skid integration singapore – BEST 2025

skid integration singapore: Complete Guide for Process & Engineering Industries

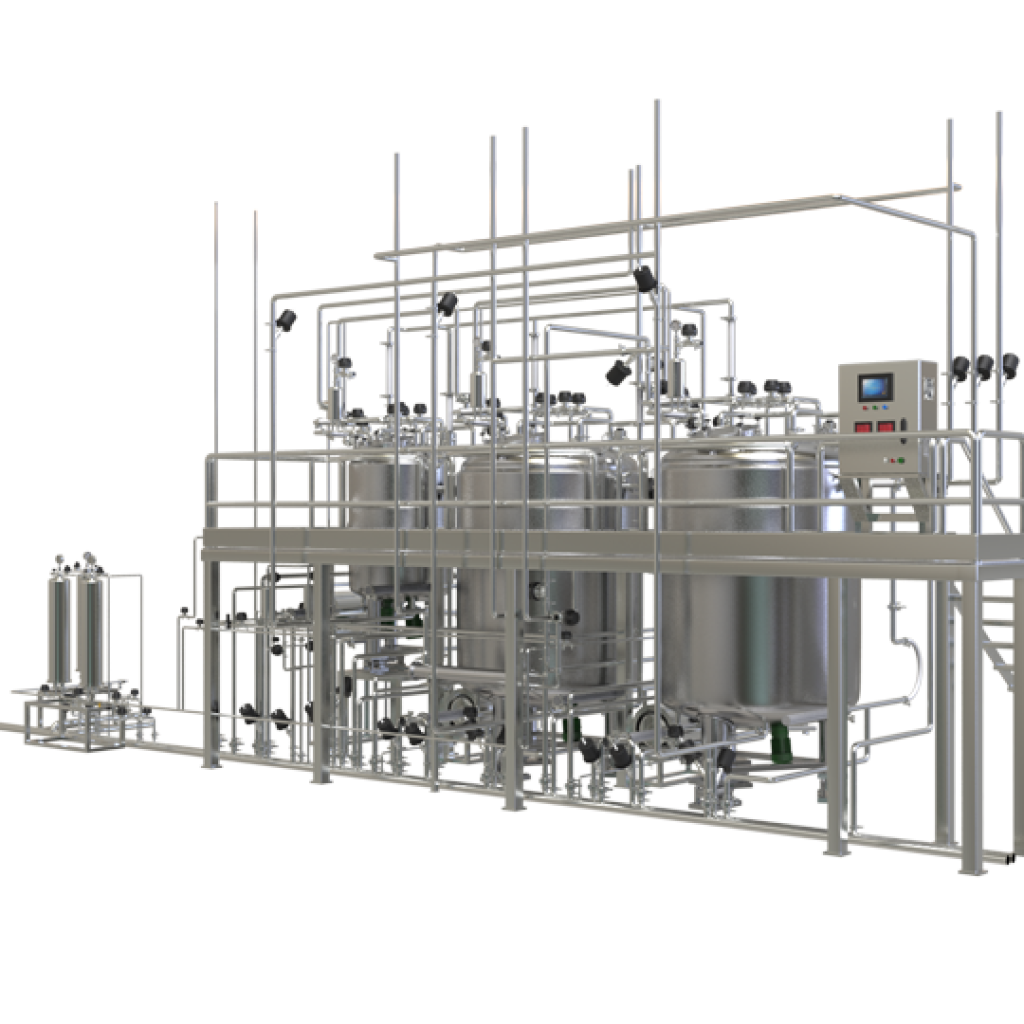

skid integration singapore is rapidly becoming the backbone of modular engineering systems across industries including oil & gas, water treatment, pharmaceuticals, and chemical processing. This guide provides an in-depth view of skid integration singapore , its advantages, applications, design process, and how expert companies like FLOMEK Singapore deliver top-quality integrated skid systems in Singapore and Southeast Asia.

What is Skid Integration?

Skid integration singapore refers to the process of designing, assembling, and testing mechanical or process systems on a compact, transportable frame (a “skid”) before being delivered to the final site for installation. These skid-mounted systems are pre-engineered and pre-fabricated units that integrate components such as pumps, filters, valves, instruments, piping, and electrical controls.

Rather than assembling systems piece by piece on-site, skid integration singapore enables manufacturers and process plants to receive plug-and-play units, minimizing fieldwork, reducing costs, and improving system quality and control.

Key Benefits of Skid Integration

Here are the main advantages that companies achieve through proper skid integration singapore:

1. Reduced Installation Time

A major benefit of skid integration singapore is significant time savings during installation. Pre-assembled and factory-tested skids eliminate the need for complex on-site assembly.

2. Quality Assurance

With all components pre-assembled in a controlled environment, skid integration singapore ensures higher manufacturing precision and superior quality testing before deployment.

3. Compact and Modular Design

Skid integration singapore makes the system compact, modular, and mobile, optimizing space in process plants and allowing for easier expansions or relocations.

4. Lower Project Costs

Because of reduced labor, material handling, and fewer onsite activities, the total project cost of skid integration singapore is often lower compared to traditional stick-built systems.

5. Easy Maintenance

Maintenance is simpler because the entire integrated system is visible and accessible, with clear routing of pipes, cables, and instruments.

Common Applications of Skid Integration

Skid integration singapore is widely used in industries requiring precision, modularity, and safety:

- Water Treatment Skids

- Chemical Dosing Skids

- Pump Skid Packages

- Booster Pump Skids

- RO Plant Skid Integration singapore

- Pilot Plant Skids

- PLC & Electrical Skid Integration singapore

- Fuel Gas Conditioning Skids

- Heat Exchanger Skids

- Lube Oil Skids

With proper skid integration singapore, these systems operate efficiently and meet international safety standards.

Components of a Skid Integration Package

Each skid integration singapore unit is a combination of mechanical, electrical, instrumentation, and control components. A standard skid integration singapore package includes:

- Skid base frame (carbon steel/stainless steel)

- Process equipment (pumps, filters, tanks)

- Interconnecting piping & fittings

- Valves (manual and automated)

- Flowmeters, pressure transmitters, level sensors

- Electrical panel with PLC/SCADA

- Instrument junction boxes

- Cable trays and wiring

- Pneumatic/hydraulic controls (if required)

- Operator interface terminal (HMI)

Skid Integration in Water & Wastewater Treatment

Skid integration singapore plays a vital role in water treatment, RO plants, and effluent recycling systems. For example, in a RO plant, the high-pressure pump, membrane housings, chemical dosing system, and control panel are integrated on one frame.

Advantages of Skid Integration singapore in RO Plants:

- Fast installation and commissioning

- Reduced on-site civil & piping work

- High-quality fabrication under QA/QC

- Consistent performance & reliability

FLOMEK Singapore is a leader in skid integration singapore for water treatment plants, delivering robust, tailor-made skids across Singapore and the region.

How Skid Integration singapore Works: Step-by-Step Process

1. Engineering Design

The process begins with detailed engineering – P&ID drawings, GA drawings, material selection, and control philosophy are finalized.

2. Fabrication

All piping, supports, and mechanical structures are fabricated based on design specs. Materials like SS316 or duplex steel are selected based on process media.

3. Equipment Assembly

Pumps, valves, instrumentation, and accessories are mounted on the skid. All interconnections are welded or flanged according to standards.

4. Electrical & Automation

The electrical skid panel, PLC, VFDs, and wiring are installed. Skid integration singapore ensures full automation for seamless field operation.

5. Factory Acceptance Testing (FAT)

Before delivery, a complete FAT is done to ensure the skid performs under simulated conditions. This guarantees system functionality, control logic accuracy, and leak-free performance.

6. Shipping & Installation

The entire skid is packed and shipped to the site. On arrival, minimal work is needed — usually limited to anchoring, utility connection, and startup.

Why Choose FLOMEK for Skid Integration singapore in Singapore?

FLOMEK Singapore offers unparalleled expertise in skid integration singapore, particularly for water treatment, chemical dosing, and pumping systems. Here’s why FLOMEK is a preferred choice:

- Complete In-House Design & Engineering

- Customized Fabrication Based on Process Requirements

- Experienced Technicians & Engineers

- Robust Skid Frames for Long Life

- Integrated PLC & Control Panels

- Local Support for Commissioning & Maintenance

- Adherence to Singapore’s Industry Standards

Our commitment to skid integration singapore excellence has enabled us to serve clients in pharmaceuticals, semiconductors, municipal utilities, and process industries.

Industries Benefiting from Skid Integration

Several industries rely heavily on skid integration singapore for safety, speed, and precision:

- Oil & Gas – for fuel conditioning and lube oil systems

- Water Treatment – RO skids, UF skids, dosing skids

- Power Plants – boiler feedwater and condensate skids

- Chemical Manufacturing – acid/alkali dosing and blending systems

- Food & Beverage – CIP skids and filtration systems

- Pharma & Biotech – clean-in-place and sanitization skids

.

Challenges in Skid Integration – And How FLOMEK Overcomes Them

While skid integration singapore offers many benefits, it’s not without challenges:

1. Space Constraints

Designing compact systems with full functionality can be tricky. FLOMEK solves this with advanced 3D modeling and ergonomic layout planning.

2. Component Compatibility

Pumps, instruments, and controls must work in harmony. FLOMEK uses only vetted suppliers and integrates PLC systems with modular logic.

3. Control Complexity

Advanced processes require integrated control logic and user interfaces. FLOMEK delivers smart skid integration singapore with PLC/SCADA systems and HMI touchscreens.

The Future of Skid Integration: Smart, Sustainable, Scalable

With the rise of Industry 4.0, skid integration is now evolving with IoT, real-time monitoring, and predictive maintenance. At FLOMEK Singapore, we design intelligent skids that:

- Transmit data wirelessly

- Self-monitor pump and valve health

- Provide alerts for preventive maintenance

- Integrate seamlessly with DCS and SCADA

Such digital skid integration singapore ensures maximum plant uptime, safety, and regulatory compliance.

Skid Integration vs Stick-Built Systems

| Feature | Skid Integration | Stick-Built Systems |

|---|---|---|

| Assembly | Off-site | On-site |

| Time | Fast | Slow |

| QA/QC | High | Variable |

| Flexibility | Modular | Rigid |

| Risk | Low | High |

| Maintenance | Easy | Complex |

Custom Skid Integration Solutions by FLOMEK

We specialize in designing and delivering:

- Water Pressure Booster Skids

- Chemical Injection Skids

- Pump Skid Packages

- Filtration Skids

- PLC & MCC Panel Integration

- Pilot Plant Skids

- Mobile Skid Units

Every skid integration singapore project by FLOMEK is designed with industry-standard CAD software, ISO welding practices, and electrical safety codes. We offer full documentation including test certificates, operation manuals, P&IDs, and panel wiring diagrams.

Advanced Concepts in Skid Integration: Elevating Plant Efficiency

As industries become more automated and digitally connected, skid integration singapore is evolving beyond simple plug-and-play systems. Today’s demand is not only for functional process skids but also for smart, connected, and sustainable skid systems.

Smart Skid Integration with IIoT & Industry 4.0

Skid integration singapore is now enhanced by the Industrial Internet of Things (IIoT). This includes sensors, data acquisition systems, remote control, and cloud-based monitoring. These features enable:

- Real-time performance tracking

- Predictive maintenance alerts

- Remote diagnostics and updates

- Energy consumption optimization

By using smart technologies in skid integration, manufacturers reduce operational risks and increase plant uptime.

Skid Integration for Cleanroom and Pharma Applications

In pharmaceutical manufacturing and cleanroom environments, skid integration ensures process containment, cleanliness, and validation. Skids used in these environments must comply with GMP (Good Manufacturing Practice) and include features such as:

- Sanitary-grade tubing and valves (e.g., Tri-Clamp fittings)

- CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems

- FDA/USP compliant materials

- 21 CFR Part 11 compliant control systems

- Full traceability and documentation

FLOMEK Singapore understands the critical requirements of the pharma industry and delivers skid integration systems that meet the highest global standards.

Role of PLC & SCADA in Skid Integration

A key component of advanced skid integration is the use of programmable logic controllers (PLC) and supervisory control and data acquisition (SCADA) systems. These technologies allow plant operators to:

- Monitor real-time values from sensors and transmitters

- Adjust parameters such as flow rate, pressure, or dosing concentration

- Record data for regulatory reporting and quality assurance

- Trigger alarms in case of deviations

Skid with full automation enables seamless integration into existing Distributed Control Systems (DCS), making the process highly efficient and scalable.

Design Considerations in Skid Integration

Designing an effective skid solution involves balancing various technical, operational, and safety factors. FLOMEK follows a structured engineering approach:

1. Process Requirement Analysis

Before starting, our team works closely with the client to understand:

- Flow rates

- Operating pressure and temperature

- Chemical compatibility

- Control logic and redundancy requirements

2. Skid Layout Optimization

In limited plant space, every inch matters. Skid requires ergonomic design, ensuring:

- Accessibility to components

- Safe walkways and lifting points

- Compact footprint

- Structural strength for transport and vibration

3. Material Selection

Choosing the right material is critical in skid . FLOMEK offers:

- SS304 / SS316 for water & food-grade applications

- Duplex steel for corrosive environments

- FRP skid bases for lightweight needs

- Explosion-proof components for hazardous zones

4. Seismic & Load Design

Skids may need to withstand specific site conditions such as wind, seismic zones, or heavy machinery proximity. FLOMEK designs skid systems using structural analysis and load calculations to ensure long-term reliability.

Testing and Quality Control in Skid Integration

Every skid project undergoes multiple levels of testing to ensure the system performs under all conditions.

Key Tests Include:

- Hydro Testing – Verifies pipeline and pressure vessel strength

- Electrical Continuity Testing – Checks wiring and safety loops

- Instrument Calibration – Ensures all transmitters, gauges, and sensors are accurate

- FAT (Factory Acceptance Test) – End-to-end dry and wet run simulation before shipment

- SAT (Site Acceptance Test) – Testing at actual plant conditions during commissioning

FLOMEK provides comprehensive test reports, calibration certificates, and FAT videos for full client transparency.

Skid Integration: Global Standards & Compliance

FLOMEK Singapore ensures that every skid system complies with international standards such as:

- ASME B31.3 – Process piping

- IECEx / ATEX – Hazardous area compliance

- API 675 / API 610 – For pumps

- UL508A / IEC 61439 – For electrical panels

- ISO 9001:2015 – Quality management

We also adhere to customer-specific standards, ensuring global acceptance and approval by EPCs and consultants.

Custom Skid Integration Examples by FLOMEK

Here are just a few of the skid projects completed by FLOMEK Singapore:

1. Water Pressure Booster Skid

- Application: Commercial buildings and high-rises

- Components: Inline pumps, VFDs, flow meters, pressure sensors

- Integration: PLC-based control with HMI interface

- Result: Stable water pressure 24/7 with low energy usage

2. Chemical Dosing Skid

- Application: Water treatment plants

- Components: Diaphragm dosing pumps, tanks, agitators, pH sensors

- Integration: Remote control via SCADA and telemetry

- Result: Accurate dosing, reduced chemical waste, improved plant stability

3. Fuel Gas Conditioning Skid

- Application: Power plants and gas engines

- Components: Coalescing filters, heaters, pressure regulators

- Integration: Safety interlocks, flow control, and flame arrestors

- Result: Safe, reliable fuel delivery with emissions compliance

These examples show the flexibility and power of skid to suit various industrial needs.

Frequently Asked Questions (FAQs) on Skid Integration

Q1. What is the average lead time for skid integration projects?

A: Depending on complexity, a skid project may take 4–12 weeks, including design, fabrication, testing, and documentation.

Q2. Can skid integration support expansion or upgrades?

A: Yes. Skid systems are modular. You can add, upgrade, or remove units without disrupting the entire plant.

Q3. What utilities are needed on-site to run the skid?

A: Typically, you’ll need power supply (3-phase), water supply, compressed air (if pneumatic), and drain points. FLOMEK designs the skid to match your utility specs.

Q4. Are there any maintenance contracts for skid systems?

A: Yes. FLOMEK provides annual maintenance contracts (AMC), spare parts kits, and 24/7 service for all skid systems.

Final Thoughts: Skid Integration is the Future

In today’s competitive, fast-paced, and high-compliance industrial environment, skid offers the best of speed, quality, flexibility, and automation. It helps companies achieve:

- Faster project execution

- Lower costs

- Safer installations

- Improved system performance

- Seamless scalability

FLOMEK Singapore is a pioneer in delivering premium skid solutions, built with engineering precision, international compliance, and a deep understanding of process requirements.

Let your next project be a success story — built on the strength of smart, efficient, and future-ready skid by FLOMEK.

Modular Engineering Excellence Through Skid Integration

In the era of digital transformation, skid has become a central element of modern modular engineering. Beyond just assembling components on a steel frame, today’s skid approach is about combining mechanical, electrical, automation, and safety systems into one coherent unit—designed for immediate deployment, scalability, and operational excellence.

Skid Integration and Sustainability

One of the rising concerns in industrial plant design is environmental sustainability. Skid aligns well with green initiatives by:

- Reducing material waste during onsite fabrication

- Minimizing transport emissions due to compact logistics

- Improving energy efficiency through smart automation

- Offering long-term reuse and reconfiguration potential

As companies strive toward carbon neutrality and sustainable operations, skid helps reduce their environmental footprint while maintaining productivity.

Lifecycle Cost Advantage of Skid Integration

A traditional stick-built system might seem cost-effective initially but often results in higher lifecycle costs due to:

- Onsite labor inefficiencies

- Quality control failures

- Delayed commissioning

- Increased maintenance burden

With skid , the entire system is built, tested, and optimized off-site, significantly lowering:

- CAPEX (Capital Expenditure) through streamlined fabrication

- OPEX (Operational Expenditure) through enhanced reliability

- Downtime due to modular plug-and-play architecture

FLOMEK’s approach to skid focuses on total cost of ownership (TCO), helping clients save money over the entire system life.

Skid Integration for Hazardous Environments

In sectors like oil & gas, petrochemicals, and marine fuel transfer, safety is paramount. Skid in these sectors demands:

- Explosion-proof enclosures (EX d / EX e)

- Flameproof motors

- Purge panels with interlocks

- Zone 1 or Zone 2 rated instrumentation

- Earthing and bonding provisions

FLOMEK ensures all skid solutions comply with ATEX, IECEx, and API standards, reducing risk in high-stakes environments.

Material Handling and Transport in Skid Integration

A major advantage of skid is that entire systems are built to be easily transported via forklift, crane, or container shipment. Each skid is designed with:

- Lift lugs for crane handling

- Forklift pockets

- Anti-vibration mounts for overseas transport

- Modular bolting provisions to link multiple skids onsite

- Protective coating for corrosion and wear resistance

Whether it’s a 2-ton chemical skid or a 10-ton RO plant module, FLOMEK provides full logistics support from workshop to end site.

Control Panel Engineering in Skid Integration

One of the most crucial components of modern skid is the control panel. FLOMEK’s engineering team specializes in the design and assembly of:

- MCC Panels (Motor Control Center)

- PLC Panels (Programmable Logic Controllers)

- Remote I/O Panels

- SCADA Interface Terminals

- Power Distribution Boards

These control panels are fully integrated within the skid, enabling:

- Local and remote operation

- Fault detection and diagnostic alerts

- VFD (Variable Frequency Drive) pump speed regulation

- Overcurrent protection and electrical interlocking

With advanced skid , you don’t just automate — you digitize the entire process.

Skid Integration in Fire Protection Systems

FLOMEK also delivers skid systems for fire water pumping stations and foam dosing units for industrial and marine use. These include:

- Diesel engine-driven and electric pumps

- Jockey pumps with pressure maintenance logic

- Foam proportioners and inline inductors

- Pressure relief and deluge valves

- FM/UL approved components and control cabinets

Integrated fire protection skids can be easily installed at warehouses, fuel terminals, marine docks, and refineries — meeting local and international fire codes.

Engineering Documentation for Skid Projects

Every skid system by FLOMEK comes with full documentation, ready for regulatory inspection and client handover. This includes:

- P&ID and general arrangement drawings

- Electrical SLD and cable schedules

- FAT & SAT protocols

- Instrument calibration certificates

- Welding and material traceability logs

- Pressure test certificates

- User manuals and training documents

FLOMEK’s engineering documentation ensures that clients can maintain, audit, and expand their systems confidently.

Modular Plant Layout Planning with Skid

In large projects like wastewater treatment plants, hydrogen refueling stations, or chemical transfer farms, multiple skid systems may be combined to form a complete modular plant. Skid allows:

- Predefined utility corridors

- Color-coded pipe routing

- Inter-skid communication via MODBUS / Profibus

- Simplified expansion through preconfigured connections

- Mobile containerized solutions for remote sites

Whether it’s five skids or fifty, skid enables flexible plant development without compromising performance or space.

Global Trends Driving Skid Demand

Global trends influencing the rise of skid include:

- Shorter Project Timelines – EPC contractors demand faster deliveries.

- Workforce Shortage – Skilled on-site labor is declining; offsite integration solves this.

- Digital Transformation – Plants want smart systems, not just mechanical ones.

- Stringent Regulations – Compliance is easier when systems are pre-tested.

- Remote Operations – Skid systems enable SCADA-based remote control.

As these trends grow, skid will continue to dominate industrial engineering.

Final Summary: Skid Integrations is the Smart Choice

To summarize, skid is more than just a mechanical solution — it’s a complete engineering philosophy that supports:

- Faster project timelines

- Superior quality and testing

- Modular and mobile deployment

- Smart automation and remote access

- Sustainable and cost-effective operations

Whether you’re in Singapore, Southeast Asia, or anywhere across the globe, FLOMEK Singapore offers skid services that help industries move toward the future of modular process systems.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply