Fuel Pump Service and Supplier SG – Singapore’s No 1 Best Pump service & suplier

Fuel Pump Service and Supplier SG — Flomek

When you need reliable Fuel Pump Service and Supplier SG, Flomek delivers. As a trusted service provider and supplier in Singapore, we cover everything from supply, installation, maintenance, to overhaul of fuel pumps for diverse industries. This page explains what Fuel Pump Service and Supplier SG means in practice, why it matters, what the features are, and how Flomek stands out as your ideal partner.

Table of Contents

- What “Fuel Pump Service and Supplier SG” Means

- Why Choose a Proper Fuel Pump Service and Supplier SG

- Types of Fuel Pumps that Suppliers and Service Providers in SG Handle

- Key Features & Specifications to Expect from a Fuel Pump Service and Supplier SG

- Applications of Fuel Pump Service and Supplier SG in Singapore

- Installation, Testing & Commissioning in Fuel Pump Service and Supplier SG

- Maintenance, Overhaul & Repairs in Fuel Pump Service and Supplier SG

- Standards, Regulations & Compliance in Singapore for Fuel Pump Service and Supplier SG

- Cost, Lifecycle & Value Proposition of Fuel Pump Service and Supplier SG

- How Flomek Performs as Your Fuel Pump Service and Supplier SG

- Future Trends & Innovations for Fuel Pump Service and Supplier SG

- Summary

1. What “Fuel Pump Service and Supplier SG” Means

“Fuel Pump Service and Supplier SG” describes the combined role of providing fuel pumps (supply) and performing service work (installation, maintenance, repair, overhaul) for fuel pumps in Singapore. In essence, when you search for Fuel Pump Service and Supplier SG, you want a partner who not only sells good quality fuel pumps, but also:

- ensures the pump is properly installed and commissioned

- offers regular maintenance, spare parts, repair & overhaul

- responds quickly when failures occur

- ensures compliance with Singapore’s safety, environmental, and industry standards

In many sectors — automotive, marine, industrial, energy — having a single vendor who can supply and service fuel pumps mitigates delays, ensures compatibility, and reduces total cost of ownership. Flomek plays exactly this dual role: we are both a Fuel Pump Service and Supplier SG.

2. Why Choose a Proper Fuel Pump Service and Supplier SG

Choosing the right Fuel Pump Service and Supplier SG matters for many reasons:

- Reliability and uptime: A pump failure at critical times (marine operations, emergency generators, industrial processes) causes huge losses. A good service supplier ensures reliable performance.

- Safety: Improper installation, weak materials, or substandard service can lead to fuel leaks, fires, environmental hazards. A competent Fuel Pump Service and Supplier SG ensures safety protocols are upheld.

- Efficiency: Fuel pumps that are not serviced regularly or that are of poor quality consume more energy, deliver less flow, and cost more in fuel, repair, or downtime.

- Compliance: Singapore has strict codes (electrical, environmental, fire safety, fuel handling). A proper Fuel Pump Service and Supplier SG will ensure that installations and supplies meet regulatory standards.

- Cost effectiveness: Upfront cost is only part of the picture. Over the lifecycle, spare parts cost, maintenance cost, downtime cost, and efficiency losses matter. Good service & supply reduce total cost.

3. Types of Fuel Pumps that Suppliers and Service Providers in SG Handle

A comprehensive Fuel Pump Service and Supplier SG should cover a wide range of fuel pump types. Flomek supplies and services many of them, including:

- Electric fuel pumps (in‑tank, external)

- Mechanical fuel pumps

- Centrifugal pumps for fuel transfer and dispensing

- Positive displacement pumps (gear pumps, diaphragm pumps, piston pumps)

- Submersible fuel pumps for large storage tanks or marine applications

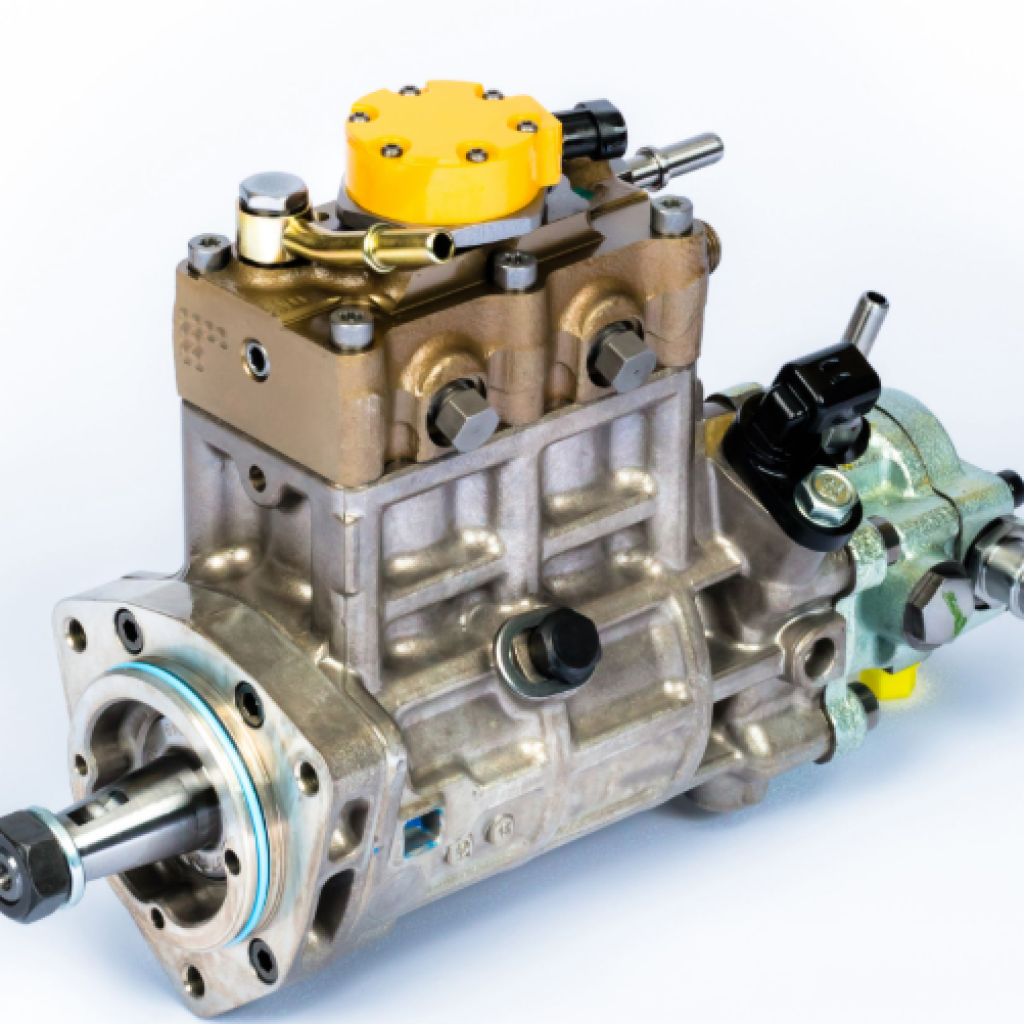

- Fuel injection pumps for diesel engines or generator sets

Each type has different use cases, pressure requirements, compatibility issues, and maintenance needs. A good Fuel Pump Service and Supplier SG will have experience across these to match your precise application.

4. Key Features & Specifications to Expect from a Fuel Pump Service and Supplier SG

When evaluating potential vendors, you should check whether they meet or provide the following in their Fuel Pump Service and Supplier SG offering:

| Feature / Spec | Why It Is Important |

|---|---|

| Flow rate / capacity (litres per hour, gallons per hour) | Ensures required volume of fuel delivery; avoids under‑supply which affects equipment performance. |

| Pressure handling (psi or bar) | Especially for fuel injection, or long pump lines, or high elevation / head situations. |

| Material of Construction (MOC) | Compatibility with fuel type (diesel, petrol, biodiesel, marine fuel), resistance to corrosion (especially in marine/salt‑air), durability. |

| Seal, lining, O‑ring materials | Resistance to chemical degradation, temperature, leak prevention. |

| Power type, voltage, motor spec | Ensures compatibility with local power supply; safety in wiring and electrical standards. |

| Safety features: explosion proof motors, leakage detection, thermal protection | Essential, especially where fuel vapour or unstable environment is involved. |

| Noise and vibration control | For operator comfort, safety, and longevity of pump. |

| Installation adaptability: mounting, size, in‑tank vs external | Site constraints matter; easy integration reduces installation costs. |

| Spare parts supply & service capability | Minimises downtime; parts must be available locally or quickly. |

| Testing, commissioning, alignment | Ensures pump operates as per spec from day one. |

| Compliance with local regulations & standard codes | Fire codes, environmental, marine, industrial, electrical safety, etc. |

A strong Fuel Pump Service and Supplier SG will provide full spec sheets, material certifications, drawings, and be able to guide you on what’s best for your scenario.

5. Applications of Fuel Pump Service and Supplier SG in Singapore

Singapore hosts a wide variety of industries and operations where fuel pumps are used and where a good Fuel Pump Service and Supplier SG is critical. Examples include:

- Generators & Backup Power Systems: In buildings, hospitals, data centres, infrastructure, requiring reliable diesel fuel pump supply & service to ensure no interruptions.

- Marine / Offshore / Bunkering: Ships docking, fuel transfer, bunkering operations; high stakes in safety, metering, precision.

- Industrial Plants & Refineries: Fuel heating, burning, chemical processing etc. Fuel Pump Service and Supplier SG must support heavy‑duty pumps, large flows, high reliability.

- Oil & Gas / Petrochemicals: Fuel handling, treating, distribution—these require high standards.

- Automotive & Transport Fleets: Diesel vehicles, petrol vehicles, requiring fuel injection pump supply & service.

- Construction Sites, Remote Installations: Fuel storage, pumping in remote or harsh environments.

Because each application has its own demands (flow, pressure, environment, fuel type), working with an experienced Fuel Pump Service and Supplier SG helps you avoid mismatches or failures.

6. Installation, Testing & Commissioning in Fuel Pump Service and Supplier SG

Supplying a pump is only part of the job. A complete Fuel Pump Service and Supplier SG must also handle installation, testing, and commissioning. Key points here:

- Proper alignment of pump to motor, minimising vibration, ensuring mechanical integrity.

- Pre‑installation inspection: checking materials, seals, piping, connections.

- Verification of electrical supply, grounding, cable sizing, overload protection.

- Pressure and flow tests: ensuring pump delivers expected flow and pressure under load.

- Leak testing, safety spill prevention, containment if needed.

- Noise, vibration testing to ensure tolerances are within acceptable limits.

- Control systems calibration, interlocks, gauges.

- Starting‑up under safe conditions, priming if needed.

Flomek’s pump testing and commissioning efforts ensure that supplied pumps start and operate correctly from day one, minimising early failures and ensuring warranty coverage.

7. Maintenance, Overhaul & Repairs in Fuel Pump Service and Supplier SG

Once installed, a pump requires regular service. A reliable Fuel Pump Service and Supplier SG will offer:

- Scheduled preventive maintenance: lubrication, seal replacement, cleaning, performance checks.

- Overhauls: when internal parts (bearings, impellers, shafts, mechanical seals) wear. Full dismantle and rebuild.

- Troubleshooting: diagnosing causes of failure such as cavitation, vibration, leaks, low flow, overheating.

- Spare parts supply: seals, bearings, impellers, shafts, motors etc.

- Upgrades or retrofits: perhaps better materials for fuel compatibility, improved safety, or newer pump technology.

Good service reduces downtime, extends pump lifetime, keeps efficiency high.

8. Standards, Regulations & Compliance in Singapore for Fuel Pump Service and Supplier SG

Singapore has a robust regulatory framework. Any serious Fuel Pump Service and Supplier SG must ensure compliance with these:

- Bunkering Standards: Standards like SS648 (mass flow metering), SS524 (Quality Management for Bunker Supply Chain), SS600:2022 (Code Practice for Bunkering) under MPA.

- Alternative Fuel Standards: Singapore is developing standards (methanol, ammonia, hydrogen refuelling etc.) to regulate safe fuel delivery.

- Industry Standards for Pumps: ASME, ISO, API etc., depending on pump type. These might cover pump design, manufacturing, safety. Flomek, for example, already follows multiple standards in its pump services.

- Environmental & Safety Regulations: Fuel spill prevention, emissions, leak detection. Fire safety codes, electrical codes.

- Testing & Commissioning Regulations: For e.g. installations in water systems, high‑rise buildings, marine facilities etc. local bodies like PUB, SCDF, BCA may have requirements.

Complying with these ensures legal safety, permits, and reduces risks.

9. Cost, Lifecycle & Value Proposition of Fuel Pump Service and Supplier SG

Understanding cost over time is crucial:

- Initial Cost: Purchase cost, installation cost, civil work, site preparation.

- Operational Cost: Power consumption, fuel loss due to inefficiency or leaks, maintenance labor.

- Maintenance & Repair Cost: Spare parts, downtime costs.

- Downtime or Failure Cost: Depending on how critical the pump is, downtime can be very expensive (lost production, emergency services).

- Resale or Salvage Value: Quality of materials, modularity may retain value.

A good Fuel Pump Service and Supplier SG will help you choose solutions that optimize this cost‑benefit ratio: sometimes paying more for a higher grade material or better pump pays off in savings later.

10. How Flomek Performs as Your Fuel Pump Service and Supplier SG

Here’s how Flomek distinguishes itself when you engage us as your Fuel Pump Service and Supplier SG:

- Full spectrum supply + service: We supply fuel pumps of various types, and also provide full service: installation, maintenance, overhaul.

- Standards adherence & certifications: Our pump supply and service operations meet international and local standards. (MOC options like SS304, SS316, Duplex etc; adherence to ASME / ISO / API etc in services). Flomek Singapore Private Limited

- High capacity range: Pumps and motors from small to large (e.g. up to 250 kW in Flomek’s scope). Flomek Singapore Private Limited

- Experienced technical team: Skilled in mechanical seals, impellers, shafts, bearings, alignment, vibration control, etc.

- Materials & customization: We offer various materials of construction to suit fuel types and environments.

- Testing & commissioning expertise: We provide pump testing and commissioning for performance validation. Flomek Singapore Private Limited

- Quick response & spare parts: Because we are both supplier and service provider, spare parts and repair resources are better integrated, leading to faster turnaround.

As your Fuel Pump Service and Supplier SG, Flomek offers a comprehensive, integrated solutions approach.

11. Future Trends & Innovations for Fuel Pump Service and Supplier SG

To stay ahead, a Fuel Pump Service and Supplier SG needs to adopt emerging technologies and trends:

- IoT & Remote Monitoring: Real‑time monitoring of flow, pressure, vibration; predictive maintenance.

- Energy‑efficient motors and variable speed drives to reduce power consumption.

- Materials science advances: fuel‑compatible sealants; corrosion resistant materials; coatings; better lubrication reducing wear.

- Alternative fuels adaptation: Preparing for biofuels, hydrogen, etc., with pumps and components that are compatible.

- Automation & safety enhancements: automatic shutdowns; leak detection; remote control & diagnostics.

- Mass flow metering and digital bunkering documentation for marine fuel supply chain.

13. Local Context & Market Dynamics in Singapore for Fuel Pump Service and Supplier SG

Understanding Singapore’s local environment is key when you are looking for a strong Fuel Pump Service and Supplier SG. Here are features of the market, demands, constraints, and what customers typically expect.

Climate & Environment Considerations

- Singapore has a tropical climate: high humidity, frequent rain, hot temperatures, and occasionally exposure to salt air (especially in marine or coastal locations). A Fuel Pump Service and Supplier SG must supply pumps and maintain them in ways that prevent corrosion, rust and deterioration of seals and metals.

- Frequent rainfall and occasional flooding in low‑lying areas mean that pumps often face moisture, water ingress, or need protection from high water tables. The materials of construction, sealing, and installation methods must account for this.

Land & Space Constraints

- Singapore’s dense urban environment often means tight spaces for installation. External pump units or large skid‑mounted pumps may need to be adapted. A good Fuel Pump Service and Supplier SG must offer compact, modular, or in‑tank solutions.

- Height constraints (if pumps are installed in basement or rooftop) or noise constraints (residential zones, near housing) affect pump selection and installation methods.

Regulatory & Safety Requirements

- Strict safety regulations in terms of fire safety, environmental protection, storage of flammable liquids. Authorities like SCDF (Singapore Civil Defence Force), NEA (National Environment Agency) enforce codes. A Fuel Pump Service and Supplier SG must ensure compliance with relevant codes for explosion proofing, venting, spill containment, etc.

- Standards for pumps and components: customers often expect certifications (ASME, ISO, API, etc.). Flomek already follows multiple standards in its pump service business. Flomek Singapore Private Limited

- Environmental reporting, permits, inspections may be required if fuel storage or dispensing is above certain thresholds.

Demand from Industries

- Many sectors in Singapore need robust fuel pump systems: marine (as Singapore is a major bunkering hub), oil & gas, industrial manufacturing, power generation, data centres, infrastructure, construction.

- Reliability is critical: downtime can mean high cost (e.g. in marine operations, emergency generator systems, industrial process).

- There is rising demand for energy efficiency, sustainability, and predictive maintenance.

14. Innovations & Emerging Technologies Impacting Fuel Pump Service and Supplier SG

To stay competitive, a Fuel Pump Service and Supplier SG should keep up with innovations. Here are some key technological trends and how they affect service & supply:

Predictive Maintenance & Condition Monitoring

- Use of IoT sensors on pumps to monitor vibration, temperature, pressure, flow rate. These data can be analyzed to detect problems early: e.g. when bearings are wearing out, shaft misalignment, cavitation risk.

- Remote monitoring allows service provider to plan maintenance rather than wait for breakdowns. As a Fuel Pump Service and Supplier SG, offering remote diagnostics gives you an edge.

Variable Speed Drives & Energy Savings

- Installing Variable Speed Drives (VSDs) so pump motors run at speeds matching demand, rather than running full speed constantly. Saves energy (electricity), reduces stress on mechanical parts, lowers wear‑and‑tear.

- Pump efficiency: pumps sized appropriately for demand, avoiding oversizing. Oversized pumps operate inefficiently. A good supplier and service provider ensures correct sizing.

Advanced Materials & Seal Technologies

- Better materials (super duplex steel, advanced stainless steels, specialty alloys) that resist corrosion from fuel, humidity, salt air, and aggressive fuel additives.

- Modern sealing technologies: mechanical seals capable of handling high temperature, higher pressures, and compatibility with blended fuels or biofuels.

- Coatings and linings (e.g. PTFE, FRP, rubber linings) inside pumps to resist wear, corrosion, and chemical attack.

Smart Controls & Automation

- Automatic safety interlocks: shutdowns if detecting abnormal vibration, reverse flow, overheating, or leakage.

- Integration with building management systems or industrial control systems (SCADA). That means pump service and supply SG providers must be able to supply and maintain instrumentation and controls as part of the system.

Sustainability & Alternative Fuels

- As global shift to cleaner fuels, demand may rise for pumps compatible with bio‑diesel blends, possibly bio‑LNG, hydrogen in future. A Fuel Pump Service and Supplier SG that anticipates compatibility is well positioned.

- Eco‑friendly designs: better efficiency, minimal leakage, lower emissions, recyclable materials.

- Waste reduction in maintenance: longer service intervals, modular parts, remanufacturing of parts.

15. Deep Dive: Technical Best Practices for Fuel Pump Service and Supplier SG

Below are technical best practices that distinguish good service + supply; content useful for both your customers and to boost SEO, because it addresses detailed client concerns.

Selection & Sizing Best Practices

- Calculating required flow rate: consider peak demand, duty cycle, safety margin. Avoid undersizing (which can starve systems) or oversizing (wasting energy).

- Calculating head pressure: including static head, friction losses in pipes, elevation differences, losses from filters, bends.

- Choose pump type (centrifugal vs positive displacement etc.) based on fluid properties (viscosity, temperature, presence of solids, gas content). For fuels, special care: fuels have certain volatility, risk of vapor lock.

- Material selection: for fuels with additives, blended fuels, or fuel with ethanol content, choose materials that resist attack and avoid swelling or sealing issues.

Installation Best Practices

- Correct alignment and mounting: misalignment causes vibration, seal failures.

- Proper inlet/outlet pipe sizing: avoid suction cavitation, ensure smooth flow.

- Vibration isolation: mount on foundations that reduce resonances; use dampers if necessary.

- Electrical installations: safe wiring, grounding, explosion‑proof components if required.

- Protection from external environment: weather, temperature, salt air, moisture.

- Priming and leak checking before full operation.

Maintenance Best Practices

- Scheduled maintenance plan: periodic checks of seals, bearings, lubrication, filters.

- Cleaning of filters and strainer, checking for clogs or contaminant ingress.

- Regularly checking performance: flow/pressure tests to measure drop in efficiency or capacity.

- Monitoring vibration/noise/harmonics to detect early mechanical issues.

- Keeping fuel in tanks clean: water contamination, microbial growth (especially in diesel) must be avoided.

- Replacement of wear parts on schedule or based on condition.

- Documenting all maintenance and incidents.

Overhaul & Repair Best Practices

- Disassembly: clean, inspect all internal parts (impellers, shafts, casing, sealing surfaces).

- Non-destructive testing when applicable (e.g. for cracks, corrosion, erosion).

- Replacing or refurbishing worn parts. Using OEM or equivalent quality components.

- Testing after repair: flow, pressure, leakage, vibration, temperature under load.

- Recommissioning with correct alignment and safety tests.

16. Case Scenarios & Use Case Examples for Fuel Pump Service and Supplier SG

These help illustrate how Flomek could position itself in various situations.

Use Case A: Marine Bunkering Operations

- Requirement: large flow fuel transfer, accurate metering, safety to avoid spill, explosion risks, corrosion from salt air, robust materials.

- How a Fuel Pump Service and Supplier SG works: supply positive displacement or screw pumps with marine specification; provide routine maintenance even while vessel docked; ensure seals and materials are marine‑grade; install automatic shutoff valves and overflow protection.

Use Case B: Backup Generator Systems in Healthcare

- Requirement: fuel pump service for diesel fuel pumps which may run rarely but must always work; failure not option.

- Approach: high reliability pumps; preventive maintenance; test runs; standby components; fast response times; monitoring systems to detect when pump is idle too long or has issues.

Use Case C: Fuel Dispensing for Industrial Fleet or Remote Site

- Requirement: remote location, variable load, possible coarse fuel quality.

- Approach: supply rugged pump units; filtration systems; fuel compatibility features; remote monitoring; emergency repair service.

17. Challenges Faced by Fuel Pump Service and Supplier SG & Mitigation Strategies

Knowing challenges helps you write content that shows you understand client pain points and how Flomek solves them.

| Challenge | Why It Matters | How a Good Fuel Pump Service and Supplier SG Overcomes It |

|---|---|---|

| Corrosion and chemical damage due to fuel additives, moisture, salt air | Pumps degrade, leaks happen, performance drops | Use corrosion‑resistant materials; good sealing; regular inspections; protective coatings |

| Fuel contamination (water, particulates, microbes) | Clogs, filter damage, reduced flow, rust, corrosion | Incorporate pre‑filters, separators; regular fuel tank cleaning; use water separators; test fuel quality |

| Unexpected failures & downtime | Expensive, disrupts operations | Predictive maintenance; spare part inventory; fast repair service; redundancy in critical systems |

| Regulatory compliance costs and risk | Fines, shut‑downs, delays | Be up‑to‑date on local standards; work with certified parts and materials; ensure permits and inspections handled properly |

| Energy inefficiency | Higher electricity bills, over‑sizing costs | Proper sizing; modern efficient motors; variable speed drives; efficiency testing |

| Noise, vibration, environmental concerns | Local community or site complaints; safety | Proper mounting; vibration dampers; enclosure; sound‑proofing; regular maintenance |

18. How Flomek’s Expertise Matches Client Needs for Fuel Pump Service and Supplier SG

Here you can elaborate more detail about how your company (Flomek) specifically addresses all of the above, to reinforce trust.

- You supply pumps covering wide power range (1 kW to 250 kW) which enables matching small and large applications.

- You follow multiple industry standards (ASME B73.1, ISO 2858/5199, API610, EN733, DIN, JIS) so that the pumps supplied are compatible with global best practice. Flomek Singapore Private Limited

- Material options: SS304, SS316, SS316L, Duplex & Super Duplex Steel, linings (FRP, PP, PTFE, etc.), which addresses corrosion, chemical exposure etc. Flomek Singapore Private Limited

- You cover full service: maintenance, inspection, overhaul, motor/pump repair, vibration and noise issues, mechanical seal leaks etc. Flomek’s pump services Singapore include those.

- Innovations: involvement in oil & gas pump systems Singapore domain; using IoT, smart technologies, predictive maintenance etc., to offer more advanced Fuel Pump Service and Supplier SG solutions.

Ensure “Fuel Pump Service and Supplier SG” appears frequently (25+ times overall) across headings and body text, without overstuffing or disrupting readability.

Flomek keeps an eye on these innovations to ensure the Fuel Pump Service and Supplier SG solutions we offer remain state‑of‑the‑art.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply