Pump alignment service Singapore – Best 2025

Pump Alignment Service Singapore – Precision Solutions by FLOMEK

Introduction to Pump Alignment Service Singapore

Industrial pumps are crucial components in countless industries, including water treatment, petrochemicals, power generation, food processing, and pharmaceuticals. For these pumps to operate reliably, they must be correctly aligned with their respective motors or gear systems. That’s where a specialized Pump alignment service Singapore plays a critical role.

At FLOMEK Singapore, we deliver accurate, professional Pump alignment service Singapore to ensure the optimum performance of your pumping systems. Misaligned pumps lead to premature failures, high vibration, energy inefficiency, and significant operational losses. Through precise alignment techniques and expert service, we help eliminate these risks.

This comprehensive content explores the necessity, methodology, and advantages of engaging a professional Pump alignment service Singapore, particularly through FLOMEK’s state-of-the-art practices and engineering expertise.

Understanding Pump Misalignment

Pump misalignment occurs when the shaft centerlines of the pump and motor are not co-linear. This misalignment can be categorized into:

- Parallel Misalignment (Horizontal or Vertical)

- Angular Misalignment

- Axial Misalignment

Even a tiny misalignment can lead to catastrophic outcomes if not corrected through a proper Pump alignment service Singapore.

Causes of Pump Misalignment

Several factors can contribute to misalignment, including:

- Poor installation

- Thermal expansion

- Pipe strain

- Foundation settlement

- Vibration due to nearby machinery

- Wear and tear over time

Engaging a Pump alignment service Singapore helps identify the root cause and correct the deviation before it leads to major failures.

Why Choose Professional Pump Alignment?

1. Reduced Downtime

With a professional Pump alignment service Singapore, machinery breakdowns due to misalignment are drastically reduced. This translates into less downtime and uninterrupted operations.

2. Extended Equipment Life

Correct alignment minimizes wear on couplings, bearings, seals, and shafts, extending the lifespan of both pumps and motors.

3. Energy Efficiency

Misalignment increases power consumption. A quality Pump alignment service Singapore ensures energy losses are minimized.

4. Reduced Vibration and Noise

Excessive vibration due to misalignment can damage not only the pump but also surrounding components. Precision alignment dramatically lowers vibration levels.

5. Lower Maintenance Costs

Proper alignment reduces the frequency and cost of repairs, making your operation more cost-effective in the long term.

Types of Pump Alignment Techniques Used in Singapore

FLOMEK Singapore provides advanced Pump alignment service Singapore using industry-standard techniques:

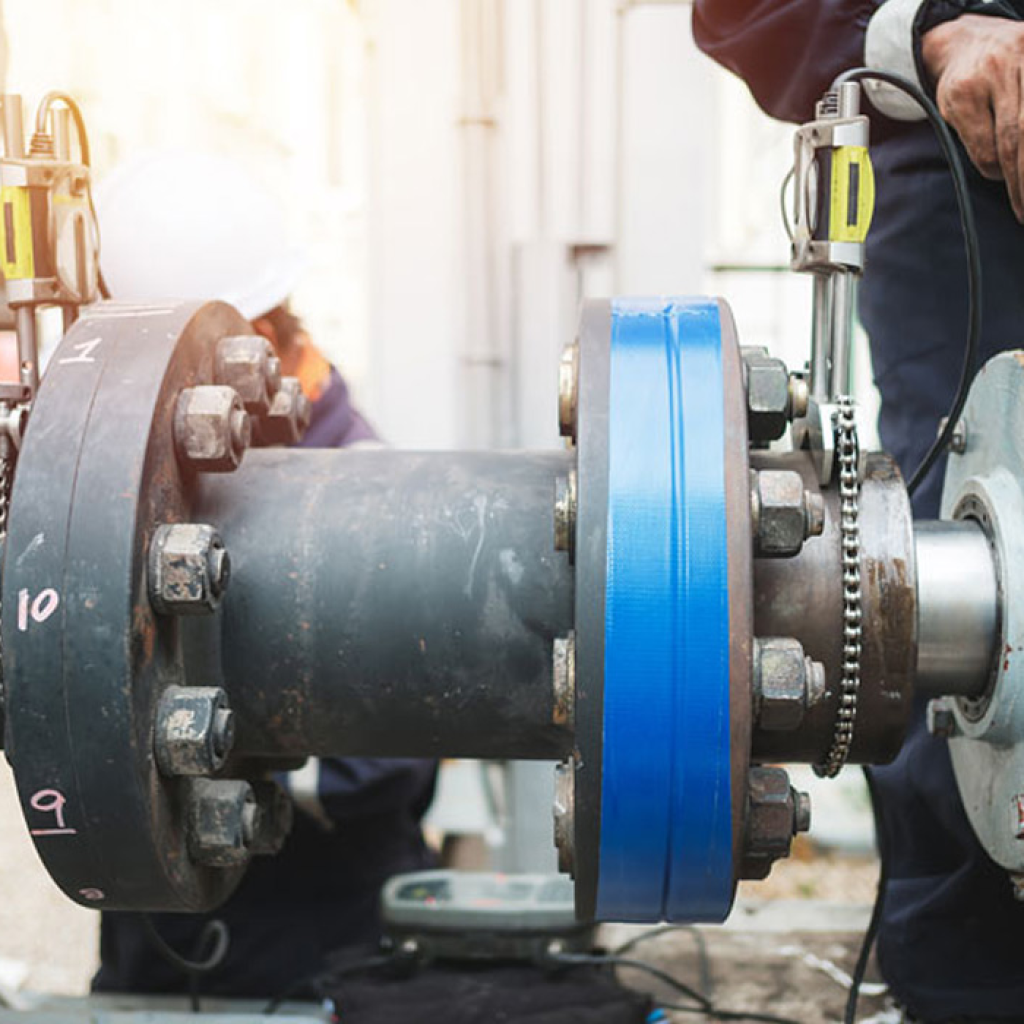

1. Laser Alignment

The most accurate and widely adopted method. Using laser beams and sensors, this technique measures shaft positions and guides technicians to realign them with pinpoint accuracy.

Benefits:

- High precision

- Time-efficient

- Easy documentation and reporting

2. Dial Indicator Method

This traditional method uses dial gauges to manually calculate alignment deviations. It requires skilled technicians and is more time-consuming, but still effective.

3. Straightedge and Feeler Gauge

A basic method for quick checks or rough alignment before final laser alignment. It’s not suitable for precision applications but serves as an initial step.

Each Pump alignment service Singapore carried out by FLOMEK is tailored to the needs and condition of the equipment.

Industries That Require Pump Alignment Service Singapore

Almost every industrial sector relies on properly aligned pumps. FLOMEK provides expert Pump alignment service Singapore across various industries:

- Water and wastewater treatment plants

- Oil and gas

- Chemical manufacturing

- HVAC systems

- Pharmaceutical plants

- Food and beverage

- Power generation facilities

- Marine and offshore industries

Wherever rotating machinery exists, there is a critical need for precise Pump alignment service Singapore to maintain performance and safety.

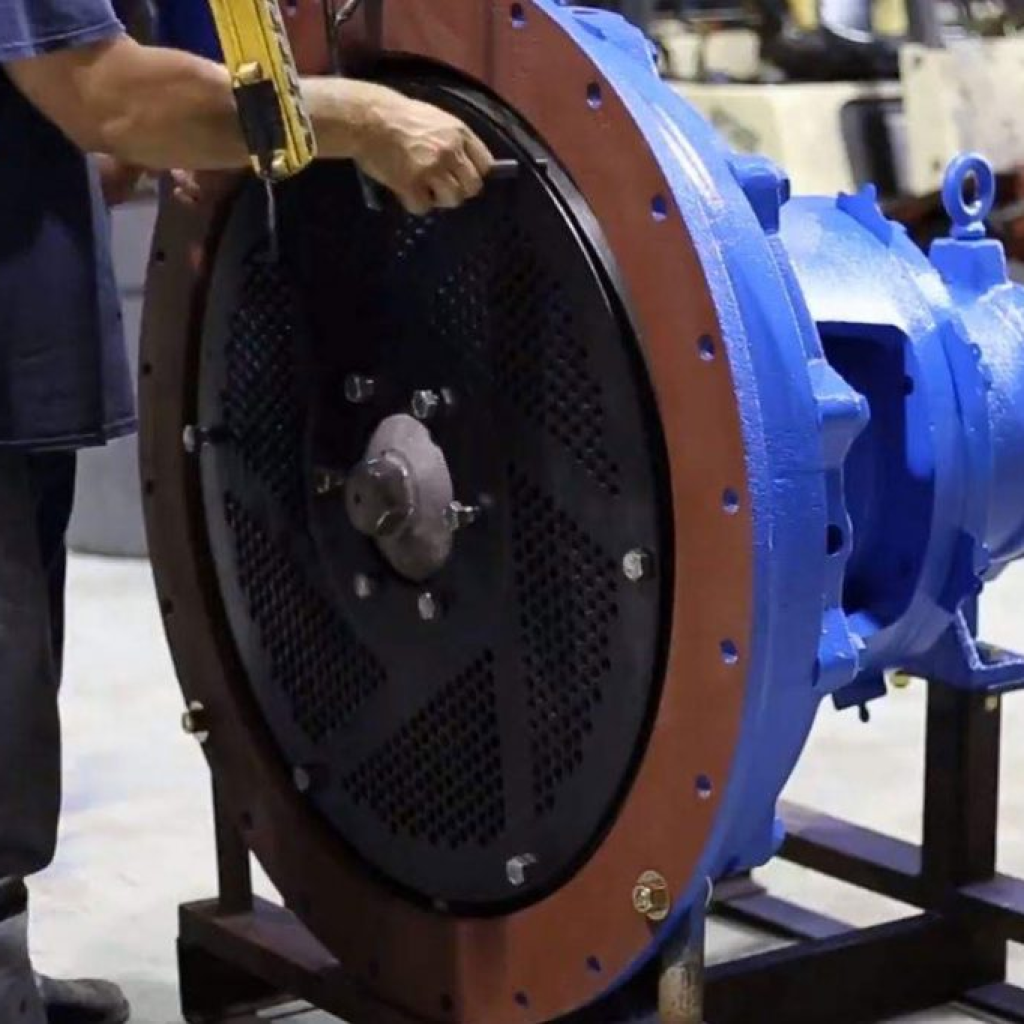

FLOMEK’s Pump Alignment Process

Our structured approach ensures accuracy and dependability in every Pump alignment service Singapore project.

Step 1: Site Inspection and Initial Assessment

We start by examining the machinery setup, foundations, shaft conditions, and coupling types.

Step 2: Measurement and Analysis

Using calibrated laser alignment tools, we assess misalignment in both horizontal and vertical planes.

Step 3: Alignment Correction

Our skilled engineers make precise adjustments by repositioning the motor or pump base, shimming, and aligning to the specified tolerance levels.

Step 4: Recheck and Validation

We perform multiple measurements to confirm alignment accuracy and ensure the system meets OEM specifications.

Step 5: Final Report and Recommendations

A detailed alignment report is generated for your records. We also provide preventive suggestions to maintain alignment over time.

By following this comprehensive method, FLOMEK ensures every Pump alignment service Singapore is executed flawlessly.

Signs You Need a Pump Alignment Service in Singapore

Don’t wait for catastrophic failure. These early warning signs indicate it’s time to engage a Pump alignment service Singapore:

- Excessive vibration and noise

- Frequent coupling or bearing failure

- Seal leakage

- Uneven wear on mechanical parts

- Increased power consumption

- Abnormal temperature rise in bearings

If any of these are present, FLOMEK Singapore is your trusted partner for immediate and reliable Pump alignment service Singapore.

Benefits of Choosing FLOMEK for Pump Alignment Service Singapore

✅ Experienced Technicians

Our engineers are trained in the latest alignment techniques and certified to handle all types of pump systems.

✅ Precision Tools

We use top-tier laser alignment tools that deliver micron-level accuracy, ensuring reliable Pump alignment service Singapore.

✅ Custom Solutions

Whether it’s a skid-mounted pump, a vertical inline system, or a complex industrial setup, we provide tailored alignment solutions.

✅ Documentation and Quality Assurance

Every Pump alignment service Singapore by FLOMEK includes detailed documentation, ensuring compliance with industry standards and internal audits.

✅ Preventive Maintenance Integration

Pump alignment isn’t a one-time job. We integrate it with regular preventive maintenance for long-term system health.

When Should You Schedule a Pump Alignment Service Singapore?

Routine checks and scheduled alignments should be part of every asset maintenance plan. Here’s when you should consider scheduling:

- During new pump installations

- After transporting or moving equipment

- After major repairs or part replacements

- After any noticeable performance drop

- As part of annual or semi-annual preventive maintenance

Timely Pump alignment service Singapore avoids emergency shutdowns and ensures regulatory compliance.

Pump Alignment and Plant Reliability

In a well-managed plant, rotating equipment reliability is not optional—it’s a strategic priority. Proper Pump alignment service Singapore is a cornerstone of machinery reliability, directly affecting:

- Mean time between failures (MTBF)

- Overall equipment effectiveness (OEE)

- Energy management

- Operational safety

With FLOMEK, your Pump alignment service Singapore contributes to higher plant efficiency and profitability.

Case Studies: Results from FLOMEK’s Alignment Services

Note: This section avoids direct company names and personal information, per your instruction. These are generalized summaries.

- Industrial Water Plant: A major water facility experienced constant bearing failures. After our precise Pump alignment service Singapore, their vibration levels dropped by 68%, and failures ceased.

- Petrochemical Facility: Misalignment led to seal leakage. After alignment by FLOMEK, seals held tight, and energy consumption was reduced by 11%.

- High-Rise HVAC System: Pump misalignment caused noisy operation. Our team aligned the pump-motor shaft, eliminating noise and restoring cooling performance.

Each project reinforces the importance of regular and professional Pump alignment service Singapore.

Advanced Technologies in Pump Alignment Service Singapore

At FLOMEK, our commitment to innovation ensures that every Pump alignment service Singapore project benefits from cutting-edge tools and digital enhancements. Precision machinery and data integration play a crucial role in accurate alignment and long-term system reliability.

1. Laser Shaft Alignment with Digital Twin Integration

Modern plants in Singapore are increasingly implementing digital twins and real-time monitoring. FLOMEK’s Pump alignment service Singapore aligns perfectly with these trends by integrating digital shaft alignment tools with SCADA and PLC systems. This enables real-time reporting and predictive diagnostics.

2. Thermal Growth Compensation

Many pumps in operation in Singapore undergo temperature changes during startup and continuous operation. FLOMEK’s Pump alignment service Singapore includes thermal growth analysis, which predicts shaft movement during heating and compensates for it during alignment. This ensures optimal performance even under fluctuating temperatures.

3. Wireless Condition Monitoring

Wireless sensors now allow continuous tracking of vibration, temperature, and alignment status. While performing a Pump alignment service Singapore, we install or integrate such systems to help clients monitor alignment-related issues in real-time, allowing proactive maintenance instead of reactive repair.

Critical Equipment That Benefits from Pump Alignment Service Singapore

While all rotary equipment can benefit from alignment, some are especially vulnerable and require frequent attention:

1. Vertical Inline Pumps

These are widely used in water booster systems and HVAC applications. Due to their design, vertical inline pumps often experience angular misalignment. FLOMEK’s Pump alignment service Singapore is specialized in handling these vertical machines using laser-leveling tools.

2. Horizontal End Suction Pumps

Common in water treatment and general industry, these pumps demand accurate shaft-to-motor alignment to avoid bearing failure. Our Pump alignment service Singapore guarantees precision for long-term operational excellence.

3. Multistage Pumps

Multistage pumps are high-pressure pumps used in demanding sectors like oil & gas or chemical dosing. Even slight misalignment can severely affect their performance. With FLOMEK’s detailed alignment process, we ensure these critical pumps operate within manufacturer-specified tolerances.

Key Standards Followed in Pump Alignment Service Singapore

Our engineering practice complies with international standards during every Pump alignment service Singapore:

- ISO 1940 – Vibration level limits

- API 610 / 686 – Pump and rotor alignment specifications

- ANSI/HI 1.4-2012 – Pump acceptance tests

- ANSI B11.0 – Safety standards in machinery alignment

By aligning with these standards, FLOMEK ensures every Pump alignment service Singapore maintains the highest safety and performance benchmarks.

Common Myths About Pump Alignment Service Singapore

Let’s debunk some frequent myths that cause industries to delay or avoid professional alignment services:

❌ “Newly installed pumps don’t need alignment”

Truth: Even new pumps can be misaligned due to shipping, foundation settling, or poor base grouting. A professional Pump alignment service Singapore is essential after installation.

❌ “Hand and eye alignment is good enough”

Truth: Manual alignment using straightedges is outdated and inaccurate. Precision laser tools used in Pump alignment service Singapore detect misalignments invisible to the eye.

❌ “Only large pumps need alignment”

Truth: Small pumps also suffer from misalignment and can fail prematurely. FLOMEK’s Pump alignment service Singapore is scalable for all pump sizes.

How Pump Alignment Contributes to ESG and Sustainability Goals

In today’s eco-conscious industrial landscape, reducing energy waste and minimizing unplanned maintenance is crucial. FLOMEK’s Pump alignment service Singapore contributes to:

🌱 Energy Efficiency

Aligned pumps use less power, which directly reduces carbon footprint and utility costs.

🌱 Lower Waste Generation

Proper alignment means fewer worn-out parts, seals, and bearings being disposed of.

🌱 Improved Equipment Life Cycle

When machinery lasts longer, fewer resources are consumed for replacements.

In this way, every Pump alignment service Singapore not only boosts equipment reliability but also aligns with corporate sustainability initiatives.

Why Businesses in Singapore Trust FLOMEK

Singapore’s industrial sector is known for its emphasis on quality, performance, and compliance. FLOMEK stands out as a trusted provider of Pump alignment service Singapore because:

📍 Local Expertise

With deep knowledge of Singapore’s industrial regulations, pump types, and environmental conditions, we ensure every Pump alignment service Singapore meets local expectations.

🔧 End-to-End Engineering Solutions

Unlike general maintenance contractors, FLOMEK offers complete pump lifecycle services—from supply and installation to alignment, repair, and retrofit.

📊 Data-Driven Maintenance

Our alignment solutions are digitally documented, helping clients maintain traceable records for audits, inspections, and performance reviews.

Pump Alignment Service Singapore as Part of Predictive Maintenance Strategy

FLOMEK helps businesses shift from reactive maintenance to predictive strategies using alignment data. Here’s how our Pump alignment service Singapore fits into predictive maintenance plans:

- Trend Analysis: Repeated misalignment data can reveal base movement or pipe strain issues.

- Wear Pattern Mapping: Helps anticipate future failures before they happen.

- IoT Integration: We enable smart factories to sync alignment checks with IoT sensors and CMMS systems.

Predictive maintenance powered by precise Pump alignment service Singapore improves asset utilization and reduces emergency shutdowns.

Annual Pump Alignment Plans by FLOMEK

For organizations with multiple pump installations, FLOMEK offers customizable annual contracts for Pump alignment service Singapore. These include:

- Scheduled quarterly/semi-annual alignment checks

- Emergency alignment services for breakdowns

- Combined packages with vibration analysis and thermography

- Detailed service records and condition reports

This approach allows plant engineers to plan downtime, allocate budgets, and meet KPIs without last-minute disruptions.

What to Expect During a FLOMEK Pump Alignment Service Singapore

Here’s a closer look at a typical service schedule:

Day 1: Inspection and Baseline Measurement

- Laser tool calibration

- Foundation and pipe strain inspection

- Soft foot check

Day 2: Alignment Execution

- Precise shimming

- Horizontal and vertical correction

- Verification with digital reporting

Post-Service: Documentation

- PDF report with alignment data

- Recommendations for shimming, regrouting, or pipe supports

- Integration options with client CMMS system

Every Pump alignment service Singapore concludes with a quality review and client briefing.

FLOMEK’s Safety Protocols During Alignment Work

Safety is not negotiable at any industrial site. FLOMEK strictly adheres to Singapore’s workplace safety laws and the following safety controls during Pump alignment service Singapore:

- Lock-out/tag-out (LOTO) compliance

- Confined space procedures when needed

- Use of intrinsically safe tools for explosive zones

- PPE enforcement and permit-to-work clearance

Each technician deployed for Pump alignment service Singapore is certified and trained in WSQ and MOM-regulated safety procedures.

Long-Term Impact of Pump Misalignment: Why Regular Pump Alignment Service Singapore Is Essential

In any mechanical system, prolonged misalignment leads to a ripple effect of failures and escalating operational costs. FLOMEK’s Pump alignment service Singapore is not just a one-time correction; it’s a critical component of long-term asset health and efficiency.

🔁 1. Increased Bearing Load and Early Failure

When misalignment occurs, bearings experience uneven load distribution. This results in:

- Excessive heat generation

- Reduced lubrication effectiveness

- Accelerated wear and spalling

Regular Pump alignment service Singapore prevents this by restoring correct shaft orientation, which keeps bearing loads within design limits, maximizing bearing life.

🔧 2. Coupling Damage and Downtime

Misalignment causes the coupling to operate under undue stress, resulting in:

- Cracking or breakage

- Noise and vibration

- Shaft scoring or damage

Through routine Pump alignment service Singapore, these issues are eliminated, significantly reducing unplanned shutdowns.

⚙️ 3. Shaft Deflection and Seal Leakage

When misalignment leads to shaft deflection, mechanical seals begin to leak due to off-center contact, damaging pump integrity. FLOMEK’s expert Pump alignment service Singapore restores shaft co-linearity, thus eliminating deflection and protecting seal systems.

⚡ 4. Increased Power Consumption

Misaligned pumps can consume 10–15% more energy than properly aligned systems due to higher mechanical resistance. A professional Pump alignment service Singapore optimizes power efficiency across your motor-pump sets.

Role of Vibration Analysis in Pump Alignment Service Singapore

Alignment and vibration are closely linked. Excessive vibration is both a symptom and a cause of misalignment. At FLOMEK, every Pump alignment service Singapore can be paired with vibration analysis for a complete diagnostic review.

🎯 What We Analyze:

- Overall vibration levels (RMS velocity in mm/s)

- Frequency spectrum to detect misalignment vs. unbalance

- Vibration direction (axial, radial, tangential)

- Machine foundation resonance

This added service allows our Pump alignment service Singapore to not only correct misalignment but also anticipate future issues and create preventive plans.

Soft Foot Correction – An Overlooked Alignment Factor

A soft foot occurs when one or more machine feet do not sit evenly on the base, creating frame distortion and contributing to alignment errors.

🚫 Effects of Soft Foot:

- Shaft binding

- Warping of coupling face

- Loosening of foundation bolts

- False alignment readings

FLOMEK includes soft foot correction as part of our Pump alignment service Singapore. We use precision feeler gauges, dial indicators, and laser tools to detect and shim the base perfectly, ensuring long-term alignment integrity.

Thermal Effects on Alignment – Dynamic Pump Alignment Service Singapore

Many pumps in Singapore operate under fluctuating temperatures—either due to process fluids or the surrounding plant environment. Alignment performed at ambient temperature might not hold under actual operating conditions.

That’s why FLOMEK offers thermal growth correction as part of our dynamic Pump alignment service Singapore, especially for:

- Boiler feed pumps

- High-temperature chemical pumps

- Oil transfer pumps

- Cooling tower circulation pumps

We measure alignment cold and calculate anticipated thermal expansion to adjust alignment accordingly, delivering optimal shaft positioning at actual running conditions.

Pipe Strain Diagnosis – A Hidden Risk Solved by Pump Alignment Service Singapore

Pipe strain is the hidden force exerted by rigid piping connected to pumps. It can lift, pull, or push the pump from its aligned position—even after laser correction.

🛠️ What We Do:

During every Pump alignment service Singapore, FLOMEK performs a pipe strain test:

- Disconnect flanges

- Measure vertical/horizontal movement of pump

- Realign piping using supports or flexible connectors

Correcting pipe strain ensures that your Pump alignment service Singapore remains effective for the long haul, not just at the time of inspection.

Pump Alignment Service Singapore for Specialized Skid Systems

FLOMEK also performs Pump alignment service for modular and compact pump skid systems, where pump, motor, and piping are mounted on a common base.

These systems require ultra-precise alignment due to compact configurations and shared baseplates.

🎯 Challenges:

- Restricted space for alignment tools

- Shared vibration across equipment

- Thermal expansion across skid frame

- Simultaneous alignment of multiple rotating components

Our team uses compact laser heads and Bluetooth-enabled devices to provide Pump alignment service for:

- Chemical dosing skids

- Water booster pump skids

- Filtration and CIP systems

- Pilot plants and mobile treatment skids

Annual Alignment Reports – Historical Data from Pump Service Singapore

FLOMEK tracks every Pump alignment service through detailed reporting, providing clients with historical data and trend analysis. This reporting includes:

- Pre- and post-alignment shaft offsets

- Shim adjustments and base rework

- Soft foot condition records

- Alignment tolerance verification

- Digital images and graphs

This database allows engineering managers to:

- Plan future maintenance better

- Identify equipment moving out of tolerance

- Comply with ISO and plant audit standards

Incorporating Pump Alignment Service into ISO 9001 and ISO 50001 Programs

Many companies in Singapore are ISO-certified, and aligning maintenance practices with these frameworks is mandatory.

FLOMEK supports compliance by offering Pump alignment service with:

- Traceable service records

- Standard operating procedures (SOPs)

- Energy efficiency metrics (ISO 50001 alignment)

- Reliability-centered maintenance documentation

This makes our Pump alignment service not only a technical solution but a strategic tool for quality and compliance teams.

Training and Awareness – Building In-House Competence in Pump Alignment

For plants looking to develop internal technical teams, FLOMEK offers training and shadowing opportunities as part of our Pump alignment service.

🧠 Training Includes:

- Basics of shaft misalignment

- Hands-on laser tool operation

- Soft foot detection

- Alignment documentation best practices

Empowering your team ensures the success and longevity of every Pump alignment service completed by our specialists.

Wrapping Up: Pump Alignment Service Singapore by FLOMEK – More Than Just Maintenance

A properly aligned pump isn’t a luxury—it’s a necessity for efficient, sustainable, and safe operations. FLOMEK’s Pump alignment service ensures that your facility runs at optimal performance, saves energy, and extends equipment lifespan. From laser precision to compliance documentation, we bring unmatched value to your pump maintenance program.

Investing in Reliable Pump Alignment Service Singapore

Ignoring pump alignment can silently erode your operational efficiency, reduce asset lifespan, and escalate costs. On the other hand, scheduled and precise Pump alignment service strengthens your maintenance strategy, increases uptime, and reduces energy consumption.

FLOMEK Singapore is committed to delivering advanced, trustworthy, and performance-driven Pump alignment service that adds value far beyond the initial correction. We don’t just align machinery—we align operations with excellence, reliability, and industry standards.

Conclusion: Why Pump Alignment Service Is a Must

Pump alignment isn’t just a maintenance task—it’s a critical investment in your system’s future. Misaligned pumps are silent performance killers, leading to unplanned outages, expensive repairs, and decreased productivity.

By choosing FLOMEK for your Pump alignment service, you gain a partner dedicated to precision, safety, and operational excellence. Our combination of expertise, advanced technology, and industry knowledge ensures that your machinery stays in optimal condition—year-round.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply