shaft alignment Singapore – Singapore’s No 1 Best Pumps Service

Expert Guide to Shaft Alignment Singapore: Precision, Performance, and Reliability

Introduction to Shaft Alignment

Shaft alignment is a critical aspect of mechanical maintenance in any industry involving rotating machinery. In simple terms, shaft alignment refers to the process of aligning two or more shafts in a straight line, both horizontally and vertically. Proper alignment ensures that machines run efficiently, reducing wear and tear, improving performance, and minimizing unexpected downtime.

When it comes to industrial and commercial setups in Singapore, shaft alignment Singapore services have become increasingly vital. From marine engineering to manufacturing plants and HVAC systems, precise alignment has a direct impact on operational efficiency and long-term cost savings.

Why Shaft Alignment Is Important in Singapore’s Industries

Singapore is a global hub for advanced manufacturing, shipbuilding, and process industries. These sectors heavily rely on machinery that needs precise operation. Poor alignment of shafts can lead to increased vibration, excessive energy consumption, and even catastrophic machine failure.

Here are some reasons why shaft alignment Singapore solutions are indispensable:

- Increased Equipment Lifespan: Correct alignment reduces mechanical stress on bearings, seals, and couplings, thereby extending the life of machinery.

- Energy Efficiency: Misaligned shafts can cause power losses due to friction and vibrations. Accurate alignment optimizes energy consumption.

- Reduced Maintenance Costs: Regular and accurate alignment significantly reduces the need for emergency maintenance and part replacements.

- Improved Safety: Aligned machines operate smoothly, minimizing risks of malfunction that can cause accidents.

Types of Shaft Misalignment

To understand the importance of shaft alignment Singapore services, one must first understand the types of misalignments typically encountered:

1. Angular Misalignment

Occurs when the shafts are at an angle to each other, either horizontally or vertically. This causes uneven load distribution and damages components quickly.

2. Parallel (Offset) Misalignment

This type of misalignment happens when the centerlines of the shafts are parallel but not collinear. This leads to increased vibrations and poor machine performance.

3. Combined Misalignment

A mix of angular and parallel misalignment, which is the most common and harmful form. This necessitates specialized tools and expertise to correct.

Common Causes of Shaft Misalignment

Many factors contribute to shaft misalignment in industrial settings. Understanding these can help prevent alignment issues before they become costly problems:

- Improper Installation: Machines not installed properly are more prone to misalignment.

- Thermal Expansion: Heat causes components to expand, affecting alignment over time.

- Foundation Settling: Concrete bases and machine foundations can settle or shift slightly.

- Vibration and Wear: Continuous operation leads to wear and vibration, which can affect alignment.

- Operational Stress: Load fluctuations or start-stop operations can lead to shaft movement.

Methods Used in Shaft Alignment Singapore Services

Technicians in shaft alignment Singapore typically use the following methods, based on the complexity and precision required:

1. Straightedge and Feeler Gauge

This traditional method is cost-effective and suitable for simple alignment jobs. However, it lacks the accuracy needed for modern high-speed equipment.

2. Dial Indicator Method

A more accurate method, using dial indicators to measure shaft position and calculate corrections. It requires a skilled technician for precise readings.

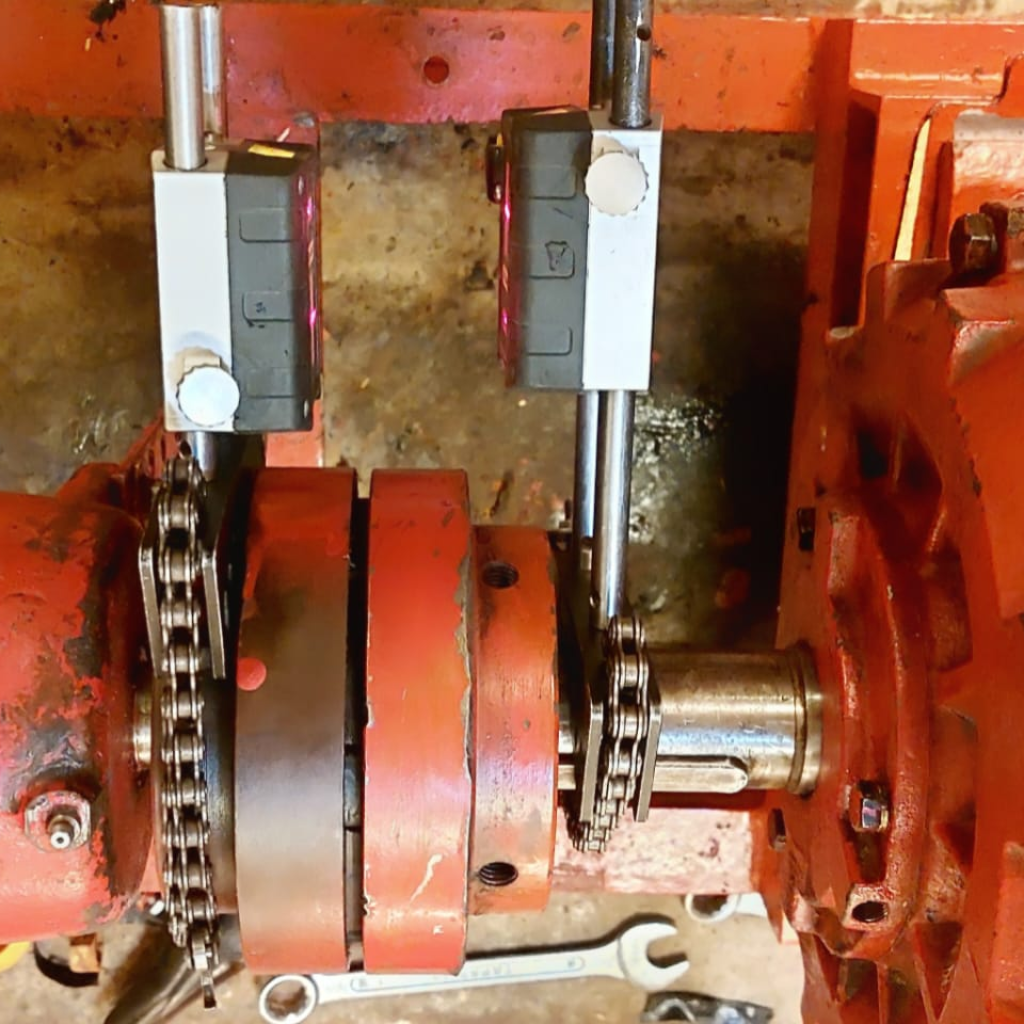

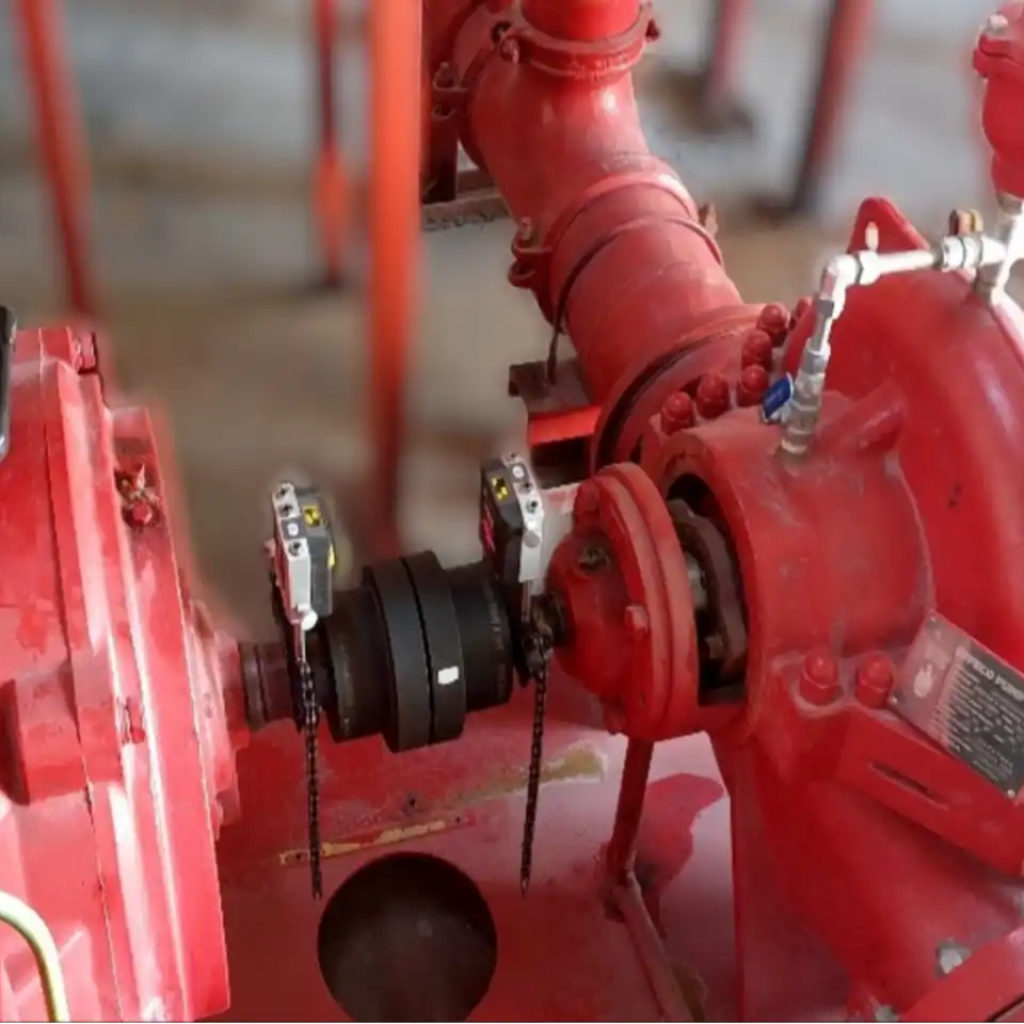

3. Laser Shaft Alignment

Currently the most advanced and preferred method in shaft alignment Singapore services. Laser alignment tools provide real-time, high-precision data with minimal margin for error.

4. Reverse Indicator Method

An older but still reliable technique using two dial indicators placed on both shafts. This method requires calculation and experience but remains effective for certain setups.

Benefits of Laser Shaft Alignment

Modern shaft alignment Singapore services increasingly rely on laser technology due to its advantages:

- Accuracy: Provides results within microns, ensuring precision alignment.

- Speed: Faster than traditional methods, reducing downtime.

- Data Logging: Stores alignment data for maintenance records and audits.

- Real-Time Adjustments: Enables immediate corrections while monitoring alignment live.

- User-Friendly: Many tools are software-assisted, reducing technician error.

Applications of Shaft Alignment in Singapore

Shaft alignment Singapore services are widely used across various industries. Each sector has specific needs, but all benefit from accurate alignment.

1. Manufacturing Plants

Production lines depend on compressors, pumps, fans, and motors—all of which require precise shaft alignment to function optimally.

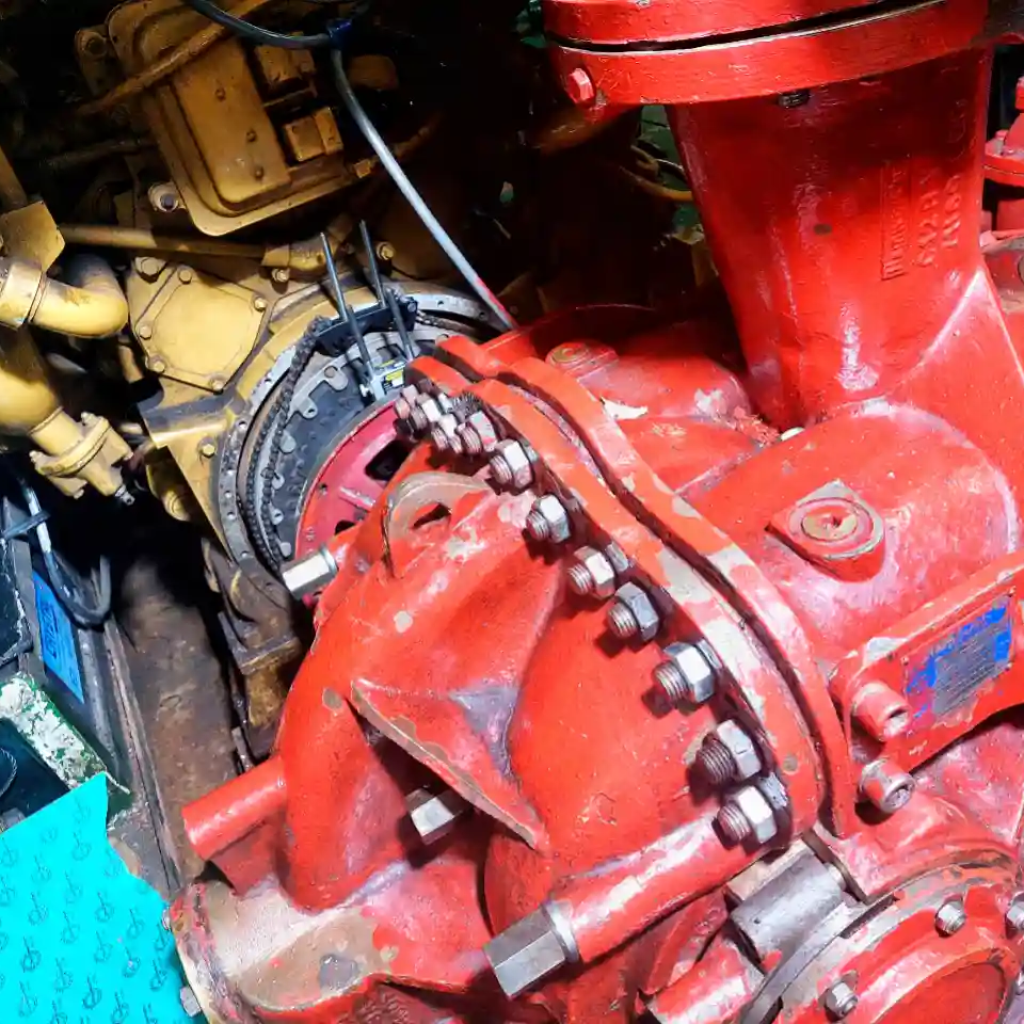

2. Maritime and Shipbuilding

Marine engines and propeller shafts must be aligned to ensure smooth sailing and compliance with maritime regulations.

3. Oil and Gas Industry

Equipment in the energy sector operates under extreme conditions. Shaft misalignment can cause dangerous situations and costly downtime.

4. Power Generation

Turbines and generators in power plants require absolute precision to avoid losses and maintain consistent power output.

5. HVAC Systems

Chillers, blowers, and air-handling units in large buildings need alignment to reduce energy use and extend system life.

6. Water Treatment Plants

Pumps and agitators must be aligned to maintain efficient operations and prevent contamination from equipment failure.

Challenges in Shaft Alignment in Singapore

Despite the availability of modern tools, several challenges exist in shaft alignment Singapore:

- Space Constraints: Many facilities in Singapore have tight equipment layouts, making alignment difficult.

- Harsh Environments: High humidity and temperature variations can affect alignment stability.

- Skilled Workforce Shortage: Precision alignment requires trained technicians, which may be limited in number.

- Downtime Restrictions: Operations often can’t afford long stoppages for alignment checks, requiring efficient service.

Shaft Alignment Procedures and Best Practices

To ensure the best outcomes, shaft alignment Singapore professionals follow strict procedures:

- Preparation:

- Lock out and tag out equipment.

- Clean mounting surfaces.

- Measure soft foot conditions.

- Initial Readings:

- Use laser or dial indicators to take initial alignment measurements.

- Adjustment:

- Make necessary horizontal and vertical corrections by moving machinery or adding shims.

- Recheck and Validate:

- Re-measure to confirm alignment.

- Document all readings for quality assurance.

- Monitoring:

- Periodic rechecks using alignment systems or vibration analysis.

Preventive Maintenance and Shaft Alignment

Incorporating shaft alignment Singapore into a preventive maintenance schedule can significantly improve machinery uptime and reliability. Here’s how:

- Scheduled Alignment Checks: Regularly assess alignment to catch issues early.

- Baseline Data Collection: Store alignment readings for comparison.

- Integrated Condition Monitoring: Combine with vibration and thermal analysis for comprehensive insights.

- Training Staff: Equip maintenance teams with alignment skills and knowledge.

Tools Used in Shaft Alignment Singapore

Professional technicians use a variety of specialized tools to ensure accurate shaft alignment:

- Laser Alignment Systems (e.g., Fixturlaser, Prüftechnik)

- Dial Indicator Sets

- Feeler Gauges and Straightedges

- Alignment Shims

- Thermal Growth Compensators

- Digital Micrometers and Calipers

- Data Logging Software

Consequences of Misalignment

Neglecting alignment issues can lead to significant problems:

- Bearing Failures

- Seal Damage

- Coupling Wear

- Excessive Vibration

- Energy Loss

- Increased Downtime

- Unexpected Shutdowns

Investing in shaft alignment Singapore services helps avoid these risks, ensuring smooth, safe, and efficient operations.

Sustainability and Energy Savings

Proper shaft alignment Singapore services contribute directly to energy savings and environmental sustainability. Misaligned equipment consumes more electricity and emits more heat due to friction. Accurate alignment:

- Reduces energy usage by up to 10%.

- Cuts down on unnecessary emissions.

- Enhances machine longevity, reducing scrap and waste.

In eco-conscious Singapore, this adds value to green certifications and compliance with government regulations.

Case Scenarios: Alignment in Action

While avoiding brand names, we can illustrate typical shaft alignment Singapore situations:

- Scenario 1: A food processing plant experiences excessive vibration in a conveyor motor. After laser alignment, vibration levels drop by 70%, increasing output efficiency.

- Scenario 2: A marine vessel reports overheating in the propulsion system. Shaft misalignment is diagnosed and corrected, resulting in smoother voyages and less fuel consumption.

- Scenario 3: An HVAC system in a downtown skyscraper consumes more power than projected. Shaft alignment of blower motors reduces energy bills significantly.

The Role of Technology in Modern Shaft Alignment Singapore Services

Technological advancement has revolutionized shaft alignment Singapore offerings:

- Cloud-Based Reporting: Enables remote monitoring and audit-ready data logs.

- Smartphone Integration: Some alignment tools connect via apps for instant feedback.

- Wireless Sensors: Improve safety and access in tight or hazardous environments.

- 3D Visualization: Some tools provide a digital twin for advanced diagnostics.

How Shaft Alignment Affects Machine Health in Singapore’s Climate

Singapore’s tropical climate presents unique challenges for machinery. High humidity and fluctuating temperatures can cause material expansion and contraction, impacting shaft alignment significantly.

Thermal Growth and Its Impact

In industrial environments, especially those dealing with high-speed rotating equipment, thermal growth must be considered. As machines heat up, the metal expands, potentially altering the alignment set during cooler, idle states.

Shaft alignment Singapore services consider thermal expansion factors, using thermal growth compensators or applying “hot alignment” techniques to ensure that machines operate optimally during full-load conditions.

Corrosion and Wear

Humidity accelerates corrosion, particularly in open or poorly ventilated spaces. Corrosion leads to pitting or wearing of contact surfaces such as bearing housings and mounting bases. As these surfaces deteriorate, alignment shifts, and vibration increases.

Routine shaft alignment Singapore checks help detect early signs of misalignment due to environmental degradation, keeping equipment safe and efficient year-round.

Importance of Shaft Alignment in Predictive Maintenance Programs

Predictive maintenance goes beyond scheduled servicing—it uses real-time data to anticipate equipment failure. Shaft alignment is a critical part of this strategy.

Professionals offering shaft alignment Singapore services often integrate their tools with vibration analysis, infrared thermography, and ultrasonic testing systems. These integrated systems:

- Detect misalignment before failure occurs

- Identify trends over time

- Provide visual reports and KPIs for facility managers

- Help extend the Mean Time Between Failures (MTBF)

By incorporating shaft alignment Singapore services into predictive maintenance plans, facilities can minimize downtime and eliminate unexpected disruptions.

Alignment of Specific Machine Types in Singapore

Different machinery types require specialized approaches to shaft alignment. Here’s how shaft alignment Singapore professionals adapt their methods:

Pump and Motor Alignment

In water treatment facilities, petrochemical plants, and HVAC systems, pumps and motors are commonly coupled. Misalignment here causes bearing and seal failure. Shaft alignment Singapore technicians use laser tools to align both horizontal and vertical axes, minimizing vibration.

Turbine Alignment

Power plants in Singapore rely on steam or gas turbines. Even the smallest misalignment can cause significant power losses. Precision shaft alignment is critical for safe and efficient turbine operation.

Gearbox Alignment

Gearboxes are often subject to torque and load variation. Misalignment increases the risk of gear tooth wear and system inefficiency. Shaft alignment Singapore experts align gearboxes using dial indicators or lasers for accuracy.

Cooling Tower Fan Alignment

Cooling towers in industrial complexes and high-rise buildings use large axial fans. Poor alignment leads to fan blade imbalance, motor overload, and excessive noise. Regular alignment is a must.

Marine Shaft Alignment

Singapore’s busy ports and maritime sector depend heavily on accurate marine shaft alignment. Misalignment in a ship’s propulsion system can affect steering, increase fuel consumption, and even damage hull structure. Marine-focused shaft alignment Singapore services address these critical needs with portable alignment kits adapted for marine use.

Advanced Techniques in Shaft Alignment Singapore

The evolution of shaft alignment methods has introduced several advanced techniques. In Singapore’s high-tech industrial ecosystem, these modern methods are gaining widespread adoption:

1. Cardan Shaft Alignment

For machines connected via universal joints or Cardan shafts, standard alignment tools don’t work. Shaft alignment Singapore providers use specialized fixtures and jigs to ensure the angularity and parallelism of such setups.

2. Bore Alignment

Critical in marine and large engine applications, bore alignment ensures that internal bores of multiple housings are colinear. This is vital in long shaft assemblies and is achieved using laser bore alignment tools.

3. Optical Alignment

Using telescopic sights and precision mirrors, optical alignment is used where laser tools may not fit or where line-of-sight is limited. This technique, although older, is still relevant in select cases within shaft alignment Singapore practices.

4. Live Trend Alignment

Live trend monitoring captures shaft movement during the alignment process. It accounts for factors like pipe strain, frame stress, or base soft foot in real time—leading to more accurate final alignment.

Common Misalignment Symptoms in Machinery

Recognizing misalignment symptoms early can prevent damage. Here are common indicators:

- Increased vibration: A clear sign that rotating elements are not in harmony.

- Excessive heat: Misalignment increases friction, which heats up bearings and couplings.

- Frequent seal replacements: Poor alignment puts axial loads on seals, causing premature wear.

- Uneven coupling wear: Misaligned couplings wear unevenly or fail outright.

- Unusual noise: Grinding or whining noises indicate rubbing components.

All of these issues can be detected and resolved through timely shaft alignment Singapore interventions.

Best Practices for Long-Term Shaft Alignment Accuracy

To maintain precision shaft alignment over time, especially in Singapore’s high-demand environments, the following best practices should be implemented:

- Use of Quality Shims: Low-quality or rusted shims lead to misalignment drift.

- Base Plate Inspection: A warped base plate can throw off alignment even if measurements seem correct.

- Proper Torque Settings: Uneven tightening of bolts can shift machine position.

- Foundation Check: A cracked or unstable foundation leads to machine movement and recurring misalignment.

- Eliminate Soft Foot: Ensure all machine feet are solidly mounted and level before alignment.

- Thermal Growth Compensation: Factor in operational temperature differences during alignment.

Professionals in shaft alignment Singapore focus not just on short-term fixes but on maintaining alignment integrity for the long term.

Training and Certification for Shaft Alignment in Singapore

With precision and safety at the forefront, skilled manpower is essential. Many technicians involved in shaft alignment Singapore services undergo international training and certifications, such as:

- ISO 9001-based alignment certification

- Vibration Analysis Category I & II

- Laser Alignment Level 1 & 2

- CMRT (Certified Maintenance & Reliability Technician)

Workshops and seminars help align local skills with global standards. This ensures that Singapore’s industries have access to competent professionals who can perform complex alignment procedures safely and accurately.

Environmental Impact of Shaft Misalignment

Poor shaft alignment doesn’t just affect your machinery—it also contributes to environmental issues:

- Higher power usage leads to increased CO₂ emissions

- Faster machine wear means more frequent part replacement and landfill waste

- Unexpected failures can lead to fluid spills or oil leaks

With Singapore’s growing emphasis on sustainability, maintaining proper alignment is part of a larger green strategy. Shaft alignment Singapore solutions play an important role in helping industries stay environmentally responsible.

Data-Driven Shaft Alignment in the Age of Industry 4.0

As part of the Smart Nation initiative, Singapore’s industries are embracing Industry 4.0 practices. Shaft alignment has also evolved into a data-driven discipline.

Modern shaft alignment Singapore services integrate with:

- CMMS (Computerized Maintenance Management Systems)

- SCADA systems

- IoT sensors for remote monitoring

- Cloud dashboards for KPI tracking

This integration allows maintenance teams to make data-backed decisions, predict misalignment trends, and plan alignment interventions at optimal times.

Cost-Benefit Analysis of Shaft Alignment

Investing in professional shaft alignment Singapore services can seem costly upfront. However, the long-term savings far outweigh initial costs.

Here’s a typical breakdown:

| Factor | Without Alignment | With Shaft Alignment Singapore |

|---|---|---|

| Energy Use | High | Optimized |

| Bearing Life | 1–2 years | 3–5 years |

| Seal Failures | Frequent | Rare |

| Coupling Replacements | Every 6–12 months | 18+ months |

| Downtime | Unpredictable | Planned & minimal |

| Operator Safety | At risk | Improved |

Even a 2% gain in operational efficiency over a year could mean hundreds of thousands of dollars saved, especially in large facilities.

Seasonal and Usage-Based Realignment

In Singapore, where certain industries ramp up operations seasonally (e.g., manufacturing before global holidays or port logistics before shipping peaks), it’s wise to plan shaft alignment Singapore sessions accordingly.

High usage during peak periods increases the chance of misalignment. Realigning after peak seasons ensures machines are reset and ready for the next cycle.

Mobile Shaft Alignment Services

Many shaft alignment Singapore providers now offer mobile alignment services where trained technicians bring equipment onsite. This is ideal for:

- Remote industrial sites

- Marine vessels docked in ports

- Critical equipment that cannot be transported

Mobile services include:

- On-the-spot diagnosis

- Live laser alignment

- Digital reporting

- Soft foot and thermal checks

This flexibility allows industries to maintain alignment without shutting down operations or disassembling machinery.

Final Thoughts: Why Shaft Alignment Matters More Than Ever in Singapore

As Singapore’s industries grow increasingly automated, digitized, and sustainable, shaft alignment Singapore services play a foundational role in achieving operational excellence.

From protecting expensive equipment and enhancing safety to supporting green initiatives and maximizing efficiency, shaft alignment is no longer just a maintenance task—it’s a strategic advantage.

Investing in precise, professional, and technologically advanced shaft alignment Singapore services ensures that businesses stay ahead, machinery stays healthy, and downtime stays at zero.

Conclusion

Shaft alignment Singapore is not just a technical requirement—it is a cornerstone of industrial efficiency, safety, and sustainability. Whether it’s in marine, manufacturing, HVAC, or energy sectors, precise shaft alignment can drastically improve machine performance, reduce costs, and extend asset lifespans.

As industries continue to grow and technologies evolve, investing in regular and professional shaft alignment Singapore services is no longer optional—it’s a necessity. Precision alignment ensures that Singapore’s industrial backbone remains strong, efficient, and future-ready.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply