Inline chemical injection skid Singapore – Best 2025

Introduction to Inline Chemical Injection

In industries where precision, reliability, and safety are critical, the Inline chemical injection skid Singapore is a game-changing innovation. Whether in water treatment, oil & gas, or chemical processing plants, accurate chemical dosing directly into the pipeline is essential for achieving process control, product quality, and regulatory compliance.

A well-designed Inline chemical injection skid Singapore ensures:

Controlled flow rates

Reliable pressure conditions

Minimal manual intervention

Leak-proof chemical handling

What is an Inline Chemical Injection Skid?

An Inline chemical injection skid Singapore is a modular, skid-mounted unit that:

Injects chemicals directly into a pressurized fluid stream

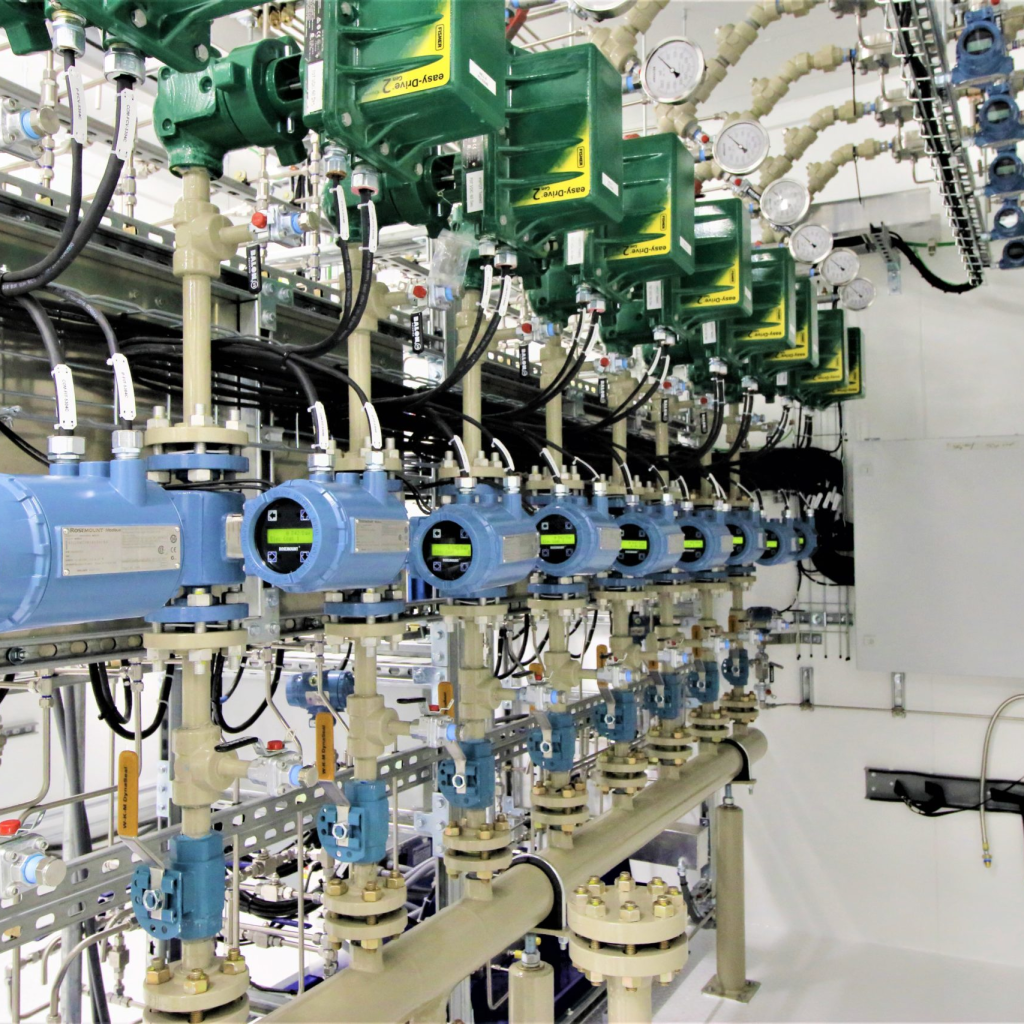

Uses dosing pumps, control valves, flow meters, and safety systems

Is mounted on a structural frame for plug-and-play installation

These systems are critical in scenarios where precise chemical control is required without storage tanks or batch mixing—hence the “inline” functionality.

Applications Across Singapore’s Industrial Sectors

Flomek supplies Inline chemical injection skid Singapore systems to a wide range of industries:

🧪 Water Treatment: For injecting chlorine, sodium hypochlorite, coagulants

🛢️ Oil & Gas: For injecting corrosion inhibitors and anti-scalants

🧬 Pharmaceutical: Inline dosing of pH adjusters in purified water lines

🧫 Food & Beverage: Safe injection of preservatives or cleaning agents

⚗️ Power Plants: Dosing of ammonia or hydrazine into boiler feed water

In each application, a properly engineered Inline chemical injection skid Singapore is crucial for consistent dosing performance.

Key Components of an Inline Chemical Injection Skid

A standard Inline chemical injection skid Singapore from Flomek includes:

High-precision metering pumps

Calibration cylinders for accurate dosing checks

Pressure gauges and flow meters

Relief valves and non-return valves

Inline mixers (if needed)

Control panel with PLC or manual interface

Primary and backup injection lines

Chemical-resistant containment frame

Every Flomek-engineered Inline chemical injection skid Singapore is tested to ensure it meets Singapore’s industrial and environmental standards.

Customization and Engineering

No two applications are the same. That’s why every Inline chemical injection skid Singapore delivered by Flomek is:

Fully engineered in-house

Built using compatible materials (SS316L, PVC, PTFE, etc.)

Sized for your required flow rate, pressure, and chemical type

Compliant with NEA, BCA, and WSH standards in Singapore

We ensure your Inline chemical injection skid Singapore matches your specific process needs and integrates seamlessly into your facility.

Safety and Containment

Safety is paramount. Each Inline chemical injection skid Singapore features:

Secondary containment trays

Pressure relief systems

Emergency shut-off valves

Leak detection sensors

Electrical protection (ATEX, IECEx for hazardous zones)

Flomek prioritizes safety in every Inline chemical injection skid Singapore, helping clients meet strict regulatory expectations.

Automation and Remote Monitoring

Modern plants demand smarter systems. Flomek’s Inline chemical injection skid Singapore supports:

PLC automation

Remote monitoring via SCADA

Real-time data logging

Cloud-enabled performance alerts

Smart automation allows operators to monitor the Inline chemical injection skid Singapore without being physically on-site—saving time and boosting efficiency.

Skid Packaging, Delivery, and Installation

Each Inline chemical injection skid Singapore is:

Tested at Flomek’s facility

Packed with IOM (Installation, Operation, Maintenance) manual

Delivered shrink-wrapped and labeled for easy identification

Installed by Flomek engineers or local contractors

Commissioned with client handover training

Our process ensures your Inline chemical injection skid Singapore is ready to perform on Day One.

Performance Benefits and ROI

With Flomek’s Inline chemical injection skid Singapore, customers report:

⏱️ Faster dosing response times

🔒 Fewer chemical handling incidents

💧 Reduced chemical waste

📉 Lower maintenance and downtime

✅ Improved process consistency

Inline vs. Offline Chemical Injection Skids

Choosing between inline and offline systems can impact operational efficiency. Here’s why an Inline chemical injection skid Singapore offers significant advantages:

FeatureOffline SkidInline chemical injection skid SingaporeChemical ContactStored, batch-basedContinuous, real-timeDowntimeFrequent during changeoverMinimalPrecisionDepends on batch accuracyReal-time control via feedback loopInstallation FootprintLargeCompact, modularComplianceManual checks neededAuto-logging, NEA-friendly

An Inline chemical injection skid Singapore keeps your system lean and responsive—no batch lag, no guesswork.

Types of Chemicals Injected Inline

Your Inline chemical injection skid Singapore must be compatible with the chemicals being used. Commonly dosed chemicals include:

Sodium Hypochlorite (NaOCl) – for disinfection

Hydrochloric Acid (HCl) – for pH control

Antiscalants – in reverse osmosis systems

Corrosion inhibitors – in pipelines

Ammonia – in power plant water systems

Biocides – in industrial cooling towers

Polymer coagulants – for wastewater clarification

Each chemical has unique flow and material compatibility requirements, which Flomek accounts for when designing an Inline chemical injection skid Singapore.

Dosing Pump Options

At the heart of any Inline chemical injection skid Singapore is the dosing pump. Flomek offers:

Diaphragm Metering Pumps – High precision, suitable for most chemicals

Peristaltic Pumps – Excellent for viscous fluids

Plunger Pumps – High-pressure applications (e.g., oil & gas)

Magnetic Drive Pumps – Leak-free, minimal maintenance

All pump types are calibrated and tested under local operating conditions before being integrated into an Inline chemical injection skid Singapore.

Safety Interlocks and Redundancy

A good Inline chemical injection skid Singapore isn’t just about performance—it’s also about fail-safe operation.

Standard safety features include:

Dual injection lines with automatic switchover

Over-pressure protection

Low chemical level alarms

Emergency stop buttons

Back-pressure valves and anti-siphon devices

These features prevent accidental overfeeding, protect the process line, and ensure chemical integrity within your Inline chemical injection skid Singapore.

Electrical & Control Integration

A high-quality Inline chemical injection skid Singapore is not a standalone system—it integrates directly into your plant’s existing control infrastructure:

HMI touch panels for on-skid operation

SCADA/PLC compatibility for remote access

Modbus, Profibus, Ethernet/IP protocols available

Data logging and alarm history export

This allows your engineering team to monitor and manage the Inline chemical injection skid Singapore from a central control room, improving responsiveness and reducing manual checks.

Structural Frame Design

The physical integrity of your Inline chemical injection skid Singapore is just as important as its internal components.

Frame designs include:

Mild steel with epoxy paint (budget)

Stainless steel SS304/SS316 (industrial/hygienic)

Modular bolt-together frames for tight spaces

Mobile skids with castors for utility rooms

All Flomek-built frames meet structural loading standards and can be customized to the plant layout. Each Inline chemical injection skid Singapore can also be seismic- or offshore-certified if required.

Frequently Asked Questions (FAQs)

Q1: What is the purpose of an Inline chemical injection skid Singapore?

A: The Inline chemical injection skid Singapore is designed to inject chemicals directly into pressurized pipelines with high accuracy, ensuring process consistency and safety.

Q2: Can the Inline chemical injection skid Singapore handle multiple chemicals?

A: Yes. Flomek designs systems with multiple dosing lines and pumps to handle different chemicals simultaneously without cross-contamination.

Q3: How long does installation take?

A: For most projects, the Inline chemical injection skid Singapore can be fully installed and commissioned within 1–3 working days, depending on site readiness.

Q4: What’s the life expectancy of the system?

A: A well-maintained Inline chemical injection skid Singapore can operate reliably for over 10 years with scheduled service.

Q5: Is remote monitoring available?

A: Yes. Our Inline chemical injection skid Singapore systems come with remote access capabilities and can be monitored via SCADA or mobile dashboards.

Maintenance Checklist

Keeping your Inline chemical injection skid Singapore in optimal condition involves routine maintenance tasks:

TaskFrequencyVisual inspection for leaksWeeklyCalibration of dosing pumpsMonthlyCleaning of filters and strainersBi-weeklyControl system diagnostic testQuarterlyVerification of electrical safety systemsBi-annuallyFull performance auditAnnually

Following this checklist ensures your Inline chemical injection skid Singapore runs efficiently and safely year-round.

Retrofit and Upgrade Options

Already using an older system? Flomek offers retrofit services to bring your outdated unit up to the performance of a new Inline chemical injection skid Singapore.

Upgrades include:

Replacing old pumps with modern metering pumps

Adding PLC and remote monitoring

Replacing single-walled piping with double containment

Updating instrumentation and control panels

These upgrades extend the life of your investment while improving dosing accuracy and regulatory compliance.

Digital Twin and Simulation Testing

To eliminate errors before fabrication, Flomek builds a digital twin of every Inline chemical injection skid Singapore. This 3D model simulates real-world operation under your site’s conditions:

Pump curves are plotted

Fluid dynamics simulated

Chemical compatibility verified

Electrical load tested

This pre-validation ensures that the final Inline chemical injection skid Singapore performs exactly as required—before it even leaves our workshop.

Common Configurations

Flomek offers several base configurations of the Inline chemical injection skid Singapore depending on application and size:

Compact Wall-Mount Skid

Ideal for labs, tight mechanical rooms

Manual operation or basic PLC

Full Industrial Skid

Up to 3 dosing lines

Full automation

Built-in containment

Mobile Skid System

Mounted on wheels

Used for emergency or utility applications

Each configuration of the Inline chemical injection skid Singapore is modular and upgradeable.

Why Choose Flomek?

Choosing the right vendor for your Inline chemical injection skids Singapore can define project success. Here’s what makes Flomek stand out:

✅ Over 15 years of industry experience

✅ In-house engineering and fabrication

✅ Fast turnaround times for Singapore-based clients

✅ Certified components and international compliance

✅ Customization without complexity

✅ Local support, fast parts availability

We’ve deployed hundreds of Inline chemical injection skid Singapore units across water treatment, oil & gas, pharma, and more.

Case Study – Water Treatment Plant, Changi

Challenge: A municipal water plant in Changi needed to automate disinfection without expanding its physical footprint.

Solution: Flomek delivered a dual-line Inline chemical injection skids Singapore with sodium hypochlorite and pH correction dosing, complete with PLC and real-time SCADA integration.

Outcome:

Dosing precision improved by 27%

Chemical waste reduced by 18%

Passed NEA audit with zero corrective actions

This demonstrates the effectiveness and reliability of the Inline chemical injection skids Singapore even in highly regulated environments.

How We Size Your Skid

Sizing your Inline chemical injection skid Singapore requires detailed input:

Flow rate (L/hr)

Line pressure (bar)

Chemical viscosity and pH

Dosing frequency

Ambient temperature

Compatibility with process line materials

Based on this, we use flow simulations, pump curves, and P&ID drafting to produce the most efficient design for your Inline chemical injection skids Singapore.

Glossary of Terms

To help buyers and engineers alike, here are common terms related to the Inline chemical injection skids Singapore:

Skid: A pre-mounted system on a frame for easy transport/install

Inline injection: Dosing chemicals directly into a flowing fluid stream

PLC: Programmable logic controller for automation

SCADA: Supervisory Control and Data Acquisition

Calibration cylinder: A tube used to confirm dosing pump accuracy

Backpressure valve: Ensures dosing system sees consistent pressure

These terms will appear in every spec sheet for your Inline chemical injection skids Singapore.

Final Takeaways

If your facility requires precision chemical dosing without complex infrastructure, then an Inline chemical injection skids Singapore is the ideal solution. It offers:

💧 High accuracy

🔒 Superior safety

🌱 Eco-conscious dosing

📉 Cost savings

⚙️ Seamless automation

📡 Remote visibility

Whether you’re upgrading, expanding, or installing from scratch, Flomek delivers end-to-end service for your Inline chemical injection skids Singapore needs.

Troubleshooting Common Issues

Even the most reliable Inline chemical injection skids Singapore may occasionally require diagnostics. Below are common problems and how Flomek helps resolve them:

IssueLikely CauseSolutionInconsistent dosingPump wear, airlocksCheck for suction line leaks and recalibratePressure dropClogged injection nozzleClean or replace inline injectorAlarm triggeringPLC sensor faultReview fault logs and verify sensor calibrationChemical leakageValve seal degradationReplace seals with compatible materialLow flow rateWorn diaphragm or blocked filterPerform pump maintenance or filter cleaning

All troubleshooting steps are outlined in the O&M manual included with every Inline chemical injection skid Singapore.

Calibration and Validation Procedures

To ensure dosing accuracy, every Inline chemical injection skid Singapore must be periodically calibrated.

Calibration Steps:

Isolate the dosing pump

Fill the calibration cylinder with a known volume

Run the pump for a fixed time

Measure the drawn volume

Adjust pump flow settings accordingly

Flomek recommends quarterly calibration checks. We provide in-person services in Singapore or remote assistance to validate your Inline chemical injection skid Singapore performance.

What’s Included in the Package?

Every Flomek-delivered Inline chemical injection skid Singapore includes:

Pre-mounted skid with pumps and instruments

HMI or manual control panel

Wiring and junction boxes

Sample calibration report

FAT documentation

IOM manual

Spare parts list

Certificate of compliance

This plug-and-play format allows rapid deployment of your Inline chemical injection skid Singapore without separate contractors or long commissioning timelines.

Export and Regional Supply

While Flomek is based in Singapore, we also export the Inline chemical injection skid Singapore to neighboring regions including:

Malaysia

Indonesia

Vietnam

Thailand

Brunei

All export units are crated for sea or air shipment and include CE/ISO certifications where required. Our logistics partners ensure timely delivery of your Inline chemical injection skid Singapore, no matter your site location.

Emergency Response and Failover Systems

Our Inline chemical injection skid Singapore designs include features for high-risk or critical operations:

Dual-pump failover logic

Battery-powered backup for PLC memory

Emergency power cut-off switch

Local and remote alarm triggers

Safe shutdown programming

Chemical spill containment sensors

This ensures operational continuity even during electrical outages or equipment failures, keeping your Inline chemical injection skid Singapore running under pressure.

Certifications and Standards

To guarantee safety and performance, each Inline chemical injection skid Singapore is built in accordance with:

ISO 9001: Quality Management System

IEC 60079: Electrical systems in explosive atmospheres (optional)

SS 586: Singapore Hazard Communication System

ATEX compliance (on request)

UL/CE certifications (region-dependent)

Third-party inspection can be arranged prior to shipment for your Inline chemical injection skid Singapore, especially for EPC or government projects.

Integration with Water Quality Analyzers

Modern dosing requires data feedback. Flomek’s Inline chemical injection skid Singapore supports direct integration with:

pH and ORP sensors

Turbidity meters

Chlorine analyzers

Conductivity sensors

Flow totalizers

Based on this feedback, the skid automatically adjusts dosing rates, optimizing performance and reducing manual input—true automation in an Inline chemical injection skid Singapore.

Warranty and Service Contracts

Every Inline chemical injection skid Singapore comes with:

12-month standard warranty

Optional 2–5 year extended service plans

Local servicing by Flomek technicians

Scheduled maintenance visits

Priority support and spare parts availability

Service contracts ensure your Inline chemical injection skid Singapore receives preventive care and keeps operating at peak efficiency.

Documentation and Digital Records

Each Inline chemical injection skid Singapore from Flomek includes:

Full as-built P&ID drawings

Skid layout diagrams

Electrical schematics

Test and inspection reports

Chemical compatibility chart

Calibration logs

Digital maintenance history (optional cloud backup)

These records are crucial for regulatory inspections and internal audits. Digital copies are stored securely and provided on delivery.

Project Timeline – From Design to Deployment

Here’s how a typical Inline chemical injection skid Singapore project flows:

PhaseTimeframeDescriptionConsultation1–3 daysSite visit, chemical reviewDesign & Approval5–7 daysP&ID, GA drawing, quotationFabrication2–3 weeksFrame building, pump setupFAT Testing2 daysOn-site or at Flomek HQDelivery1–2 daysTransport to facilityInstallation & Commissioning1–3 daysPiping, wiring, startup

In less than a month, your Inline chemical injection skid Singapore can be designed, built, and online.

Environmental Compliance in Singapore

Singapore’s regulatory environment is strict. A well-documented Inline chemical injection skid Singapore helps companies comply with:

NEA – Pollution Control Guidelines

PUB – Sewerage and Drainage Act

WSH – Workplace Safety and Health regulations

BCA – Construction guidelines for hazardous systems

SS 586 – Singapore’s Hazard Communication standards

Flomek ensures each Inline chemical injection skid Singapore is delivered with the documentation required to pass inspections and audits.

ROI and Long-Term Value

Investing in an Inline chemical injection skid Singapore pays off in both direct and indirect returns:

Reduced chemical waste (up to 15%)

Minimized downtime due to inline calibration

Improved production consistency

Lower risk of NEA non-compliance fines

Less manpower needed for manual dosing

The total cost of ownership is often lower than traditional systems, especially when you factor in Flomek’s after-sales support and system reliability.

System Expansion Capabilities

Your Inline chemical injection skid Singapore should scale with your operations. Flomek offers:

Expandable control panels

Additional pump stations with space allocated on skid

Future chemical compatibility evaluation

Spare digital/analog input ports on PLC

This means your system is future-ready and adaptable, a major benefit for facilities that evolve or expand frequently.

Ready for Installation? Contact Flomek

Flomek is Singapore’s trusted provider for all things related to inline chemical dos

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply