Pump vibration analysis Singapore – Best 2025

Pump Vibration Analysis Singapore: The Key to Enhanced Pump Performance

In Singapore’s bustling industrial sector, ensuring the proper functioning of equipment like pumps is essential for maintaining optimal productivity and minimizing downtime. One of the most critical yet often overlooked aspects of pump maintenance is Pump vibration analysis Singapore. This diagnostic technique plays a pivotal role in identifying potential problems before they escalate, ensuring your operations stay efficient and cost-effective.

What is Pump Vibration Analysis Singapore?

Pump vibration analysis Singapore refers to the method of monitoring and evaluating the vibration levels produced by a pump during operation. This analysis helps identify any irregularities that might indicate a malfunction or wear. By using advanced vibration monitoring tools, industries in Singapore can pinpoint issues like misalignment, imbalance, bearing failure, or cavitation early on. With Pump vibration analysis Singapore, businesses can prevent equipment failure, saving time and money on costly repairs or replacements.

Why is Pump Vibration Analysis Singapore Crucial?

Effective Pump vibration analysis Singapore is essential for maintaining the reliability and efficiency of your pumps. Without regular vibration monitoring, problems can go unnoticed until they lead to severe equipment breakdowns, causing expensive repairs and downtime. In industries like oil & gas, water treatment, manufacturing, and chemical processing in Singapore, where pumps play a vital role, it’s essential to implement Pump vibration analysis Singapore as a preventive maintenance tool.

Benefits of Pump Vibration Analysis Singapore

- Early Detection of Problems: By conducting Pump vibration analysis Singapore, you can detect problems like pump imbalance, misalignment, or bearing wear early on, minimizing the risk of unplanned shutdowns.

- Increased Equipment Lifespan: Regular vibration analysis can significantly extend the life of your pump. Preventive maintenance through Pump vibration analysis Singapore helps you avoid premature equipment failure, maximizing your ROI.

- Cost Savings: The cost of repairing or replacing a failed pump is far higher than the expense of conducting Pump vibration analysis Singapore. Early detection helps you save money on costly repairs, parts replacement, and operational downtime.

- Improved Performance: By reducing vibration-related issues, your pump will operate at its optimal efficiency, leading to better performance and energy savings.

Industries in Singapore Benefiting from Pump Vibration Analysis

Various industries in Singapore rely on pumps for their operations, making Pump vibration analysis Singapore a vital part of their maintenance strategy. Some industries include:

- Oil & Gas: Pumps are essential for transporting fluids in pipelines and processing plants. Early detection of vibration anomalies through Pump vibration analysis Singapore can prevent hazardous incidents.

- Water Treatment: Pumps are used extensively in water treatment plants to move large volumes of water. A sudden failure can halt operations, making Pump vibration analysis Singapore critical.

- Manufacturing: Manufacturing processes require reliable pumps for efficient production. Implementing Pump vibration analysis Singapore ensures uninterrupted production cycles.

- Chemical Processing: Pumps move dangerous chemicals in chemical plants. Vibration analysis helps ensure safety and compliance with industry standards in Singapore.

How Does Pump Vibration Analysis Work?

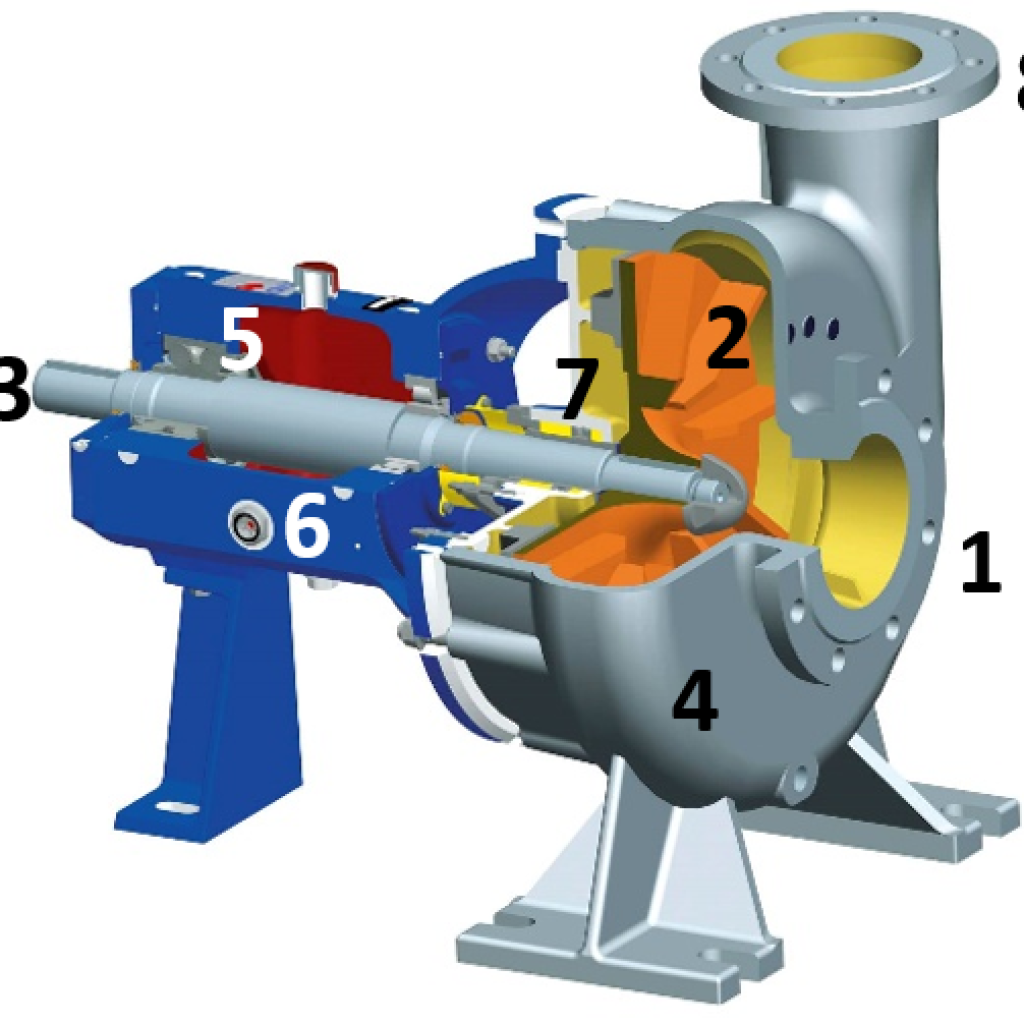

Pump vibration analysis uses sensors placed on the pump to measure vibrations. These sensors track both the frequency and amplitude of the vibration. By analyzing the data, specialists can detect issues that could lead to more severe damage if left unchecked.

Some common vibration problems detected through Pump vibration analysis Singapore include:

- Imbalance: This occurs when there is unequal weight distribution within the pump, leading to excessive vibration.

- Misalignment: Misalignment of pump shafts or couplings causes vibrations, and Pump vibration analysis Singapore helps in identifying and correcting this.

- Bearing Wear: Worn-out bearings can lead to dangerous vibrations and impact the overall performance of the pump.

Choosing the Right Service for Pump Vibration Analysis Singapore

When selecting a service provider for Pump vibration analysis Singapore, look for a company that offers:

- Advanced Equipment: Modern vibration monitoring tools to provide accurate readings and diagnostics.

- Experienced Technicians: Professionals who understand the nuances of pump operation and can interpret vibration data correctly.

- Proven Track Record: A company with a reputation for providing reliable and efficient Pump vibration analysis Singapore services.

At Flomek, we specialize in Pump vibration analysis Singapore, providing top-tier vibration monitoring services to help your business avoid costly downtime and maintain peak pump performance.

Flomek: Your Partner for Pump Vibration Analysis Singapore

Flomek is a leading provider of Pump vibration analysis Singapore. We utilize cutting-edge technology to monitor the vibrations of your pumps, ensuring that potential issues are identified before they disrupt your operations. Our team of experts has years of experience in vibration analysis, and we are committed to delivering fast and accurate results for your business. Whether you are operating in the oil and gas sector, manufacturing, or any other industry, Flomek is your trusted partner for Pump vibration analysis Singapore.

Pump Vibration Analysis Singapore: A Critical Maintenance Solution for Industrial Efficiency

In today’s competitive industrial landscape, maintaining the smooth operation of machinery is paramount. One key aspect often overlooked in pump maintenance is Pump vibration analysis Singapore. This specialized diagnostic technique helps identify early signs of trouble in pumps, enabling companies to address issues before they lead to catastrophic failures. Whether you’re in the manufacturing, chemical, or water treatment sectors, Pump vibration analysis Singapore can significantly improve the reliability of your pump systems.

What is Pump Vibration Analysis Singapore?

Pump vibration analysis Singapore involves monitoring the vibrations produced by pumps during their normal operation. Vibration analysis is an essential tool used by industrial maintenance teams to detect irregularities or wear and tear in a pump’s components, such as the motor, bearings, and impellers. This non-invasive method helps pinpoint problems like imbalance, misalignment, and bearing defects, allowing businesses to take preventive actions and avoid costly repairs.

By conducting Pump vibration analysis Singapore, companies can avoid unexpected breakdowns, reduce downtime, and optimize their operations. This proactive approach leads to longer pump lifespans and better performance, ultimately saving money and resources.

Why is Pump Vibration Analysis Singapore Essential?

In high-demand industries where pumps are essential to daily operations, ensuring that they are in optimal condition is crucial. Regular Pump vibration analysis Singapore plays a vital role in identifying faults early, before they cause severe damage. If vibration issues are left unchecked, they can escalate into complete pump failures, resulting in costly shutdowns, repairs, or even complete replacement.

By adopting Pump vibration analysis Singapore, industrial facilities can operate more efficiently and reduce unnecessary maintenance costs. The technique enables maintenance teams to diagnose problems quickly, allowing for faster resolution without compromising productivity.

Benefits of Pump Vibration Analysis Singapore

- Prevention of Downtime: The primary benefit of Pump vibration analysis Singapore is the ability to detect issues before they lead to unexpected shutdowns. With early identification of problems, such as misalignment or bearing failure, your pumps can continue running without interruptions, ensuring smoother operations.

- Enhanced Safety: Vibration abnormalities often signal unsafe conditions. By using Pump vibration analysis Singapore, hazardous situations can be detected early, protecting both the equipment and workers from potential dangers.

- Cost-Efficiency: The cost of conducting Pump vibration analysis Singapore is minimal compared to the expenses incurred from equipment failure, which can result in expensive repairs, parts replacement, and long downtime. Regular analysis prevents major malfunctions, keeping your pumps running smoothly and efficiently.

- Optimized Pump Performance: A pump that operates with minimal vibration runs more efficiently, uses less energy, and performs better overall. With regular Pump vibration analysis Singapore, companies can ensure that their pumps are running at peak performance, leading to long-term savings.

Industries in Singapore That Benefit from Pump Vibration Analysis

Various industries in Singapore rely on pump systems for essential operations, making Pump vibration analysis Singapore crucial for preventing operational disruptions. Some industries that particularly benefit from this analysis include:

- Water and Wastewater Treatment: Pumps play a key role in moving water or wastewater through treatment plants. With Pump vibration analysis Singapore, maintenance teams can identify pump issues early, ensuring continuous water flow and minimizing service interruptions.

- Oil and Gas Industry: Pumps are critical in the oil and gas industry for transporting fluids like oil and gas through pipelines. Pump vibration analysis Singapore ensures that the pumps are running at full capacity and that any issues are addressed before causing severe damage.

- Manufacturing: In manufacturing plants, pumps are used for moving chemicals, water, or other materials. Pump vibration analysis Singapore helps manufacturers keep their processes running without unexpected pump failures.

- Chemical Processing: Pumps in chemical plants need to be monitored regularly for vibrations that could indicate issues such as cavitation or bearing failure. Pump vibration analysis Singapore ensures safe and continuous operations in these critical environments.

How Does Pump Vibration Analysis Singapore Work?

Pump vibration analysis Singapore uses specialized sensors to monitor the vibrations produced by pumps. These sensors detect and measure the frequency, amplitude, and direction of the vibration. Data collected from these sensors is then analyzed to identify abnormalities in the pump’s operation. Common problems detected by Pump vibration analysis Singapore include:

- Imbalance: A pump that is imbalanced can cause vibrations that affect the overall system. Early identification of imbalance can help with corrective actions, such as balancing the pump to prevent further damage.

- Misalignment: Misalignment between the pump’s shaft and motor can lead to vibrations that indicate significant wear. Pump vibration analysis Singapore helps pinpoint misalignment before it leads to severe damage.

- Bearing Failure: Worn-out or damaged bearings can cause excessive vibrations. With Pump vibration analysis Singapore, technicians can spot bearing problems early and replace them before they cause a complete failure.

Choosing the Right Provider for Pump Vibration Analysis Singapore

When selecting a provider for Pump vibration analysis Singapore, it’s essential to choose a company that offers reliable, accurate, and timely services. Look for the following qualities in a provider:

- Expertise and Experience: A company with extensive experience in Pump vibration analysis Singapore can quickly diagnose problems and provide actionable insights.

- Advanced Technology: Ensure that the provider uses state-of-the-art vibration monitoring tools for precise and thorough analysis.

- Comprehensive Reports: The best providers offer detailed reports that outline the condition of your pumps and recommend necessary corrective actions.

- Prompt Service: Time is of the essence, so it’s important to select a provider who can deliver quick and efficient results.

Flomek is your trusted partner for Pump vibration analysis Singapore, offering reliable services to ensure that your pumps remain in peak condition. Our experienced technicians use cutting-edge tools to provide accurate diagnostics and effective maintenance solutions.

Flomek’s Expertise in Pump Vibration Analysis Singapore

At Flomek, we specialize in providing professional Pump vibration analysis Singapore services. With a team of highly skilled engineers, we utilize the latest vibration monitoring equipment to assess the condition of your pumps accurately. By implementing regular Pump vibration analysis Singapore, businesses can prevent downtime, improve pump efficiency, and reduce maintenance costs. Our commitment to excellence ensures that your pump systems will continue to operate at their best.

Maximizing Efficiency with Pump Vibration Analysis Singapore

In the dynamic industries of Singapore, where machinery plays a critical role, Pump vibration analysis has become an indispensable tool for maintaining pump performance. Pumps are vital components in several sectors, from water treatment to manufacturing, and ensuring their optimal functioning is key to preventing breakdowns and costly repairs. Pump vibration analysis enables businesses to detect early signs of wear and tear, leading to more efficient, longer-lasting equipment.

What is Pump Vibration Analysis Singapore?

Pump vibration analysis is a technique used to measure the vibrations emitted by pumps during operation. By analyzing these vibrations, specialists can detect abnormalities, such as misalignment, imbalance, and damaged bearings, which may signal underlying issues in the pump. This process is essential for proactive maintenance, allowing industries to address potential failures before they cause significant damage to the equipment.

In Singapore’s industrial landscape, where equipment downtime can lead to serious financial losses, implementing Pump vibration analysis is a crucial step in preventing unexpected disruptions.

Why Should You Implement Pump Vibration Analysis Singapore?

The importance of Pump vibration analysis cannot be overstated. Regular vibration monitoring helps maintain peak efficiency and prolong the lifespan of pumps, ensuring smooth operations across various industries. By conducting Pump vibration analysis , businesses can:

- Prevent Unexpected Failures: Early detection of issues like imbalance or misalignment helps prevent unexpected pump breakdowns, reducing the risk of costly downtime.

- Improve Energy Efficiency: Pumps that are properly aligned and balanced consume less energy. Pump vibration analysis Singapore identifies inefficiencies that can be corrected to reduce energy consumption.

- Extend Equipment Lifespan: Identifying issues early through Pump vibration analysis allows businesses to address them before they cause irreversible damage to the pump components.

- Ensure Safety: Excessive vibrations often signal unsafe conditions. By using Pump vibration analysis industries can take corrective actions to enhance workplace safety.

Key Benefits of Pump Vibration Analysis Singapore

- Increased Reliability: Pumps are critical to many industrial processes, and downtime can be costly. Through Pump vibration analysis Singapore, companies can achieve higher reliability by identifying and addressing potential issues early on.

- Cost-Effectiveness: The cost of diagnosing pump problems through Pump vibration analysis is far lower than the cost of repairing or replacing a failed pump. Early identification of problems leads to better budgeting and reduced maintenance expenses.

- Improved Performance and Efficiency: Pump vibration analysis ensures that pumps are running at their optimal efficiency by identifying problems like misalignment and imbalance that may hinder performance. This leads to smoother, faster, and more energy-efficient operations.

- Data-Driven Decisions: Pump vibration analysis Singapore provides companies with detailed data on pump health, allowing decision-makers to plan and schedule maintenance, replacements, or repairs based on actual data rather than guesswork.

How Does Pump Vibration Analysis Singapore Work?

The process of Pump vibration analysis begins with installing sensors that monitor the vibrations produced by the pump. These sensors capture data on frequency, amplitude, and the overall behavior of the vibrations. The data is then analyzed to identify any abnormal patterns that could indicate a problem.

Common issues detected through Pump vibration analysis Singapore include:

- Imbalance: An imbalanced pump can cause excessive vibration and damage to surrounding components. Pump vibration analysis Singapore helps identify these problems early.

- Misalignment: Misalignment of the pump shaft can lead to wear and tear on bearings and seals, resulting in inefficient performance. Pump vibration analysis can detect these issues before they cause extensive damage.

- Bearing Wear: Worn-out bearings create abnormal vibrations and can eventually lead to pump failure. Pump vibration analysis Singapore is crucial in detecting bearing problems early.

Industries That Benefit from Pump Vibration Analysis Singapore

A wide range of industries in Singapore can benefit from Pump vibration analysis . Some of the most significant sectors include:

- Manufacturing Industry: Pumps are essential in various manufacturing processes, including fluid transfer, mixing, and circulation. Regular Pump vibration analysis ensures that these pumps remain in top condition, avoiding production delays.

- Water and Wastewater Treatment: The consistent operation of pumps is critical in water treatment plants, where any breakdown can disrupt the entire facility. Pump vibration analysis is vital in ensuring that pumps run smoothly and efficiently.

- Oil and Gas Industry: In the oil and gas industry, pumps are used to move fluids across long distances. Detecting vibration anomalies through Pump vibration analysis helps prevent catastrophic pump failures and delays in production.

- Chemical Processing: Pumps in chemical plants handle volatile substances, making reliability crucial. Pump vibration analysis Singapore helps maintain pump performance and safety in these high-risk environments.

How Often Should You Perform Pump Vibration Analysis Singapore?

The frequency of Pump vibration analysis largely depends on the type of pump and its operating environment. For pumps that run continuously or operate in harsh conditions, more frequent vibration analysis is recommended. Regular monitoring can ensure that potential issues are detected early, minimizing the risk of unscheduled maintenance or repairs.

For most industries, quarterly or semi-annual Pump vibration analysis is adequate to keep pumps in optimal working condition. However, in more critical applications, monthly or even weekly monitoring may be necessary.

Why Choose Flomek for Pump Vibration Analysis Singapore?

Flomek specializes in offering top-notch Pump vibration analysis services. We understand the importance of maintaining the health of your pumps, and our team is dedicated to delivering accurate diagnostics and effective solutions. Using state-of-the-art vibration monitoring tools, Flomek ensures that your pumps are performing at their best, reducing the risk of failure and maximizing uptime.

The Flomek Advantage:

- Advanced Diagnostic Tools: Flomek uses the latest technology for Pump vibration analysis , ensuring precise and reliable results.

- Experienced Technicians: Our team has extensive experience in pump diagnostics, enabling us to detect and resolve issues quickly and effectively.

- Comprehensive Reporting: After each analysis, we provide a detailed report with actionable recommendations, allowing you to make informed decisions about your equipment.

- Timely Service: Flomek prides itself on providing fast and efficient services, ensuring minimal disruption to your operations.

Conclusion

In conclusion, Pump vibration analysis Singapore is an indispensable tool for any business that relies on pump systems. The ability to detect and address problems early will prevent costly repairs, reduce downtime, and extend the life of your equipment. Flomek offers industry-leading Pump vibration analysis services that will ensure your pumps operate at peak efficiency, safeguarding your operations. For reliable, cost-effective, and professional vibration analysis, trust Flomek to keep your pumps running smoothly.

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply