Pump parts replacement Singapore – Best 2025

Introduction to Pump Parts Replacement in Singapore

In the dynamic and high-demand environment of Singapore’s industrial and infrastructure sectors, pump systems play a crucial role in ensuring efficient operations. Whether in water treatment plants, manufacturing facilities, or high-rise buildings, pumps are vital in moving fluids efficiently. However, over time, even the most robust pumps undergo wear and tear. This is where pump parts replacement Singapore services become essential for operational continuity and cost-effective maintenance.

Pump parts replacement Singapore is not just about fixing faulty equipment; it’s about ensuring that systems run with minimal downtime, maximum efficiency, and extended service life. For organizations in sectors like oil & gas, construction, pharmaceuticals, marine, and manufacturing, timely and reliable pump parts replacement Singapore solutions are non-negotiable.

Understanding the Need for Pump Parts Replacement in Singapore

Singapore’s tropical climate, combined with industrial and municipal demands, subjects pumps to extreme conditions. Whether handling clean water, wastewater, chemicals, or abrasive slurries, pump components experience erosion, corrosion, fatigue, and mechanical stress.

Key reasons for pump parts replacement Singapore include:

- Performance degradation: Reduced flow rate or pressure output due to worn impellers or clogged internals.

- Mechanical failure: Damaged seals, bearings, or shafts can lead to pump shutdown.

- Preventive maintenance: Scheduled pump parts replacement Singapore helps avoid unplanned downtimes.

- Upgrades: Replacing outdated components to improve efficiency, energy consumption, and environmental compliance.

As the demand for precise, responsive, and efficient solutions increases, choosing a dependable pump parts replacement Singapore provider is a strategic decision.

What Components Typically Require Replacement?

Understanding which parts commonly fail or degrade helps in planning a robust pump maintenance schedule. Here are critical components covered under pump parts replacement Singapore services:

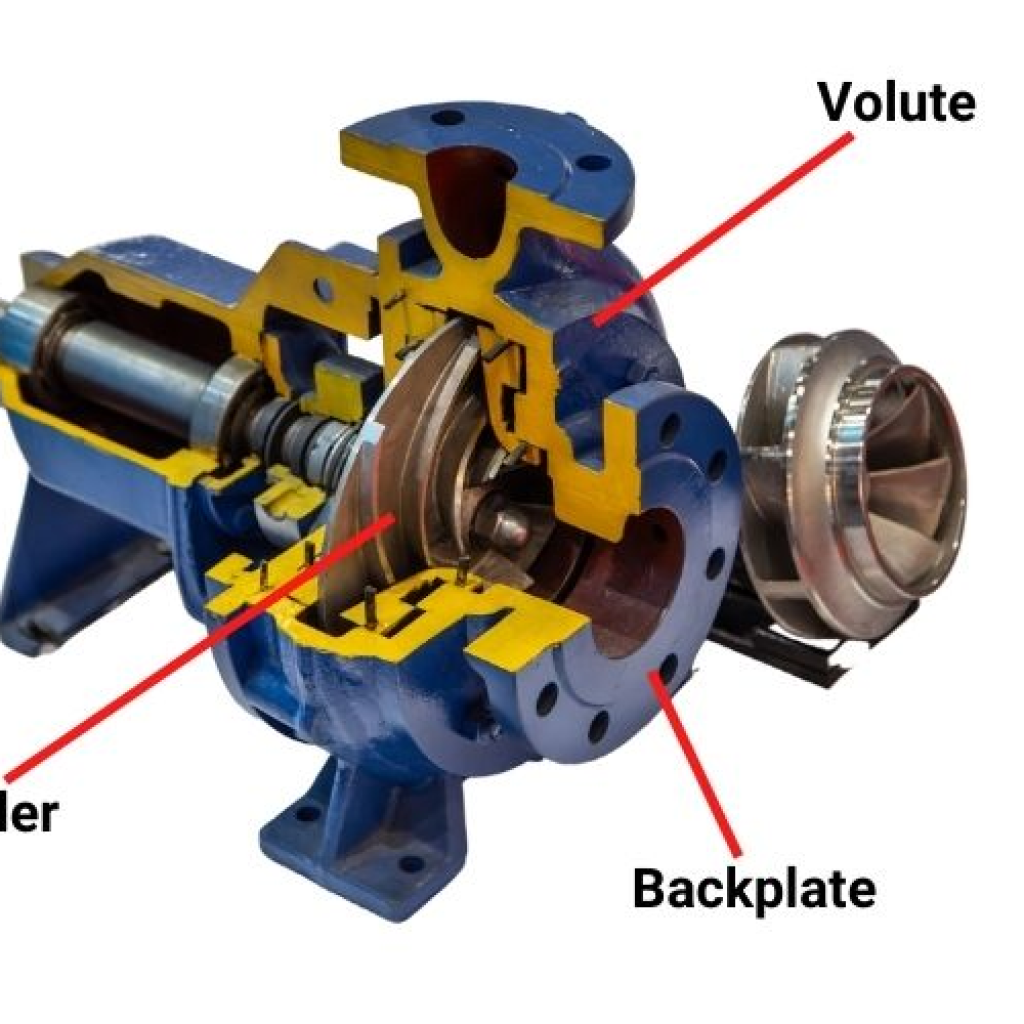

1. Impellers

Impellers are the heart of a centrifugal pump. Constant exposure to fluid motion and particles causes impeller wear. Regular pump parts replacement Singapore includes impeller upgrades or exact OEM replacements.

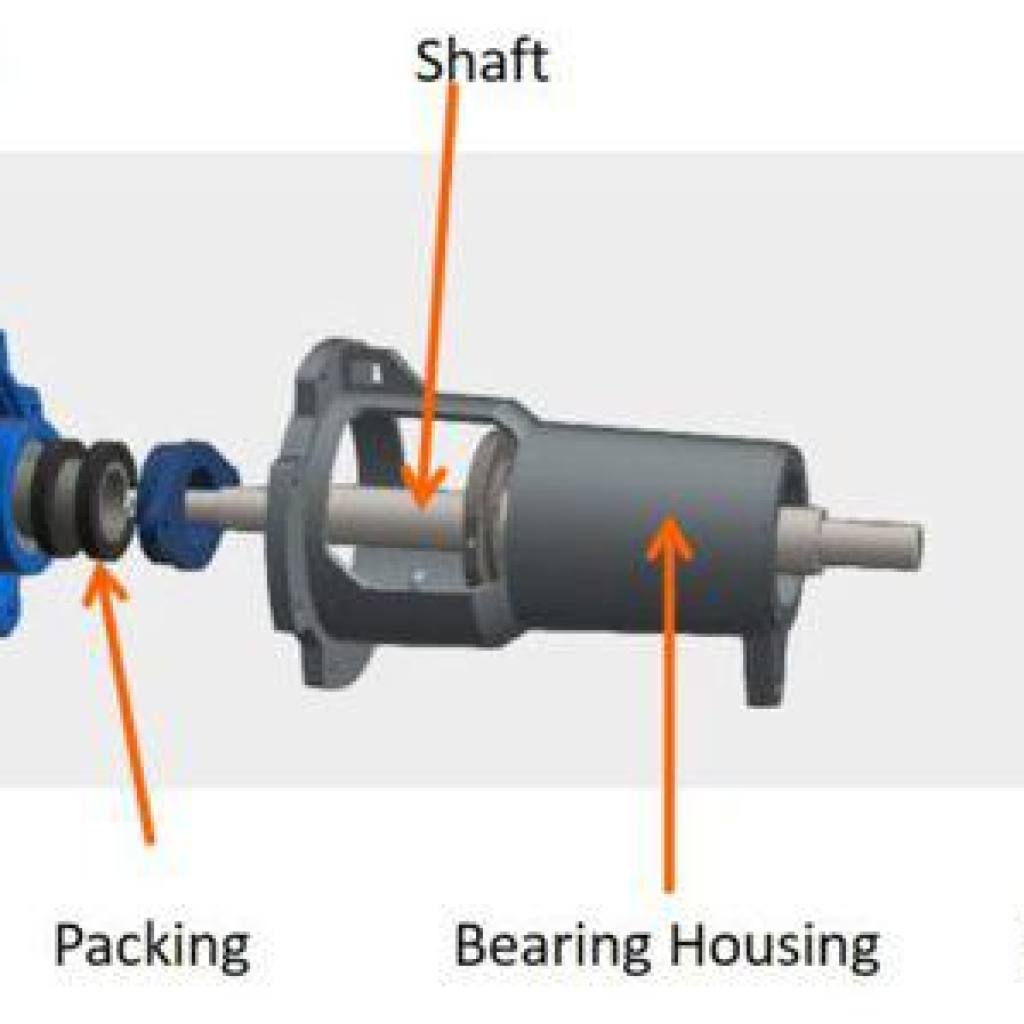

2. Mechanical Seals and Packing

Seals prevent leakage around the rotating shaft. In pump parts replacement Singapore, seals are frequently replaced due to thermal stress, chemical exposure, or improper installation.

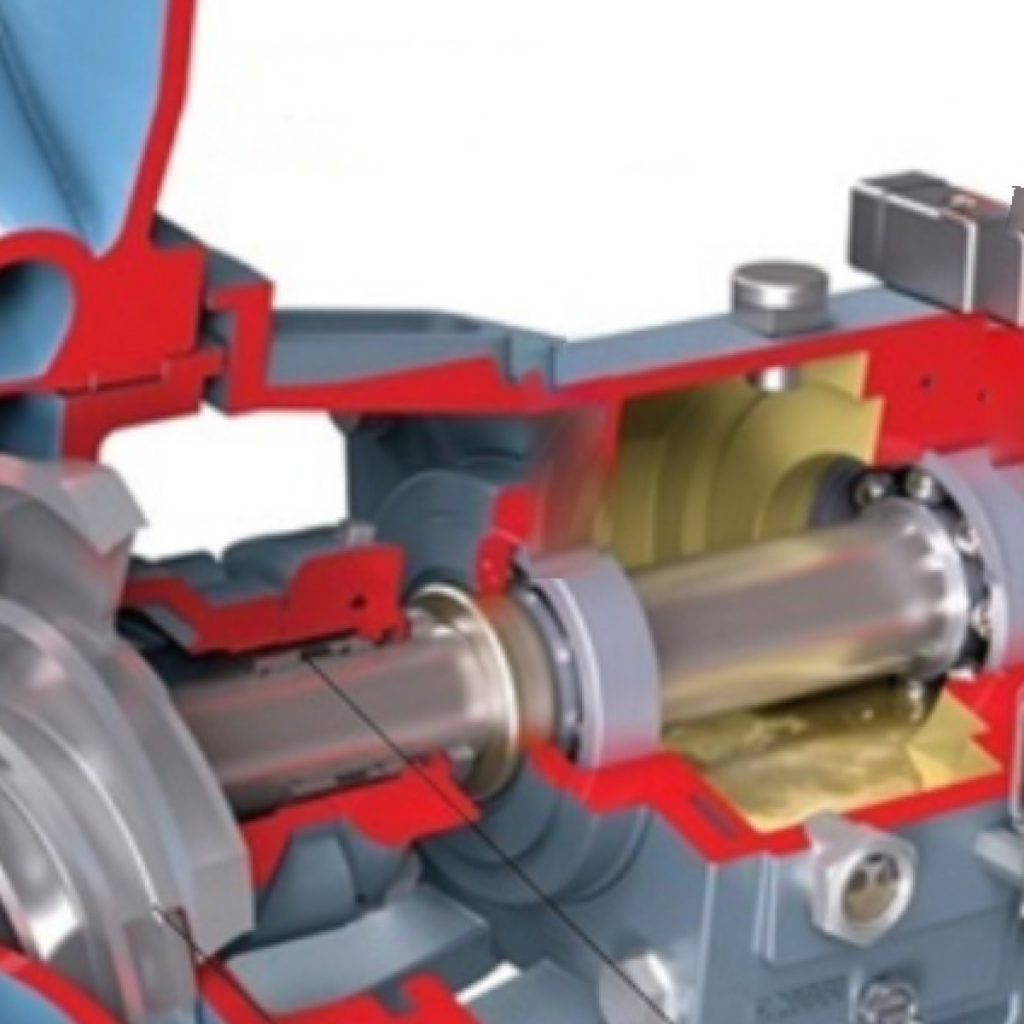

3. Bearings

Bearings reduce friction and support the shaft. In high-speed pumps, bearing failure is common and requires expert pump parts replacement Singapore intervention.

4. Shafts and Sleeves

Pump shafts transfer rotational energy to the impeller. If the shaft gets bent or corroded, pump parts replacement Singapore services provide precision-machined replacements.

5. Casings and Volutes

These house the pumping mechanisms and are prone to corrosion. Pump parts replacement Singapore offers cast or fabricated casing options for full restoration.

6. O-rings and Gaskets

These are crucial for maintaining internal pressure. Over time, elastomers harden or degrade, requiring reliable pump parts replacement Singapore to avoid leaks.

7. Couplings and Wear Rings

These minor components play a significant role in alignment and efficiency. Many pump parts replacement Singapore professionals advise periodic inspection and replacement.

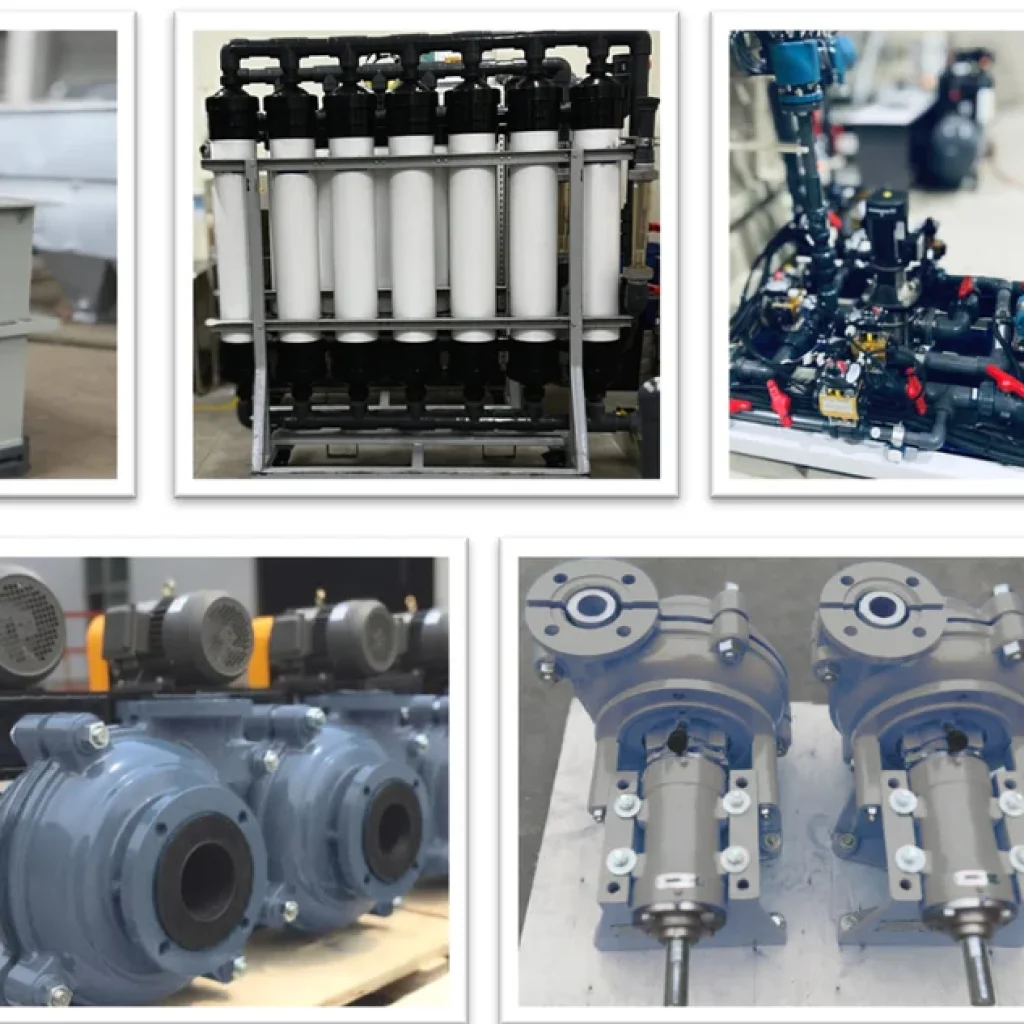

Industries That Rely on Pump Parts Replacement in Singapore

Various industries in Singapore rely on high-performance pumps for continuous operations. Their reliance on pump parts replacement Singapore services is critical for long-term productivity and equipment ROI.

- Water & Wastewater Treatment

Water processing facilities demand high uptime. Pump parts replacement Singapore ensures sludge, effluent, and clean water pumps operate without interruption. - Oil & Gas and Petrochemical

Corrosive and explosive environments mean every part must be in peak condition. Pump parts replacement Singapore providers ensure fast turnaround on seal kits, impellers, and more. - Marine & Offshore

From ballast systems to engine room pumps, pump parts replacement Singapore keeps marine systems ready for demanding sea conditions. - Manufacturing & Electronics

Precision matters. Downtime can disrupt production. Timely pump parts replacement Singapore helps prevent costly process interruptions. - Construction & Infrastructure

Dewatering pumps and concrete mixing pumps often need quick pump parts replacement Singapore to meet project timelines. - Pharmaceutical & Food Processing

Sanitary pump parts must be replaced under strict quality standards. Pump parts replacement Singapore guarantees compliance and cleanliness.

Why Choose Professional Pump Parts Replacement Singapore Services

Choosing the right service provider for pump parts replacement Singapore ensures your equipment returns to service with confidence. Here are reasons businesses trust reliable vendors:

1. OEM and Equivalent Spare Parts Availability

Professional pump parts replacement Singapore providers offer OEM-quality parts, including brand-specific components for Grundfos, KSB, Ebara, Wilo, and Sulzer pumps.

2. Skilled Technicians and Engineers

Technicians trained in rotating equipment service perform inspections, alignments, and pump parts replacement Singapore with precision.

3. Quick Turnaround and On-Site Replacement

Minimizing downtime is key. Many pump parts replacement Singapore specialists offer on-site inspections and immediate replacements.

4. Customized Parts Fabrication

Some vendors offer reverse engineering and fabrication of discontinued parts – a critical feature of effective pump parts replacement Singapore.

5. Laser Alignment and Vibration Analysis

Advanced tools ensure pump alignment after pump parts replacement Singapore, maximizing equipment lifespan.

Steps Involved in Professional Pump Parts Replacement Singapore

Understanding the process of pump parts replacement Singapore helps asset managers plan maintenance schedules better. A typical workflow includes:

- Inspection & Diagnosis:

Technicians assess the condition of internal parts. - Parts Identification:

OEM specifications are matched, or custom solutions are fabricated. - Disassembly & Cleaning:

Pumps are dismantled, and worn components are removed. - Pump Parts Replacement Singapore Execution:

Replacement of impellers, seals, bearings, and worn shafts. - Reassembly & Alignment:

Parts are refitted using torque guidelines and alignment tools. - Performance Testing:

Flow rate, pressure, and vibration levels are tested post-installation. - Documentation & Reporting:

A final report ensures compliance with safety and operational standards.

Benefits of Regular Pump Parts Replacement in Singapore

A scheduled approach to pump parts replacement Singapore provides multiple advantages:

- Increased Reliability: Pumps perform consistently under demanding conditions.

- Energy Efficiency: New impellers and seals reduce energy consumption.

- Cost Savings: Preventing major failures avoids expensive downtime or full replacements.

- Operational Safety: Minimized leakage and vibration reduce risk.

- Extended Equipment Life: Regular pump parts replacement Singapore adds years to pump lifespan.

Local Expertise in Pump Parts Replacement Singapore

Singapore’s strategic location and advanced industrial ecosystem offer several advantages:

- Rapid Logistics: Easy access to international OEMs and spares.

- Highly Skilled Workforce: Engineers with expertise in rotating machinery and mechanical servicing.

- Strong Regulatory Framework: Compliance with PUB, NEA, and MOM safety standards.

- Marine and Port Access: Ideal for offshore pump service and pump parts replacement Singapore.

Signs You Need Immediate Pump Parts Replacement Singapore Services

Ignoring early symptoms of failure can escalate costs and risks. Here are red flags:

- Unusual noises and vibrations

- Overheating motors or components

- Drop in flow or pressure

- Seal or bearing leaks

- Increase in energy consumption

- Frequent system trips

If you encounter any of these issues, prompt pump parts replacement Singapore is essential.

Choosing the Right Partner for Pump Parts Replacement Singapore

A dependable partner for pump parts replacement Singapore must offer more than just spares. They must deliver value across the equipment lifecycle.

Look for:

- Experience in diverse pump types – centrifugal, submersible, multistage, chemical dosing, etc.

- Capability to handle emergency repairs

- Stock of genuine and critical parts

- Proven track record with various industries

- Detailed inspection and service reports

FLOMEK Singapore – Your Pump Parts Replacement Singapore Expert

As a recognized industry leader, FLOMEK Singapore provides complete solutions for pump parts replacement Singapore, covering various sectors and pump configurations. Whether you need spare impellers, seals, bearings, shafts, or casings, FLOMEK ensures fast delivery, expert installation, and rigorous testing.

Our engineers are trained in pump parts replacement Singapore protocols and equipped with advanced diagnostic tools to maintain or restore optimal performance. With in-house machining, fabrication capabilities, and a full stock of genuine OEM parts, we ensure your pumping systems stay resilient.

From scheduled shutdowns to emergency field repairs, FLOMEK remains the go-to name for pump parts replacement Singapore.

Advanced Technologies in Pump Parts Replacement Singapore

Modern pump parts replacement Singapore is no longer just about swapping worn-out components. It integrates smart diagnostics, predictive analytics, and advanced materials engineering to enhance the reliability and efficiency of your pump systems.

Predictive Maintenance with IoT Integration

With the rise of Industrial IoT, many companies now monitor pump performance using sensors for pressure, vibration, temperature, and flow rate. These sensors detect deviations before failure occurs. A key part of this ecosystem is timely pump parts replacement Singapore, triggered based on real-time data rather than fixed schedules.

FLOMEK Singapore provides intelligent pump parts replacement Singapore services integrated with predictive maintenance models. This proactive approach helps clients save energy, reduce costs, and extend pump lifespans.

3D Scanning and Reverse Engineering

One common challenge during pump parts replacement Singapore is the unavailability of older or discontinued components. Leading service providers solve this using:

- 3D scanning to capture precise geometries of worn-out parts

- CAD modeling to digitally reconstruct the part

- In-house fabrication or CNC machining to reproduce exact replacements

This ensures uninterrupted operations even when OEM parts are obsolete. For complex pumps in water treatment and petrochemical plants, reverse engineering has revolutionized pump parts replacement Singapore.

High-Performance Materials

Upgrading to better materials during pump parts replacement Singapore significantly boosts pump life and system performance. Examples include:

- Ceramic-coated shafts for abrasion resistance

- Duplex stainless steel impellers for seawater resistance

- PTFE or Viton seals for chemical processing

- Carbon-graphite bushings in high-speed pumps

The use of advanced materials ensures your pump parts replacement Singapore not only restores function but also enhances reliability under harsh conditions.

Environmental and Energy Efficiency Considerations

Pumps account for over 25% of industrial energy usage. Hence, pump parts replacement Singapore is not just about repair – it’s an opportunity to improve efficiency and sustainability.

Energy-Efficient Upgrades

By replacing outdated impellers with hydraulic-optimized versions or switching to low-friction bearings, energy consumption drops significantly. This form of pump parts replacement Singapore pays back in reduced utility bills and lower carbon emissions.

Green Compliance

Singapore enforces strict environmental guidelines. By aligning pump parts replacement Singapore with these regulations—like leak-proof seals, noise control upgrades, and lower vibration systems—facilities stay compliant with PUB and NEA requirements.

Common Challenges in Pump Parts Replacement Singapore

Despite being critical, many companies face difficulties in managing pump parts replacement Singapore efficiently:

1. Sourcing Rare Components

Some older pump models have discontinued parts. Without a proactive vendor, sourcing them becomes time-consuming. FLOMEK’s stock and fabrication network support quick pump parts replacement Singapore for even legacy systems.

2. Skill Gap in Field Technicians

Not all technicians understand the tolerance and alignment requirements of high-precision parts. Poor installation leads to premature failures. FLOMEK ensures pump parts replacement Singapore is carried out only by certified, experienced personnel.

3. Delayed Replacement

Neglecting minor symptoms—like small vibrations or reduced pressure—often leads to bigger breakdowns. A delay in pump parts replacement Singapore can result in total equipment failure, causing unplanned shutdowns and production loss.

4. Misfit Components

Using substandard or ill-fitting parts from unverified sources causes alignment issues, leaks, and energy loss. That’s why FLOMEK emphasizes certified spares in every pump parts replacement Singapore job.

Types of Pumps Covered in Pump Parts Replacement Singapore

A comprehensive pump parts replacement Singapore provider like FLOMEK caters to a broad range of pump types:

- Centrifugal Pumps (single-stage & multistage)

- Vertical Inline and End Suction Pumps

- Submersible Pumps (for drainage, sewage)

- Positive Displacement Pumps (diaphragm, gear, rotary vane)

- Chemical Process Pumps

- Booster Pump Skids

- Dosing Pumps & Skids

- Fire Pumps (diesel/electric/jockey)

- Screw and Sludge Pumps

Each type has unique spare requirements, making tailored pump parts replacement Singapore essential.

Case Study: Successful Pump Parts Replacement Singapore by FLOMEK

Client: Municipal Wastewater Treatment Plant

Problem: High vibration and pressure drops in sludge pumps

Solution:

- Full inspection and analysis

- Replacement of worn impellers and misaligned bearings

- Precision shaft realignment using laser tools

- Upgrade to ceramic-coated shaft sleeves

- Testing and re-certification

Results:

- Pump efficiency increased by 17%

- Noise and vibration levels reduced significantly

- System downtime reduced by 40% over the next 12 months

This is a real-world example of how pump parts replacement Singapore enhances system reliability and operational value.

Routine Schedules and Best Practices

Implementing a scheduled program for pump parts replacement Singapore helps facilities avoid emergencies.

Recommended Intervals:

| Component | Replacement Interval |

|---|---|

| Mechanical Seals | Every 6-12 months |

| Bearings | Every 12-24 months |

| Impellers | Every 18-36 months |

| Shaft Sleeves | Based on vibration analysis |

| Wear Rings | Every 12 months |

| Gaskets & O-rings | During every pump overhaul |

Following these intervals under a structured pump parts replacement Singapore plan can dramatically extend your pump system’s lifespan.

Training and Technical Support

FLOMEK doesn’t just offer spare parts—it empowers clients with technical know-how and training. For long-term success in pump parts replacement Singapore, operator education is key.

We provide:

- Operator training modules

- Best practices for daily checks

- Vibration interpretation charts

- Seal installation guides

- Troubleshooting support

This knowledge-sharing model makes pump parts replacement Singapore not just a service, but a complete lifecycle solution.

Lifecycle Management through Pump Parts Replacement Singapore

One of the key pillars of industrial asset management is the pump lifecycle strategy. Implementing a reliable and structured pump parts replacement Singapore routine ensures that every stage of the pump’s life is optimized for performance and cost.

Stages of Pump Lifecycle Management:

- Installation & Commissioning

The beginning of a pump’s life requires correct installation and startup. Choosing the right accessories and spare kits from the start ensures minimal need for immediate pump parts replacement Singapore. - Early Operation (0–2 years)

During this phase, issues related to design mismatches or operating conditions become visible. Minor seal leaks or misaligned couplings often require immediate pump parts replacement Singapore to stabilize operations. - Mid-life Service (3–7 years)

Wear and tear from prolonged use begin to show—impellers thin out, bearings wear, and seals start failing. This is where pump parts replacement Singapore becomes the most cost-effective option to prevent major breakdowns. - Late-life or Rejuvenation Phase (8–15+ years)

At this point, full overhauls or major retrofits are needed. Reverse-engineered spares, efficiency upgrades, and digital monitoring integrations become part of a strategic pump parts replacement Singapore plan to extend usable life.

Custom Fabrication and Local Manufacturing in Singapore

For specific industrial applications where OEM parts are no longer available or extremely costly, custom fabrication becomes vital. FLOMEK Singapore leads in customized pump-parts replacement Singapore by using:

- 3D modeling software (AutoCAD, SolidWorks)

- High-precision CNC machining

- Advanced coatings like HVOF, PTFE, Epoxy-lined interiors

- Material testing & metallurgical reports

Industries like marine offshore, petrochemical, and semiconductor require pump-parts replacement Singapore that adheres to niche specifications, such as food-grade finish, corrosion resistance, or explosive-proof certification.

Singapore’s Competitive Edge in Pump Servicing

Singapore’s globally renowned engineering infrastructure makes it an ideal hub for pump-parts replacement Singapore due to:

- Proximity to major OEM distribution centers

- Advanced port connectivity for marine pumps

- High-skilled technical workforce and industry certifications

- Strict environmental and equipment safety compliance

These factors make FLOMEK a top choice for companies needing fast, reliable, and regulatory-compliant pump-parts replacement Singapore solutions.

Digital Documentation & Service Reporting

In large facilities or plants, keeping track of past maintenance is crucial. FLOMEK Singapore includes:

- Detailed service reports after every pump-parts replacement Singapore

- Photographic documentation of before/after part conditions

- Vibration, temperature, and alignment test results

- Predictive analytics based on wear history

- QR-coded service logs for digital archiving

This level of documentation supports audits, warranty claims, and internal quality assurance systems.

Industry-Specific Demands for Pump-Parts Replacement Singapore

Each sector in Singapore brings its own set of technical expectations and challenges. Here’s how pump parts replacement Singapore is customized across industries:

1. Pharmaceutical and Life Sciences

- GMP and FDA compliance

- Use of stainless steel (SS316L) and PTFE components

- Electro-polished impellers and smooth interior surfaces

- Chemical compatibility of seals

- Sanitary designs with zero dead-leg zones

Pump-parts replacement Singapore in this domain includes pre-validated components and hygiene-certified installations.

2. Semiconductor and Electronics Manufacturing

- Pumps handling ultrapure water (UPW) or corrosive etching agents

- High resistance to hydrofluoric acid, nitric acid, etc.

- PFA-lined or PVDF components

- Ultra-low vibration to prevent contamination

Here, pump-parts replacement Singapore involves high-grade materials with semiconductor-grade finishes and anti-static designs.

3. Oil & Gas and Refinery

- ATEX/IECEx-certified components

- High-temperature seals and explosion-proof casings

- Abrasion-resistant impellers

- Gas-tight shaft sleeves

Pump-parts replacement Singapore in this domain is safety-critical, requiring quick-response spares, 24/7 service, and strong supply chain support.

4. Food & Beverage Processing

- FDA and HACCP-compliant gaskets and seals

- Use of CIP (Clean-in-Place) and SIP (Steam-in-Place) compatible parts

- Full stainless steel construction

- Electro-polishing and passivation certification

Pump-parts replacement Singapore in this sector ensures taste integrity, safety, and hygiene in production.

Turnaround Support and Shutdown Maintenance

Planned shutdowns are the best opportunities to perform comprehensive pump-parts replacement Singapore operations. FLOMEK supports clients during:

- Annual plant maintenance windows

- Turnarounds and utility outages

- Scheduled plant commissioning or expansions

- Equipment health audits

We mobilize spare parts, diagnostic tools, and technicians to complete all pump-parts replacement Singapore tasks within your downtime window.

Pump Parts Replacement Singapore in Emergency Situations

Not all failures happen during scheduled shutdowns. For critical systems like fire pumps, boiler feedwater pumps, or medical equipment, FLOMEK offers:

- 24/7 emergency pump-parts replacement Singapore

- Temporary replacement pumps or bypass skids

- Rapid dispatch of spares and technicians

- Mobile workshop units for on-site machining and alignment

Our dedicated emergency response team ensures minimal disruption to your operations.

KPIs and Performance Metrics After Pump Parts Replacement

After a professional pump-parts replacement Singapore, we monitor performance improvements using:

| KPI | Typical Improvement |

|---|---|

| Flow Rate | +5% to +20% |

| Energy Efficiency | +8% to +25% |

| Downtime Reduction | Up to 80% |

| Vibration Level Drop | Up to 60% |

| Operating Noise Reduction | Up to 30 dB |

These data points not only show the immediate benefits of pump-parts replacement Singapore but also help in ROI justification for maintenance budgeting.

Global Standards Applied in Singapore’s Pump Replacement Industry

Singapore’s engineering service providers, including FLOMEK, strictly follow international standards such as:

- ISO 9001 – Quality Management

- API 610 – Centrifugal Pumps for Petroleum

- ANSI/HI Standards – Hydraulic Institute Guidelines

- DIN/EN – European Mechanical Standards

- SS 531 – Local Singapore pump standard regulations

This ensures that every pump-parts replacement Singapore project aligns with global best practices.

Looking Ahead: Future of Pump-Parts Replacement Singapore

With increasing automation, environmental regulations, and sustainability targets, the future of pump parts replacement Singapore will focus on:

- Predictive AI-based part failure modeling

- Digital twin simulations before physical replacement

- Eco-friendly materials and coatings

- Energy-optimized impeller designs

- Blockchain-based maintenance logs for transparency

FLOMEK is already investing in next-gen capabilities to keep leading in pump-parts replacement Singapore.

The FLOMEK Advantage in Pump-Parts Replacement Singapore

Here’s what sets FLOMEK apart as a trusted leader in pumpparts replacement Singapore:

✅ Wide inventory of genuine spare parts

✅ In-house machining and fabrication

✅ Experienced field service engineers

✅ 24/7 emergency response capability

✅ ISO-compliant quality assurance

✅ Industry-specific expertise (marine, pharma, infrastructure)

✅ Transparent reporting and post-replacement documentation

With these strengths, FLOMEK continues to be a preferred name in pumpparts replacement Singapore, trusted by industry leaders and government projects alike.

Conclusion

In a fast-paced industrial environment like Singapore, equipment efficiency determines competitive advantage. Ensuring consistent, cost-effective operation begins with reliable pumpparts replacement Singapore. Whether your systems support water distribution, cooling, chemical processing, or sewage handling, don’t wait for failures. Choose a professional and proven partner to keep your operations running at peak performance.

For dependable and long-lasting solutions, always trust experts in pumpparts replacement Singapore – your first line of defense against costly pump failures and downtime.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply