Pump laser alignment Singapore – Singapore’s No 1 Best Pump service & supplier

Pump Laser Alignment Singapore – Precision Solutions by FLOMEK

In the modern industrial landscape, maintaining the efficiency and longevity of pumps is crucial. At FLOMEK Singapore, we specialize in Pump laser alignment Singapore, offering state-of-the-art solutions to ensure your pumping systems operate at peak performance. Proper pump alignment is essential to minimize wear and tear, reduce energy consumption, and prevent unexpected downtime, making laser alignment the most reliable method for achieving precise results.

What is Pump Laser Alignment?

Pump laser alignment Singapore involves the use of advanced laser technology to align the shafts of pumps and motors with extreme precision. Unlike traditional methods, laser alignment provides an accurate and quick assessment of misalignment, enabling engineers to correct deviations efficiently. Misaligned pumps can cause vibration, excessive bearing wear, and mechanical seal failures, leading to costly repairs and production losses.

Why Choose Laser Alignment Over Traditional Methods?

Traditional alignment methods, such as dial indicators or straightedges, are often time-consuming and prone to human error. Laser alignment ensures:

- High Accuracy: Alignments are measured in microns, significantly improving precision.

- Reduced Downtime: Faster setup and alignment mean less interruption to operations.

- Lower Maintenance Costs: Correct alignment reduces wear on bearings, seals, and couplings.

- Energy Efficiency: Properly aligned pumps consume less power, reducing operational costs.

By choosing Pump laser alignment Singapore from FLOMEK, businesses can achieve reliability, efficiency, and longevity for their pumping systems.

Applications of Pump Laser Alignment

Laser alignment is critical across multiple industries where pumps are vital, including:

- Water and Wastewater Treatment Plants

Accurate pump alignment ensures continuous operation, minimizing maintenance interruptions. - Industrial Manufacturing

Process plants rely on precision alignment to maintain production efficiency and reduce equipment wear. - HVAC Systems

Split-case and centrifugal pumps benefit from laser alignment for smoother operation and reduced energy consumption. - Chemical and Pharmaceutical Industries

Pumps handling sensitive fluids require precise alignment to prevent contamination and system failures.

At FLOMEK, our Pump laser alignment Singapore services cater to all these sectors, ensuring optimal performance and safety.

Key Advantages of Pump Laser Alignment

Investing in professional laser alignment services provides several long-term benefits:

1. Increased Equipment Lifespan

Misaligned pumps and motors experience uneven stress on bearings and couplings. Laser alignment corrects these deviations, significantly extending the service life of the equipment.

2. Improved Operational Efficiency

A perfectly aligned pump reduces vibration and friction, which translates into smoother operation and reduced energy consumption. Businesses benefit from lower electricity costs and consistent production output.

3. Reduced Maintenance Costs

Proper alignment reduces mechanical stress, decreasing the frequency of component replacements and unexpected breakdowns. FLOMEK’s Pump laser alignment Singapore ensures your pumps run reliably, minimizing maintenance expenses.

4. Enhanced Safety

Vibrations and misalignment can lead to hazardous conditions in industrial setups. Laser alignment ensures safer working conditions by preventing excessive wear and catastrophic failures.

5. Time-Saving and Accurate

Laser alignment allows engineers to achieve perfect alignment in a fraction of the time compared to traditional methods. This efficiency is critical for industries where downtime directly impacts production and revenue.

Our Pump Laser Alignment Process

At FLOMEK, we follow a structured and precise approach to Pump laser alignment Singapore:

Step 1: Initial Inspection

Our experts inspect the pump and motor setup to assess the current alignment condition. We check for wear, looseness, and other factors that may affect the alignment process.

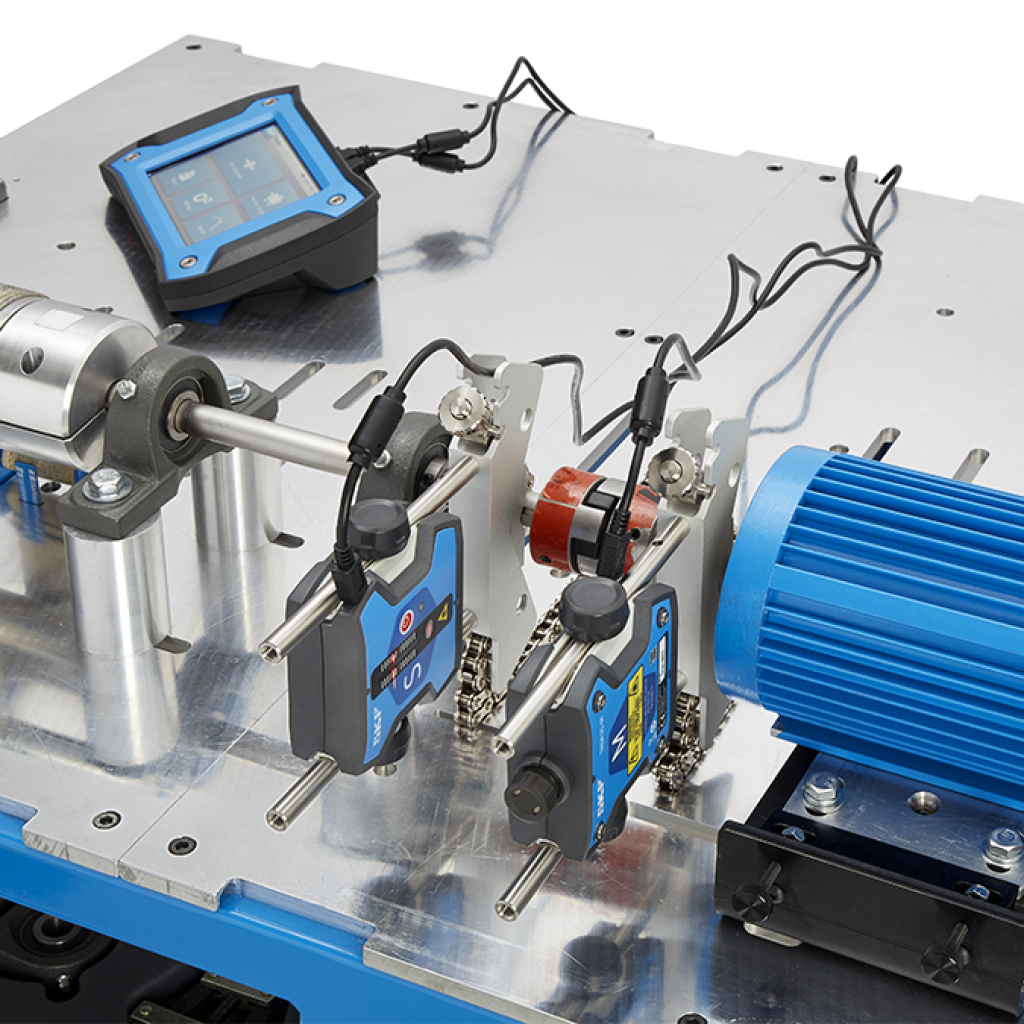

Step 2: Laser Measurement

Using advanced laser alignment tools, we measure shaft deviation and coupling alignment with high precision. The laser system provides instant data, allowing real-time corrections.

Step 3: Alignment Adjustment

Our technicians adjust the pump and motor positioning based on laser readings, ensuring perfect shaft alignment. Shims and coupling adjustments are made as required.

Step 4: Verification

After alignment, a verification check is conducted using the laser system to confirm optimal alignment. This step guarantees that the pump is operating within the recommended tolerances.

Step 5: Documentation and Reporting

FLOMEK provides detailed alignment reports for every project, ensuring transparency and traceability. Businesses can track maintenance improvements and equipment performance over time.

Types of Pump Laser Alignment Services

FLOMEK offers comprehensive Pump laser alignment Singapore services for various pump types:

- Centrifugal Pumps

- Split Case Pumps

- Horizontal and Vertical Pumps

- End Suction Pumps

- Process and Chemical Pumps

Our team has the expertise to handle pumps of all sizes and configurations, delivering precise alignment that maximizes performance and reliability.

Common Issues Resolved by Laser Alignment

Proper laser alignment addresses several common pump problems:

- Excessive Vibration – Misalignment is a leading cause of vibration in pumping systems.

- Bearing and Seal Failures – Correct alignment reduces uneven stress, extending bearing and seal life.

- Energy Inefficiency – Misaligned pumps consume more power; laser alignment optimizes energy usage.

- Premature Equipment Wear – Alignment ensures even load distribution, reducing wear on couplings and shafts.

By resolving these issues, FLOMEK’s Pump laser alignment Singapore services enhance operational reliability and reduce total lifecycle costs.

Why Choose FLOMEK Singapore for Pump Laser Alignment?

As a leading provider of pumping solutions in Singapore, FLOMEK offers unmatched expertise in Pump laser alignment Singapore:

- Highly Trained Engineers – Our team is experienced in aligning pumps of all sizes and complexities.

- State-of-the-Art Tools – We use advanced laser alignment systems for maximum precision.

- Industry Compliance – All services adhere to international standards for safety and quality.

- Customized Solutions – Alignment services are tailored to meet your specific operational needs.

With FLOMEK, businesses can ensure their pumps operate efficiently, safely, and with minimal downtime.

Benefits Across Industries

Whether in water treatment, manufacturing, or chemical processing, laser alignment offers measurable benefits:

- Water & Wastewater Treatment: Reduced pump downtime and improved plant efficiency.

- Industrial Manufacturing: Consistent production output and lower energy consumption.

- HVAC & Cooling Systems: Quiet, smooth operation of pumps and motors.

- Chemical & Pharmaceutical: Minimized contamination risk and enhanced equipment reliability.

Pump Laser Alignment Singapore – Precision Solutions by FLOMEK

In modern industrial operations, pump efficiency and reliability are crucial. Misaligned pumps can lead to excessive vibration, mechanical failures, higher energy consumption, and costly downtime. FLOMEK Singapore provides professional Pump laser alignment Singapore services using advanced laser technology, ensuring precise alignment, optimal performance, and longer equipment lifespan.

Understanding Pump Laser Alignment

Pump laser alignment Singapore is a method that uses laser measurement technology to align pumps and motors with extreme accuracy. Unlike conventional methods such as straightedges or dial indicators, laser alignment provides:

- Micron-level precision

- Quick and efficient alignment

- Reduced human error

- Verification in real-time

Misalignment is a leading cause of equipment failure. Pumps and motors that are not aligned correctly experience uneven stress on bearings, couplings, and mechanical seals, which can result in repeated breakdowns. Laser alignment addresses these issues before they escalate, making it the preferred choice in industries requiring high reliability.

Why Laser Alignment is Critical

1. Increased Equipment Lifespan

Proper shaft alignment reduces wear on critical components. Bearings, mechanical seals, and couplings experience less stress, resulting in longer service intervals and lower maintenance costs.

2. Enhanced Operational Efficiency

Aligned pumps operate smoothly with minimal vibration. This reduces energy loss, leading to significant savings on electricity bills over time.

3. Reduced Maintenance Costs

Frequent breakdowns caused by misalignment can cost time and money. Laser alignment prevents premature failures, reducing overall maintenance expenses.

4. Safety Assurance

Vibration and mechanical stress from misaligned pumps pose safety risks in industrial setups. Laser alignment ensures safer operations by minimizing the potential for catastrophic failures.

5. Faster Alignment Process

Traditional alignment methods can take hours or even days. Laser systems allow engineers to complete alignment quickly, minimizing downtime and improving plant productivity.

Applications of Pump Laser Alignment

Pump laser alignment Singapore is essential across multiple industries:

- Water & Wastewater Treatment Plants

Misaligned pumps can cause process interruptions and energy inefficiency. Laser alignment ensures continuous operation and optimizes pump life. - Industrial Manufacturing

Process plants rely on pumps for production lines. Proper alignment reduces downtime and enhances efficiency. - HVAC Systems

Pumps in cooling systems require smooth operation. Laser alignment reduces vibration and noise. - Chemical & Pharmaceutical Industries

Pumps handling sensitive fluids must operate precisely to prevent contamination and mechanical failures. - Oil & Gas Industry

High-capacity pumps in refineries and petrochemical plants demand accurate alignment to avoid critical failures.

Types of Pumps Requiring Laser Alignment

FLOMEK specializes in Pump laser alignment Singapore for various pump types:

- Centrifugal Pumps – Common in water and industrial applications.

- Split Case Pumps – High-capacity pumps used in HVAC and municipal water systems.

- End Suction Pumps – Compact pumps for process industries.

- Horizontal & Vertical Pumps – For both industrial and utility applications.

- Chemical Process Pumps – Precision alignment is critical due to sensitive fluids.

Each pump type has unique alignment requirements, which FLOMEK addresses with specialized techniques.

Pump Laser Alignment Procedure

Step 1: Pre-Alignment Inspection

Before alignment, our engineers inspect the pump and motor assembly to identify:

- Loose foundation bolts

- Worn bearings or couplings

- Shaft damage or bent components

- Existing misalignment levels

This ensures that the alignment process starts with accurate data.

Step 2: Laser Measurement Setup

Using advanced laser alignment equipment, the pump and motor shafts are measured in real-time. The laser system detects angular and parallel misalignment, providing precise numerical feedback.

Step 3: Adjustment

Based on laser measurements, engineers make the necessary adjustments:

- Shimming or leveling the pump base

- Adjusting motor or pump position

- Correcting angular or parallel misalignment

The laser system provides immediate feedback, allowing corrections to be verified instantly.

Step 4: Verification

After adjustments, a verification run ensures that the shafts are aligned within the manufacturer’s recommended tolerance. This step guarantees optimal performance and longevity.

Step 5: Reporting

FLOMEK provides a detailed alignment report documenting:

- Initial misalignment

- Adjustments made

- Final alignment status

This report helps in future maintenance and performance monitoring.

Common Issues Addressed by Laser Alignment

Proper Pump laser alignment Singapore can resolve several critical issues:

- Vibration – Excessive vibration is reduced, ensuring smooth operation.

- Bearing Failures – Prevents uneven stress on bearings, extending life.

- Mechanical Seal Failures – Proper alignment reduces seal wear and leaks.

- Coupling Damage – Even load distribution prevents premature coupling failure.

- Energy Loss – Aligned pumps operate efficiently, lowering electricity consumption.

Benefits of Pump Laser Alignment by Industry

Water & Wastewater Treatment

- Continuous plant operation

- Reduced maintenance costs

- Efficient energy usage

Industrial Manufacturing

- Reduced downtime in production lines

- Extended equipment life

- Enhanced operational efficiency

HVAC & Cooling Systems

- Smooth operation of pumps and motors

- Reduced vibration and noise

- Lower energy consumption

Chemical & Pharmaceutical

- Accurate and reliable pump operation

- Reduced contamination risk

- Safe handling of sensitive fluids

Oil & Gas

- Prevents catastrophic pump failures

- Optimizes high-capacity pump performance

- Reduces operational risk and maintenance cost

Advantages of FLOMEK’s Pump Laser Alignment Singapore

Choosing FLOMEK for Pump laser alignment Singapore guarantees:

- Expert Engineers – Skilled in handling pumps of all sizes and types.

- Advanced Laser Tools – High-precision measurement and alignment equipment.

- Customized Solutions – Tailored to your plant’s operational needs.

- Compliance with Standards – Alignment performed according to international industrial standards.

- Documentation and Traceability – Detailed alignment reports for future reference.

FLOMEK ensures your pumps operate efficiently, safely, and reliably.

Best Practices for Maintaining Pump Alignment

After laser alignment, maintaining alignment is crucial:

- Regular Inspections: Schedule periodic checks to detect misalignment early.

- Monitor Vibration: Use vibration sensors to track pump performance.

- Foundation Stability: Ensure pump foundations remain level and secure.

- Avoid Overloading: Operate pumps within designed parameters to prevent misalignment.

- Document Adjustments: Keep a record of all maintenance and alignment work.

Common Misalignment Challenges

Even with laser alignment, pumps can develop misalignment over time due to:

- Thermal expansion

- Shaft deflection

- Settling of foundations

- Coupling wear

FLOMEK’s Pump laser alignment Singapore service addresses these challenges by combining advanced technology with experienced technicians.

Pump Laser Alignment Singapore – Precision Solutions by FLOMEK

Maintaining pump efficiency is critical for industries that rely on consistent fluid transfer. Misaligned pumps can cause vibration, mechanical failures, increased energy consumption, and unexpected downtime. At FLOMEK Singapore, we specialize in Pump laser alignment Singapore, providing advanced, precise solutions that maximize pump performance, reduce maintenance costs, and improve operational safety.

Understanding Pump Laser Alignment

Pump laser alignment Singapore uses advanced laser technology to align pump and motor shafts with micron-level accuracy. Traditional alignment methods such as straightedges or dial indicators often result in human errors and require long downtime. Laser alignment, on the other hand:

- Provides precise measurements of angular and parallel misalignment

- Reduces equipment wear and tear

- Minimizes energy loss due to misalignment

- Allows verification in real-time

Proper alignment is vital because misaligned pumps can lead to:

- Excessive vibration

- Bearing and mechanical seal failure

- Premature coupling wear

- Increased energy costs

Laser alignment ensures pumps run smoothly, safely, and efficiently.

Types of Pump Misalignment

Understanding misalignment types is essential for effective Pump laser alignment Singapore:

- Angular Misalignment – Occurs when the shafts of the pump and motor intersect at an angle rather than being perfectly parallel. This leads to uneven bearing loads and vibrations.

- Parallel (Offset) Misalignment – Shafts are parallel but not in line, causing stress on couplings and bearings.

- Combined Misalignment – A mix of angular and parallel misalignment, which is the most common in industrial setups.

FLOMEK’s laser alignment technology detects all misalignment types quickly and precisely, ensuring pumps operate within recommended tolerances.

Importance of Pump Laser Alignment

1. Extended Equipment Life

Correct alignment reduces uneven stress on bearings, seals, and couplings, significantly extending the life of pump systems.

2. Energy Efficiency

Misaligned pumps consume more power due to friction and vibration. Laser alignment reduces energy losses, saving operational costs.

3. Reduced Maintenance Costs

Alignment prevents premature equipment failure, reducing unscheduled maintenance and spare part replacements.

4. Safety Improvement

Excessive vibration or component stress can lead to catastrophic failures. Proper alignment ensures a safer industrial environment.

5. Faster and Accurate

Laser alignment provides immediate feedback, drastically reducing downtime compared to traditional alignment methods.

Applications of Pump Laser Alignment

Laser alignment is critical across industries:

- Water & Wastewater Treatment Plants: Ensures continuous operation, reduces pump failures, and optimizes energy consumption.

- Industrial Manufacturing: Improves efficiency and prevents costly downtime in production lines.

- HVAC Systems: Reduces vibration and noise in cooling and heating systems.

- Chemical & Pharmaceutical: Precision alignment is essential for pumps handling sensitive or hazardous fluids.

- Oil & Gas: High-capacity pumps in refineries require accurate alignment to prevent critical failures.

FLOMEK’s Pump laser alignment Singapore services cater to all these industries, offering tailored solutions for different operational requirements.

Types of Pumps Covered

We provide laser alignment services for all major pump types:

- Centrifugal Pumps – Used in water treatment, chemical, and industrial applications.

- Split Case Pumps – High-capacity pumps for HVAC and municipal water systems.

- End Suction Pumps – Compact pumps for industrial processes.

- Horizontal and Vertical Pumps – Applicable in both industrial and utility operations.

- Chemical Process Pumps – Sensitive pumps requiring precise alignment for safe operation.

Every pump type has unique alignment requirements. FLOMEK ensures each is addressed with precision using laser technology.

Laser Alignment Tools and Technology

FLOMEK uses state-of-the-art laser alignment systems for Pump laser alignment Singapore. Key features include:

- High-Precision Lasers: Measure angular and parallel misalignment in microns.

- Digital Readouts: Instant results allow real-time adjustments.

- User-Friendly Software: Alignment data is visualized, helping technicians make precise corrections.

- Wireless Connectivity: Data can be transmitted and stored for future analysis.

These tools enable FLOMEK to deliver accurate, fast, and repeatable results.

Step-by-Step Pump Laser Alignment Procedure

Step 1: Pre-Alignment Inspection

- Check for loose foundation bolts

- Inspect bearings, couplings, and shafts

- Measure base flatness and leveling

Step 2: Laser Measurement Setup

- Position laser transmitters on pump and motor shafts

- Record initial angular and parallel misalignment

- Software calculates required adjustments

Step 3: Shaft Alignment Adjustment

- Adjust pump or motor position based on laser readings

- Shim or level pump base as necessary

- Real-time feedback ensures accuracy

Step 4: Verification

- Perform a verification check using the laser system

- Confirm alignment within manufacturer-recommended tolerances

Step 5: Documentation

- Detailed report includes initial misalignment, adjustments made, and final alignment readings

- Helps in monitoring future maintenance and performance

Common Problems Solved by Laser Alignment

- Vibration Issues – Proper alignment reduces harmful vibrations.

- Bearing Failure – Misalignment causes uneven stress on bearings.

- Mechanical Seal Damage – Proper alignment reduces seal wear.

- Coupling Damage – Aligning shafts ensures even load distribution.

- Energy Waste – Correct alignment improves operational efficiency.

FLOMEK’s Pump laser alignment Singapore addresses all these challenges effectively.

Maintenance Strategies

Post-alignment maintenance is crucial for long-term pump performance:

- Schedule periodic alignment checks

- Monitor vibration levels continuously

- Maintain stable and level pump foundations

- Operate pumps within design specifications

- Keep detailed alignment records for future reference

Following these strategies ensures pumps remain efficient, safe, and reliable.

Industry-Specific Benefits

Water & Wastewater Treatment

- Continuous operation

- Reduced downtime

- Energy-efficient pumping

Industrial Manufacturing

- Smooth production operations

- Extended equipment life

- Cost-effective maintenance

HVAC Systems

- Quiet, efficient pump operation

- Reduced vibration and noise

- Lower power consumption

Chemical & Pharmaceutical

- Safe handling of sensitive fluids

- Reliable, precise pump operation

- Reduced contamination risk

Oil & Gas

- Optimized high-capacity pump performance

- Prevents critical failures

- Minimizes operational risk and maintenance costs

Energy Efficiency and Cost Savings

Laser-aligned pumps reduce friction, vibration, and mechanical stress, resulting in:

- Up to 10% energy savings in industrial operations

- Extended equipment lifespan, reducing capital expenditure on replacements

- Lower maintenance costs due to fewer component failures

FLOMEK’s Pump laser alignment Singapore ensures measurable energy and cost savings for businesses.

Case Study – Industrial Pump Alignment (Generic Example)

Scenario: An industrial plant experienced frequent bearing failures in centrifugal pumps.

Solution: FLOMEK conducted Pump laser alignment Singapore, identifying parallel misalignment. Adjustments were made, verified using laser readings, and the pump was returned to optimal operation.

Outcome: Bearings lasted three times longer, vibration decreased, and energy consumption reduced by 8%.

Why Choose FLOMEK Singapore

FLOMEK is a leading provider of Pump laser alignment Singapore, offering:

- Experienced engineers with expertise in complex pump systems

- Advanced laser alignment tools for precise results

- Customized solutions for various industrial requirements

- Alignment services adhering to international standards

- Detailed documentation for traceability and future maintenance

With FLOMEK, businesses achieve efficient, reliable, and safe pump operations.

Case Study: Generic Example

Scenario: A mid-size industrial plant experienced repeated bearing failures in centrifugal pumps.

Solution: FLOMEK conducted Pump laser alignment Singapore, identifying parallel misalignment. Shims and coupling adjustments were made, and the laser system verified alignment within microns.

Result: Bearings lasted three times longer, vibration decreased, and energy consumption was reduced by 8%.

Conclusion

FLOMEK Singapore offers Pump laser alignment Singapore services that guarantee:

- High precision and reliability

- Increased pump lifespan

- Reduced maintenance and energy costs

- Enhanced operational safety

Laser alignment is essential for any industry relying on pumps, from water treatment to chemical processing. FLOMEK’s expert team ensures that every pump is aligned accurately, efficiently, and according to the highest standards.

Invest in professional Pump laser alignment Singapore services from FLOMEK today and experience the benefits of perfectly aligned pumps – reduced downtime, energy efficiency, and extended equipment life.

FLOMEK Singapore is your trusted partner for Pump laser alignment Singapore, providing precision, reliability, and efficiency for your pumping systems. By leveraging advanced laser technology, we help industries prevent costly downtime, extend equipment lifespan, and optimize energy usage.

Invest in professional Pump laser alignment Singapore today and experience the benefits of perfectly aligned pumps – longer equipment life, safer operations, and higher productivity. FLOMEK’s expert team ensures every alignment is done accurately, efficiently, and tailored to your industrial needs.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply