Industrial dosing skid supplier singapore – Singapore’s No 1 Best Pumps Service

Industrial Dosing Skid Supplier Singapore

Your Trusted Partner in Precision Chemical Handling & Fluid Engineering Solutions

Introduction to Industrial Dosing Skid Systems

In today’s industrial landscape, where accuracy, consistency, and operational safety are paramount, the use of dosing skid systems has become a standard in various sectors, including water treatment, petrochemical, food and beverage, pharmaceuticals, and power generation. For facilities operating in Southeast Asia, finding a reliable industrial dosing skid supplier Singapore is crucial for operational success and environmental compliance.

An industrial dosing skid supplier Singapore offers tailor-made systems that are essential for automated chemical dosing, allowing end users to maintain strict process control, reduce chemical wastage, and ensure safety for operators and the environment.

What Is an Industrial Dosing Skid?

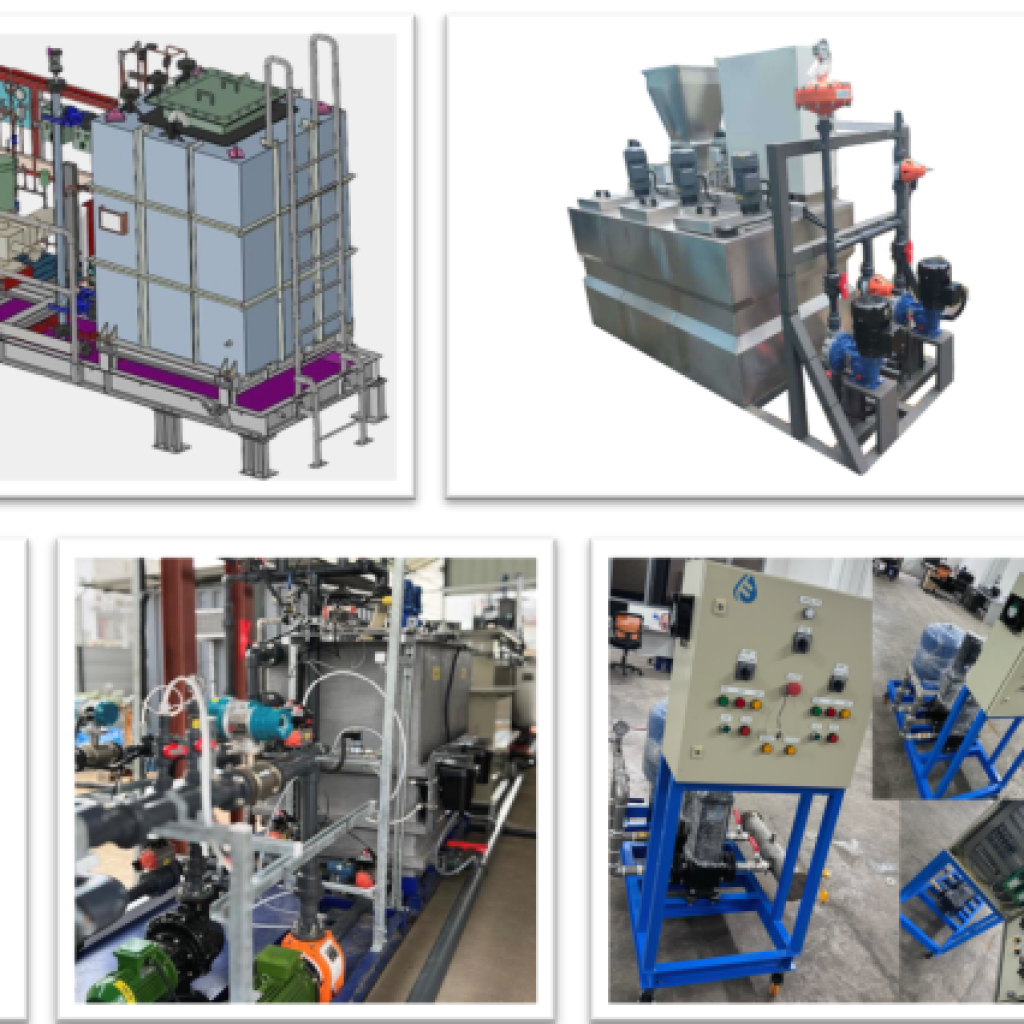

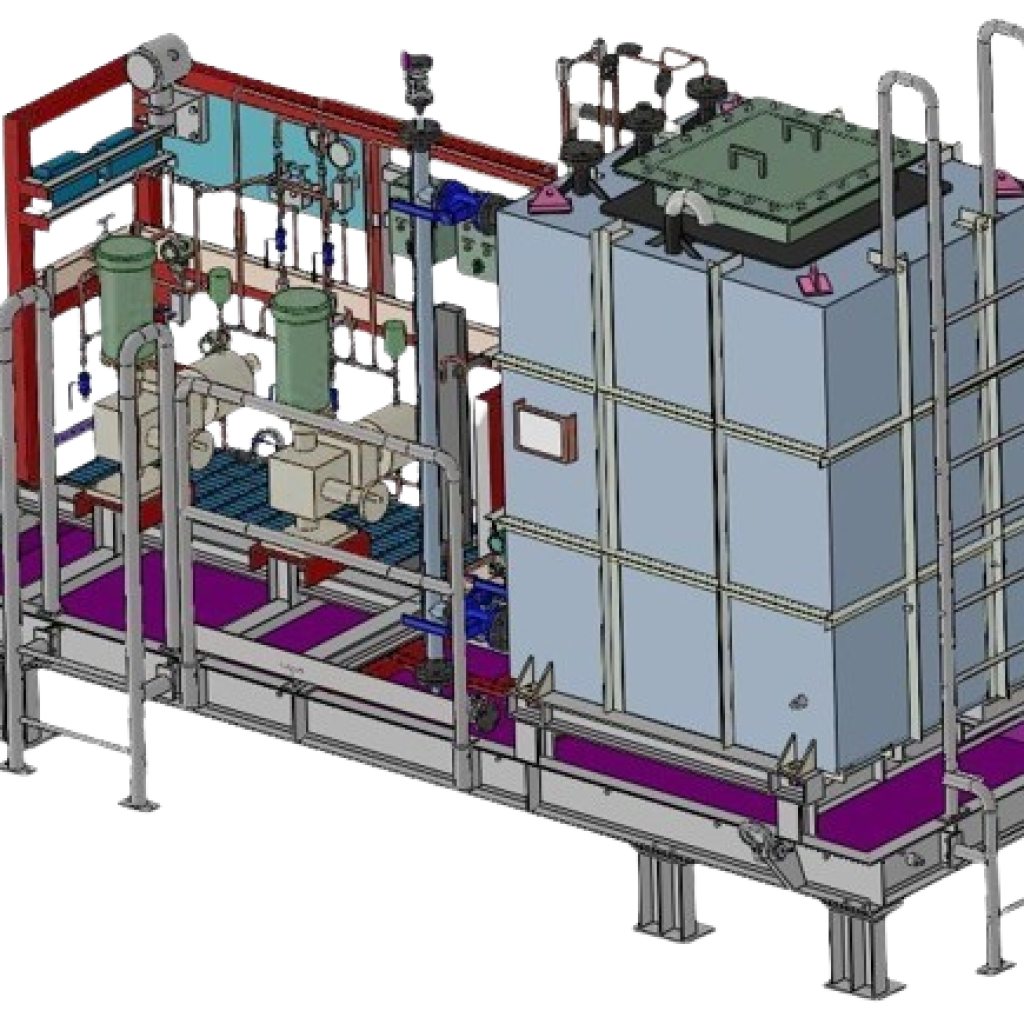

An industrial dosing skid is a pre-engineered, pre-assembled system that includes:

- Chemical dosing pumps

- Storage tanks

- Instrumentation and control panels

- Valves and fittings

- Flow meters and pressure gauges

- PLC or manual control logic

Designed as a plug-and-play solution, these systems are skid-mounted, which means they can be easily transported, installed, and integrated into existing industrial setups. A dependable industrial dosing skid supplier Singapore ensures that each unit is built with industry-specific compliance, ISO standards, and precise engineering.

Importance of a Trusted Industrial Dosing Skid Supplier Singapore

Choosing the right industrial dosing skid supplier Singapore is not just a procurement decision—it’s a partnership for operational excellence. The supplier must offer:

- Customized engineering solutions

- Material compatibility analysis

- Process-specific pump and instrumentation selection

- Long-term support and maintenance

- Compliance with Singapore environmental and industrial regulations

In a highly regulated and quality-driven economy like Singapore, partnering with an experienced industrial dosing skid supplier Singapore ensures efficiency, safety, and compliance across your operations.

Applications of Industrial Dosing Skid Systems

An industrial dosing skid supplier Singapore caters to a wide range of industries, including:

1. Water & Wastewater Treatment

Chemical dosing is integral to processes like coagulation, flocculation, pH correction, disinfection, and odor control. An industrial dosing skid supplier Singapore provides systems designed for continuous and batch processes.

2. Power Plants

In boiler feedwater and cooling tower systems, chemical dosing is critical to prevent corrosion and scaling. A reliable industrial dosing skid supplier Singapore ensures accurate chemical injection for optimal plant performance.

3. Oil & Gas and Petrochemical

From anti-foaming agents to corrosion inhibitors, dosing skids handle high-risk chemical dosing in upstream and downstream operations. The right industrial dosing skid supplier Singapore provides ATEX-rated and explosion-proof skid designs.

4. Food & Beverage

For CIP (Cleaning in Place) systems and dosing food-grade additives, hygiene and material compatibility are crucial. The best industrial dosing skid supplier Singapore uses FDA-approved materials and hygienic process design.

5. Pharmaceuticals

Precision and contamination control are key in pharmaceutical manufacturing. A trusted industrial dosing skid supplier Singapore delivers systems with high repeatability and precision dosing capabilities.

Components Engineered by an Industrial Dosing Skid Supplier Singapore

A. Dosing Pumps

The heart of every skid system. Pumps are selected based on flow rate, pressure, chemical compatibility, and pulsation tolerance. An industrial dosing skid supplier Singapore ensures the right selection between diaphragm, plunger, or peristaltic pumps.

B. Storage Tanks

Chemical-resistant tanks with level indicators and agitation systems if required. A quality industrial dosing skid supplier Singapore will offer PP, HDPE, SS316, or PVDF tank materials depending on the application.

C. Instrumentation

Pressure gauges, flow meters, pH sensors, conductivity sensors, and dosing monitors are integrated for full automation. A forward-thinking industrial dosing skid supplier Singapore includes smart instrumentation compatible with SCADA and PLC.

D. Control Panel

Manual or automated control with HMI/PLC interfaces, ensuring real-time process monitoring. A competent industrial dosing skid supplier Singapore designs control panels compliant with IEC standards and local codes.

E. Safety Features

Emergency stop, over-pressure protection, leakage containment, and chemical spill control mechanisms. A responsible industrial dosing skid supplier Singapore places safety as a design priority.

Design Features Offered by a Professional Industrial Dosing Skid Supplier Singapore

- Compact Skid Layouts – Optimized footprint for easy integration into existing plants.

- Modular Systems – For future scalability and easier maintenance.

- Fully Assembled and Tested – Skids are delivered ready for plug-and-play installation.

- Corrosion Resistance – Designed with durable materials for harsh environments.

- Automation Ready – Compatible with DCS/PLC systems for remote monitoring.

- Documentation and Drawings – P&ID, GA, IOM, and electrical drawings included.

- Compliance Certifications – PED, ASME, ISO, and local statutory approvals.

Only a well-established industrial dosing skid supplier Singapore can guarantee these value-driven design advantages.

How an Industrial Dosing Skid Supplier Singapore Supports Your Business

Choosing the right industrial dosing skid supplier Singapore brings long-term business value:

- Reduced Downtime: Skid systems are tested before delivery.

- Ease of Maintenance: Modular design allows quick access to components.

- Improved Efficiency: Accurate dosing reduces chemical usage.

- Better Compliance: Skids are built to meet environmental and industry standards in Singapore.

- Scalability: Units can be upgraded or expanded as the business grows.

- One-Stop Solution: From design and fabrication to commissioning and training, everything is handled by the same industrial dosing skid supplier Singapore.

Benefits of Skid-Based Systems

The use of skid-mounted systems from a reliable industrial dosing skid supplier Singapore offers the following advantages:

- Mobility: Easy transport and repositioning within facilities.

- Pre-Fabricated: Fabrication and testing are done off-site to save time and cost.

- Less Site Work: Reduces on-site installation time and labor.

- Lower Project Risk: Factory acceptance testing (FAT) is conducted before delivery.

- Reduced Commissioning Time: Systems arrive ready for connection and integration.

What to Look for in an Industrial Dosing Skid Supplier Singapore

✔ Experience and Track Record

Choose an industrial dosing skid supplier Singapore with a strong history of projects across various industries.

✔ In-House Engineering

A supplier with in-house engineers provides better customization, documentation, and technical support.

✔ Quality Assurance

The supplier must follow ISO quality procedures, conduct material traceability, and ensure FAT and SAT documentation.

✔ After-Sales Support

Ensure the industrial dosing skid supplier Singapore offers preventive maintenance, spare parts, and technical services.

✔ Compliance

Must be aware of NEA, PUB, and SCDF regulations for handling chemicals and wastewater in Singapore.

Customization by Industrial Dosing Skid Supplier Singapore

Every industry has unique requirements, and a competent industrial dosing skid supplier Singapore provides tailor-made systems that include:

- Multichannel dosing skids for complex processes

- Double containment systems for hazardous chemical dosing

- Redundancy dosing systems for uninterrupted operations

- Solar-powered skids for remote locations

- Corrosion-resistant enclosures for offshore or marine use

Customization ensures that the system aligns perfectly with operational goals, budget, and regulatory needs.

Why Skid Integration Matters

A forward-looking industrial dosing skid supplier Singapore integrates the skid with:

- Building Management Systems (BMS)

- Process Automation Control Systems (SCADA/PLC)

- Data Logging and Remote Monitoring

- IIoT and Cloud Dashboards

This allows industries to remotely monitor pH, flow, temperature, and chemical concentrations, and make real-time adjustments, increasing productivity and reducing manual errors.

Skid Testing & Commissioning Process

A reliable industrial dosing skid supplier Singapore follows strict FAT and SAT protocols, including:

- Hydrostatic Testing

- Leak Test

- Dry Run of Pumps

- PLC Functional Testing

- I/O Signal Verification

- Simulation of Process Scenarios

Documentation is provided for every test to ensure transparency and performance validation.

Environmental and Regulatory Compliance

The Singapore government enforces strict regulations for chemical handling, effluent discharge, and plant safety. An established industrial dosing skid supplier Singapore will ensure:

- NEA Compliance (for chemical use and wastewater)

- PUB Standards (for water discharge)

- SCDF Requirements (for fire and safety in chemical storage areas)

- WSH Guidelines (for occupational safety)

Future Trends in Dosing Skid Technology

As industries grow more dependent on automation, digital integration, and sustainability, the expectations from an industrial dosing skid supplier Singapore are also evolving. Today’s systems must not only deliver accurate dosing but also integrate seamlessly with smart technologies, offer predictive maintenance capabilities, and support environmental sustainability goals.

A. Smart Dosing Systems

Modern skids from an innovative industrial dosing skid supplier Singapore incorporate sensors, flow verification systems, and remote dashboards. These IoT-enabled skids monitor dosage, temperature, pressure, and consumption trends in real time.

B. Predictive Maintenance

Instead of waiting for faults, today’s dosing systems proactively alert users before issues arise. An advanced industrial dosing skid supplier Singapore builds systems with vibration sensors and usage pattern recognition that predict when maintenance is due.

C. Sustainable and Green Design

Eco-conscious industries are now requesting dosing skids designed with minimal chemical waste, energy-efficient motors, and environmentally friendly materials. A leading industrial dosing skid supplier Singapore will include features such as:

- Closed-loop dosing feedback

- Energy-saving VFDs for pump motors

- Low-emission tank designs

- Recyclable piping materials like PVDF or HDPE

Turnkey Project Capabilities of an Industrial Dosing Skid Supplier Singapore

A full-scope industrial dosing skid supplier Singapore doesn’t just supply the equipment—they deliver complete turnkey solutions that include:

- Site survey and requirement gathering

- Process flow development and chemical consumption analysis

- Mechanical, electrical, and instrumentation engineering

- 3D modeling and simulation

- Factory fabrication, integration, and testing

- On-site installation and commissioning

- Operator training and system handover

This turnkey capability reduces project risks, ensures compatibility, and accelerates deployment timelines.

Commissioning Support from an Industrial Dosing Skid Supplier Singapore

An expert industrial dosing skid supplier Singapore provides comprehensive commissioning support, including:

- System startup and flushing

- Pump priming and testing

- Instrument calibration

- Signal loop testing

- Trial runs under load

- Alarm and fail-safe validation

- Safety interlock verification

- Training for O&M team

In the commissioning stage, the supplier must verify performance against the design intent and compliance checklists. Only a technically skilled industrial dosing skid supplier Singapore can ensure a smooth transition from setup to operation.

Maintenance and Lifecycle Support

The relationship with your industrial dosing skid supplier Singapore doesn’t end at commissioning. A reliable supplier offers:

- Preventive maintenance contracts

- Troubleshooting services

- On-site emergency support

- Spare part stocking

- Annual calibration and validation

- System upgrades and optimization

Routine servicing and remote diagnostics provided by an industrial dosing skid supplier Singapore help extend the system lifespan, minimize downtime, and ensure continuous compliance.

Export and Offshore Capability

If your operations extend beyond Singapore to regional plants in Malaysia, Indonesia, Thailand, or the Middle East, a global-ready industrial dosing skid supplier Singapore can deliver skids with:

- IECEx or ATEX certification

- Multilingual documentation

- Skids built to CE, ASME, or API standards

- Custom voltages and frequencies (e.g., 220V/60Hz or 400V/50Hz)

- Marine-grade painting and packaging

An international-ready industrial dosing skid supplier Singapore supports regional expansion and multi-site standardization for large corporations.

Common Chemicals Dosed by Industrial Skids

An experienced industrial dosing skid supplier Singapore provides systems capable of handling a wide range of chemicals, including:

| Chemical | Purpose |

|---|---|

| Sodium Hypochlorite (NaOCl) | Disinfection, chlorination |

| Alum (Aluminium Sulphate) | Coagulation in water treatment |

| Sulfuric Acid (H₂SO₄) | pH correction |

| Sodium Hydroxide (NaOH) | Alkalinity adjustment |

| Ferric Chloride | Phosphorus removal |

| Antiscalants | Reverse osmosis system protection |

| Corrosion Inhibitors | Cooling tower and boiler systems |

| Anti-foaming Agents | Process chemical stability |

Only a process-knowledgeable industrial dosing skid supplier Singapore can provide compatibility, material selection, and safety protocols for handling these chemicals.

Compliance and Certification Considerations

To operate legally and safely in Singapore, systems provided by an industrial dosing skid supplier Singapore must comply with:

- NEA (National Environment Agency): Environmental discharge limits

- PUB (Public Utilities Board): Water quality and recycling standards

- SCDF (Singapore Civil Defence Force): Fire code and hazardous chemical storage

- BCA (Building and Construction Authority): Plant layout and installation permits

- WSH (Workplace Safety & Health Council): Equipment safety and worker protection

- ISO Standards: ISO 9001 for quality, ISO 14001 for environment, ISO 45001 for safety

A licensed industrial dosing skid supplier Singapore ensures documentation, certification, and inspections are met without delays.

Key Factors that Differentiate a Professional Industrial Dosing Skid Supplier Singapore

- Engineering Depth: Ability to design skids based on real application data.

- Testing Rigor: Comprehensive FAT with simulation-based validation.

- On-Time Delivery: Commitment to realistic and timely project delivery.

- Traceability: Use of traceable components, MTCs, and serial tagging.

- Documentation Support: High-quality datasheets, manuals, and drawings.

- Training Programs: On-site or virtual training for engineers and operators.

Selecting a capable industrial dosing skid supplier Singapore guarantees that your project is not just delivered—it is optimized, documented, and supported across its full lifecycle.

Common Mistakes When Choosing an Industrial Dosing Skid Supplier Singapore

Avoid these pitfalls by choosing a competent and experienced industrial dosing skid supplier Singapore:

- Choosing based on price alone instead of value and support

- Overlooking FAT and testing capability

- Ignoring local compliance and NEA/PUB approvals

- No post-installation support or spare parts availability

- Poor customization options and rigid designs

- Lack of experience in your specific industry

Working with a credible industrial dosing skid supplier Singapore ensures that you receive a long-term engineered solution—not just a commodity product.

Summary: Why Partner with a Top Industrial Dosing Skid Supplier Singapore

An industrial dosing skid supplier Singapore offers more than just equipment. You gain:

- 💡 Engineering know-how for complex dosing processes

- 🛠 Reliable fabrication with precision component selection

- 📦 Factory-tested skids ready for immediate deployment

- 🔄 Scalable systems adaptable to your future needs

- 🔧 Full lifecycle service from installation to after-sales support

- 🧪 Chemical expertise to ensure material compatibility and dosing accuracy

- 🏗 Project execution capability that keeps your operations compliant and efficient

In a highly technical and regulated industrial environment like Singapore, trusting your dosing system to a verified industrial dosing skid supplier Singapore guarantees peace of mind, sustainability, and performance.

Advanced Technical Design Considerations from a Reliable Industrial Dosing Skid Supplier Singapore

When working with a reputable industrial dosing skid supplier Singapore, clients can expect in-depth engineering tailored to their operating environment and chemical requirements. This includes:

1. Pump Selection Based on Application Dynamics

An expert industrial dosing skid supplier Singapore considers dynamic process variables such as:

- Suction lift or flooded suction

- Discharge head height

- Required accuracy (±1%, ±0.5%, or ±0.1%)

- Duty cycle (continuous vs intermittent)

- Viscosity and abrasiveness of the chemical

Based on these variables, pumps are selected from various technologies:

- Diaphragm metering pumps for accurate and repeatable dosing

- Plunger pumps for high-pressure applications

- Peristaltic pumps for viscous or shear-sensitive fluids

- Gear pumps for oil-based chemical dosing

- Magnetic drive pumps for leak-proof operation

A skilled industrial dosing skid supplier Singapore uses simulation software to validate the pump curve against the process need before system design.

2. Materials of Construction (MOC) Selection

Chemical compatibility is the foundation of safe and effective dosing. Depending on the chemical’s pH, reactivity, and temperature, an industrial dosing skid supplier Singapore may recommend:

- PVC/PP/PVDF for corrosive acids and alkalis

- SS304/SS316L for food-grade or neutral chemicals

- Hastelloy or Alloy-20 for aggressive industrial solvents

- PTFE lining for ultimate chemical resistance in tubing or valves

The material choice is validated with chemical resistance charts and practical field experience — a standard service expected from a world-class industrial dosing skid supplier Singapore.

3. Containment and Safety Measures

Handling hazardous chemicals demands rigorous safety design. The best industrial dosing skid supplier Singapore integrates:

- Double containment dosing lines

- Bunded chemical tanks with leak sensors

- Eye-wash and emergency drench shower points near skids

- Interlocks for low tank level shutdown

- Explosion-proof (EX d) electrical panels when dosing flammables

Ensuring operator safety and system longevity is a hallmark of a qualified industrial dosing skid supplier Singapore.

Sector-Specific Expertise of an Industrial Dosing Skid Supplier Singapore

Different industries present unique challenges that must be addressed by a knowledgeable industrial dosing skid supplier Singapore. Below are specific case studies and expectations:

🔷 Municipal Water Treatment (PUB Projects)

- High flow dosing systems for alum, lime, and polymer

- Built-in flow pacing and dosing proportionality

- Integrated redundancy for critical dosing points

- 100% compliance with PUB and NEA discharge requirements

🔷 Pharmaceutical and Biotech

- Validation support with FAT/SAT and IQ/OQ documents

- Skids designed for cleanroom and GMP zones

- Use of FDA-approved materials

- Sanitization options like CIP/SIP skids

Only a compliance-focused industrial dosing skid supplier Singapore understands these nuances.

🔷 Food & Beverage

- Hygienic design with EHEDG principles

- Skids for sweeteners, colorants, and preservatives

- CIP integration with food-safe pump materials

- Avoidance of cross-contamination through clean routing

🔷 Semiconductor/Chemical Manufacturing

- High-purity chemical dosing with contamination-free handling

- Use of PVDF tubing and cleanroom-compliant systems

- Skids with HF, HCl, H₂SO₄ dosing

- ETFE-coated pumps and ATEX compliance for cleanrooms

Partnering with an experienced industrial dosing skid supplier Singapore ensures these sectoral requirements are met.

Energy-Efficient Design by a Quality Industrial Dosing Skid Supplier Singapore

As energy costs rise, industries seek greener solutions. A forward-thinking industrial dosing skid supplier Singapore includes:

- VFDs (Variable Frequency Drives) for motor speed optimization

- Low wattage sensors and instruments for minimal power draw

- Solar-powered dosing skids for remote water tanks or treatment sites

- Timer-controlled operation to reduce idle runtime

- Eco-mode for pump duty-cycling

These green designs reduce carbon footprints, operational costs, and help comply with Singapore’s Green Mark and Energy Conservation Act initiatives.

Skid Transport, Handling & Installation

The transport and installation phase is as crucial as the design. A responsible industrial dosing skid supplier Singapore ensures:

✅ Skid Structure Design

- Skids designed with ISO lifting lugs for crane/lifter movement

- Base frame with vibration isolators

- Corrosion-resistant frame coatings (epoxy or marine-grade)

✅ Packaging & Crating

- Shrink wrap and fumigated wooden crates for export

- Moisture control bags for electronics

- Clear labeling and unboxing guidelines

✅ Site Services

- On-site piping integration

- Electrical termination

- System flushing and startup

- SOP handover and operator walkthrough

Efficient logistics and support minimize disruption, something only a detail-oriented industrial dosing skid supplier Singapore can guarantee.

Remote Monitoring and Digital Integration

Digitalization is now standard in modern dosing systems. A future-ready industrial dosing skid supplier Singapore offers:

- SCADA/BMS/PLC integration for process control

- Ethernet or Modbus communication for plant-wide connectivity

- Cloud-based dashboards for chemical consumption tracking

- SMS/email alerts for system faults or low chemical levels

- IoT flow meters and level sensors with real-time data logging

With digital features, end-users can reduce downtime and manage chemical dosing from anywhere — a strategic edge offered by an intelligent industrial dosing skid supplier Singapore.

Long-Term Benefits of a Quality Dosing Skid System

When you invest in a dosing skid from a trusted industrial dosing skid supplier Singapore, you unlock significant long-term advantages:

| Benefit | Impact |

|---|---|

| Accurate Dosing | Reduces chemical overuse and costs |

| Automation | Minimizes manual labor and errors |

| Compact Skid Design | Saves space in plant layout |

| Durable Materials | Extends system lifespan under harsh conditions |

| Quick Installation | Fast commissioning reduces plant downtime |

| Maintenance-Friendly Design | Easy access reduces repair time |

| Compliance-Ready | Avoids regulatory penalties and shutdowns |

| Scalable Systems | Supports future capacity expansion |

This value proposition is why choosing the right industrial dosing skid Singapore is a strategic decision, not just a purchase.

The Competitive Edge with a Proven Industrial Dosing Skid Supplier Singapore

A high-performing industrial dosing skid Singapore doesn’t just sell equipment—they deliver engineered assurance, regulatory compliance, operational precision, and long-term performance.

Choosing a reliable industrial dosing skid Singapore means you’re investing in:

- Process safety

- Environmental responsibility

- Downtime reduction

- Manpower optimization

- Regulatory peace of mind

- Smart and digitalized operation

In Singapore’s tightly regulated and high-tech industrial environment, this decision will impact your productivity, compliance, and bottom line for years to come.

Conclusion

Finding the right industrial dosing skid supplier Singapore is vital for businesses that rely on precise chemical dosing, regulatory compliance, and process safety. Whether you’re operating in the water treatment sector, petrochemical industry, food production, or pharmaceutical plant, a well-engineered dosing skid system can transform your operations.

By choosing a trusted industrial dosing skid supplier Singapore, you are ensuring long-term reliability, operational efficiency, and complete peace of mind. With the right partner, your dosing skid system will deliver unmatched performance and value across the lifecycle of your industrial application.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply