- Calibration columns

- Piping and valves

- Instrumentation (flow meters, pressure gauges, transmitters)

- Electrical panels and control systems

These are designed, tested, and assembled in a controlled environment and then transported to the project site for plug-and-play installation.

As the top dosing skid supplier Singapore, the provider must ensure that the systems are designed according to client-specific chemical dosing applications—whether it’s acid dosing, chlorine injection, or polymer feed.

Industries Served by the Top Dosing Skid Supplier Singapore

The top dosing skid supplier Singapore caters to multiple industrial domains:

- Water & Wastewater Treatment Plants

- Power Generation

- Oil & Gas

- Petrochemical Industries

- Pharmaceuticals

- Semiconductor Manufacturing

- Food & Beverage Industry

Each of these sectors requires custom-engineered solutions. The top dosing skid supplier Singapore must understand these industry-specific challenges and deliver systems that enhance process safety and reduce chemical consumption.

Advantages of Choosing the Top Dosing Skid Supplier Singapore

1. Customization & Engineering Expertise

The top dosing skid supplier Singapore offers full customization based on application parameters like flow rate, pressure, chemical compatibility, and control interface. The design is engineered to meet specific customer needs and regulatory standards.

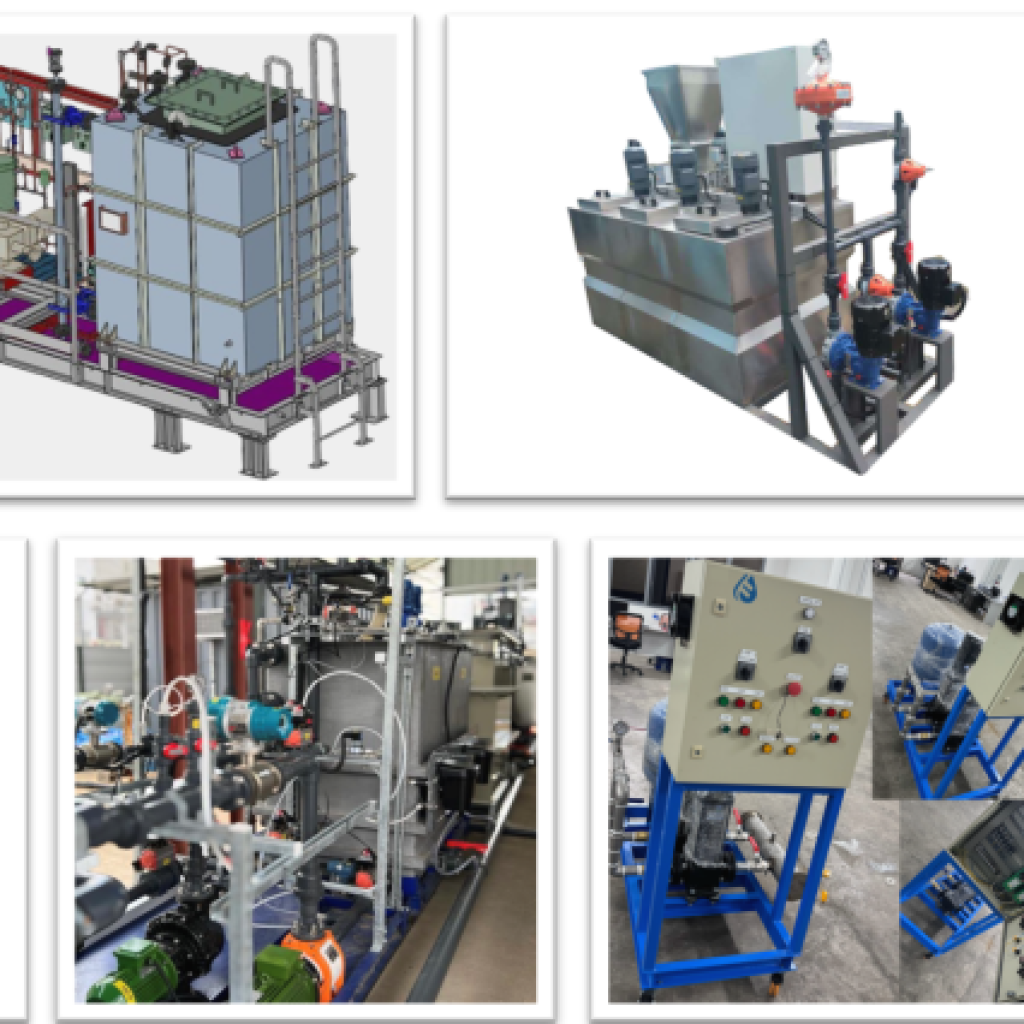

2. Compact and Modular Design

The best suppliers deliver dosing skid systems in compact, space-saving layouts. These modular systems can be rapidly deployed, minimizing site work and civil modifications.

3. Cost Efficiency

When you work with the top dosing skid supplier Singapore, you gain access to prefabricated, pre-tested systems. This reduces installation time and commissioning costs.

4. Reliable, Accurate, and Safe

Accuracy in chemical injection is critical. The top dosing skid supplier Singapore must ensure high repeatability and safe handling, even for corrosive or hazardous chemicals.

5. Easy Maintenance and Integration

Superior design means easier integration into existing process pipelines and DCS/PLC systems. The top dosing skid supplier Singapore delivers systems that simplify maintenance and minimize downtime.

Key Components Provided by the Top Dosing Skid Supplier Singapore

A top-tier dosing skid comprises:

1. Dosing Pumps

The heart of the system, responsible for injecting precise volumes. The top dosing skid supplier Singapore ensures compatibility with chemical properties, required flow rate, and pressure.

2. Chemical Storage Tanks

Built with HDPE, PP, SS316, or lined carbon steel, based on chemical properties. The top dosing skid supplier Singapore selects appropriate materials to prevent degradation.

3. Control Panel (PLC/SCADA Ready)

Smart dosing requires automation. The top dosing skid supplier Singapore delivers skids with intelligent controllers, alarms, interlocks, and HMI screens for full process control.

4. Calibration Columns

Used to calibrate dosing pump flow rates manually. A hallmark of a system from the top dosing skid supplier Singapore.

5. Flowmeters and Level Sensors

Ensures precise flow measurement and tank level monitoring. Accuracy is a key promise of the top dosing skid supplier Singapore.

Design Considerations by the Top Dosing Skid Supplier Singapore

Each dosing skid is engineered with the following criteria:

- Chemical properties (pH, viscosity, reactivity)

- Required dosing flow rate (L/hr or m³/hr)

- Backpressure and suction head

- Ambient and process temperatures

- Electrical classification (ATEX, IECEx if required)

- Integration with PLC or SCADA systems

By understanding and evaluating these parameters, the top dosing skid supplier Singapore delivers tailored solutions that perform reliably in demanding environments.

Applications Delivered by the Top Dosing Skid Supplier Singapore

1. Disinfection Skids

For chlorine, sodium hypochlorite, or ozone dosing in water treatment.

2. Coagulant/Flocculant Dosing

Critical for sedimentation and filtration processes in water plants.

3. pH Adjustment Skids

For acid or alkali dosing systems with automatic feedback loops.

4. Boiler and Cooling Tower Chemical Injection

Dosing of anti-scalants, corrosion inhibitors, and biocides.

5. Oil & Gas Process Additive Injection

Methanol, corrosion inhibitors, and demulsifier dosing.

In all cases, the top dosing skid supplier Singapore ensures quality, safety, and durability.

Compliance and Standards

The top dosing skid supplier Singapore ensures that systems are compliant with:

- ASME, ANSI, and ISO standards

- SS 532: Code of Practice for Storage of Toxic Substances

- PUB water regulations (where applicable)

- ATEX / IECEx zone classifications for hazardous areas

- MOM guidelines for pressure and chemical systems

Working with the top dosing skid supplier Singapore guarantees adherence to local and international compliance standards.

Why Choose the Top Dosing Skid Supplier Singapore for Turnkey Projects

The top dosing skid supplier Singapore offers complete EPC services:

- Engineering design

- Material procurement

- Skid fabrication and assembly

- Instrumentation & electrical installation

- Factory Acceptance Testing (FAT)

- Site installation & commissioning

- Operator training and maintenance support

Turnkey capabilities make the top dosing skid supplier Singapore a one-stop solution provider, reducing vendor complexity for the client.

Quality Assurance from the Top Dosing Skid Supplier Singapore

Every dosing skid undergoes:

- Mechanical Inspection

- Hydrotesting of lines and tanks

- Electrical loop checking

- Functional Testing

- FAT with client inspection

- Pre-dispatch QA documents

The top dosing skid supplier Singapore has a documented QA/QC program to ensure that all skids delivered are error-free and ready for operation.

Digital & Remote Monitoring Capabilities

Modern systems delivered by the top dosing skid supplier Singapore come with IoT features:

- Remote monitoring via web portals

- Real-time data logging

- Alarm notifications (SMS/email)

- Energy consumption tracking

- Predictive maintenance alerts

This is crucial for large-scale infrastructure projects across Singapore, where manned operation may not be feasible at all times.

Maintenance & After-Sales Support

Choosing the top dosing skid supplier ensures access to spare parts, trained engineers, and annual maintenance contracts. These services extend the life and reliability of the system.

Comprehensive lifecycle support is what separates the top dosing skid supplier from ordinary vendors.

How to Identify the Top Dosing Skid Supplier Singapore

Here are essential attributes of the top dosing skid supplier:

- Proven experience in local and regional projects

- Strong in-house engineering & fabrication capabilities

- Ability to handle complex chemical applications

- Fast delivery and customization

- In-house testing and QA procedures

- Local support and rapid response team

These are key indicators of a trustworthy and competent supplier that offers dependable performance for years.

Trust the Top Dosing Skid Supplier for Superior Performance

Chemical dosing systems are the backbone of process control across industries. Choosing the top dosing skid supplier is not just a procurement decision—it’s a long-term investment in safety, accuracy, and reliability.

Whether you’re involved in water treatment, oil & gas, power generation, or food production, you deserve a partner who delivers more than just equipment. The top dosing skid supplier provides complete, integrated, and value-driven solutions customized to your needs.

Let precision dosing become your operational advantage—work with the top dosing skid supplier and ensure your process runs flawlessly.

Smart Automation by the Top Dosing Skid Supplier Singapore

The modern industrial ecosystem in Singapore demands smarter, more connected solutions. The top dosing skid supplier incorporates advanced automation into every system design. From remote SCADA integration to local HMI panels and real-time monitoring, automation plays a crucial role in enhancing reliability and reducing human error.

Advanced features include:

- Auto-dosing based on sensor inputs (pH, conductivity, chlorine, ORP)

- Adaptive flow control via VFDs (Variable Frequency Drives)

- Real-time tank level management

- Integration with plant PLC and BMS systems

Only the top dosing skid supplier ensures your system is Industry 4.0-ready, minimizing risks while maximizing process efficiency.

Material Selection – A Priority for the Top Dosing Skid Supplier Singapore

One of the most critical aspects of chemical dosing system design is material selection. The top dosing skid supplier uses only corrosion-resistant, long-lasting materials to ensure equipment longevity and safety.

Material options offered include:

- HDPE or PP: for non-corrosive or mildly acidic chemicals

- PVC or CPVC: ideal for chlorine and sodium hypochlorite

- SS316 or Duplex SS: used for high-pressure or high-temperature chemical processes

- PTFE lining or PVDF: for highly corrosive or reactive chemical dosing

Each dosing application is different, and the top dosing skid supplier thoroughly analyzes the chemical compatibility before system design. This ensures zero leaks, minimal maintenance, and full compliance with HAZMAT handling standards.

Factory Acceptance Testing (FAT) – A Standard Practice of the Top Dosing Skid Supplier Singapore

Before dispatch, all systems delivered by the top dosing skid supplier undergo rigorous FAT procedures in a dedicated testing environment. Clients are encouraged to witness these tests, which validate:

- Pump flow and pressure calibration

- Electrical and instrumentation loops

- Alarm simulations

- Software functionality

- Panel interlocks and communication signals

- Leak test and hydrostatic test of pipelines and tanks

FAT ensures that the delivered skid operates precisely as per specifications. This significantly reduces commissioning time on-site.

Onsite Installation & Commissioning by the Top Dosing Skid Supplier Singapore

While many vendors ship products and leave clients to manage the installation, the top dosing skid supplier takes full ownership. A skilled team handles:

- Site installation and mechanical tie-ins

- Electrical cabling and interconnection

- Commissioning and site acceptance testing (SAT)

- Operator training and SOP handover

- Post-installation fine-tuning

This end-to-end execution guarantees seamless integration and 100% operational readiness. It’s why customers consistently rank us as the top dosing skid supplier.

Sustainable Chemical Dosing – A Focus Area for the Top Dosing Skid Supplier Singapore

Sustainability is no longer optional. Leading clients seek suppliers who support energy and chemical savings. The top dosing skid supplier integrates sustainable dosing practices into every design:

- Lower energy consumption per liter dosed

- Optimized chemical feed through auto-control

- Reduced chemical wastage

- Use of recyclable materials and efficient VFD-driven pumps

Through sustainable engineering, the top dosing skid supplier not only protects your process but also the environment.

Skid Customization for Hazardous Areas – ATEX & IEC Compliance

Certain chemical applications occur in flammable or explosive atmospheres. The top dosing skid supplier specializes in delivering systems for hazardous zones, fully compliant with:

- ATEX (EU directive for explosive atmospheres)

- IECEx (international equivalent)

- IP65/IP66 rated enclosures

- Explosion-proof motors and instrumentation

- Intrinsically safe control loops

Each component is selected and certified to match the zone classification (Zone 1 or Zone 2), making the top dosing skid supplier a reliable partner in critical environments.

Training & Documentation – Ensuring Safe Operation

A reliable system is only as effective as the team operating it. The top dosing skid supplier offers comprehensive training and documentation packages:

- Equipment operation manuals

- Wiring diagrams and P&IDs

- Maintenance schedules

- Troubleshooting guides

- Safety handling procedures

- Hands-on training during SAT

These resources empower plant teams to operate and maintain the system independently while maximizing performance.

Annual Maintenance Contracts (AMC) by the Top Dosing Skid Supplier Singapore

Post-installation support is a hallmark of a professional supplier. The top dosing skid supplier provides AMC services to ensure continued reliability:

- Routine servicing and preventive checks

- Performance auditing of dosing pumps

- Calibration of sensors and instruments

- Replacement of worn-out components

- Emergency breakdown response

With a strong after-sales commitment, the top dosing skid supplier safeguards your investment year after year.

Case Study-Based Engineering Approach

The top dosing skid supplier follows a solution-driven design philosophy. Every project is treated as unique, with site-specific challenges, chemical behaviors, space limitations, and integration needs factored in from the start.

This method includes:

- Site visits for real-world assessment

- Chemical compatibility analysis

- Process flow simulations

- 3D modeling of the dosing skid before fabrication

By aligning with your exact requirements, the top dosing skid supplier creates high-performance, fit-for-purpose solutions.

Why Singapore Prefers the Top Dosing Skid Supplier Singapore

Singapore’s industrial sector thrives on quality, innovation, and sustainability. The top dosing skid supplier aligns with national goals of water security, green energy, and industrial automation. Some key reasons for being the preferred choice include:

- Singapore-built solutions that understand local compliance needs

- In-house fabrication and testing facilities

- Customization without compromising on timelines

- Technological integration aligned with PUB and NEA standards

- Rapid lead times and responsive service

In short, industries across Singapore trust the top dosing skid supplier to deliver excellence on every front.

Future-Proofing with the Top Dosing Skid Supplier Singapore

As technology advances and environmental regulations become more stringent, future-ready dosing systems are a necessity. The top dosing skid supplier is constantly evolving to deliver:

- Remote IoT-enabled dosing control

- Energy-optimized pump algorithms

- AI-based chemical demand prediction

- Smart sensor calibration and feedback loops

- Integration with digital twins for predictive maintenance

Choosing the top dosing skid supplier means choosing a partner committed to staying ahead of the curve.

Key Features Include:

- Remote system access for monitoring and control via secure VPN networks

- Cloud-based data logging for dosage reports, chemical consumption, and pump performance

- Alarm and alert triggers delivered via SMS or email

- Integration with centralized DCS/PLC systems through Modbus, Profibus, or Ethernet IP protocols

- Custom dashboards and HMIs tailored to site needs

With intelligent control and diagnostics, the top dosing skid supplier ensures that each skid is not only functional but also future-ready.

Role of the Top Dosing Skid Supplier in Smart Water Management

Singapore has positioned itself as a global leader in sustainable water management. A key enabler of this vision is the integration of smart chemical dosing systems into municipal and industrial water treatment processes.

The top dosing skid supplier is actively involved in supporting water reuse, desalination, and wastewater treatment initiatives with high-precision, low-footprint, and energy-efficient dosing solutions.

Typical Water Applications:

- Chlorine and hypochlorite injection for disinfection

- Alum and PAC dosing for coagulation

- Lime and caustic dosing for pH correction

- Polymer dosing for sludge dewatering

- Sulfuric acid or citric acid dosing for RO membrane cleaning

These dosing packages are delivered by the top dosing skid supplier with full calibration, redundancy, and automation for non-stop operation in 24/7 treatment facilities.

Flexible Skid Configurations Offered by the Top Dosing Skid Supplier Singapore

Different industries and process sites have varied layout limitations. The top dosing skid Singapore offers highly adaptable dosing skid configurations to fit all types of site requirements.

Configuration Types:

- Single-pump skid (compact footprint for limited-space facilities)

- Duplex pump skid (one duty, one standby for uninterrupted dosing)

- Multi-chemical skid (for dosing multiple chemicals from a common frame)

- Containerized skid systems (fully enclosed systems for outdoor or remote operations)

- Wall-mounted mini skids (for laboratories and compact treatment systems)

Every configuration is designed by the top dosing skid Singapore for ergonomic operation, minimal maintenance, and safe chemical handling.

Conclusion: Invest with the Top Dosing Skid Singapore

In an industry where operational safety, dosing accuracy, and lifecycle value matter, selecting the top dosing skid supplier Singapore is the smartest decision. Whether you’re a facility owner, EPC contractor, or OEM integrator, your dosing system must perform with precision every single time.

From engineering to installation, support to scalability, trust only the top dosing skid Singapore to deliver equipment that matches your ambition.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply