Pressure pump system Singapore – Best 2025

Pressure Pump System Singapore – Reliable, Efficient, and Engineered for Excellence

In the industrial and commercial sectors, consistent water pressure is not a luxury—it is a necessity. The increasing demand for stable water distribution systems has made the Pressure Pump System Singapore market highly specialized and critical for infrastructure development. A well-designed pressure pump system ensures smooth operation in high-rise buildings, industrial facilities, and process plants where pressure consistency and reliability are crucial.

This article explores the importance, benefits, technical aspects, and applications of the Pressure Pump System Singapore market, focusing on industrial, municipal, and commercial usage.

Introduction to Pressure Pump Systems in Singapore

A Pressure Pump System Singapore refers to an engineered pump assembly designed to regulate, boost, and maintain water pressure levels across various flow rates and usage demands. In Singapore, where infrastructure is sophisticated and vertical development is common, such systems are indispensable.

Whether you manage a manufacturing plant, residential complex, hospital, or hotel, you need a Pressure Pump System Singapore that is both robust and intelligent enough to adapt to fluctuating demand.

Why Pressure Pump Systems are Critical in Singapore

Singapore’s architecture is known for its skyscrapers, water treatment plants, and complex piping networks. The need for reliable water pressure is essential, especially in:

- High-rise buildings

- Hospitals and medical facilities

- Manufacturing and process plants

- Commercial complexes

- Condos and residential towers

- Data centers and laboratories

Each of these facilities depends heavily on a high-quality Pressure Pump System Singapore to maintain hygiene, cooling, processing, or even fire safety systems.

Types of Pressure Pump System Singapore Offers

Singapore’s engineering community offers several types of pressure pump systems to suit different operational needs:

1. Vertical Multistage Pressure Pump Systems

Ideal for tall buildings and systems requiring a higher head, these pumps are energy-efficient and designed for space-saving vertical installation.

2. Horizontal Multistage Pressure Pump Systems

Used where space permits horizontal installation, these offer excellent flow rates and operational stability.

3. Booster Pump Skids

Custom-built for applications where sudden demand fluctuations occur, booster skids ensure consistent output without delay.

4. Inverter-Controlled Pressure Pump Systems

With smart controls, these systems automatically adjust speed based on real-time demand. This leads to optimal energy consumption and less wear-and-tear.

5. Constant Pressure Systems

These maintain a set pressure irrespective of the usage. Particularly useful in water distribution networks and manufacturing units.

The choice of Pressure Pump System Singapore depends on the application, pressure requirement, system integration complexity, and energy efficiency needs.

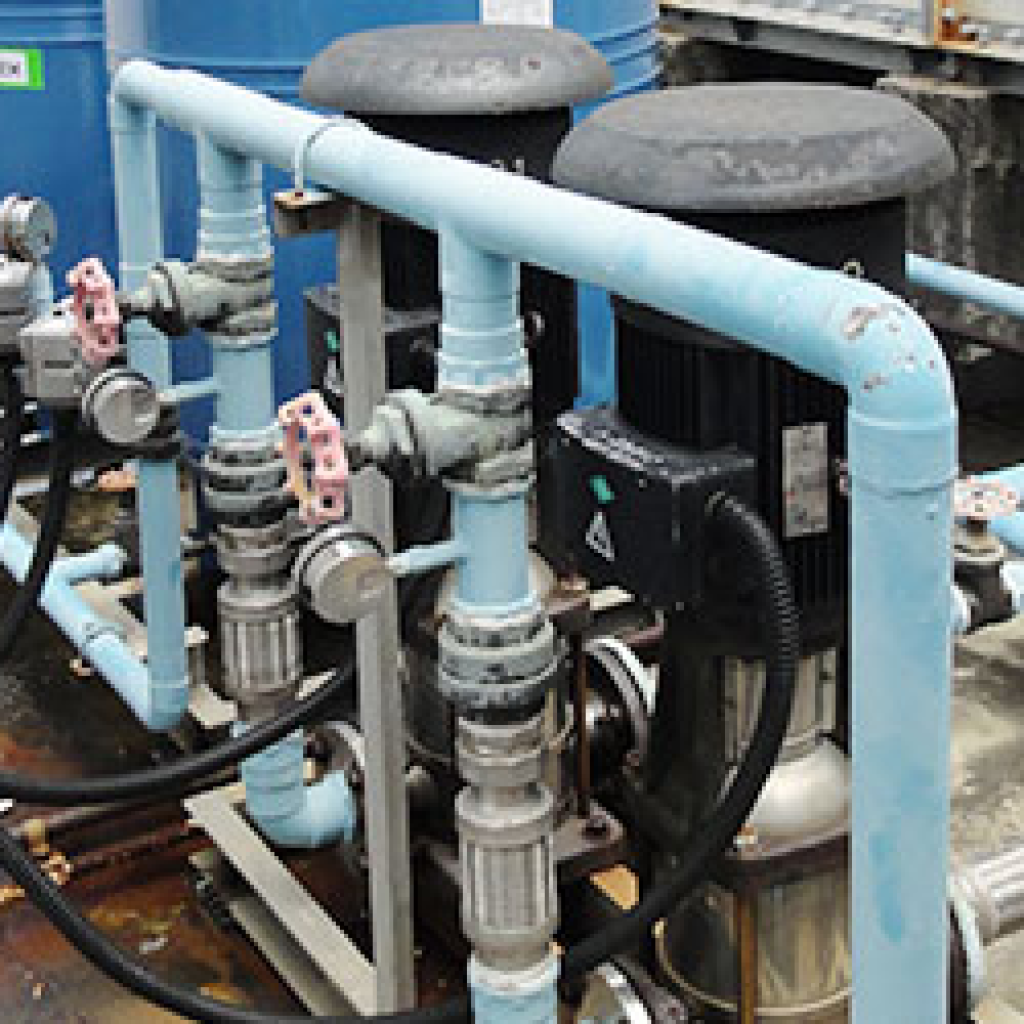

Core Components of a Pressure Pump System Singapore

A typical Pressure Pump System Singapore includes:

- Pressure Booster Pumps

- Pressure Transducers

- Control Panel (PLC/SCADA)

- VFD Drives (Inverter)

- Non-Return Valves and Isolation Valves

- Pressure Tanks

- Flow Meters

- Base Frame or Skid

All components are integrated to work as a single, reliable unit. The control system manages operation, shutdowns, fault alerts, and speed modulation.

Industrial Applications of Pressure Pump System Singapore

Pressure pump systems are used across a variety of industries:

1. Water Treatment Plants

In Singapore’s sustainable water strategies, treated water must be pumped with consistent pressure across urban areas. A reliable Pressure Pump System Singapore is essential for that.

2. Pharmaceutical Industry

Critical processes require precision. A Pressure Pump System Singapore ensures sterility and control in manufacturing areas.

3. Food and Beverage Sector

Production lines rely on stable water pressure for cleaning, ingredient mixing, and sanitation.

4. Chemical and Petrochemical Plants

Corrosive materials demand robust and pressure-optimized systems with safety integration.

5. HVAC and Cooling Systems

Pressure pump systems help circulate chilled water through large buildings, ensuring climate control efficiency.

Advantages of Using a Pressure Pump System Singapore

✅ Stable Pressure Output

A key advantage of using a Pressure Pump System Singapore is consistent pressure. Pressure drops and surges can damage equipment and disrupt processes.

✅ Energy Efficiency

Modern systems include inverter-driven motors that adjust pump speed based on load. This leads to reduced electricity bills and sustainability compliance.

✅ Space Optimization

Skid-mounted Pressure Pump System Singapore designs allow for compact installation in mechanical rooms or basements.

✅ Minimal Downtime

Most systems are designed with redundancy, ensuring one pump takes over if another fails—ideal for mission-critical facilities.

✅ Smart Monitoring

Integration with SCADA or IoT-based platforms means you can remotely monitor system performance, faults, and operating conditions in real time.

Custom-Engineered Solutions for Pressure Pump System Singapore

Every facility has unique flow requirements, inlet/outlet pressure needs, and layout restrictions. Therefore, custom solutions are crucial.

Engineers specializing in Pressure Pump System Singapore will:

- Assess site flow rate and pressure demands

- Conduct a hydraulic study

- Recommend pump types and control systems

- Design a skid-based or modular pressure booster package

- Provide installation and commissioning support

- Offer maintenance contracts

This turnkey approach ensures smooth integration with existing infrastructure.

Energy Saving with Variable Speed Drives (VFD)

VFDs are becoming standard in Pressure Pump System Singapore packages. Their ability to vary the pump speed as per demand helps:

- Save energy by 20–40%

- Extend motor and impeller life

- Reduce system noise and vibration

- Minimize water hammer effects

For buildings with varying peak and off-peak usage (like offices, hotels, and malls), VFDs are indispensable.

Design Considerations for Pressure Pump System Singapore

Key design factors include:

- Total Dynamic Head (TDH)

- Flow Rate Requirement

- Pump Curve Analysis

- Pump Material Compatibility (SS, CI, Bronze, etc.)

- Footprint Availability

- Noise Level Restrictions

- Integration with Fire and Utility Systems

- Accessibility for Maintenance

A well-designed Pressure Pump System Singapore factors in lifecycle cost, ease of replacement, and future scalability.

Preventive Maintenance for Pressure Pump Systems in Singapore

Routine servicing is vital to keep your system operating at peak performance. Proper maintenance of a Pressure Pump System Singapore includes:

- Checking and replacing seals, gaskets

- Inspecting control panels and VFDs

- Monitoring motor bearings

- Verifying pressure sensor calibration

- Lubricating pump components

- Cleaning filters and strainers

Scheduled preventive maintenance reduces unexpected breakdowns and extends system life.

Skid-Based Modular Systems – The Future of Pressure Pump System Singapore

Skid-mounted units offer plug-and-play convenience, compactness, and speed of deployment. Skid systems are pre-tested and pre-wired in workshops, reducing onsite errors and startup delays.

Advantages of skid-based Pressure Pump System Singapore units:

- Factory tested before delivery

- Faster commissioning time

- Integrated instrumentation and control

- Ease of transport and relocation

- Lower installation cost

Whether for permanent installation or pilot setups, skid-based solutions are becoming the preferred approach in Singapore.

Compliance and Safety Standards

In Singapore, pump systems must meet various compliance regulations. A professional Pressure Pump System Singapore supplier ensures alignment with:

- PUB water pressure requirements

- SS531 and ASME mechanical codes

- ISO 9001 manufacturing standards

- IEC standards for control panels

- BCA green building certifications

Safety features such as dry-run protection, over-temperature shutdown, and motor fault indicators are included in modern systems.

Emerging Trends in the Pressure Pump System Singapore Market

The landscape is evolving with technology and urban demands. Key trends include:

- IoT-enabled pump systems

- Predictive maintenance alerts

- Green-certified energy-saving motors

- AI-based water demand forecasting

- Remote mobile app monitoring

- Smart integration with fire, HVAC & building automation systems

These innovations will redefine how Pressure Pump System Singapore solutions are deployed and maintained in the coming years.

Choosing the Right Partner for Pressure Pump System Singapore

When selecting a pressure pump system provider in Singapore, ensure that the supplier offers:

- Engineering consultation

- Custom design

- High-quality pump components

- In-house control panel design

- PLC/SCADA integration

- Skilled installation and commissioning

- Warranty and local spare parts support

- After-sales preventive maintenance contracts

A strategic and experienced partner will help your Pressure Pump System Singapore investment deliver maximum ROI over its lifespan.

Smart Control Systems in Pressure Pump System Singapore

The evolution of pump technology has introduced intelligent control systems that enhance efficiency and reliability. In Singapore, where demand fluctuation is common across commercial, residential, and industrial sectors, incorporating advanced controls is crucial for the success of any Pressure Pump System Singapore installation.

✳️ SCADA & PLC Integration

The majority of modern Pressure Pump System Singapore solutions are integrated with Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems. These systems allow:

- Real-time system monitoring

- Remote diagnostics and control

- Data logging for preventive action

- Alarm and fault notification

This level of automation in your Pressure Pump System Singapore ensures continuous operation with minimal manual intervention.

✳️ Pressure Sensor Feedback Loops

Pressure sensors constantly provide feedback to the controller. This enables the system to automatically adjust the motor speed to meet exact pressure requirements, reducing energy consumption and system wear.

Design Best Practices for Pressure Pump System Singapore

When planning and implementing a new Pressure Pump System Singapore, following industry-standard best practices ensures safety, efficiency, and long-term success.

🔧 1. Redundancy Planning

Always design your Pressure Pump System Singapore with at least one standby pump. This ensures continuous operation even during servicing or unplanned pump failure.

🔧 2. Pressure Zoning in High-Rise Buildings

Singapore’s skyline includes numerous towers and skyscrapers. A proper Pressure Pump System Singapore design involves pressure zoning, where the building is divided into zones with dedicated pumps for each level, preventing over-pressurization.

🔧 3. NPSH Consideration

Net Positive Suction Head (NPSH) calculations are vital to avoid cavitation. A good Pressure Pump System Singapore design prevents pump damage and ensures long-term efficiency.

🔧 4. Isolation Valves and Bypass Lines

These features allow safe maintenance and ensure the pump system stays operational during repairs or upgrades.

Energy Conservation through Smart Pump Selection

Singapore places strong emphasis on sustainability and energy conservation. Selecting high-efficiency motors and using pressure modulation drives help meet green building goals. Energy-efficient Pressure Pump System Singapore units offer:

- Lower lifecycle costs

- Improved LEED/BCA Green Mark scoring

- Less noise and vibration

- Reduced carbon footprint

✅ IE3 and IE4 Motors

Use of premium efficiency motors (IE3/IE4 compliant) is a standard in modern Pressure Pump System Singapore designs. They reduce power consumption and meet Singapore’s MEPS (Minimum Energy Performance Standards).

Noise and Vibration Control in Pressure Pump System Singapore

In urban buildings and sensitive installations like hospitals and laboratories, noise levels matter. A professional Pressure Pump System Singapore should include:

- Anti-vibration mounts

- Flexible connectors

- Acoustic enclosures

- Rubber bushings on base frames

Noise reduction isn’t just about comfort—it’s also about extending pump life and ensuring reliable performance under varying operating conditions.

Materials Selection for Pressure Pump System Singapore

Singapore’s water quality is closely regulated, but depending on the application—whether potable water, seawater, chemical dosing, or greywater—the material selection of the pump and accessories is essential.

⚙️ Common Materials Used:

- Stainless Steel (SS316, SS304) – for corrosion resistance in potable and marine environments

- Cast Iron – widely used for general applications

- Bronze and Brass – suitable for seawater and fire systems

- PFA/PTFE-lined pumps – for aggressive chemical usage

Using the right materials ensures that your Pressure Pump System Singapore is safe, reliable, and compliant with industry requirements.

Pressure Pump System Singapore in Fire Protection

Fire suppression systems are a critical aspect of any infrastructure. In Singapore, a well-designed Pressure Pump System Singapore is often integrated with the building’s fire fighting network to ensure rapid response during emergencies.

These systems include:

- Fire booster pumps

- Jockey pumps

- Dedicated fire tanks

- Fire-rated control panels

All equipment used in fire protection Pressure Pump System Singapore setups must comply with Singapore Civil Defence Force (SCDF) regulations.

Case Use: Industrial Application of Pressure Pump System Singapore

Consider a food manufacturing plant in Jurong that operates 24/7 and requires stable water pressure for:

- Cleaning processes

- Boiler feedwater

- Ingredient mixing

- Cooling systems

A multi-pump VFD-controlled Pressure Pump System Singapore ensures energy efficiency, process consistency, and hygiene compliance. With SCADA integration, plant managers can monitor system conditions, alarms, and pressure fluctuations remotely—reducing manpower while improving uptime.

Cost Considerations for Pressure Pump System Singapore

💰 Initial Cost Components:

- Pump units (with motor and impellers)

- Skid and piping layout

- Pressure tanks and sensors

- VFD/PLC/Control Panels

- Electrical wiring

- Installation and commissioning

💰 Long-Term Cost Factors:

- Energy consumption

- Maintenance frequency

- Downtime losses

- Spare parts availability

Choosing a durable and serviceable Pressure Pump System Singapore helps reduce the total cost of ownership (TCO) over time.

Environmental Impact and Sustainability

Eco-conscious buildings and industries in Singapore aim for water conservation and energy efficiency. An intelligently controlled Pressure Pump System Singapore helps by:

- Reducing water leakage due to overpressure

- Minimizing electrical wastage through VFD use

- Lowering noise and vibration pollution

- Offering high-recyclability in system components

Supporting Singapore’s Green Plan 2030, modern Pressure Pump System Singapore setups are designed with the future in mind.

Retrofit Solutions for Older Buildings

Many older buildings in Singapore struggle with inconsistent water pressure. A Pressure Pump System Singapore retrofit solution can rejuvenate performance by:

- Replacing old constant-speed pumps with VFD-based systems

- Upgrading control panels to PLC-based logic

- Installing energy-efficient motors

- Improving flow balance through zoning

Retrofitting helps meet current water regulations and reduce utility bills while extending the life of legacy systems.

After-Sales Support for Pressure Pump System Singapore

Reliable support and maintenance are key to long-term performance. Essential services for a Pressure Pump System Singapore include:

- Annual/quarterly health checks

- On-site repairs and replacements

- Remote monitoring services

- Calibration of pressure and flow sensors

- Software updates for control systems

- Emergency breakdown support

Choose a trusted team to provide full lifecycle service of your Pressure Pump System Singapore for peace of mind.

Summing Up – Investing in the Right Pressure Pump System Singapore

An efficient and reliable Pressure Pump System Singapore is a backbone component for any building or facility’s operations. From energy savings and water flow consistency to smart monitoring and fire protection integration, pressure pump systems serve diverse needs in Singapore’s built environment.

To future-proof your infrastructure, ensure that your Pressure Pump System Singapore includes:

- Advanced control systems

- Efficient pump selections

- Compliance with local codes

- Redundancy and safety features

- Quality construction and materials

- Strong after-sales technical support

The right Pressure Pump System Singapore will not only meet today’s operational requirements but also adapt to tomorrow’s growth and sustainability demands.

Integration of Pressure Pump System Singapore with Building Management Systems (BMS)

In modern infrastructure, automation is not a luxury—it’s an operational necessity. One of the most forward-thinking approaches in Singapore’s construction and industrial sectors is integrating a Pressure Pump System Singapore with Building Management Systems (BMS). This allows centralized control and visibility over all utilities, including HVAC, lighting, water distribution, and pressure systems.

💡 Benefits of BMS Integration:

- Centralized Pressure Monitoring: Operators can monitor pump pressure status on a central dashboard.

- Automated Alerts: Any deviation from pressure norms triggers an alarm and sends notifications.

- Energy Data Collection: Records pump energy usage for energy audits.

- Real-Time Troubleshooting: Pinpoint faults faster and reduce pump system downtime.

A BMS-integrated Pressure Pump System Singapore not only enhances reliability but also aligns with green building initiatives.

Pressure Pump System for District Cooling Plants

District cooling systems are widely used in Singapore’s urban infrastructure for efficient air conditioning across multiple buildings. These systems rely heavily on stable water pressure in their chilled water circuits.

A Pressure Pump System is critical to maintain:

- Constant flow rate of chilled water to buildings

- Uniform pressure for thermal exchange

- Backup systems for redundancy in mission-critical facilities

In such plants, Pressure Pump System configurations often include:

- High-capacity multistage centrifugal pumps

- VFDs for energy optimization

- SCADA-linked pressure control

- Skid-mounted modular layouts

The resilience and efficiency of a Pressure Pump System directly influence the performance of district cooling applications across campuses, business parks, and integrated developments.

Water Recycling and Pressure Pump System Singapore

Singapore’s strong focus on sustainability, including NEWater and greywater recycling, requires reliable and energy-efficient pumping. Pressure consistency is vital in these applications due to varying demand and water quality.

In water recycling, the Pressure Pump System Singapore is used to:

- Pressurize treated water to distribution points

- Feed water into filtration membranes

- Maintain tank circulation loops

- Pump greywater for flushing, cleaning, or irrigation

These systems often include corrosion-resistant pump materials, automatic self-cleaning filters, and real-time flow regulation. Engineers custom-build such Pressure Pump System designs to comply with PUB’s standards for water reuse and treatment.

Data Center Cooling and the Role of Pressure Pump System Singapore

Data centers are vital to Singapore’s economy and digital future. Maintaining optimal temperature in data halls is critical—and chilled water cooling systems form the core of this strategy.

A well-designed Pressure Pump System ensures:

- Continuous chilled water pressure to air handling units (AHUs)

- Balance in return/supply pressure in loop circuits

- Adaptability for varying server loads

- Redundancy to prevent downtime or overheating

In such sensitive environments, even a slight dip in pressure can lead to temperature rise, potential equipment damage, or service interruptions. This makes the Pressure Pump System a mission-critical asset in the data center ecosystem.

Pressure Pump System Singapore in Marine and Offshore Installations

Offshore platforms and shipboard systems require rugged, space-efficient, and corrosion-resistant pumping systems. A marine-certified Pressure Pump System typically supports:

- Potable water pressure boosting

- Ballast water treatment systems

- Fire suppression systems

- Cooling water circulation

- Sewage and bilge system pressurization

Due to limited space and harsh environments, marine versions of the Pressure Pump System are often compact, lightweight, and built with stainless steel or bronze components. Shock resistance, vibration control, and redundancy are designed into these systems.

Fire Pump Integration in Pressure Pump System Singapore

The Singapore Fire Code mandates reliable fire protection systems in buildings. In many commercial buildings, the Pressure Pump System is integrated with the fire-fighting infrastructure to ensure immediate water pressure availability in case of emergencies.

A typical fire-integrated Pressure Pump System includes:

- A main electric-driven pump

- A backup diesel-driven pump

- A jockey pump for pressure maintenance

- Fire-rated control panels and sensors

- Pressure and flow switches

This system is kept on standby but ready to activate instantly during an emergency, delivering high flow and pressure to sprinkler systems, hydrants, and hose reels. It’s critical that the Pressure Pump System complies with Singapore Civil Defence Force (SCDF) standards.

Pressure Pump System for Healthcare and Laboratories

Hospitals and research laboratories depend on water for sterilization, cooling, diagnostics, and sanitation. These applications require ultra-reliable, clean, and often variable-pressure pumping solutions.

A hospital-grade Pressure Pump System supports:

- Centralized water distribution across wards and labs

- Sterile processing units (CSSD) and autoclaves

- HVAC chilled water pressure regulation

- Operating theater humidity and temperature control

- Backup pressure systems for emergencies

Failure in such systems is unacceptable. Therefore, systems are built with redundant motors, pressure sensors, and emergency override controls. These critical facilities benefit immensely from tailor-made Pressure Pump System designs.

The Role of Pressure Tanks in Pressure Pump System Singapore

Pressure tanks are essential in pump system design, acting as a buffer to maintain pressure levels even when pumps are idle. A properly sized pressure tank helps reduce the number of starts/stops and prolongs pump life.

In a typical Pressure Pump System, pressure tanks:

- Absorb pressure fluctuations

- Stabilize pump cycles

- Prevent short cycling

- Reduce water hammer

- Extend system component lifespan

Diaphragm-type, vertical, and bladder tanks are often used depending on system size, application, and available space. Selecting the right tank is as important as choosing the pump itself in a Pressure Pump System.

Common Challenges in Pressure Pump System and How to Overcome Them

❌ Cavitation Issues

Occurs when NPSH is too low. Solution: Proper system elevation and suction line sizing.

❌ Frequent Start/Stop Cycling

Usually due to wrong tank sizing or controller setting. Solution: Use larger tanks and smart controls.

❌ Pressure Drop in Upper Floors

Common in older buildings. Solution: Zone-based Pressure Pump System with variable-speed drives.

❌ Noisy Operations

Often from misaligned pumps or rigid piping. Solution: Use vibration isolators, rubber pads, and flexible connectors.

❌ Overpressure Causing Pipe Damage

Caused by pressure spikes. Solution: Install pressure relief valves and surge protectors in your Pressure Pump System.

Conclusion – Pressure Pump System is the Backbone of Modern Infrastructure

From data centers to hospitals, skyscrapers to manufacturing plants, Pressure Pump System Singapore solutions are critical to the functioning of water distribution, cooling systems, and utility networks. As Singapore continues to grow vertically and technologically, the demand for high-performance pressure systems will only rise.

A future-ready Pressure Pump System should be:

- Energy-efficient

- SCADA-integrated

- Zone-capable

- Redundant by design

- Compliant with safety and environmental standards

Choosing the right system ensures not only consistent water pressure but also operational savings, system longevity, and reduced downtime. For sustainable urban infrastructure, a well-engineered Pressure Pump System is no longer optional—it’s essential.

Conclusion: Future-Ready Pressure Pump System Singapore Solutions

From high-rise buildings and industrial plants to specialized process facilities, having a reliable Pressure Pump System setup is essential for operational excellence. With increasing water demands, sustainability targets, and automation needs, the importance of energy-efficient and smart pump systems has never been higher.

A professionally engineered Pressure Pump System is not just a utility—it’s an asset to ensure performance, safety, and energy savings in today’s competitive landscape.

By investing in robust, intelligent, and future-ready systems, Singaporean industries and infrastructure can achieve optimal water pressure management for decades to come.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply