pump repair Singapore – Singapore’s No 1 Best Pumps Supplier

Pump Repair Singapore: Complete Guide to Efficient and Reliable Pump Solutions

Introduction

In an urban environment like Singapore, where industrial, commercial, and residential infrastructures are built for durability and functionality, the importance of pump repair Singapore services cannot be overstated. Pumps are critical to numerous applications—from water distribution and drainage to HVAC systems, wastewater treatment, and manufacturing processes. Yet, like any mechanical equipment, pumps are subject to wear, damage, and failure.

This comprehensive guide explores the relevance, scope, techniques, and value of pump repair Singapore, empowering you with knowledge to maintain pump efficiency, reduce downtime, and extend equipment life.

Chapter 1: Understanding Pump Systems

1.1 What Are Pumps?

Pumps are mechanical devices designed to move fluids (liquids or gases) from one point to another using mechanical action. They are integral in systems that require water flow, chemical distribution, oil movement, and much more.

1.2 Common Types of Pumps in Singapore

To appreciate the importance of pump repair Singapore, it is essential to understand the different pump types used locally:

- Centrifugal Pumps: Common in water supply and HVAC systems.

- Submersible Pumps: Used in drainage and sewage systems.

- Booster Pumps: Enhance water pressure in residential and commercial buildings.

- Vacuum Pumps: Crucial in manufacturing and laboratory settings.

- Diaphragm Pumps: Widely used in chemical processing.

- Gear Pumps: Ideal for handling viscous fluids like oil and adhesives.

Each of these has unique operational mechanisms and maintenance needs, reinforcing why pump repair Singapore services must be tailored and highly specialized.

Chapter 2: Why Pump Repair Is Crucial in Singapore

2.1 High Usage Environments

Singapore’s tropical climate and dense urban infrastructure place significant stress on pumps, especially in high-rise buildings, data centers, and flood-prone areas. Efficient pump repair Singapore solutions ensure systems continue operating without costly interruptions.

2.2 Regulatory Compliance

Singapore enforces strict regulations for environmental management and public safety. Faulty pumps, particularly in wastewater and chemical systems, can cause legal liabilities. Hence, proper pump repair Singapore services help businesses and households stay compliant.

2.3 Cost-Efficiency

Regular maintenance and timely pump repair Singapore can prevent catastrophic failures. Replacing a pump is significantly more expensive than repairing or refurbishing one.

Chapter 3: Common Pump Problems in Singapore

A key part of understanding pump repair Singapore involves recognizing symptoms of failure. Here are some common issues faced:

3.1 Overheating

Overheating may result from poor lubrication, clogged filters, or motor faults. Timely intervention by pump repair Singapore professionals prevents permanent damage.

3.2 Reduced Flow Rate

This could be caused by blockages, airlocks, or worn impellers. A thorough inspection and pump repair Singapore service can restore performance.

3.3 Noise and Vibration

Unusual noise or vibration often indicates misalignment, bearing wear, or cavitation. These issues are common in aging systems and require expert pump repair Singapore attention.

3.4 Seal and Gasket Leaks

Seal failures can lead to fluid leakage, reduced efficiency, and environmental hazards. Seals must be inspected and replaced during pump repair Singapore servicing.

Chapter 4: Step-by-Step Pump Repair Process

Professionally managed pump repair Singapore involves systematic inspection and servicing stages:

4.1 Initial Diagnosis

Technicians evaluate the pump’s condition using vibration analysis, infrared thermography, or flow rate measurements.

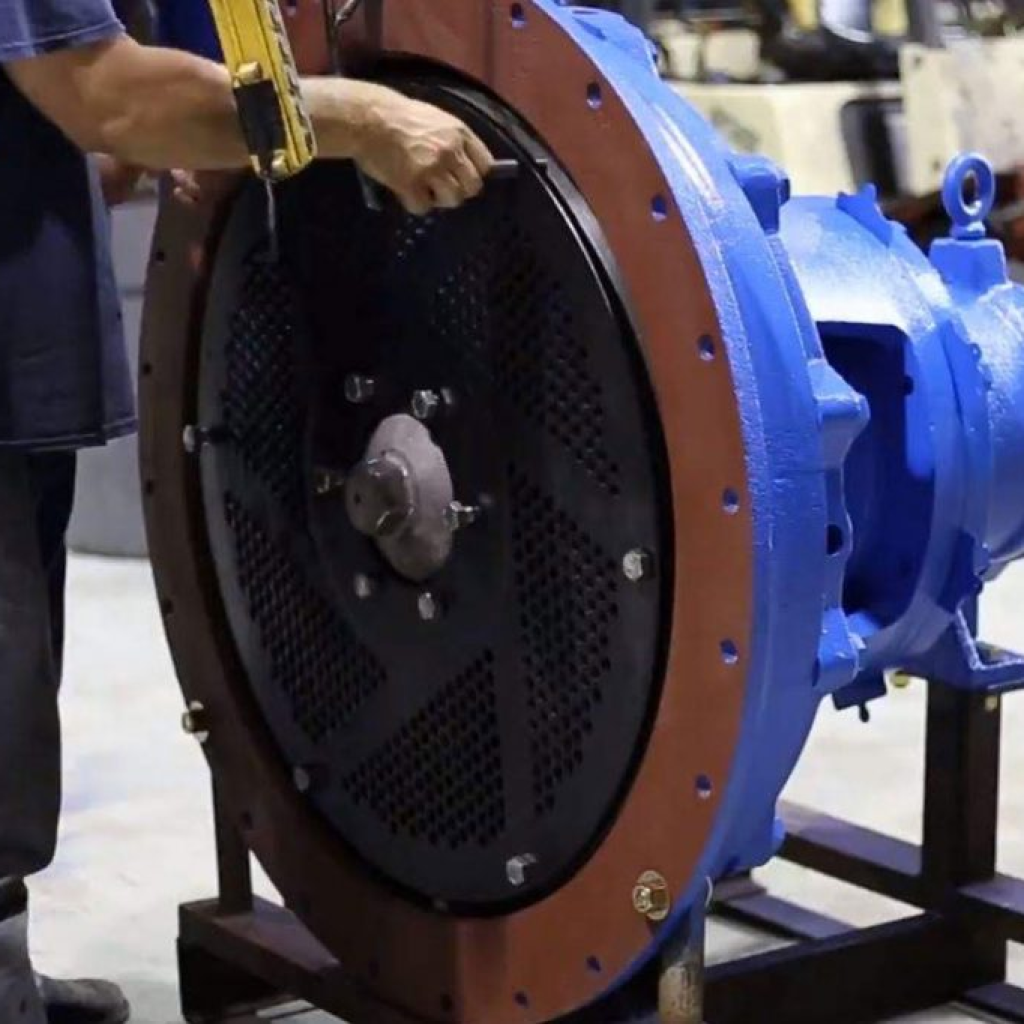

4.2 Disassembly

The pump is carefully disassembled, and worn or broken components are identified.

4.3 Component Replacement

Impellers, bearings, seals, and gaskets are the most frequently replaced parts during pump repair Singapore processes.

4.4 Reassembly and Testing

Once components are replaced, the pump is reassembled and tested for performance, pressure, and leak resistance.

4.5 On-Site or Off-Site Repair

Depending on the severity of the issue, pump repair Singapore can be conducted on-site (minimizing downtime) or in a workshop with specialized equipment.

Chapter 5: Preventive Maintenance in Pump Repair Singapore

Preventive maintenance is the cornerstone of minimizing downtime and maximizing the lifespan of pumps.

5.1 Scheduled Inspections

Regular inspection schedules prevent minor issues from becoming costly repairs. Many pump repair Singapore providers offer service contracts with scheduled visits.

5.2 Lubrication Management

Pumps require proper lubrication to reduce friction and prevent wear. Maintenance includes checking oil levels, quality, and proper grease application.

5.3 Alignment and Balancing

Misaligned pumps cause premature bearing failure and vibration. Laser alignment tools are often used during pump repair Singapore services.

5.4 Monitoring and Data Logging

Smart sensors and data loggers can help track performance metrics, enabling proactive pump repair Singapore interventions before breakdowns occur.

Chapter 6: Industries That Rely on Pump Repair Singapore

Many industries in Singapore depend heavily on reliable pump systems. Here’s how pump repair Singapore plays a critical role across sectors:

6.1 Commercial Buildings

HVAC, booster, and drainage pumps require constant monitoring. Timely pump repair Singapore ensures comfort and safety in malls, offices, and condominiums.

6.2 Industrial Manufacturing

Factories rely on centrifugal, vacuum, and process pumps. Any failure can halt operations, making pump repair Singapore essential to minimize production loss.

6.3 Wastewater Management

Sewage treatment plants use submersible and centrifugal pumps extensively. Regular pump repair Singapore is vital to prevent contamination and maintain compliance.

6.4 Marine and Offshore

Bilge pumps and fuel transfer pumps must function reliably. The harsh marine environment makes pump repair Singapore a continuous need for the sector.

6.5 Agriculture and Landscaping

Irrigation pumps require regular servicing to ensure optimal flow rates. Efficient pump repair Singapore solutions help conserve water and energy.

Chapter 7: Choosing the Right Pump Repair Service

Choosing the right service provider ensures quality and reliability.

7.1 Look for Experience

Experience with diverse pump types and industries is a hallmark of competent pump repair Singapore technicians.

7.2 Comprehensive Services

Providers that offer inspection, repair, installation, and testing ensure a full-cycle pump repair Singapore experience.

7.3 Use of Advanced Tools

Modern diagnostic tools and techniques enhance accuracy and speed. Look for service providers who use ultrasound, thermal imaging, and vibration analysis in their pump repair Singapore processes.

Chapter 8: Energy Efficiency and Cost Savings

Effective pump repair Singapore is not just about fixing equipment—it’s about enhancing performance.

8.1 Reducing Power Consumption

A well-maintained pump operates at optimal efficiency, reducing electricity bills significantly.

8.2 Avoiding Unscheduled Downtime

Breakdowns lead to operational delays and emergency costs. Scheduled pump repair Singapore minimizes these risks.

8.3 Prolonging Equipment Life

By replacing only necessary parts and servicing components proactively, pump repair Singapore helps you get more years out of your pump systems.

Chapter 9: Emergency Pump Repair Singapore Services

When critical systems fail, emergency services are the lifeline.

9.1 24/7 Availability

Many pump repair Singapore teams offer round-the-clock support for vital systems such as sump pumps during heavy rains or HVAC systems in data centers.

9.2 Mobile Repair Units

On-site diagnostic vans equipped with essential tools and spare parts can execute pump repair Singapore jobs quickly, avoiding transport delays.

Chapter 10: Upgrading and Retrofitting in Pump Repair Singapore

Sometimes, older systems need more than just a repair.

10.1 Retrofitting with Modern Components

Older pumps can be fitted with energy-efficient motors, smart sensors, and better seals. This merges the benefits of pump repair Singapore with technological upgrades.

10.2 Control Panel Upgrades

Modern control systems improve performance monitoring. Many pump repair Singapore services also offer control system integration and software upgrades.

Chapter 11: Environmental Responsibility

11.1 Reducing Waste

Repairing instead of replacing aligns with sustainability goals. Through pump repair Singapore, less waste is sent to landfills.

11.2 Energy Conservation

Well-maintained pumps use less power, reducing the carbon footprint of industrial and commercial facilities.

11.3 Fluid Containment

Proper pump repair Singapore prevents leaks that could contaminate water or soil, making it a key component of eco-responsible operations.

Chapter 12: Technological Advancements in Pump Repair Singapore

The pump repair landscape has evolved significantly with modern technology. Today’s pump repair Singapore providers utilize advanced tools to ensure repairs are faster, more precise, and more sustainable.

12.1 Smart Diagnostic Tools

Advanced diagnostics such as thermal cameras, acoustic sensors, and ultrasonic leak detectors play a vital role in pump repair Singapore operations. These tools detect internal damage and performance inefficiencies that are invisible to the naked eye.

12.2 3D Printing for Spare Parts

Some modern workshops supporting pump repair Singapore are now utilizing 3D printing to produce rare or discontinued components. This minimizes wait time for spare parts and helps restore old systems faster.

12.3 Predictive Maintenance Using IoT

IoT sensors installed in pump systems continuously monitor vibration, temperature, and flow rates. The data collected allows experts in pump repair Singapore to forecast failures before they happen, enabling predictive repairs rather than reactive solutions.

Chapter 13: Customization in Pump Repair Services

Every system is different, and a one-size-fits-all approach doesn’t work in pump maintenance. This is why pump repair Singapore increasingly focuses on customized repair and maintenance strategies.

13.1 Tailored Service Plans

Different facilities—hotels, factories, residential complexes—have unique operational needs. Customized pump repair Singapore plans address specific challenges, such as fluctuating water demand, high humidity, or chemical exposure.

13.2 Material-Specific Repairs

Pumps made of bronze, stainless steel, or composite materials each require specific repair techniques. High-quality pump repair Singapore services understand these differences and choose materials and tools accordingly.

13.3 Location-Sensitive Approaches

Urban, coastal, and industrial environments each influence pump wear in different ways. Professionals handling pump repair Singapore adjust strategies based on whether the pump is located underground, exposed to seawater, or used in an enclosed plant.

Chapter 14: Challenges Faced in Pump Repair Singapore

Despite technological advancements, challenges still exist in the field of pump repair Singapore.

14.1 Limited Access in Confined Spaces

Many pumps in Singapore are installed in compact or underground spaces. Repairing them requires experience, specialized tools, and safety precautions.

14.2 Weather Impact on Outdoor Systems

Singapore’s heavy rains and high humidity can accelerate corrosion and electronic failure. Outdoor pumps demand more frequent pump repair Singapore and weather-proofing techniques.

14.3 Downtime Pressure

In commercial and industrial environments, every second of pump failure means lost revenue. That’s why speed and reliability are non-negotiable aspects of pump repair Singapore.

Chapter 15: Pump Refurbishment vs. Replacement

Another important concept within pump repair Singapore is knowing when to repair, refurbish, or replace.

15.1 Cost-Benefit Analysis

If a pump has multiple failing components or is severely corroded, it may be more cost-effective to replace. However, many pump repair Singapore professionals can fully refurbish systems for a fraction of replacement cost.

15.2 Environmental Impact

Repairing and refurbishing reduces waste. Opting for pump repair Singapore over replacement aligns with Singapore’s green building and waste reduction goals.

15.3 Performance Optimization

Refurbishment can include performance upgrades such as energy-efficient motors, better impellers, or digital monitoring—making pump repair Singapore an opportunity for modernization.

Chapter 16: Pump Repair Singapore for Sustainable Infrastructure

Singapore’s push for sustainable infrastructure includes efficient water and waste management, where pump systems play a central role.

16.1 Reducing Water Waste

Leaking or faulty pumps can cause significant water loss. Prompt and effective pump repair Singapore ensures better conservation of water resources.

16.2 Energy Efficient Systems

Modern pump repair Singapore techniques aim to restore systems to optimal efficiency, lowering electricity usage and operational costs.

16.3 Supporting the Green Mark Initiative

Proper pump maintenance and repair help commercial buildings comply with Singapore’s BCA Green Mark requirements by improving energy efficiency and system reliability.

Chapter 17: Safety Considerations in Pump Repair Singapore

Safety is a non-negotiable component of any pump repair Singapore service, especially in high-risk environments like chemical plants, basements, and underwater systems.

17.1 Electrical Safety

Before performing repairs, all power sources must be isolated. High-voltage systems require certified electricians trained in pump repair Singapore protocols.

17.2 Confined Space Entry

Repairing pumps in tanks or underground vaults requires confined-space permits, gas monitoring, and ventilation—standards upheld by reliable pump repair Singapore providers.

17.3 Fire and Explosion Hazards

In chemical or fuel environments, pump failure can pose explosion risks. Proper sealing, grounding, and leak prevention during pump repair Singapore is critical to avoid hazards.

Chapter 18: Signs You Need Immediate Pump Repair Singapore

Recognizing early warning signs can prevent major breakdowns. Here are indicators that your system needs urgent pump repair Singapore attention:

- Significant drop in water pressure or flow rate

- Abnormal noise or rattling

- Excessive energy usage

- Water or fluid leaks

- Unusual heat generation

- System alarms or shutdowns

Delaying repairs may result in greater damage, costlier service, or even safety risks.

Chapter 19: Maintenance Contracts and Long-Term Benefits

Many facilities now opt for yearly or bi-annual maintenance agreements to avoid emergency repairs.

19.1 Scheduled Inspections and Repairs

These agreements ensure that a trained pump repair Singapore team inspects your systems at fixed intervals, reducing unexpected failures.

19.2 Priority Support

Maintenance contract holders often receive priority response in case of breakdowns, ensuring minimal disruption.

19.3 Inventory Management

For businesses with multiple pumps, the pump repair Singapore team can help maintain an inventory of critical spare parts, reducing wait times for component replacement.

Chapter 20: The Future of Pump Repair Singapore

The future of pump repair Singapore is driven by digital technology, automation, and sustainability.

20.1 AI and Machine Learning Integration

Smart systems will soon predict pump failures using AI, allowing pump repair Singapore to become predictive and proactive.

20.2 Remote Monitoring and Repairs

With IoT-connected pumps, many faults can be diagnosed—and even corrected—remotely, reducing downtime and technician travel.

20.3 Eco-Friendly Materials and Solutions

From biodegradable lubricants to recyclable components, the pump repair Singapore sector is moving toward greener materials and sustainable repair techniques.

Chapter 21: Seasonal Maintenance and Pump Repair Singapore

Singapore’s tropical climate creates unique seasonal challenges for pump systems. Continuous humidity, heavy rains, and temperature fluctuations affect pump performance and durability. This makes pump repair Singapore essential, especially during monsoon and hot seasons.

21.1 Pre-Monsoon Checks

In preparation for heavy rains, sump pumps, submersible pumps, and drainage systems must be thoroughly inspected. Pump repair Singapore technicians usually recommend:

- Clearing blockages from drain lines

- Checking float switch functions

- Replacing corroded or weakened wiring

- Testing emergency backup power systems

These proactive steps help prevent flooding, especially in basement areas, tunnels, and low-lying buildings.

21.2 Post-Monsoon Recovery

After intense rainfall, many systems experience wear and tear. Post-monsoon pump repair Singapore includes:

- Motor rewinding

- Impeller inspection for sediment damage

- Cleaning and drying moisture-sensitive components

- Restoring corroded parts to prevent long-term damage

Seasonal services ensure long-term reliability and reduce emergency repair frequency.

Chapter 22: Pump Repair Singapore in Construction Projects

Construction projects rely on pump systems for dewatering, concrete mixing, groundwater management, and material transfer. When these systems fail, projects can face costly delays. This is where construction-specific pump repair Singapore solutions play a critical role.

22.1 Dewatering Pump Repairs

Construction sites often use high-power dewatering pumps to remove water from excavation areas. If these systems clog or overheat, pump repair Singapore specialists must intervene quickly to restore operation and avoid flooding.

22.2 Concrete Transfer and Slurry Pumps

These specialized pumps endure high wear due to abrasive materials. Frequent pump repair Singapore is required to:

- Replace seals and bearings

- Restore flow through clogged lines

- Maintain proper pressure for even material distribution

Proper maintenance ensures smooth construction timelines and worker safety.

Chapter 23: Residential Pump Repair Singapore

Though often overlooked, homes across Singapore depend on pumps for water pressure, filtration, rainwater harvesting, and garden irrigation. Timely pump repair Singapore services for residences ensure comfort, safety, and utility efficiency.

23.1 Booster Pump Repairs

Many HDB flats, condos, and landed properties use booster pumps to maintain water pressure. Common issues requiring pump repair Singapore include:

- Intermittent power

- Motor failures

- Pressure switch malfunction

- Pipe vibration and noise

23.2 Rainwater and Irrigation Pumps

Eco-conscious households may use pumps to recycle water for landscaping. These systems can clog due to debris or fail from overuse. Proper pump repair Singapore prevents wastage and reduces water bills.

Chapter 24: Pump Repair in Singapore for Data Centers and Tech Facilities

Singapore is home to many data centers and IT facilities, where cooling systems rely heavily on continuous pump performance. The need for high-reliability pump repair in Singapore solutions in this sector is growing rapidly.

24.1 Chilled Water Circulation

Chillers rely on pumps to circulate water across massive server rooms. If these pumps fail, it can cause temperature spikes and hardware damage. Preventive pump repair in Singapore ensures consistent performance and system uptime.

24.2 Redundancy and Failover Support

High-tier data centers have redundant systems. Pump repair in Singapore experts often rotate units, test failovers, and service standby pumps to ensure no single point of failure.

Chapter 25: Fire Safety Systems and Pump Repair in Singapore

Fire pumps are a crucial component of building safety. These are not used frequently, but they must work flawlessly during emergencies. Regular pump repair in Singapore is essential for compliance and safety.

25.1 Types of Fire Pumps

- Jockey Pumps maintain system pressure

- Main Fire Pumps deliver high-pressure water when triggered

- Diesel and Electric Motors must be tested and repaired regularly

25.2 Key Repair Needs

- Controller faults

- Air leaks in suction lines

- Low-pressure output due to valve or impeller issues

- Corrosion from long-term inactivity

Authorities in Singapore require annual testing and inspection, making pump repair in Singapore a mandatory part of fire system maintenance.

Chapter 26: Long-Term Planning with Pump Repair in Singapore

Rather than treating pump repair as a reactive task, many businesses and property managers in Singapore now plan repairs as part of a long-term asset management strategy.

26.1 Asset Lifecycle Management

Pumps typically last between 8–15 years depending on type and usage. Using data from routine inspections, pump repair in Singapore specialists can map:

- Predicted failure points

- Upgrade timelines

- Component wear rates

- Budget forecasting for repairs

26.2 Capital Budget Planning

When major repairs or replacements are expected, early forecasting helps organizations spread out costs and avoid emergency funding needs. Strategic pump repair in Singapore planning reduces financial shocks.

Chapter 27: Training and Certification in Pump Repair Singapore

Not every technician is qualified to perform high-standard repairs. The pump repair in Singapore sector now emphasizes certified training, safety compliance, and specialized knowledge.

27.1 Safety Certifications

Technicians working in high-risk zones (chemical plants, marine, confined spaces) must hold:

- Work-at-height certifications

- Confined space permits

- Hazardous location electrical training

27.2 Specialized Pump Training

High-end pump repair in Singapore services often involve:

- Vibration analysis certification

- Laser shaft alignment training

- PLC controller diagnostics

- Material science for seal and gasket engineering

Chapter 28: Rental Pumps and Temporary Systems in Singapore

During large-scale maintenance, pump failures, or flood responses, temporary pump systems may be deployed. These require their own pump repair in Singapore protocols to stay reliable during their use period.

28.1 Emergency Deployments

Flood-prone areas may request short-term pump deployments. These pumps must be inspected and serviced daily by pump repair in Singapore teams.

28.2 Mobile Units

Mobile pump trucks are used in construction, events, and emergency water transfers. Onboard systems demand regular pump repair in Singapore checks to ensure they are field-ready.

Chapter 29: Documentation and Reporting in Pump Repair Singapore

Reliable recordkeeping is critical for operational audits, insurance claims, and performance tracking.

29.1 Maintenance Logs

Each pump repair in Singapore activity should be logged with details like:

- Time, date, and location

- Fault description

- Repair procedures

- Components replaced

- Technician name and certification

29.2 Digital Reporting

Modern pump repair in Singapore providers often generate digital service reports with images, flow data, and thermal scans. This ensures transparent records for future reference and compliance audits.

Chapter 30: Summary and Strategic Benefits

To summarize, pump repair in Singapore is not a one-time service—it’s a long-term strategy. From reducing costs and improving system lifespan to ensuring compliance and supporting sustainability, proactive pump servicing offers measurable value.

Organizations that adopt a data-driven, scheduled approach to pump repair in Singapore enjoy:

- Reduced emergency downtime

- Better energy efficiency

- Higher asset value

- Safer operations

- More accurate budgeting

Investing in skilled, certified professionals ensures your pumping systems stay operational, efficient, and compliant—no matter the size or scope of your property or facility.

Final Thoughts

From high-rise booster systems and basement sump pumps to industrial chemical pumps and marine bilge pumps, the demand for reliable, efficient, and quick pump repair in Singapore is only growing. By investing in regular inspections, advanced diagnostics, predictive maintenance, and professional repairs, facilities can reduce costs, stay compliant, and maintain high performance.

Whether you’re managing a factory, condominium, commercial tower, or municipal facility, building a long-term relationship with a skilled pump repair in Singapore team is one of the smartest decisions you can make.

Conclusion

In an advanced economy like Singapore, where efficiency, compliance, and reliability are critical, the role of pump repair in Singapore is undeniably vital. From commercial towers and factories to homes and institutions, pumps are the unseen force keeping systems flowing. Neglecting pump maintenance can lead to severe disruptions, high repair costs, and compliance risks.

Whether it’s preventive maintenance, emergency services, retrofitting, or performance optimization, investing in regular pump repair services ensures your systems remain durable, cost-effective, and environmentally friendly.

To ensure operational excellence, organizations and homeowners must prioritize pump repair as a routine requirement rather than a reactive solution. As infrastructure continues to evolve, so too will the demand for advanced, eco-conscious, and timely pump repair services.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply