Pharmaceutical dosing pumps Singapore – Best 2025

Introduction: The Essential Role of Pharmaceutical Dosing Pumps Singapore in the Industry

In the highly regulated and dynamic pharmaceutical industry, precision is everything. From the formulation of medicines to the accurate delivery of active ingredients, Pharmaceutical dosing pumps Singapore play an essential role in ensuring the success of pharmaceutical operations. These dosing pumps are designed to deliver specific volumes of liquid with great accuracy, making them vital for drug manufacturing, compounding, and processing.

At Flomek, we specialize in providing high-quality Pharmaceutical dosing pumps Singapore that meet international standards for accuracy, efficiency, and reliability. Our solutions are tailored to address the unique demands of the pharmaceutical industry, offering innovative dosing technologies that enhance operational precision and compliance with regulatory requirements.

The Importance of Pharmaceutical Dosing Pumps Singapore in Drug Manufacturing

The pharmaceutical industry relies heavily on Pharmaceutical dosing pumps Singapore for precise liquid measurement. These pumps are responsible for accurately transferring active pharmaceutical ingredients (APIs), solvents, excipients, and other critical substances during the manufacturing process. Whether for oral liquid formulations, injectable solutions, or topical products, Pharmaceutical dosing pumps Singapore ensure that each batch meets the stringent requirements for consistency and dosage.

Flomek’s Pharmaceutical dosing pumps Singapore are engineered to handle a wide range of liquids, from low viscosity solutions to thick, viscous suspensions. Our pumps ensure that your formulations are made with the utmost precision, enhancing both product quality and patient safety.

Applications of Pharmaceutical Dosing Pumps Singapore

Pharmaceutical dosing pumps Singapore are versatile and used in various applications within the pharmaceutical sector. Some of the key uses include:

- API and Solvent Dosing: In the production of pharmaceutical products, accurate dosing of active pharmaceutical ingredients (APIs) is crucial. Pharmaceutical dosing pumps Singapore allow for precise control over the volume of APIs added to the formulation, ensuring the correct concentration in every batch.

- Liquid Formulation: Whether for syrups, suspensions, or injectables, liquid formulations require accurate and consistent dosing. Pharmaceutical dosing pumps Singapore are designed to handle precise amounts of liquids, ensuring that each formulation meets stringent quality control standards.

- Mixing and Blending: In pharmaceutical production, dosing pumps are often used for accurate blending of multiple ingredients. Pharmaceutical dosing pumps Singapore ensure that all components are added in the correct proportions, facilitating the uniformity of the final product.

- Chemical Injection: Some pharmaceutical processes require the injection of certain chemicals into production lines. Pharmaceutical dosing pumps Singapore are utilized for precise and controlled injection, preventing over-dosing and ensuring the safety and integrity of the final product.

- Sterile Processing: Maintaining sterility in pharmaceutical manufacturing is vital. Pharmaceutical dosing pumps Singapore are often employed in sterile environments to dose liquid substances without compromising cleanliness or sterility.

Features and Benefits of Pharmaceutical Dosing Pumps Singapore

When choosing Pharmaceutical dosing pumps Singapore, several features are crucial in ensuring optimal performance in pharmaceutical processes:

- Precision and Accuracy: The most important factor in pharmaceutical dosing is accuracy. Pharmaceutical dosing pumps Singapore are designed to deliver precise quantities of liquids, with tolerances as low as fractions of a milliliter, ensuring accurate formulations.

- Corrosion Resistance: Given the highly sensitive nature of pharmaceutical formulations, Pharmaceutical dosing pumps Singapore must be made from corrosion-resistant materials to avoid contamination. Our pumps use high-quality, durable materials that ensure reliability even with aggressive chemicals.

- Ease of Maintenance: Pharmaceutical dosing systems need to be easy to maintain and clean to ensure compliance with GMP (Good Manufacturing Practice) standards. Pharmaceutical dosing pumps Singapore are designed with user-friendly features that make maintenance and cleaning quick and efficient.

- Flow Control: Our Pharmaceutical dosing pumps Singapore provide excellent flow control, allowing operators to fine-tune the flow rates for different production needs. This control is critical when dealing with liquids that require precise dosing in small quantities.

- Compliance with Regulations: The pharmaceutical industry is highly regulated, and Pharmaceutical dosing pumps Singapore must meet strict industry standards, including those set by the FDA and EMA. Flomek’s pumps are designed to comply with these regulations, ensuring safe and reliable operation.

Challenges in Pharmaceutical Dosing Pumps Singapore

While Pharmaceutical dosing pumps Singapore offer significant benefits, there are challenges that businesses in the pharmaceutical industry need to address. Some of the common issues include:

- Contamination Risk: Contaminants in the production environment can lead to compromised products. Choosing the right Pharmaceutical dosing pumps Singapore is crucial to maintaining clean processes and preventing contamination.

- Viscosity Handling: Some pharmaceutical formulations, such as ointments and creams, require pumps that can handle highly viscous materials. Pharmaceutical dosing pumps must be equipped with the right features to accommodate these thicker liquids without compromising performance.

- Energy Efficiency: With rising operational costs, energy efficiency has become a key consideration. Pharmaceutical dosing pumps are designed to operate efficiently, minimizing energy consumption while maintaining precise dosing.

- Calibration and Testing: Regular calibration and testing of Pharmaceutical dosing pumps are necessary to ensure ongoing accuracy. Our systems are equipped with tools that allow for easy calibration and maintenance, ensuring consistent performance.

Choosing the Right Pharmaceutical Dosing Pumps Singapore for Your Business

Selecting the right Pharmaceutical dosing pumps Singapore for your business requires an understanding of your specific requirements. Factors to consider include:

- Type of Liquid: Whether you are dealing with low viscosity liquids or thicker formulations, choosing the appropriate pump type (e.g., diaphragm, piston, peristaltic) is essential.

- Required Flow Rates: The required flow rate depends on your production needs. Flomek offers Pharmaceutical dosing pumps that can handle a wide range of flow rates, ensuring that you meet the demands of your operations.

- Integration with Existing Systems: Your dosing pumps must integrate seamlessly with other equipment in your production line. Flomek’s Pharmaceutical dosing pumps are designed for easy integration, minimizing disruptions to your operations.

- Regulatory Compliance: Compliance with regulations such as GMP is non-negotiable in the pharmaceutical industry. Flomek ensures that our Pharmaceutical dosing pumps meet all relevant standards for safety and quality.

Understanding Pharmaceutical Dosing Pumps Singapore

In the pharmaceutical industry, precision is everything. Pharmaceutical dosing pumps play an integral role in ensuring that active ingredients and other liquids are dispensed accurately during the production of medications. These pumps help pharmaceutical manufacturers maintain the required standards for dosage accuracy and consistency, which are critical to the safety and efficacy of the final product.

At Flomek, we understand the importance of reliability and precision in pharmaceutical manufacturing. Our Pharmaceutical dosing pumps are designed with cutting-edge technology to meet the highest industry standards and ensure maximum operational efficiency.

Why Pharmaceutical Dosing Pumps Singapore Are Essential for Quality Production

Pharmaceutical dosing pumps are vital for maintaining quality control during the production process. Accurate dosing of both active pharmaceutical ingredients (APIs) and excipients is essential for the effectiveness of the drug. Whether creating syrups, suspensions, injectables, or other liquid-based formulations, the precise measurement of ingredients directly impacts the quality and consistency of the final product.

For pharmaceutical companies in Singapore, Pharmaceutical dosing pumps offer the ability to streamline production while reducing the risk of errors, ensuring that each batch meets regulatory standards and delivers the intended therapeutic effect.

How Pharmaceutical Dosing Pumps Singapore Contribute to Compliance and Safety

Compliance with industry regulations is paramount in the pharmaceutical sector. The Health Sciences Authority (HSA) and other global regulatory bodies enforce strict standards for pharmaceutical manufacturing, including the precise dosing of ingredients. Pharmaceutical dosing pumps are built to adhere to these stringent requirements, providing manufacturers with the tools they need to maintain compliance and meet Good Manufacturing Practices (GMP).

The use of Pharmaceutical dosing pumps helps pharmaceutical companies stay compliant by ensuring accurate and repeatable dosing of liquid formulations. These pumps are also designed with safety in mind, reducing the risk of contamination and ensuring that products are produced in a clean and controlled environment.

Key Features of Pharmaceutical Dosing Pumps Singapore

When selecting Pharmaceutical dosing pumps Singapore, it is essential to consider the features that will best suit your manufacturing needs. Some of the most important features include:

- Precision: Pharmaceutical dosing pumps offer incredibly accurate liquid dosing, ensuring that every batch contains the correct amount of active ingredients. This level of precision is essential for maintaining the quality of pharmaceutical products.

- Corrosion Resistance: Given the nature of many pharmaceutical liquids, such as solvents and APIs, Pharmaceutical dosing pumps are built with corrosion-resistant materials to ensure they can handle harsh chemicals without degrading.

- Flexibility: Different formulations require different dosing capacities. Pharmaceutical dosing pumps can be configured to handle a wide range of liquid types, including low- and high-viscosity fluids, making them versatile enough for various applications.

- Easy Integration: Pharmaceutical dosing pumps can be easily integrated into existing manufacturing systems. This ensures a smooth transition and enables pharmaceutical companies to optimize their production lines without the need for significant adjustments.

Types of Pharmaceutical Dosing Pumps Singapore

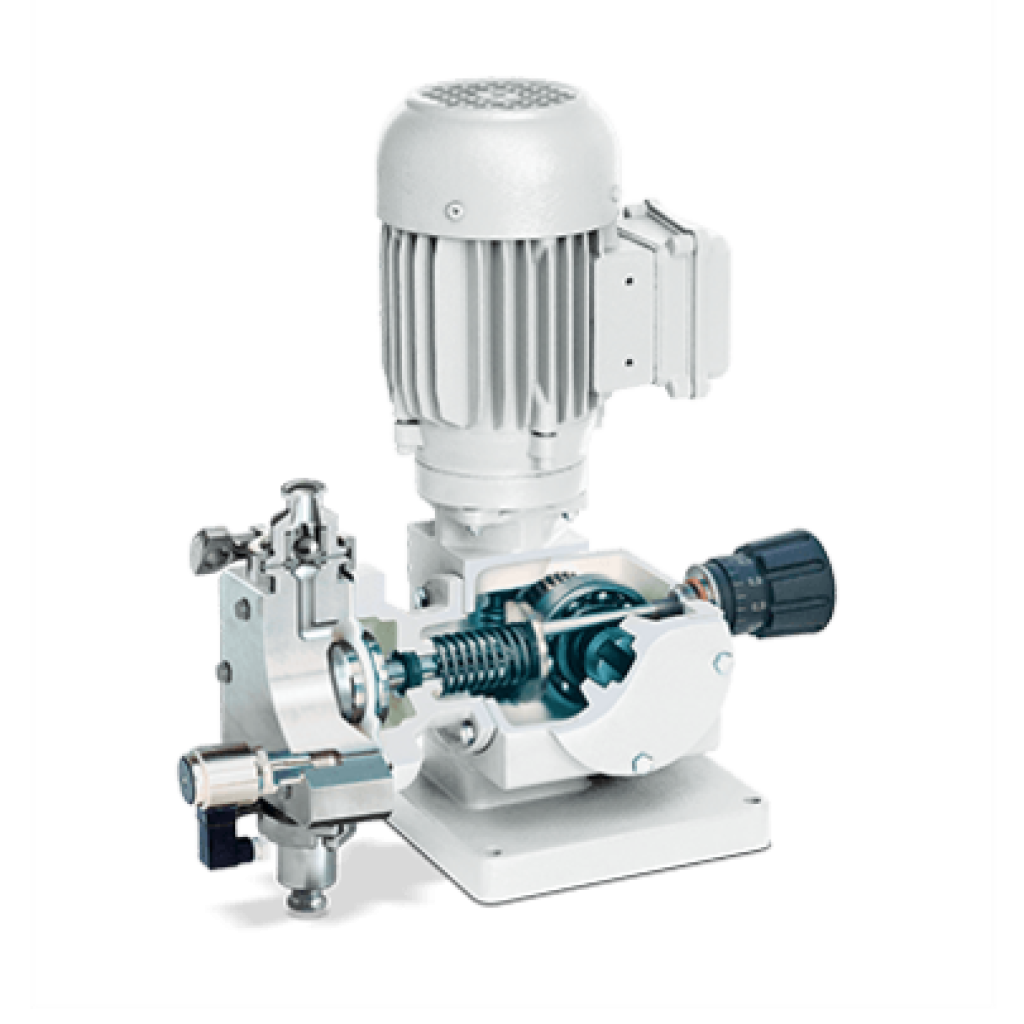

There are several different types of Pharmaceutical dosing pumps , each suited for specific applications within the pharmaceutical manufacturing process:

- Peristaltic Pumps: These pumps are ideal for applications where accurate dosing and gentle handling of fluids are required. Pharmaceutical dosing pumps with peristaltic technology are commonly used for low-volume dosing of sensitive formulations.

- Diaphragm Pumps: For applications that require the handling of aggressive chemicals or solvents, Pharmaceutical dosing pumps featuring diaphragm technology offer the necessary precision and durability.

- Piston Pumps: Pharmaceutical dosing pumps that use piston technology are well-suited for high-precision, high-volume applications. These pumps offer excellent accuracy and are commonly used in the production of injectable medications and high-concentration formulations.

- Gear Pumps: Pharmaceutical dosing pumps Singapore using gear technology provide high pressure and are used in applications that require consistent flow rates, making them suitable for more demanding dosing tasks.

The Role of Pharmaceutical Dosing Pumps Singapore in Drug Development

The role of Pharmaceutical dosing pumps extends beyond manufacturing; they are also vital in drug development processes. During the research and development phase, accurate dosing of active ingredients and excipients is crucial for formulating the right composition.

As new drugs are developed, Pharmaceutical dosing pumps help researchers and scientists measure small quantities of compounds with precision. This enables the formulation of consistent batches for clinical trials, which is essential for determining the safety and efficacy of new medications.

How to Choose the Best Pharmaceutical Dosing Pumps for Your Needs

Selecting the right Pharmaceutical dosing pumps Singapore requires a careful evaluation of several factors to ensure that the pump meets the specific needs of your manufacturing processes:

- Dosing Requirements: Consider the viscosity and type of fluid being dosed. Pharmaceutical dosing pumps vary in their ability to handle different liquids, so choose one that is compatible with your specific formulation.

- Flow Rate Control: The ability to control the flow rate of the pump is essential for achieving precise dosing. Pharmaceutical dosing pumps that offer adjustable flow rates give manufacturers the flexibility they need to optimize production processes.

- Size and Scale: The size and scale of your manufacturing operation will dictate the capacity and number of pumps needed. Whether you need small-volume, high-precision pumps for R&D or large-scale pumps for mass production, Pharmaceutical dosing pumps can be tailored to fit your production needs.

- Maintenance and Support: Choose Pharmaceutical dosing pumps that are easy to maintain and come with robust customer support. Flomek provides pumps that are not only reliable but also backed by ongoing maintenance and troubleshooting services.

Advantages of Pharmaceutical Dosing Pumps Singapore

The advantages of using Pharmaceutical dosing pumps are numerous and impactful for pharmaceutical manufacturers. These pumps help ensure:

Improved Product Quality: By ensuring each formulation is dosed accurately, Pharmaceutical dosing pumps help maintain the consistency and quality of the final product, which is essential for meeting regulatory standards and consumer expectations.Pharmaceutical Dosing Pumps Singapore

High Efficiency: With precise control over liquid dosing, Pharmaceutical dosing pumps Singapore reduce the time and effort spent on manual dosing, allowing for faster production cycles and increased output.

Reduced Human Error: Automated dosing with eliminates the potential for human error, ensuring that each batch is produced with consistent quality and quantity.

Cost Savings: Accurate dosing reduces material waste and lowers production costs. By investing in manufacturers can reduce the amount of active ingredients and solvents wasted during the production process.

The pharmaceutical industry in Singapore is known for its high standards in product quality, efficiency, and safety. In this rapidly growing sector, precision is key, especially when it comes to liquid dosing. are designed to provide the utmost accuracy in the delivery of liquids, whether it’s for active pharmaceutical ingredients (APIs), solvents, or excipients. These pumps are indispensable in ensuring consistency and meeting the rigorous requirements of the pharmaceutical industry.

At Flomek, we specialize in providing state-of-the-art that help pharmaceutical manufacturers ensure their products are formulated correctly every time. Our dosing pumps are designed for precision, reliability, and efficiency, which makes them the preferred choice for companies across Singapore.

Why Pharmaceutical Dosing Pumps Singapore are Crucial

Pharmaceutical dosing pumps Singapore are integral to the manufacturing process of pharmaceutical products. Their primary function is to accurately dose specific amounts of liquids during the production of various medications. Whether for injectable solutions, syrups, or other liquid formulations, Pharmaceutical dosing pumps Singapore ensure that each batch meets stringent safety and quality standards.

These pumps are often used for dosing APIs, which require extreme precision to ensure that the dosage aligns with regulatory standards. By using Pharmaceutical dosing pumps Singapore, manufacturers can minimize errors, reduce waste, and maintain product consistency.

How Pharmaceutical Dosing Pumps Singapore Support Regulatory Compliance

The pharmaceutical industry in Singapore adheres to strict regulatory guidelines set by the Health Sciences Authority (HSA) and other global standards. Pharmaceutical dosing pumps Singapore play a significant role in maintaining compliance with these regulations. Accuracy in dosing is essential for meeting GMP (Good Manufacturing Practice) guidelines and ensuring the safety of the end-user.

Flomek’s Pharmaceutical dosing pumps Singapore are engineered to meet the highest industry standards, which not only helps pharmaceutical companies stay compliant but also ensures the safety and efficacy of their products. Our dosing pumps are built to withstand the strictest quality control measures, making them a reliable choice for manufacturers in Singapore.

Different Types of Pharmaceutical Dosing Pumps Singapore

There are several types of Pharmaceutical dosing pumps Singapore, each designed to meet specific needs within the pharmaceutical industry. Some of the most commonly used types include:

- Peristaltic Dosing Pumps: These are ideal for handling high-viscosity liquids or liquids with suspended solids. Pharmaceutical dosing pumps Singapore of this type ensure precise dosing while preventing contamination.

- Diaphragm Dosing Pumps: Known for their ability to handle aggressive chemicals, Pharmaceutical dosing pumps Singapore with diaphragm technology are perfect for precise dosing of hazardous substances.

- Piston Dosing Pumps: These pumps offer accurate dosing in smaller amounts and are often used for metering precise quantities of active ingredients in liquid formulations.

- Gear Dosing Pumps: Used for high-pressure applications, Pharmaceutical dosing pumps Singapore with gear technology offer highly accurate and efficient dosing, particularly for low to medium viscosity liquids.

Each of these pumps is carefully designed to offer the best performance depending on the pharmaceutical application, making Pharmaceutical dosing pumps Singapore an indispensable part of the manufacturing process.

Benefits of Pharmaceutical Dosing Pumps Singapore

When choosing Pharmaceutical dosing pumps Singapore, manufacturers can expect several benefits that help improve the efficiency and accuracy of their production processes. Some key advantages include:

- Precision: Pharmaceutical dosing pumps Singapore are engineered for exact dosing, ensuring that the correct amount of liquid is dispensed every time. This level of precision is essential in pharmaceutical production, where even a slight deviation can result in regulatory issues.

- Reliability: Flomek’s Pharmaceutical dosing pumps Singapore are built to last, offering long-term durability and minimal maintenance. With reliable pumps, pharmaceutical manufacturers can reduce downtime and improve productivity.

- Flexibility: Whether you are working with liquids of varying viscosities or dealing with hazardous substances, Pharmaceutical dosing pumps Singapore offer flexibility in meeting diverse pharmaceutical production needs.

- Cost-Effectiveness: By reducing waste and improving operational efficiency, Pharmaceutical dosing pumps Singapore contribute to lower overall production costs. Manufacturers can improve their bottom line while maintaining the highest standards of product quality.

Applications of Pharmaceutical Dosing Pumps Singapore

Pharmaceutical dosing pumps Singapore are used across various stages of pharmaceutical production. Some common applications include:

- Active Pharmaceutical Ingredient (API) Dosing: One of the most critical uses of Pharmaceutical dosing pumps Singapore is for the precise delivery of APIs into formulations. Accurate dosing ensures that each batch contains the correct amount of active ingredients, which is essential for the effectiveness of the medication.

- Solvent and Excipients Dosing: Pharmaceutical dosing pumps Singapore are also used for dosing solvents and excipients, which are essential components in the manufacturing of medications. The accuracy in delivering these substances ensures that the final product has the desired consistency and quality.

- Sterile Liquids Dosing: For injectable medications, the accuracy of dosing is even more crucial. Pharmaceutical dosing pumps Singapore are used in the sterile manufacturing of injectable solutions, ensuring that contaminants are kept at bay and that each dosage is precise.

Choosing the Right Pharmaceutical Dosing Pumps Singapore for Your Needs

Selecting the right Pharmaceutical dosing pumps Singapore is critical for achieving the desired results in your pharmaceutical production. Here are some key factors to consider:

- Flow Rate: Different pharmaceutical processes require different flow rates. Whether you need a high-flow or low-flow solution, choosing the right flow capacity is vital when selecting Pharmaceutical dosing pumps Singapore.

- Chemical Compatibility: The liquids used in pharmaceutical manufacturing vary in terms of chemical composition and viscosity. Pharmaceutical dosing pumps Singapore should be compatible with the specific substances being used to avoid any degradation of materials.

- Accuracy: Accuracy is the most critical factor in dosing. Pharmaceutical dosing pumps Singapore are engineered to deliver precise quantities of liquids, ensuring that you meet all required specifications and regulatory guidelines.

- Maintenance and Cleaning: It’s essential to choose Pharmaceutical dosing pumps Singapore that are easy to maintain and clean, especially in industries with strict hygiene standards. Flomek’s pumps are designed with maintenance in mind, making them ideal for GMP-compliant facilities.

Innovations in Pharmaceutical Dosing Pumps Singapore

The pharmaceutical industry is continuously evolving, and so are the technologies behind Pharmaceutical dosing pumps Singapore. At Flomek, we are committed to staying ahead of the curve by offering the latest innovations in pump technology, including:

- Smart Pump Technology: Many of our Pharmaceutical dosing pumps Singapore are equipped with sensors and real-time monitoring capabilities, enabling operators to track pump performance and ensure the highest level of accuracy at all times.

- Energy Efficiency: As energy costs rise, more pharmaceutical companies are turning to energy-efficient Pharmaceutical dosing pumps Singapore. Our pumps are designed to minimize energy consumption while maintaining peak performance.

- Automated Calibration: Modern Pharmaceutical dosing pumps Singapore feature automated calibration systems that ensure the dosing system remains precise and compliant with regulatory standards, reducing the need for manual intervention.

Flomek’s Pharmaceutical Dosing Pumps Singapore: Why Choose Us?

Flomek is a trusted provider of Pharmaceutical dosing pumps Singapore, known for our dedication to quality, precision, and customer satisfaction. Some reasons to choose Flomek include:

- Expertise: With years of experience in the pharmaceutical sector, Flomek understands the unique requirements of Pharmaceutical dosing pumps Singapore. We offer customized solutions to meet your operational needs.

- Quality Assurance: All of our Pharmaceutical dosing pumps Singapore are rigorously tested to ensure they meet the highest standards of performance and safety.

- Customer Support: At Flomek, we provide ongoing support for all of our Pharmaceutical dosing pumps Singapore, ensuring that you have the assistance you need throughout the lifespan of the equipment.

- Innovative Solutions: We continue to innovate and improve our Pharmaceutical dosing pumps Singapore, incorporating the latest technology to enhance accuracy, reliability, and energy efficiency.

Conclusion: Partner with Flomek for Your Pharmaceutical Dosing Pumps Singapore Needs

When it comes to Pharmaceutical dosing pumps Singapore, Flomek is the trusted name in the industry. We provide top-quality, reliable, and efficient dosing systems that ensure precise formulation, enhance operational performance, and comply with all relevant regulations. Partner with Flomek today to ensure the success of your pharmaceutical manufacturing operations with our state-of-the-art Pharmaceutical dosing pumps Singapore.

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply