Fuel pump supplier in SG – Singapore’s No 1 Best Pump service & suplier

Introduction

In the fast‑paced industrial, marine, oil & gas, and infrastructure sectors of Singapore, reliable fuel delivery systems are non‑negotiable. That’s why choosing the right fuel pump supplier in SG is critical to operational efficiency, compliance, and long‑term reliability. Whether you need fuel pumps for marine operations, diesel generator sets, fuel storage systems, or skid assemblies, a trusted fuel pump supplier in SG can make all the difference.

As a partner at Sulzer and as part of Flomek, you understand that precision, durability, and engineering support are essential in fuel handling systems. In this content, we go deep into what it takes to be a top fuel pump supplier in SG, how to select one, key technical considerations, and how Flomek is positioned to serve that role.

The Role and Importance of a Fuel Pump Supplier in SG

Fuel Handling in Singapore’s Industrial Context

Singapore is a hub of energy infrastructure, marine traffic, petrochemical plants, and supporting logistics. Fuel systems here must meet stringent regulatory standards, safety protocols, and performance expectations under heavy duty cycles. A fuel pump supplier in SG must therefore not only deliver hardware but also deep domain expertise in fuel systems.

Fuel pumps are integral in transferring diesel, gasoline, jet fuel, and other hydrocarbon fluids, often under pressure, temperature, and sometimes corrosive or abrasive conditions. Malfunction or inefficiency in fuel pumps can lead to costly downtime, safety incidents, or regulatory noncompliance.

Key Responsibilities of a Fuel Pump Supplier in SG

A competent fuel pump supplier in SG should handle:

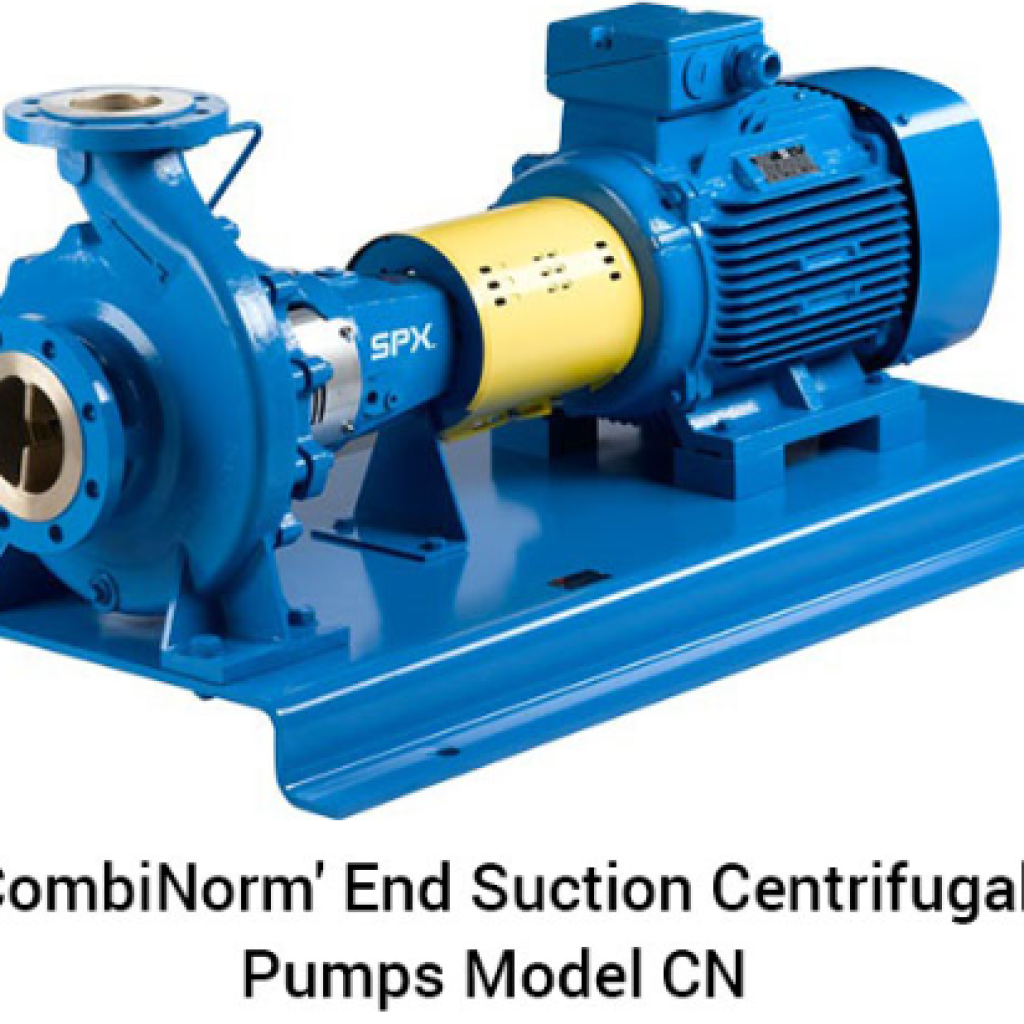

- Design and specification: Help customers select the proper pump types (e.g. gear pumps, vane pumps, centrifugal pumps, positive displacement pumps) based on fluid properties, flow/pressure requirements, suction conditions, and regulatory compliance.

- Manufacture and sourcing: Either manufacture in‑house or source high quality pumps and components.

- Customization: Design fuel skid packages, pump modules, enclosure systems, instrumentation and control integrations.

- Testing & validation: Perform performance tests (hydraulic curves, leakage, endurance) and ensure pumps meet safety and emission standards.

- Installation & commissioning: Provide site support, alignments, piping, connections, safety systems (venting, flame arrestors).

- After‑sales support: Provide maintenance, overhauls, spare parts, troubleshooting, and performance optimization.

- Regulatory support & compliance: Ensure adherence to local and international standards (e.g. explosion proofing, fuel safety standards).

All these tasks are hallmarks of a capable fuel pump supplier in SG rather than just a vendor.

Benefits of Working with a Local Fuel Pump Supplier in SG

Choosing a Singapore‑based fuel pump supplier in SG brings real advantages:

- Faster delivery times and lower logistics costs

- Local service teams for maintenance and emergency response

- Knowledge of Singapore’s regulatory and environmental norms

- Better coordination with engineers, on‑site teams, and integration with other systems

- Easier coordination for warranty, training, and system upgrades

Technical Considerations When Choosing a Fuel Pump Supplier in SG

When vetting a potential fuel pump supplier in SG, here are the crucial technical and commercial criteria to evaluate:

Fluid & Application Matching

- Fuel type & properties: Diesel, gasoline, biofuels, kerosene, jet fuel: viscosity, density, vapor pressure, temperature range.

- Operating conditions: Suction lift, discharge head, required flow rate, ambient temperature, pressure drop factors.

- Material compatibility: Corrosion resistance, sealing materials, temperature ratings.

- Filtration & cleanliness: Fuel contamination is a major risk; supplier should offer or integrate filters, strainers, and condition monitoring.

Pump Type & Design Choices

- Positive displacement vs centrifugal: For low flow high pressure, gear or vane pumps might be needed; for higher flow, centrifugal pumps are typical.

- Sealing and leak control: Mechanical seals, magnetic seals, gland packing, double seals—must be chosen based on fluid volatility and safety standards.

- Explosion proof / hazardous area design: For pumps in fuel environments (e.g. pump rooms, refueling stations), motors, controls, and enclosures must meet ATEX, IECEx, or other standards.

- Redundancy and safety features: Duplicate pumps, bypass lines, failover systems, overpressure protection.

Performance and Efficiency

- Pump curve matching: The supplier should provide performance curves and match pump operating points to the system’s duty point.

- Hydraulic efficiency: Higher efficiency reduces power draw and running cost.

- Minimum flow, NPSH (Net Positive Suction Head) margin: Avoid cavitation and ensure stable operation under variable conditions.

- Dynamic behavior: Start/stop cycles, transient behavior, and pulsations must be managed.

Integration, Controls, and Instrumentation

- Instrumentation: Flow meters, pressure gauges, temperature sensors, level sensors.

- Control logic: Integration with PLC, SCADA, alarm systems, remote monitoring.

- Pump skids or packaged systems: Pre-assembled modules with piping, valves, safety devices, wiring.

- Monitoring & diagnostics: Vibration sensors, condition monitoring, predictive maintenance capabilities.

Maintenance, Reliability & Lifecycle Services

- Spare parts support: Critical parts must be locally available to minimize downtime.

- Overhaul capability: The supplier should have workshops or partnerships for major maintenance.

- Service agreements: Annual maintenance, condition inspections, preventive maintenance.

- Performance reviews: The supplier should assist in performance audits, retrofits, or upgrades when necessary.

Standards, Safety & Compliance

- Certification & quality assurance: ISO 9001, relevant pump industry certifications.

- Fuel safety & handling codes: Compliance with petroleum regulations, fire codes, environmental regulations.

- Hazardous area equipment: Certification for electrical and mechanical equipment in explosive atmospheres.

- Documentation: Provide datasheets, test reports, safety manuals, operation manuals.

Why Flomek Is the Ideal Fuel Pump Supplier in SG

Given your partnership and engineering credentials, you are already well-aligned to leverage Flomek’s strengths. Below is how we present your positioning in this domain, which you can refine to your internal brand style.

Deep Engineering & Process Experience

Flomek is not merely a pump vendor — we embed engineering, process insight, and domain knowledge in every offering. We understand fluid dynamics, fuel chemistry, and system integration at a deep level. This allows us to act as a trusted fuel pump supplier in SG that adds value in design reviews, system optimizations, and troubleshooting.

Custom & Packaged Solutions

We offer turnkey fuel pump skid systems, modular pumping packages, integration with instrumentation and control logic, and customized mechanical design. As a fuel pump supplier in SG, providing packaged solutions reduces installation risk, site delays, and integration complexity.

Local Presence & Support

Flomek’s operations in Singapore ensure that we are locally present and responsive. As a fuel pump supplier in SG, we maintain inventories of critical spares, dispatch local service teams, and provide swift commissioning and maintenance support.

Quality Assurance & Testing

We perform rigorous hydraulics testing, performance verification, leak testing, and compliance checks to ensure every pump we supply as a fuel pump supplier in SG meets or exceeds expectations.

After‑Sales Service & Lifecycle Support

Operating as your long‑term fuel pump supplier in SG, Flomek provides scheduled maintenance, emergency repair, performance tuning, upgrades, and retrofits. We remain engaged across the asset lifecycle.

Safety & Compliance Focus

We rigorously adhere to fuel handling safety norms, explosion safety standards, and environmental compliance. As your fuel pump supplier in SG, we aim not just to supply but to ensure safe, certified, and legally compliant systems.

Cost Efficiency & Total Cost of Ownership

By optimizing design, choosing efficient motors, and reducing losses, we aim to minimize total lifecycle cost rather than just upfront cost. As your fuel pump supplier in SG, we help balance capital expenditure and operational savings.

Use Cases & Applications in Singapore

Let’s explore some of the major application verticals in which a fuel pump supplier in SG like Flomek can deliver value:

1. Marine, Ports & Offshore

Singapore’s status as a global port hub demands fuel systems for vessels, bunkering, and offshore operations. Fuel pumps here often must handle heavy fuel oil, gas oil, or blends, and integrate with vessel fueling, storage, or bunkering systems.

A fuel pump supplier in SG must manage vibration, marine environment corrosion, discharge pressures, filtration, and safety under marine standards.

2. Diesel Generator / Power Backup Systems

Data centers, hospitals, commercial buildings, and infrastructure often run diesel generators for backup. Fuel pump supply in SG must cover transfer pumps from fuel tanks, priming pumps, booster systems, and filtration.

A well‑engineered solution from a fuel pump supplier in SG ensures reliable starting and fuel supply, even under transient loads.

3. Fuel Storage & Distribution Terminals

Fuel terminals, depots, and distribution centers need high throughput pumps, blending systems, leak detection, safety systems, and instrumentation. A fuel pump supplier in SG in this domain is responsible not just for pump hardware, but system integration, safety interlocks, and regulatory compliance.

4. Industrial & Process Plants

Industrial customers such as petrochemical, chemical, manufacturing, and energy plants often have on-site fuel systems (e.g. for burners, furnaces). A fuel pump supplier in SG supports integration with process controls, safe handling, and system redundancy.

5. Mobile Refueling & Fuel Trucks

Fuel trucks, mobile refueling units, and remote refueling require compact, efficient, and robust fuel pumps. A specialist fuel pump supplier in SG can design and integrate mobile skid systems, meter systems, and safety controls.

Best Practices & Pitfalls in Fuel Pump Projects

To help ensure success in fuel pump projects, here are some best practices (and pitfalls to avoid) that a discerning customer should watch out for when dealing with a fuel pump supplier in SG.

Best Practices

- Detailed specification up front

Capture all duty points (min, normal, max), temperature ranges, suction conditions, and safety margins. - Conduct site surveys

Measure actual piping lengths, elevation changes, ambient conditions, hazards. - Select safety margins & redundancies

Avoid running pump at extremes continuously; include backup pumps or parallel units. - Instrumentation & monitoring

Integrate sensors (flow, pressure, vibration, temperature) and enable predictive maintenance. - Commissioning & fine tuning

Do full acceptance tests onsite, baseline performance, and adjust as needed. - Spare parts & service planning

Ensure supplier commits to spare part stocks, service turnaround time, and training. - Periodic review & retrofits

Fuel systems can benefit from periodic audits and upgrades over time.

Common Pitfalls / Risks

- Underestimating suction losses, poor NPSH margin → cavitation

- Oversizing pump leading to inefficient operation

- Inadequate sealing or incompatible materials leading to leaks

- Ignoring vibration or transient effects

- Inadequate support for control, monitoring, or alarm integration

- Lack of local service capability → long downtime

- Noncompliance with safety or fuel standards

A fuel pump supplier in SG that proactively addresses these risks is far more valuable than one offering only hardware.

Fuel Pump Supplier in SG: Your Partner for Reliable Fuel Handling

In Singapore’s competitive and regulated industrial landscape, the integrity of your fuel infrastructure is critical. That is why selecting a trusted fuel pump supplier in SG can be a key differentiator in operational uptime, safety, and cost efficiency. At Flomek, we bring engineering rigor, fuel system specialization, and local responsiveness to every project, making us your ideal fuel pump supplier in SG.

Why the Role of a Fuel Pump Supplier in SG Is Vital

Fuel is the lifeblood of many operations—power generation, marine propulsion, industrial heating, and backup systems. A fuel pump supplier in SG must ensure that fuel movement is accurate, safe, and continuous. Any failure in flow or pressure can cascade into operational failures. Hence, a supplier must offer not just pumps, but system-level expertise.

What a Fuel Pump Supplier in SG Should Offer

As a full‑service fuel pump supplier in SG, your partner must deliver:

- Design & specification services

A capable supplier assesses your system’s hydraulic needs, suction conditions, temperature, fluid properties, and safety margins, producing detailed pump and system specifications. - Pump supply & manufacturing

Whether sourcing or fabricating, the supplier must provide robust pumps suited for fuel applications—gear, vane, centrifugal, or custom designs. - Package & skid solutions

Prefabricated modules integrate pumps, piping, valves, and instrumentation. A fuel pump supplier in SG offering skids minimizes on‑site complexity and improves commissioning efficiency. - Instrumentation & control integration

Your supplier should offer flow meters, pressure sensors, level sensors, PLC/SCADA integration, remote monitoring, and diagnostics. - Testing & validation

Performance tests, leak checks, endurance runs, and compliance verification must be part of the offering. - Installation & commissioning

On-site support, alignment, piping, and functional testing must be covered to ensure smooth handover. - After‑sales support & lifecycle services

Maintenance, parts supply, periodic audits, and performance optimization round out the value proposition of a fuel pump supplier in SG. - Regulatory & safety compliance

The supplier ensures all equipment and systems meet local fuel safety regulations, explosion protection standards, and environmental norms.

By offering these services, a fuel pump supplier in SG becomes a strategic partner rather than a vendor.

Technical Foundations: What to Demand

When evaluating a fuel pump supplier in SG, insist on technical rigor:

- Accurate pump curve matching with head and flow margins

- Adequate NPSH margin to avoid cavitation

- Efficient design to minimize energy losses

- Proper sealing and leak control mechanisms

- Material compatibility with fuel chemistry

- Redundancy or safety bypasses

- Integration of sensors, alarms, and diagnostics

- Certified components for hazardous area usage

Only with solid technical foundations can a fuel pump supplier in SG deliver a solution that is reliable and durable.

Application Areas Where a Fuel Pump Supplier in SG Adds Value

Marine & Offshore Fuel Systems

Fuel supply in marine settings demands vibration tolerance, corrosion resistance, and compliance with marine safety codes. A specialist fuel pump supplier in SG must understand bunkering systems, vessel integration, and marine safety design.

Diesel Generator / Backup Fuel Supply

Data centers, hospitals, and essential infrastructure rely on diesel generators. A fault in the fuel pump chain can cost millions in downtime. A fuel pump supplier in SG must deliver high reliability, redundant systems, and fast support.

Fuel Depots & Terminal Pumps

Large throughput fuel terminals require high capacity pumps, leak detection, blending control, and safety systems. Here, a fuel pump supplier in SG integrates pumps into robust infrastructure.

Industrial Fuel Applications

Plants that use fuel in boilers, furnaces, or process heating depend on fuel pumps that integrate with process control. A fuel pump supplier in SG must design for control integration, transient response, and safe handling.

Mobile Fueling & Vehicle Pumps

For fuel trucks or on‑site refueling, compact yet powerful pumps are needed. A fuel pump supplier in SG capable of designing rugged skid units, control systems, and mobile integration is indispensable.

Why Flomek Stands Out as Your Fuel Pump Supplier in SG

At Flomek, our identity is not just pump sales — we are your engineering partner and lifecycle ally. Here’s how we deliver:

Engineered Excellence

We bring advanced fluid mechanics knowledge, fuel system design expertise, and domain experience. As a credible fuel pump supplier in SG, we contribute to your project’s technical architecture, not just supply parts.

Custom & Modular Solutions

We deliver tailor‑made fuel pump skid assemblies, modular designs, and scalable solutions. As your fuel pump supplier in SG, we adapt to your system scope and integration needs.

Local Singapore Presence

Being locally based in SG ensures response agility, shorter lead times, and alignment with local codes. As your fuel pump supplier in SG, you gain access to local inventory and support.

Commitment to Quality & Testing

Every unit we supply undergoes rigorous tests and quality assurance practices. A fuel pump supplier in SG under our banner ensures your fuel pumps perform reliably from day one.

Lifecycle Services & Support

We back your investment with maintenance, parts, retrofits, and upgrades. A fuel pump supplier in SG commitment must extend across the full lifecycle — and Flomek does just that.

Safety & Regulatory Compliance

We design for fuel safety, explosion protection, and environmental compliance. As your fuel pump supplier in SG, we ensure systems are safe by design, and regulatory aligned.

Cost Efficiency through Design Optimization

We help optimize pump sizing, minimize energy losses, and reduce operational cost. By selecting Flomek as your fuel pump supplier in SG, you get more than hardware — you get a performance partner.

How to Vet and Choose a Fuel Pump Supplier in SG

Here’s a checklist to help you evaluate a candidate fuel pump supplier in SG:

| Criteria | Why It Matters |

|---|---|

| Technical capability & design services | Ensures system integrity, not just product supply |

| Local support & spare parts | Critical for uptime in Singapore |

| Testing & certification capability | Validates performance and compliance |

| Integration & controls expertise | For instrumentation, SCADA, diagnostics |

| After‑sales and maintenance track record | For lifecycle reliability |

| Safety & regulatory compliance awareness | To meet fuel safety norms |

| Case histories / references | Real evidence of performance |

| Warranty and response commitments | To protect your investment |

By using this checklist, you can distinguish superficial vendors from a full‑service fuel pump supplier in SG.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply