Operation & Maintenance

- Water Treatment Plants Operation And Process Supports ( Etp | stp | ro | wtp )

- Filter Press | belt Press | screw Press Process & Operation

- Annual & Maintenance Contract

- Operation And Maintenance

- Rotating And Static Equipment’s Service And Support

- Plant Operation Team And Service

O&M & AMC

O&M activities typically include performing routine maintenance on repair equipment, taking pressure and/or vacuum readings from equipment and monitoring points, cleaning filters, flow meters, and repair piping. Additional data collected from monitoring points may include dissolved oxygen or oxidation potential measurements, depth or groundwater sampling for constituents of concern (COC), or biological parameters.

Specification

| Capacity | 100KLD to 5MLD |

|---|---|

| Plant | ETP | STP | WTP | RO | UF | Bio Gas |

| Construction | Portable and constructed |

| Stage | Stage 1 Upto Ultra filtration | Nano filtration |

| Efficiency | Based on the raw water and design parameters |

| MOC Skid | MS, EN-8, SS304, SS316, SS316L, Duplex & Super Duplex Steel, (Comes with Various Lining RL, FRP, PP, PTFE)…Civil |

Effluent Treatment Plant

Filter and Belt Press

Reverse Osmosis Plant

Waste Water Treatment

Flomek Water Treatment Plant Operation & Maintenance service

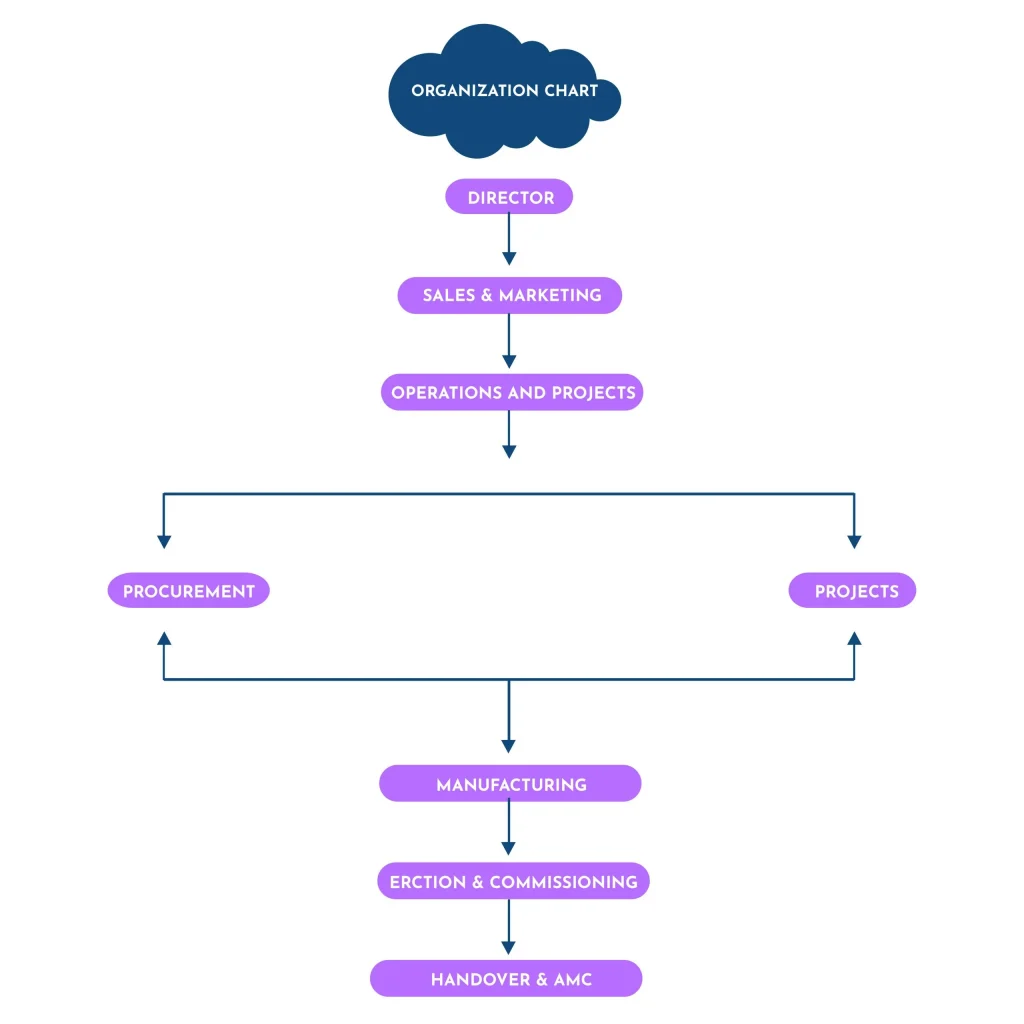

Introduction

The efficient operation and maintenance of Water Treatment Plants is critical to ensuring that communities, industries, and businesses have access to clean, safe, and reliable water. Whether for drinking, industrial use, or wastewater treatment, a well-maintained Water Treatment Plant is essential for optimal performance and longevity.

In Singapore, the importance of proper Water Treatment Plant Operation & Maintenance is amplified due to the country’s limited water resources and commitment to sustainable water management. Having a reliable and experienced Water Treatment Process Plant Operation & Maintenance team in Singapore, like the one at FLOMEK Singapore, ensures the smooth functioning of these vital facilities.

In this comprehensive guide, we will explore the importance, challenges, and best practices of Water Treatment Plant Operation & Maintenance, and how FLOMEK Singapore can help you achieve efficient water management solutions.

What is Water Treatment Plant Operation & Maintenance?

Water Treatment Plant Operation & Maintenance refers to the continuous activities involved in managing and caring for a water treatment facility to ensure its reliable and efficient performance. This includes overseeing the processes that treat raw water into potable water or wastewater into safe dischargeable water, and maintaining the equipment, pipelines, and infrastructure involved.

A skilled Water Treatment Process Plant Operation & Maintenance team in Singapore ensures that the plant complies with regulatory standards, minimizes downtime, and optimizes energy and resource use.

Key Components of Water Treatment Plant Operation & Maintenance

- Routine Inspection and Monitoring: Regular inspection of equipment and processes is vital to detecting any early signs of malfunction or wear.

- Preventive Maintenance: Preventive maintenance involves routine servicing of equipment to prevent breakdowns. This can include lubricating machinery, replacing worn parts, and cleaning systems.

- Process Control: The operation team ensures that water treatment processes like coagulation, filtration, and disinfection are running smoothly and meeting quality standards.

- Energy Efficiency Management: A well-maintained plant operates more efficiently, reducing energy consumption and minimizing environmental impact.

- Compliance with Environmental Regulations: Ensuring that the plant operates in line with the regulatory standards set by Singapore’s Public Utilities Board (PUB) and the National Environment Agency (NEA).

By following these key principles, Water Treatment Plant Operation & Maintenance ensures the optimal functionality of water treatment facilities, reducing operational costs and extending the life of the equipment.

Importance of Water Treatment Plant Operation & Maintenance in Singapore

- Safeguarding Public Health One of the primary goals of Water Treatment Plant Operation & Maintenance is to ensure the production of clean, safe water for public consumption. Any failure in operation or maintenance could result in contamination, leading to serious public health risks. Proper operation and maintenance reduce the chances of waterborne diseases, ensuring the well-being of Singapore’s population.

- Optimizing Operational Efficiency In a bustling city-state like Singapore, where water resources are scarce, efficiency is paramount. Regular Water Treatment Plant Operation & Maintenance enhances process efficiency, allowing plants to treat more water with fewer resources, such as energy and chemicals. FLOMEK Singapore’s Water Treatment Process Plant Operation & Maintenance team in Singapore focuses on minimizing energy consumption while maintaining high output levels, which is essential for reducing operational costs.

- Preventing Unplanned Downtime Breakdowns or equipment failures in a Water Treatment Plant can lead to unplanned downtime, interrupting water supply to homes, businesses, or industries. By implementing regular Water Treatment Plant Operation & Maintenance, operators can prevent such downtime by addressing issues before they become critical. FLOMEK’s proactive maintenance approach ensures that Singapore’s water treatment plants run smoothly around the clock.

- Compliance with Regulatory Standards Singapore has strict regulations governing water quality and environmental protection. Non-compliance can result in hefty fines, reputational damage, and environmental harm. With a professional Water Treatment Process Plant Operation & Maintenance team in Singapore, you can be confident that your plant meets all local and international standards. FLOMEK ensures that all water treatment operations comply with Singapore’s stringent environmental regulations, protecting your facility from legal and financial penalties.

- Environmental Protection Efficient water treatment processes play a critical role in protecting the environment by ensuring that wastewater is treated before being discharged back into natural water bodies. Proper Water Treatment Plant Operation & Maintenance reduces the risk of accidental discharges of untreated or inadequately treated water, which could harm ecosystems.

Key Challenges in Water Treatment Plant Operation & Maintenance

- Aging Infrastructure Many Water Treatment Plants in Singapore and around the world are aging, making them more prone to breakdowns and inefficiencies. Proper maintenance is essential for extending the life of older equipment and avoiding the high costs of replacing infrastructure.

- Energy Consumption Water treatment processes are energy-intensive. Without proper operation and maintenance, plants can consume excessive amounts of energy, leading to increased operational costs. Ensuring that all components of the plant are functioning efficiently can significantly reduce energy usage.

- Skilled Workforce Operating and maintaining a Water Treatment Process Plant requires a skilled workforce with in-depth knowledge of the plant’s systems and processes. Finding and retaining trained personnel is a challenge many plants face. FLOMEK’s Water Treatment Process Plant Operation & Maintenance team in Singapore offers highly trained and experienced staff to ensure the smooth operation of the plant.

FLOMEK Singapore: Your Trusted Partner in Water Treatment Plant Operation & Maintenance

At FLOMEK Singapore, we provide comprehensive Water Treatment Plant Operation & Maintenance services designed to meet the unique needs of each client. Our team is dedicated to ensuring the highest standards of plant performance, safety, and efficiency.

Best Practices for Water Treatment Plant Operation & Maintenance

- Regular Training for Personnel: Ensuring that staff is well-trained on the latest maintenance techniques and technology is key to smooth operations.

- Scheduled Maintenance: A proactive maintenance schedule helps detect potential problems early and prevent breakdowns.

- Energy Audits: Regular energy audits can identify opportunities to reduce energy consumption and improve operational efficiency.

- Use of Technology: Implementing technologies like predictive maintenance software and real-time monitoring systems can help prevent equipment failures and optimize plant performance.

Conclusion

Water Treatment Plant Operation & Maintenance is vital to ensuring the continued production of clean, safe water for residential, commercial, and industrial use. With proper maintenance and expert operation, these plants can operate efficiently and reliably for years to come.

At FLOMEK Singapore, we pride ourselves on providing top-tier Water Treatment Process Plant Operation & Maintenance services in Singapore. Our team is committed to delivering efficient, reliable, and sustainable solutions that ensure your plant operates at peak performance.

Contact us today to learn more about our Water Treatment Plant Operation & Maintenance services and how we can help your facility achieve greater efficiency and compliance.

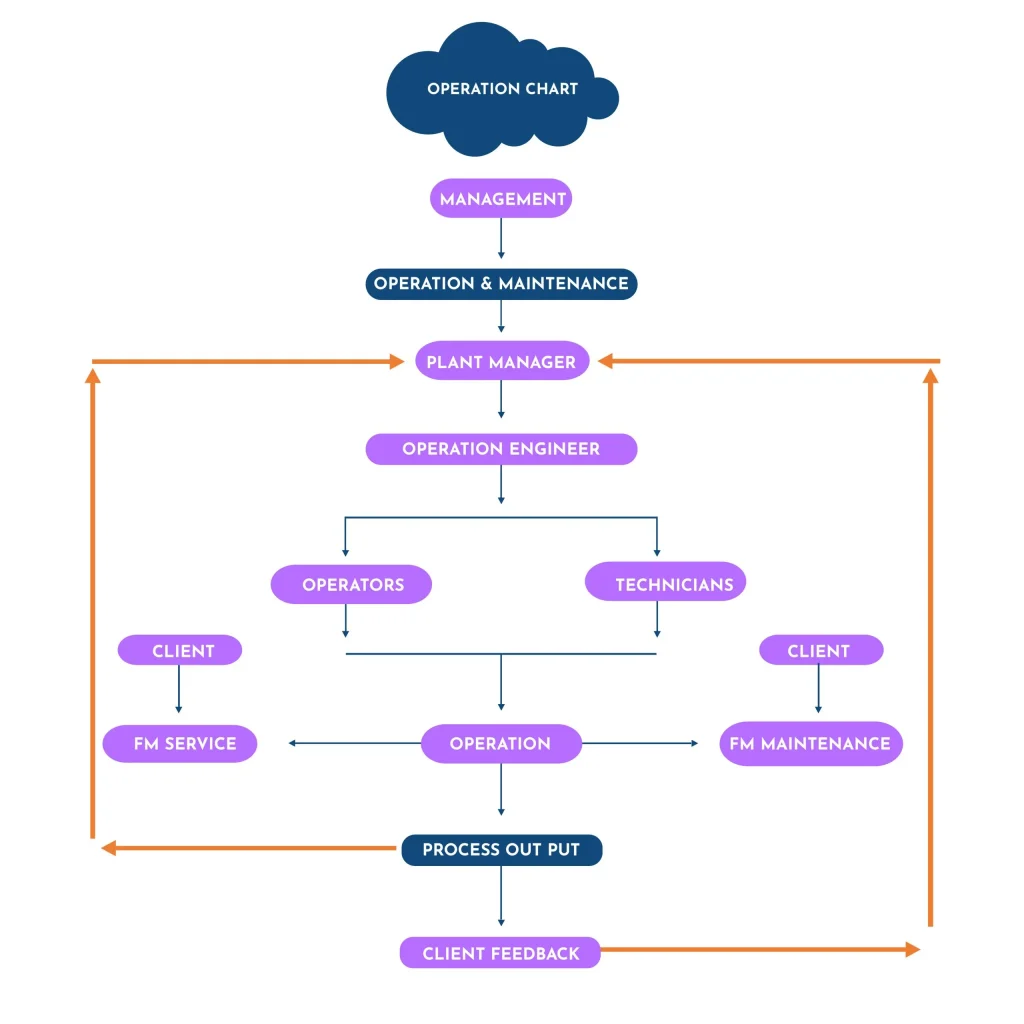

Plant Operation and Maintenance

-

Flomek Singapore Private Limited provides Operation and Maintenance of the Plants across various industries such as Water treatment, Waste water treatment, Chemical process, Pharmaceutical, Food & Beverage, Manufacturing, Oil and Gas, Power generation and Renewable energy.

-

Operating and maintaining a plant consist of careful monitoring and process control, regular preventive maintenance, carrying out of safety protocols, staff training and certification, and diligent record keeping and reporting.

-

Monitoring and Process Control – FSPL Technicians carryout continuous monitoring and process control which are crucial for the effective operation of a plant to ensure that the processes are functioning as intended. FSPL Technicians perform the variables monitoring such as flow rates, chemical levels, pH levels, and the contaminants level through manual sampling and analysis system and automated sensors and control systems. When required FSPL Technicians adjust process parameters to optimize the efficiency of the plant and maintain compliance with the required standards.

-

Preventive Maintenance – Regular preventive maintenance is essential for maintaining the reliability and efficiency of a plant, and can help extend the life of equipment, reduce the risk of unexpected failures, and minimize overall operational costs. FSPL Technicians establish a well-documented maintenance schedule to ensure all the equipment and systems in the plant are maintained regularly and involve in routine inspection, cleaning and servicing of equipment such as pumps, motors, mixers, blowers, filter press, tanks, and control systems.

-

Staff Training and Certification – FSPL has skilled workforce with specialized knowledge in plant operation and maintenance. FSPL Technicians receive regular training to stay up-to-date with the latest industry standards, technologies, and regulations, and FSPL provides continuing education and professional development opportunities to support the growth and development of the Technicians and required to obtain certification to demonstrate their competency.

-

Record Keeping and Reporting – FSPL Technicians maintain accurate and up-to-date records which is a critical aspect plant operation and maintenance. This includes maintaining logs of process data, maintenance activities, safety incidents, and staff training. These records can be used to identify trends, assess performance, and support decision-making.