Fuel Pump Service SG – Singapore’s No 1 Best Pump service & suplier

Fuel Pump Service SG — Flomek

If you’re looking for a trusted partner in Fuel Pump Service SG, Flomek is here to deliver. As a specialist in servicing, maintenance, overhaul, and supply of fuel pumps across Singapore, we combine technical expertise, regulatory compliance, and reliability to ensure your operations run smoothly. Below is a comprehensive overview of what Fuel Pump Service SG entails, why it matters, what features to expect, how Flomek delivers, and how you can get the best out of your fuel pump system.

Table of Contents

- What is “Fuel Pump Service SG”

- Why Fuel Pump Service SG is Critical in Singapore

- Key Components of Fuel Pump Service SG

- Common Types of Fuel Pumps & Their Service Needs

- Technical Specifications & Performance Metrics for Fuel Pump Service SG

- Best Practices in Installation & Commissioning under Fuel Pump Service SG

- Routine Maintenance, Overhaul & Fault Diagnostics in Fuel Pump Service SG

- Regulatory, Safety & Environmental Standards Relevant for Fuel Pump Service SG

- Challenges Unique to Fuel Pump Service SG in Singapore & How to Mitigate Them

- Innovations & Trends in Fuel Pump Service SG

- How Flomek Provides Premier Fuel Pump Service SG

- Value‑Proposition & Total Cost of Ownership in Fuel Pump Service SG

- Summary

1. What is “Fuel Pump Service SG”

Fuel Pump Service SG refers to the full spectrum of activities involved in keeping fuel pumps operating safely, reliably, and efficiently in Singapore. It includes:

- Inspection, diagnosis, cleaning, repair, and overhaul of fuel pumps

- Preventive maintenance to avoid unexpected breakdowns

- Installation, alignment, commissioning of new pumps

- Replacement of worn parts (seals, bearings, impellers, shafts)

- Monitoring performance metrics (flow, pressure, vibration, noise)

- Ensuring compliance with Singapore’s industrial, safety, environmental, and fire standards

When you engage Flomek for Fuel Pump Service SG, you get this complete lifecycle support. We are not just fixing problems — we help prevent them and optimize system performance.

2. Why Fuel Pump Service SG is Critical in Singapore

There are several reasons why proper and professional Fuel Pump Service SG is indispensable here:

- Reliability in tropical environment: High humidity, heat, and salt air (in coastal or marine settings) accelerate wear and corrosion. Regular servicing under Fuel Pump Service SG ensures that these environmental stresses don’t lead to failure.

- Safety: Fuel pumps deal with flammable liquids, pressures, electrical connections. Poor maintenance or installation could lead to leaks, fires, vapour hazards. Fuel Pump Service SG ensures safety protocols are observed.

- Regulatory compliance: Singapore has strict standards (e.g., for bunkering, fuel quality, environmental protection, explosion proofing). Fuel Pump Service SG providers need to know these, design and maintain to meet them.

- Operational continuity: In many industries — marine, oil & gas, backup generators, industrial plants — pump failure means downtime, financial loss, safety risk. Fuel Pump Service SG reduces unplanned downtime.

- Efficiency and cost savings: Pumps that are well serviced operate at higher efficiency, use less fuel or energy, avoid losses, and have longer lifespan. Fuel Pump Service SG helps reduce lifetime costs.

- Environmental responsibility: Leaks, inefficient pumping, vapour emissions, leakages — all have environmental cost. Good Fuel Pump Service SG helps minimize environmental footprint.

3. Key Components of Fuel Pump Service SG

A robust Fuel Pump Service SG consists of several components. Understanding these helps you know what to expect and what to ask for.

| Component | What It Involves |

|---|---|

| Inspection & Diagnostics | Checking pump body, seals, integrity, measuring flow rates, pressure drop, vibration, thermal behavior, alignment. |

| Preventive/Predictive Maintenance | Scheduled servicing, replacing wear parts before failure, monitoring trends (noise, temperature, vibration) to predict issues. |

| Repair & Overhaul | When parts have worn beyond tolerance — replacing mechanical seals, impellers, bearings, shafts, restoring casing, re‑coating. |

| Installation & Commissioning | Proper mounting, alignment, piping, electrical wiring, priming, leak testing, flow/pressure testing. |

| Performance Testing & Calibration | Verifying that pump delivers required flow and pressure under operational conditions; calibrating gauges, meters. |

| Spare Parts Supply & Upgrades | Quality of parts (seals, impellers etc.), compatibility with fuel types (including biofuels etc.), offering upgraded materials if needed. |

| Emergency Breakdown Service | Rapid response for failures, temporary solutions or replacement to minimize downtime under urgent situations. |

| Regulatory & Safety Compliance Services | Ensuring installation and service meet all safety standards, environmental regulations, fire codes, electrical codes etc. |

| Monitoring & Reporting | Logging performance, maintenance events, trends, alerts on deviations — helps for audits, guarantee, and planning. |

4. Common Types of Fuel Pumps & Their Service Needs

Different pump types have different service and maintenance needs. A complete Fuel Pump Service SG should be experienced across these types:

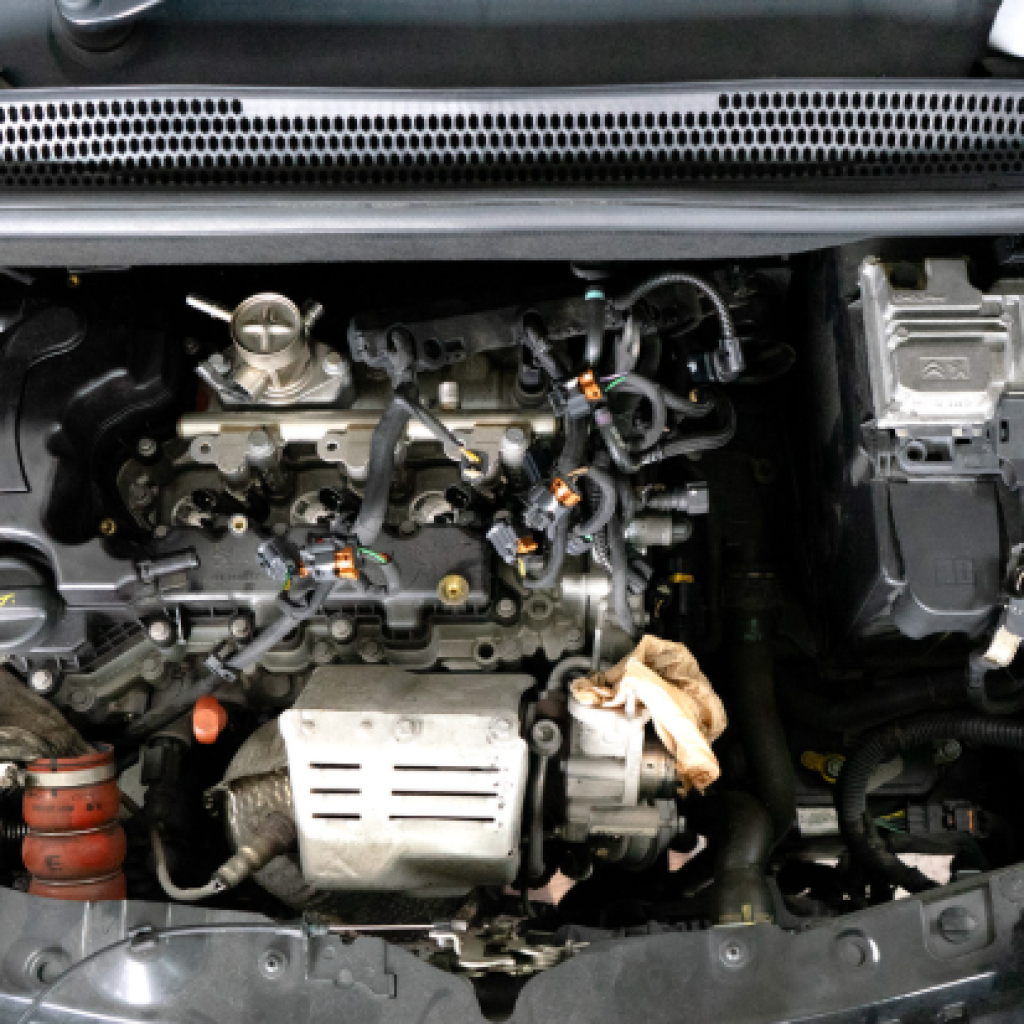

- In‑tank electric fuel pumps: Used in vehicles, station tanks. Service needs: checking wiring, corrosion at connectors, seal integrity, filter cleaning.

- External electric pumps: Often used for generators, industrial fuel supply. Service needs: motor maintenance, sealing, ensuring correct mounting and alignment.

- Centrifugal pumps: For fuel transfer, dispensing, bunkering. Service: impeller wear, casing erosion, monitoring flow/pressure drops, bearings.

- Positive displacement pumps (gear, screw, diaphragm): For precise flow, high pressure. Service needs: internal parts wear, seal leaks, calibration accuracy.

- Submersible pumps: Installed in fuel tanks. Unique service needs: ensuring seals are intact, preventing water ingress, corrosion, checking motor windings.

- Fuel injection pumps / diesel engine pumps: High precision, must deliver correct pressure and timing. Service: calibration, injector interface, timing, leak prevention, high pressure seals.

Understanding which type of pump your system uses is essential for choosing the right Fuel Pump Service SG.

5. Technical Specifications & Performance Metrics for Fuel Pump Service SG

When evaluating or specifying a Fuel Pump Service SG partner, these are the metrics and technical specs you should demand and monitor:

- Flow rate (volume per time): litres per hour or gallons per hour. The service must ensure actual delivered flow matches specification.

- Head / pressure: maximum pressure pump must deliver, and pressure losses in system (pipes, fittings). Service should test pressure under load.

- Power rating: motor KW, voltage, current draw. Monitoring power usage helps identify inefficiencies.

- Efficiency / Pump curves: how performance varies with flow vs head. Servicing should aim to keep pump operating near its best efficiency point.

- Vibration & noise levels: high vibration or noise often indicates misalignment or internal wear. Fuel Pump Service SG must include vibration measurement and correction.

- Temperature: motor and pump body temperatures under load; overheating indicates issues (bearings, lubrication, sealing).

- Material compatibility: materials of construction (MOC) should be compatible with fuel type (diesel, petrol, biofuels etc.), environment (salt air, humidity). Seals and lining material, casing, impeller, all matter.

- Sealing & leakage: mechanical seals, gaskets must prevent fuel leaks; small leaks have safety, environmental and performance costs.

- Electrical safety & protection: insulation, grounding, explosion proofing (if required), motor protection, overload protection.

- Response Time for Service: how quickly the service provider responds to breakdowns matters. Fuel Pump Service SG must include provisions for emergencies.

6. Best Practices in Installation & Commissioning under Fuel Pump Service SG

Even the best fuel pump fails if poorly installed. Flomek’s Fuel Pump Service SG follows best practices to ensure installation and commissioning go smoothly:

- Site assessment: understand environmental factors (temperature, humidity, exposure), fuel type, space, flow requirements.

- Correct alignment: alignment between pump shaft and motor shaft (laser alignment helps) to reduce vibration and wear.

- Proper piping and suction conditions: ensure inlet is free of obstructions, suction lift is minimized, pipe diameters correct.

- Priming and venting: avoid air locks, ensure pump is primed where needed, venting to prevent vapour lock.

- Electrical wiring & safety: ensure power supply matches pump/motor rating, proper protection, grounding, safety devices installed.

- Performance testing: After installation, test for flow, pressure, temperature, leakage, noise and vibration. Document test results.

- Commissioning checklist: verifying all connections, mechanical and electrical, verifying materials, checking safety and regulatory compliance.

- Training and documentation: operation manuals, preventive maintenance schedule, safety procedures.

7. Routine Maintenance, Overhaul & Fault Diagnostics in Fuel Pump Service SG

Maintaining fuel pumps in Singapore requires scheduled care plus prompt handling of faults. Here are best practices:

Routine Maintenance

- Inspect seals, gaskets, mechanical seals for leaks at regular intervals.

- Replace filters and strainers as needed.

- Lubricate bearings and moving parts.

- Check for corrosion, especially in humid or coastal locations.

- Monitor vibration and noise — base‑line vs follow‑up readings.

- Record motor current draw and temperatures.

- Clean combustion areas if fuel is combustion fuel or biofuel; remove deposits.

- Check fuel compatibility (blends, additive content)‑ related wear on materials or seals.

Overhaul

- When components reach wear limits: impeller erosion, shaft wear, casing damage.

- Remove, inspect, and either repair or replace worn parts.

- Re‑balance rotating parts.

- Replace mechanical seals, bearings.

- Reassemble with correct tolerances and alignment.

- Re‑coating or lining of parts that are corroded or worn.

Fault Diagnostics

- Low flow / pressure: likely causes—blocked inlet/filter, suction issues, worn internal parts, leaks.

- Noise/vibration: misalignment, worn bearings, cavitation, loose mounting.

- Leakages: check mechanical seals, sealing surfaces, gaskets, filler vents.

- Motor issues: check power supply, overheating, insulation, winding damage.

- Corrosion: examine material degradation, water ingress, salt exposure.

- Fuel contamination: water in fuel, particulates, microbial growth—these cause blockages and damage.

8. Regulatory, Safety & Environmental Standards Relevant for Fuel Pump Service SG

Since your operations are in Singapore, compliance with national standards is not optional. Key areas for Fuel Pump Service SG:

- Bunkering & fuel measurement standards: Singapore’s MPA Bunkering Standards, e.g. mass flow metering (SS648:2019), codes for bunker fuel quality and documentation.

- Material and equipment standards: International / regional standards like ISO, API, ASME, EN, JIS, DIN etc. Flomek follows standards like ASME B73.1, ISO 2858, ISO 5199 etc.

- Fire safety, electrical safety: Explosion proofing if handling flammables, proper wiring, grounding, fire suppression.

- Environmental regulations: NEA regulations on fuel spills, emissions, waste disposal.

- Marine regulations: for fuel pumps used in bunkering or vessel operations, rules under MPA.

- Standards for fuel injection pump components: materials, marking etc., e.g. standards for fuel system components for vehicles and LPG etc.

- Quality control and documenting service: For audit, regulatory, insurance purposes, maintenance logs, inspection reports etc.

9. Challenges Unique to Fuel Pump Service SG in Singapore & How to Mitigate Them

Singapore has unique environmental, regulatory, and operational conditions. Fuel Pump Service SG must address them.

| Challenge | Why It Matters | Mitigation Strategy |

|---|---|---|

| High humidity, salt air, corrosion | Accelerated wear, rusting of metal parts, seals degrading | Use corrosion‑resistant materials (stainless steels, duplex, etc.), protective coatings, regular inspections, proper housing of pumps. |

| Compact installation spaces, urban constraints | Limited room for large external pumps; noise & vibration can affect nearby structures | Use compact designs, in‑tank or close coupled pumps; vibration dampening; acoustic enclosures; proper alignment to minimize noise. |

| Fuel type variability and biofuel blends | Some fuels with additives or blends are more aggressive, degrade seals or materials | Use materials and seals compatible with such fuels; specify fuel‑type in servicing; plan for more frequent maintenance if needed. |

| Regulatory compliance & permit delays | Failure to comply can lead to fines, delays, shutdowns | Work with experienced service providers familiar with local codes; ensure documentation; use certified parts. |

| Unpredictable power supply issues, or RPM stability | Affects motor & pump longevity | Use stabilised electrical supply, motor protection, proper installation. |

| Emergency breakdowns with high cost | Downtime, operational losses | Keep spare parts inventory; provide emergency response service; preventive maintenance. |

10. Innovations & Trends in Fuel Pump Service SG

To stay ahead and deliver better Fuel Pump Service SG, providers and clients can adopt these innovations:

- IoT & remote monitoring of pumps: sensors to track vibration, temperature, flow → predictive maintenance.

- Variable Speed Drives (VSDs) to adjust pump motor speed to demand, saving energy.

- Better materials & advanced sealing technologies, especially for biofuel compatibility and resistance to corrosion.

- Advanced diagnostics tools — thermal imaging, ultrasonic testing, laser alignment tools.

- Eco‑friendly practices: leak detection, spill containment, energy efficient motors, waste oil handling, more efficient pump designs.

- Digital documentation & reporting: maintenance logs, trend charts, digital dashboards.

11. How Flomek Provides Premier Fuel Pump Service SG

Here’s how Flomek ensures its Fuel Pump Service SG is top‑tier across Singapore:

- Wide capacity and standards coverage: Flomek services pump sizes from 1 kW to 250 kW, and follows standards such as ASME B73.1, ISO 2858, ISO 5199, API610, EN733, DIN, JIS.

- Material expertise: Offering multiple materials of construction (SS304, SS316, SS316L, Duplex & Super Duplex Steel) plus various lining options (FRP, PP, PTFE etc.) to suit fuel types and environmental exposure.

- Comprehensive services: Flomek handles leak repairs (mechanical seals), bearing replacements, impeller maintenance, shaft replacement, oil change, full overhauls.

- Alignment & vibration control: Laser alignment services, precise alignment between motor and pump shafts to reduce wear and noise.

- Experienced technical team: Skilled in diagnostics, fault detection, performance testing, repair.

- Regulatory familiarity: Knowledge of Singapore’s regulatory environment, safety & environmental standards, bunkering standards etc.

- Rapid response & emergency service: Minimizing downtime by having spare parts, on‑site service, and scheduled maintenance.

- Performance optimization: Regular testing, monitoring, proactive replacement of wear parts ensures pump runs near designed performance.

12. Value‑Proposition & Total Cost of Ownership in Fuel Pump Service SG

When considering Fuel Pump Service SG, total cost over time is as important as upfront cost. Flomek helps clients understand value in these terms:

- Initial investment: Pump supply cost (if applicable), installation cost, commissioning.

- Service and maintenance costs: parts, labor, preventative work.

- Downtime and loss: unplanned shutdowns are expensive. Good service reduces risk.

- Energy / fuel loss: inefficient pumps or ones operating off‑curve consume more power / fuel.

- Life span: With regular service, quality materials, correct operation, pumps last much longer — meaning fewer replacements.

- Environmental / safety risk costs: Leaks, spills, regulatory noncompliance can lead to fines, remediation costs, reputational damage.

By investing in rigorous Fuel Pump Service SG, clients often see payback in lower maintenance, fewer failures, more consistent operation, and lower overall expenses.

14. Deep Regulatory & Standardization Detail for Fuel Pump Service SG in Singapore

To provide top‑level Fuel Pump Service SG, understanding and aligning with relevant Singapore standards is vital:

- MPA Bunkering Standards: Singapore’s Maritime & Port Authority requires compliance with SS648:2019 (Mass Flow Metering for bunkers), SS524:2021 (Quality Management for Bunker Supply Chain) and SS600:2022 (Code Practice for Bunkering). These affect fuel pump equipment used in marine bunkering and fuel supply operations.

- Singapore Standards for Fuel Systems: There are technical references/standards like ISO 20766‑8:2023 for LPG fuel system components including requirements for fuel pumps.

- Fuel Injector and Fuel Connection Standards: For example, ISO 13948‑2:2024 covers fuel injection pumps and injector low‑pressure connections (push‑on types) to ensure sealing and safety. This is relevant in Fuel Pump Service SG when servicing or replacing injection pump components.

- Quality Management & Documentation: Fuel pump service providers should keep accurate logs, service reports, parts certification to satisfy regulatory and operational auditing. This is especially critical in marine, oil & gas, and bunkering where traceability, fuel quality, and safety are heavily governed.

Aligning with these gives confidence to clients and regulators, and helps avoid legal, safety, or environmental risks.

15. Common Failure Modes & Diagnostics Specific to Fuel Pump Service SG

To market sophisticated service, including problem‑diagnosis, here are common failure modes in fuel pump systems in Singapore, typical symptoms, and diagnostics strategies:

| Failure Mode | Typical Symptoms | Diagnostic Steps |

|---|---|---|

| Contaminated Fuel / Particulates | Filter clogging, reduced flow, pump noise, erratic pressure, overheating | Check and analyse fuel filters; test fuel for particulates (micron size); isolate sections and clean or replace pre‑filters; use hot filters for marine fuel systems. |

| Water / Moisture Ingress | Corrosion, seal failure, sludge in pump, poor lubrication, cavitation | Inspect fuel tanks for water; check for leaks; design moisture separators; perform regular draining of water holding sections; inspect mechanical seals and casing. |

| Mechanical Wear (Impeller / Bearings / Shaft Misalignment) | Vibration, noise, reduction in pressure/flow, overheating, possible seizures | Use vibration analysis; inspect bearings; measure shaft alignment with laser tools; inspect impeller vanes for wear or erosion; monitor temperature rises. |

| Seal / O‑Ring Deterioration | Visible leaks, odours, drop in performance, external fuel smell | Examine seals’ material compatibility with fuel blends; inspect under load; replace worn seals; verify sealing surfaces. |

| Dry Running or Low Fuel Level | Pump running but no flow, overheating, temporary failure, noise | Ensure reliable fuel supply / priming; avoid low tank levels; use sensors or float switches; include design to prevent suction lift issues. |

| Electrical Problems (Wiring / Motor / Voltage Issues) | Motor overheating, inconsistent speed, intermittent operation, short circuits | Test voltage supply; check wiring insulation; ensure motor protection (thermal, overload); examine motor windings; examine power quality. |

| Fuel Volatility & Vapor Lock | Engine stuttering, failure at hot ambient temperature, hard starting, poor performance | Vent systems properly; keep suction lines short; avoid high ambient exposure; ensure fuel pump service includes vapor control; prime and bleed lines as needed. |

By including diagnostic checklists like these in your Fuel Pump Service SG content, you show expertise and help clients anticipate problems.

16. Sector‑Specific Challenges & Considerations in Fuel Pump Service SG

Different sectors in Singapore impose different demands; being explicit shows depth.

Marine & Bunkering

- Fuel quality control (e.g. cat fines, sulfur limits, water content) is critical. High levels of particulates or impurities damage fuel pumps.

- Materials must resist salt corrosion, vibration from ship movement.

- Mass flow metering requirements: pumps used in bunkering operations may need to interface with or comply with meters and equipment defined in SS648.

- Rapid response and exchange spares are often needed when ships are docked to avoid operational delays.

Industrial & Generation Plants

- Continuous duty cycles, high load variations require pumps rated for endurance.

- Fuel supply line integrity: filtering, water separation, thermal control.

- Electrical stability: fluctuating voltage or supply issues may cause premature pump motor failure.

Automotive / Road Transport Fleet

- For fuel pump service related to vehicle fuel pumps, issues like regulatory fuel standards, contamination, unreliable fuel station quality may play a bigger role.

- Diagnosing performance drop, misfires, fuel consumption spikes related to pump inefficiencies.

Remote or Offshore Installations

- Accessibility becomes critical: transporting spare parts, performing maintenance is more complex.

- Environmental exposure (salt water, wind, temperature extremes) increases corrosion, seal wear.

- Predictive / remote monitoring becomes more valuable to avoid downtime.

17. Preventive Measures & Best Maintenance Intervals in Fuel Pump Service SG

To position Flomek as proactive and disciplined, you can include recommended maintenance intervals and preventive practices:

| Component / Area | Recommended Maintenance Interval | Preventive Measures |

|---|---|---|

| Fuel Filters & Pre‑Filters | Every 3‑6 months (or as per usage) | Use fine mesh filters; inspect frequently; replace before clogging causes strain |

| Mechanical Seals & O‑Rings | Yearly or after certain operational hours / per fuel type | Use correct seal materials; inspect for wear, replace before leakage develops |

| Pump Bearings & Impellers | Bi‑annually or every X operating hours | Lubrication where applicable; inspect for wear or imbalance; use vibration monitoring |

| Electrical Connections & Wiring | Every 6 months | Ensure tight connections; check insulation; detect corrosion; test for proper voltage |

| Performance Testing (flow/pressure) | Every 6‑12 months | Test under load; compare with baseline; detect early drops in performance |

| Alignment & Mounting | At installation & after any service; check annually | Use proper alignment tools; ensure mount is stable; correct for vibration and shifts |

| Clean & Corrosion Control | Every maintenance session | Clean external housing; protect from moisture; apply anti‑corrosion coatings; environmental sealing |

These guidelines reinforce that Fuel Pump Service SG is not just reactive, but structured and predictable.

18. Strategic Planning, Spare Parts & Stocking for Fuel Pump Service SG

To provide high‑quality service, supply of spare parts and strategic stocking are critical:

- Maintain inventory of critical wear parts: mechanical seals, gaskets, bearings, impellers, shafts. Enables fast turnaround.

- Use parts with compatible specifications and materials; avoid generic low‑quality substitutes.

- Maintain logs of parts usage, failure rates to predict which parts require frequent replacement.

- For pumps under warranty or in high‑demand systems, consider spare pumps or modular assemblies to reduce downtime.

- Ensure spares meet required standards and certifications.

19. Cost‑Benefit Narratives & ROI to Include in Fuel Pump Service SG Content

Including cost‑benefit / ROI narratives helps potential clients see value. Some illustrative calculation ideas:

- Reduced fuel/energy cost: show how an inefficient pump consuming more power or running off its best curve can increase energy use; regular service attunes performance to efficiency.

- Avoided downtime cost: for industrial/manufacturing / marine operations, even short downtimes cost heavily; total cost saved by preventive maintenance vs emergency breakdowns.

- Longer equipment life: Replacement pumps are expensive; extending lifespan by servicing adds value.

- Regulatory risk avoidance: Fines, insurance cost, reputational damage if equipment and operations not compliant.

- Environmental cost savings: Less fuel leakage, less waste, less emissions help with corporate sustainability goals.

You can frame case‑studies (hypothetical or anonymized) such as: “A generator system whose fuel pump was serviced twice a year had a reduction of energy consumption by X% and saved SGD Y over Z years.”

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply