Made in Singapore chemical dosing skid – Best 2025

Made in Singapore Chemical Dosing Skid – Precision Engineering & Local Innovation

Introduction to Made in Singapore Chemical Dosing Skid

The term Made in Singapore chemical dosing skid stands as a symbol of high-quality engineering, consistent performance, and reliability in fluid handling systems. As the global demand for precise chemical dosing in water treatment, petrochemical, food processing, and industrial sectors grows, there is increasing recognition of locally engineered systems. Singapore, with its strong engineering foundation and industrial excellence, delivers chemical dosing skids that meet international standards, yet cater to region-specific requirements.

A Made in Singapore chemical dosing skid is not just a machine—it is an integrated solution meticulously designed, fabricated, and tested in Singapore. This makes it ideal for industries that demand accuracy, safety, and durability in chemical handling.

What is a Chemical Dosing Skid?

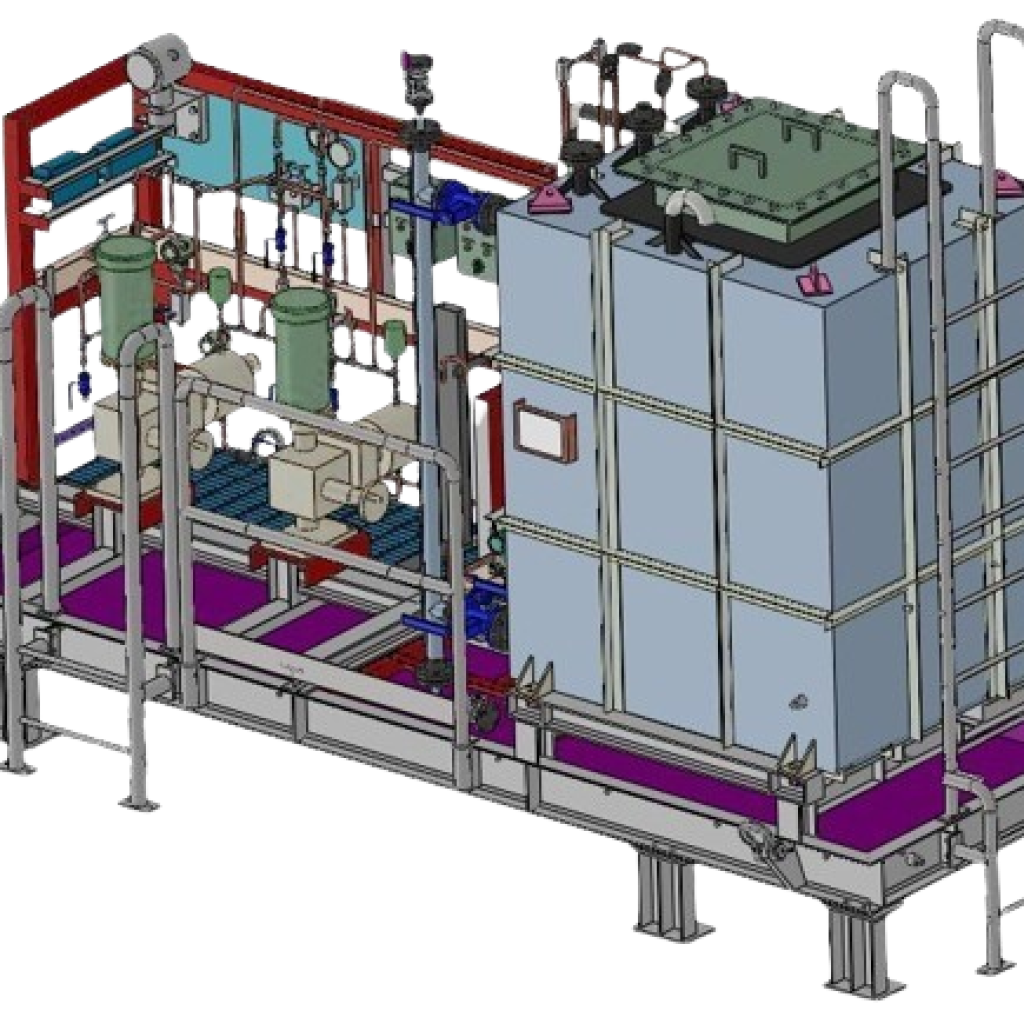

A chemical dosing skid is a modular system that automates the controlled injection of chemicals into a process stream. It consists of:

- Dosing Pumps

- Storage Tanks

- Mixing Units

- Control Panels

- Flow Meters and Sensors

- Pipes and Valves

A Made in Singapore chemical dosing skid includes all of these components in a compact frame, pre-assembled, tested, and optimized for plug-and-play operation.

Why Choose a Made in Singapore Chemical Dosing Skid?

- Superior Engineering Standards

Singapore has earned a reputation for engineering excellence. A Made in Singapore chemical dosing skid is built with precision and designed to last in the harshest industrial environments. - Custom-Tailored for Local & Regional Needs

Climate, water chemistry, and industry-specific requirements vary. A Made in Singapore chemical dosing skid is customized with materials and features that address these needs directly. - Compliance with Global Certifications

Locally manufactured systems comply with ISO standards, CE markings, and safety norms, making the Made in Singapore chemical dosing skid suitable for both domestic and international applications. - Faster Lead Times and Support

Local manufacturing ensures quicker delivery and reduced downtime. With a Made in Singapore chemical dosing skid, industries enjoy streamlined commissioning and support processes. - Cost Efficiency

The logistics and import duties for international systems often increase costs. A Made in Singapore chemical dosing skid avoids such overheads, delivering better value.

Key Features of Made in Singapore Chemical Dosing Skid

1. Modular Design

Every Made in Singapore chemical dosing skid is designed for easy integration into new or existing systems. Modular layouts allow for quick setup, maintenance, and scaling.

2. High-Accuracy Metering Pumps

The core of a Made in Singapore chemical dosing skid is its metering pump. Local systems use high-precision diaphragm or plunger pumps to maintain consistent dosing with ±1% accuracy.

3. Corrosion-Resistant Materials

From SS316 to PVC, PP, and PTFE-lined systems, a Made in Singapore chemical dosing skid utilizes materials that resist chemical attacks and environmental degradation.

4. Advanced Control Systems

Smart PLCs and HMI-based panels are integrated to provide real-time monitoring, alarms, and data logging in every Made in Singapore chemical dosing skid.

5. Pre-Tested & Validated Systems

Each Made in Singapore chemical dosing skid undergoes factory acceptance testing (FAT) before dispatch, ensuring zero-error operation upon installation.

Applications of Made in Singapore Chemical Dosing Skid

1. Water & Wastewater Treatment

In treatment plants, a Made in Singapore chemical dosing skid is used for pH adjustment, coagulation, chlorination, anti-scalant dosing, and flocculation.

2. Power Generation

For boiler feed water treatment and cooling tower conditioning, industries rely on the consistency of a Made in Singapore chemical dosing skid.

3. Food and Beverage

Hygiene and safety in F&B industries demand sanitized dosing. A Made in Singapore chemical dosing skid delivers hygienic, food-grade chemical injection.

4. Petrochemical and Oil & Gas

High-pressure, high-temperature environments in O&G require rugged systems. A Made in Singapore chemical dosing skid provides explosion-proof, ATEX-compliant skids.

5. Marine & Offshore

Saltwater corrosion resistance and space optimization make a Made in Singapore chemical dosing skid ideal for shipboard chemical dosing applications.

Technical Advantages of Made in Singapore Chemical Dosing Skid

| Feature | Advantage |

|---|---|

| Precision Dosing | Flow control accuracy up to ±1% |

| Space Optimization | Compact and skid-mounted |

| Maintenance-Friendly | Easy access layout for service |

| Local Fabrication | Shorter lead times |

| Smart Controls | Remote monitoring and SCADA-ready |

| Safety Compliance | Built-in alarms, leak sensors, interlocks |

Types of Made in Singapore Chemical Dosing Skid

1. Single Chemical Dosing Skid

Ideal for simple processes. Compact, affordable, and easy to install.

2. Multi-Chemical Dosing Skid

For complex industrial setups requiring multiple chemicals injected at various rates.

3. Batch Dosing Skid

Delivers measured quantities per batch cycle with excellent repeatability.

4. Continuous Dosing Skid

For processes needing uninterrupted, automated dosing over long durations.

5. Customized Dosing Skid

Fully bespoke Made in Singapore chemical dosing skid, tailored to your P&ID and process needs.

Components in a Made in Singapore Chemical Dosing Skid

- Chemical Tanks: HDPE, SS304/316, or FRP-based tanks

- Dosing Pumps: Mechanical or hydraulic diaphragm

- Flow Sensors & Pressure Gauges

- Calibration Columns

- Static Mixers

- Control Panels with PLC Integration

- Non-return Valves & Pressure Relief Valves

Manufacturing Process of Made in Singapore Chemical Dosing Skid

- Client Requirement Gathering

- P&ID and GA Drawing Preparation

- Component Selection

- Fabrication of Frame and Tank

- Pump & Instrument Integration

- Wiring & Panel Assembly

- Testing & Validation (FAT)

- Packing & Dispatch

This meticulous process ensures every Made in Singapore chemical dosing skid meets project specifications and compliance standards.

Quality Assurance in Made in Singapore Chemical Dosing Skid

Every Made in Singapore chemical dosing skid follows a rigorous QA/QC process:

- Visual Inspection

- Hydrostatic Pressure Testing

- Electrical Loop Checks

- Pump Flow Calibration

- Chemical Compatibility Tests

- Leak Tests

- Safety Interlock Testing

Sustainability and Green Engineering

Singapore’s industrial framework emphasizes green innovation. A Made in Singapore chemical dosing skid often includes:

- Energy-efficient pumps

- Low-footprint designs

- Recyclable components

- Waste minimization through precise dosing

Digital Integration & IIoT Readiness

A modern Made in Singapore chemical dosing skid supports:

- Remote Monitoring

- SCADA & DCS Integration

- Cloud Data Storage

- Predictive Maintenance Features

These digital features ensure predictive control and intelligent dosing.

Industries Benefiting from Made in Singapore Chemical Dosing Skid

| Industry | Usage |

|---|---|

| Water Treatment | Chlorine, anti-scalants |

| Oil & Gas | Biocides, corrosion inhibitors |

| Food Industry | Sanitizers, pH control agents |

| Pharmaceuticals | Cleaning agents, buffers |

| Semiconductors | High-purity chemical delivery |

Each sector gains from the robust design and efficiency of a Made in Singapore chemical dosing skid.

Installation & Commissioning

A Made in Singapore chemical dosing skid is delivered pre-tested and ready for installation. On-site support is minimized due to pre-engineered, plug-and-play design. Commissioning involves simple connection of utility lines and electricals, with start-up verification handled in a short time.

Maintenance Tips for Made in Singapore Chemical Dosing Skid

- Schedule quarterly inspection of pump diaphragms

- Check calibration column readings monthly

- Test leak sensors and interlocks

- Ensure chemical compatibility with seals

- Maintain a maintenance log for audit compliance

By following these steps, the life and performance of your Made in Singapore chemical dosing skid can be significantly extended.

Engineering Excellence Behind Every Made in Singapore Chemical Dosing Skid

When it comes to fluid handling and chemical injection, the phrase Made in Singapore chemical dosing skid conveys more than just origin. It represents a powerful combination of precision engineering, process reliability, and local manufacturing innovation. Singapore’s robust industrial base has enabled the development of dosing systems that meet the stringent operational demands of both local and global industries.

From the early design phase to final system integration, every Made in Singapore chemical dosing skid is engineered with a deep understanding of process automation, safety requirements, and efficiency needs.

Design Principles That Define a Made in Singapore Chemical Dosing Skid

Each Made in Singapore chemical dosing skid is engineered based on four core principles:

- Process Accuracy

The dosing process must match the exact flow rate, pressure, and chemical concentration demanded by the end-user process. Every Made in Singapore chemical dosing skid is calibrated to maintain consistent dosing across operating conditions. - Safety and Reliability

Chemical dosing often involves hazardous and corrosive substances. Therefore, each Made in Singapore chemical dosing skid includes leak detectors, overflow protection, and emergency shutoffs to ensure safety. - Modularity

Local manufacturers prioritize modular engineering to simplify future expansion or servicing. The modularity of a Made in Singapore chemical dosing skid allows flexible scaling and easy replacement of components. - Digital Readiness

With Singapore’s push towards smart factories and Industry 4.0, every Made in Singapore chemical dosing skid is engineered to support digital controls, IIoT connectivity, and real-time analytics.

Smart Control Integration in Made in Singapore Chemical Dosing Skid

Today’s dosing systems are not just mechanical; they are intelligent control units that interact with SCADA, PLCs, and enterprise resource planning (ERP) systems.

Advanced digital integration in a Made in Singapore chemical dosing skid includes:

- Programmable Logic Controllers (PLC) for autonomous operation

- Human-Machine Interface (HMI) touchscreens for operator control

- Remote access capabilities via VPN or web interface

- Alarm systems for leak, underdose/overdose, or pump failure

- Auto-adjustment based on sensor feedback (closed-loop control)

This smart capability enhances operational efficiency and ensures that a Made in Singapore chemical dosing skid becomes part of a connected plant ecosystem.

Case Studies: Real-World Use of Made in Singapore Chemical Dosing Skid

While we avoid brand and client names as per your request, typical industries benefiting from a Made in Singapore chemical dosing skid include:

- Semiconductor Plants: Utilizing ultra-pure chemical dosing systems in confined cleanroom environments

- Municipal Water Boards: Implementing flocculant and pH dosing skids for regional water supply treatment

- Offshore Drilling Operators: Relying on explosion-proof, stainless-steel skids to dose methanol or corrosion inhibitors in marine environments

- Beverage Manufacturers: Automating dosing of sanitizing chemicals during CIP (Clean-In-Place) operations

These real-world applications highlight the robustness and flexibility of every Made in Singapore chemical dosing skid.

Quality Control & Certifications in Made in Singapore Chemical Dosing Skid

Each Made in Singapore chemical dosing skid follows stringent QA/QC protocols, often exceeding international benchmarks.

Typical certifications and testing protocols include:

- ISO 9001: Quality Management Systems

- ASME & ASTM Standards for Piping and Pressure Parts

- IEC or ATEX Standards for Electrical Safety

- Factory Acceptance Test (FAT)

- Performance Test Reports

- Welding Certifications for Stainless Steel Fabrications

This attention to quality guarantees that every Made in Singapore chemical dosing skid delivers operational uptime and safety across industries.

Material Selection in Made in Singapore Chemical Dosing Skid

The material choice in a Made in Singapore chemical dosing skid is critical based on chemical type and operating environment:

| Chemical Type | Recommended Material in Dosing Skid |

|---|---|

| Acids (HCl, H₂SO₄) | PTFE-lined piping, PP tanks |

| Alkaline solutions | HDPE tanks, EPDM gaskets |

| Chlorine | CPVC components |

| Solvents | Stainless Steel SS316 |

| Food-grade liquids | FDA-approved plastics, SS316L |

This materials versatility makes a Made in Singapore chemical dosing skid suitable for nearly any chemical dosing requirement.

Lifecycle Cost Savings with Made in Singapore Chemical Dosing Skid

Although initial investment is important, Total Cost of Ownership (TCO) over 5–10 years defines the true value of any system. A Made in Singapore chemical dosing skid delivers significant lifecycle savings due to:

- Minimal downtime due to superior QA

- Reduced import and logistics cost

- Availability of spare parts locally

- Faster technical support

- Energy-efficient pumps and motors

- Low chemical wastage through accurate metering

All of these reduce OPEX, making a Made in Singapore chemical dosing skid a smart, future-proof investment.

Custom Engineering Capabilities

Many industries have unique needs that off-the-shelf systems cannot meet. Singapore-based manufacturers of chemical dosing skids offer extensive customization options:

- Pump Sizing Calculations

- Skid Footprint Adjustments

- Remote Installation Kits

- High-pressure dosing designs

- Explosion-proof skids for hazardous zones

- Integration with existing control infrastructure

This makes every Made in Singapore chemical dosing skid capable of adapting to complex engineering projects.

Environmental Responsibility in Design

Sustainability is a core principle in Singapore’s industrial strategy. Every Made in chemical dosing skid is designed with eco-friendly practices:

- Energy-efficient dosing pumps (low kWh/volume)

- Chemical spill containment trays

- Low-footprint, recyclable skid frames

- Leak-proof pipework and seals

- Eco-mode dosing logic in PLC to reduce overuse

This makes the Made in chemical dosing skid compliant with green building standards and ISO 14001.

Installation Versatility of Made in Singapore Chemical Dosing Skid

Whether installed in a factory, containerized plant, marine vessel, or treatment plant, a Made in chemical dosing skid is designed to accommodate:

- Indoor & Outdoor Installations

- Wall-mounted, floor-mounted or suspended

- Seismic-rated for earthquake zones

- Tropicalized components for high humidity

- Container integration for portable solutions

These options allow a Made in chemical dosing skid to be deployed in the most challenging environments.

Advantages Recap – Why Invest in a Made in Singapore Chemical Dosing Skid

| Benefit | Description |

|---|---|

| Local Engineering | Fast customization, spare availability |

| Proven Reliability | Tested under tropical and industrial stress |

| Reduced Downtime | Fast commissioning and maintenance |

| Compliance Ready | International quality and safety certifications |

| Sustainable | Eco-friendly and energy-saving operation |

| Plug-and-Play | Simple integration with existing systems |

| Intelligent | Smart control features and IIoT ready |

Made in Singapore Chemical Dosing Skid in the Era of Industry 4.0

The future of process dosing is connected, automated, and intelligent. With Singapore leading the ASEAN Smart Industry transformation, the Made in chemical dosing skid is at the forefront of this revolution.

These systems come with features such as:

- Predictive Maintenance Alerts

- Dosing Pattern Optimization using AI

- Mobile App-based Monitoring

- Cloud Storage of Operation Logs

- Digital Twin for Simulation & Diagnostics

The Made in chemical dosing skid is no longer just hardware—it’s a smart ecosystem component.

Comparative Advantage: Made in Chemical Dosing Skid vs. Imported Systems

When comparing a Made in chemical dosing skid to imported equivalents, it becomes clear why more industries are choosing local engineering. Here’s a breakdown of critical differentiators:

| Criteria | Made in Singapore | Imported Systems |

|---|---|---|

| Lead Time | 4–6 weeks | 10–16 weeks |

| Technical Support | Local, on-call, on-site | Remote, time-zone delays |

| Customization | Fully tailored to site and process | Limited customization |

| Spare Parts Availability | Immediate | Delayed, costly imports |

| Adaptability | Built for regional conditions | Designed for foreign environments |

| Warranty & Service | Direct and extended | Through third parties |

| Regulatory Compliance | Built per local codes | May need adaptation |

With a Made in chemical dosing skid, businesses enjoy smoother procurement, faster deployment, and a stronger partnership with local engineering teams.

Innovations in Made in Singapore Chemical Dosing Skid Design

The Singapore manufacturing ecosystem thrives on process innovation and design upgrades. The latest generation of Made in Singapore dosing skid units offer several innovations:

1. Dual-Pump Redundancy Systems

Some industries can’t afford downtime. Redundant dosing skids provide one primary and one backup pump in the same frame—automatically switching over in case of failure. This is a standard innovation in many Made in Singapore dosing skid designs.

2. Zero-Leak Mechanical Seals

Upgraded pump technology ensures leak-free performance, critical for hazardous chemical dosing applications.

3. Chemical Mixing and Dilution Modules

In some cases, the chemical needs to be diluted before dosing. A Made in chemical dosing skid can include inline dilution and mixing chambers to reduce chemical concentrations on the fly.

4. Integrated Flow Monitoring

Using electromagnetic or ultrasonic flow meters, every Made in chemical dosing skid can now deliver live dosing reports, totalized flow data, and real-time feedback to central systems.

5. Mobile Skid Units

Some clients prefer movable, containerized skids for multiple sites. Singapore-based manufacturers now offer mobile Made in chemical dosing skid solutions that are plug-and-play for remote locations.

Long-Term Reliability of Made in Chemical Dosing Skid

One of the top priorities for plant managers is downtime prevention. This is where a Made in chemical dosing skid excels. Here’s why:

- Precision machining and component quality reduce wear and tear

- Singapore’s strong QA culture ensures product consistency

- Real-time monitoring prevents catastrophic failure

- Redundant alarms help operators act early

- Stainless steel and chemical-resistant materials last 10+ years

Investing in a Made in chemical dosing skid is a long-term decision that ensures steady plant performance.

Final Thoughts

In an age where quality, efficiency, and sustainability are non-negotiable, the Made in chemical dosing skid offers industries a local yet globally competitive solution. From advanced control features to robust mechanical engineering, these skids define operational excellence.

Whether you’re operating a water treatment facility, a food processing unit, a chemical refinery, or a semiconductor plant, integrating a Made in chemical dosing skid into your process guarantees:

- Long-term reliability

- Regulatory compliance

- High dosing accuracy

- Operational cost savings

- Immediate local support

- Scalable and modular design

The Made in chemical dosing skid is not just built in Singapore—it’s built for performance, built for safety, and built for the future.

Conclusion

The future of industrial dosing lies in quality, precision, and reliability—qualities embedded in every Made in chemical dosing skid. From initial design to final commissioning, these locally produced systems offer unmatched engineering value, digital readiness, and sustainability.

For industries seeking durable, customizable, and intelligent dosing solutions, choosing a Made in chemical dosing skid is a commitment to operational excellence and long-term efficiency.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply