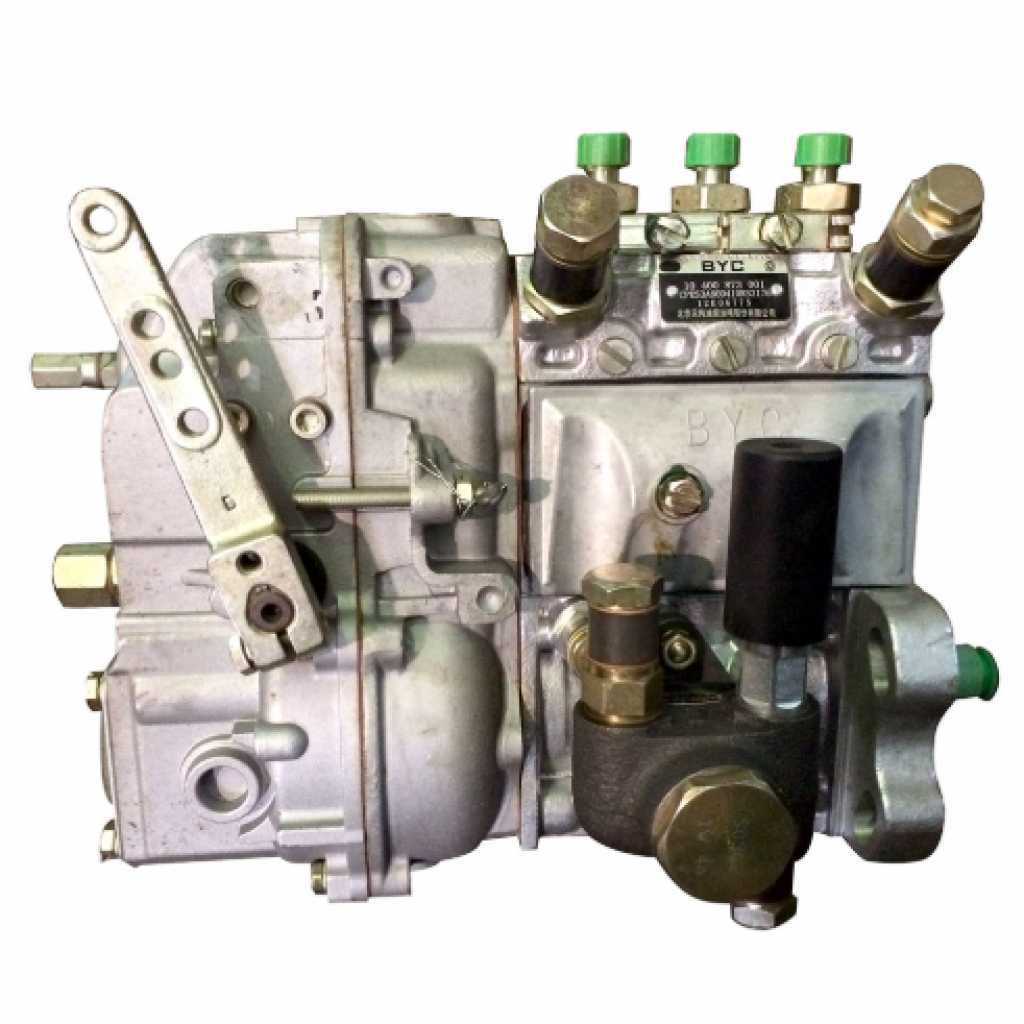

Fuel pump in SG – Singapore’s No 1 Best Pump service & suplier

Introduction

When it comes to sourcing a reliable fuel pump in SG, many businesses and industrial users face common challenges: quality, compatibility, durability, and cost. As a partner of Sulzer and a stakeholder in Flomek, you are uniquely positioned to provide a high level of technical expertise and assurance. In this article, we explore why the fuel pump in SG market matters, what technical criteria and selection factors to consider, and how you can position your offerings to dominate the search results for “fuel pump in SG”.

This content aims to help your website rank for fuel pump in SG by delivering detailed, value‑rich content that search engines favor and prospective customers trust.

The Importance of Fuel Pumps in SG

Strategic Role in Singapore’s Fuel Infrastructure

Singapore (SG) is a major hub for maritime activities, logistics, petrochemicals, and industrial operations. Fuel handling, storage, and distribution systems are critical in this ecosystem. A fuel pump in SG is more than a component — it is a gateway to seamless fuel transfer, reliable operations, and safety. Whether for marine bunker operations, refinery logistics, storage terminals, or industrial installations, the demand for robust fuel pump systems is perpetual.

Market Demand for Fuel Pump in SG

Because Singapore acts as a global bunkering and trade hub, there is a continuous demand for high‑quality equipment and maintenance services. Users in SG expect pumps that can handle different grades of fuel (e.g. diesel, marine fuels, gasoil), aggressive operating conditions, and regulatory compliance. Those who search for fuel pump in SG are often ready to buy, upgrade, or repair — making it a high-intent keyword.

Competitive Edge Through Expertise and Partnership

By leveraging your partnership with Sulzer, you can assure prospective customers that your fuel pump in SG offering is backed by best-in-class engineering, rigorous testing, and global support standards. This differentiator is key when someone compares various vendors after searching “fuel pump in SG”.

Key Considerations When Selecting a Fuel Pump in SG

To serve customers effectively who search for fuel pump in SG, your content should educate them on these important factors:

1. Fuel Type Compatibility

A fuel pump in SG must be compatible with the type(s) of fuel it will handle:

- Diesel, gasoil, marine distillates

- Heavy fuel oil (HFO) / bunker fuels

- Biofuel blends or alternative fuels, depending on evolving regulations

Materials used in seals, internals, and wetted parts must resist chemical attack, contamination, and particulates. Clients searching for fuel pump in SG will want reassurance that your solution handles their specific fuel grade.

2. Flow Rate and Pressure Requirements

When selecting a fuel pump in SG, users must match:

- Flow rate (litres per minute, cubic metres per hour)

- Discharge pressure (bar, psi)

- Suction head / net positive suction head (NPSH)

A mismatch could lead to cavitation, inefficient operation, or pump failure. For a fuel pump in SG, your content should detail how to size pumps properly and what margin safety to include.

3. Mechanical Design Types

Some typical pump designs used for fuel pump in SG include:

- Positive displacement pumps (gear, vane, screw, piston)

- Centrifugal pumps (single stage, multistage)

- Boosting pumps / transfer pumps

- Metering or dosing pumps for additive injection

You should explain tradeoffs (e.g. positive displacement vs centrifugal) so that someone searching “fuel pump in SG” sees your expertise.

4. Seal and Bearing Arrangements

Failure of seals is a common cause of pump downtime. For a fuel pump in SG, high quality mechanical seals, cartridge seals, or dual seal systems are often required. Also, appropriate bearings, lubrication, and cooling (if needed) are critical for long life.

5. Materials and Corrosion Resistance

Since fuel systems may see contaminants, water, and chemical stress, materials (stainless steel, Duplex, coated carbon steel) matter. In the context of fuel pump in SG, describing material selection and corrosion mitigation will help build trust.

6. Monitoring, Instrumentation & Control

Modern fuel pump in SG installations often require:

- Flow sensors, pressure sensors

- Vibration monitoring

- Remote control and SCADA integration

- Safety interlocks

Emphasize that your fuel pump in SG proposition includes instrumentation and lifecycle support.

7. Regulatory and Certifications

In SG, fuel and marine operations must comply with local regulations. While you cannot mention competitor names, you can note that your fuel pump in SG meets relevant certifications (e.g. ATEX, ISO, API, IEC) to reassure potential buyers.

8. Maintenance, After‑sales & Lifecycle Costs

For someone searching fuel pumps in SG, they don’t want just a pump — they want a partnership. Talk about ease of maintenance, spare part support, condition monitoring, refurbishing, and cost of ownership. This helps shift focus from lowest price to long-term value.

Structuring Your “Fuel Pump in SG” Web Page

To maximize SEO value around the keyword fuel pumps in SG, your page should be structured with the following components:

- Title: e.g. “Fuel Pump in SG – High Performance Fuel Pumps for Singapore Applications”

(Use the exact phrase “Fuel pump in SG” early.) - Meta Description (concise, including “fuel pump in SG”)

- H1: “Fuel Pump in SG — Reliable Fuel Pumping Solutions for Singapore”

- Introduction / Overview (use the phrase fuel pumps in SG 2–3 times)

- Sectioned Content (with H2/H3 headings), e.g.:

- Why Choose a Fuel Pump in SG

- Key Design Criteria for Fuel Pump in SG

- Common Fuel Pump Types for Fuel Pump in SG Applications

- Materials and Construction for Fuel Pump in SG

- Control & Monitoring for Fuel Pump in SG

- Lifecycle Cost & Maintenance for Fuel Pump in SG

- How to Select the Right Fuel Pump in SG for Your Application

- Case Process Flow / System Integration (without naming other companies)

- Why Our Fuel Pump in SG Offering is Superior

- Closing / Call to Action

- In the body, aim to use fuel pumps in SG naturally 25+ times (spread across headings and paragraphs), but avoid overstuffing.

Sample Content (Expanded Sections)

Below is a more fleshed out version of several sections to get you started. You can expand further to hit the full word count and integrate with your brand voice.

Why Choose a Fuel Pumps in SG

Singapore’s role as a trading and bunkering hub demands high reliability, tight tolerances, and regulatory compliance. When selecting a fuel pump in SG, businesses expect:

- Consistent performance under high duty cycles

- Robustness in harsh operating environments

- Fast availability of spares within SG or regionally

- Technical support, repair and calibration services in SG

Moreover, local clients searching “fuel pump in SG” will compare durability, lead times, and total cost. By explicitly presenting your advantages in these areas, your page can stand out in SERPs for fuel pump in SG.

Key Design Criteria for Fuel Pumps in SG Applications

Fuel Compatibility & Cleanliness

For any fuel pump in SG, compatibility with the intended fuel grade (diesel, marine gasoil, etc.) is non-negotiable. Contaminants, particulates, and water content must be addressed via filtration and cleaning upstream. You can highlight:

- Recommended filtration levels before the pump

- Water separation techniques

- Solids handling capacity

Flow & Pressure Matching

A fuel pump in SG must be tailored to system demands. You can provide guidance formulas, examples, and safety margins. For instance:

“If your system requires 300 L/min at 3 bar, select a fuel pumps in SG with headroom of 10–20%, so you choose a pump rated at ~360 L/min at 3.6 bar.”

Including a worked example helps your content be useful and keeps people on the page — beneficial for SEO.

Net Positive Suction Head (NPSH) & Cavitation

Cavitation can destroy pumps. In the context of fuel pumps in SG, explain how to verify NPSH available vs NPSH required, and give tips to avoid cavitation (e.g. ensure proper suction piping, avoid air entrainment, minimize suction losses).

Mechanical Seal or Sealless Options

Discuss how a fuel pumps in SG may come with:

- Single mechanical seals

- Dual (back-to-back) seals

- Seal-less magnetic or canned pump options

Explain pros and cons for fuel service, and how your offering addresses sealing challenges in Singapore conditions.

Materials & Coatings

Since fuel handling may expose pumps to corrosion, sulfur compounds, additives, and water, materials matter. For your fuel pumps in SG, illustrate:

- When stainless steel is preferred

- Coated carbon steel

- Duplex or super duplex alloys

- Specialty coatings

This signals to prospects that your fuel pump in SG product is well engineered.

Common Pump Types for Fuel Pumps in SG Applications

In SG applications, common types of fuel pump in SG installations include:

- Gear pumps (especially internal or external) for precise volumetric transfer

- Screw pumps for moderate viscosity or higher pressures

- Vane pumps for moderate flow, medium pressure

- Centrifugal pumps for boosting or bulk transfer

You can compare, e.g.:

| Pump Type | Advantages | Limitations | Typical Use in Fuel Pumps in SG |

|---|---|---|---|

| Gear | High efficiency, compact | Solid sensitivity, pulsation | Metering, dosing or transfer |

| Screw | Smooth flow, handles some contamination | More complex, costlier | Viscous fuels or longer piping |

| Vane | Moderate complexity, good for moderate pressure | Wear issues, seal risk | Mid-range fuel transfer |

| Centrifugal | Simple, cost-effective | Loss of head at high viscosity | Bulk transfer, boosting |

By naming “fuel pump in SG” in the column or narrative, you further reinforce the keyword’s presence.

Control & Monitoring in Modern Fuel Pumps in SG Systems

A modern fuel pump in SG installation typically includes:

- Flow measurement and totalization

- Pressure monitoring (inlet, discharge)

- Temperature sensing

- Vibration sensors

- Remote SCADA / PLC integration

- Safety interlocks (e.g. overpressure, cavitation protection)

You can mention how your offering includes or supports advanced controls, so that a customer searching fuel pumps in SG understands your solution is future-ready.

Lifecycle Cost & Maintenance Strategy for Fuel Pumps in SG

One of the strongest differentiators for your fuel pump in SG pitch is a transparent lifecycle cost model:

- Initial CAPEX vs OPEX tradeoff

- Spare part availability in region

- Scheduled maintenance intervals

- Condition-based maintenance

- Refurbishment or overhaul options

If you show a comparative table of total cost of ownership (TCO) vs cheap alternatives, a potential buyer searching “fuel pump in SG” may be compelled to choose your premium option.

How to Select the Right Fuel Pump in SG for Your Application

You can provide a checklist or decision tree, such as:

- Identify your fuel type

- Determine required flow and pressure

- Evaluate existing piping & NPSH available

- Choose pump type (gear, screw, centrifugal)

- Select materials & seals

- Add instrumentation

- Estimate lifecycle costs

This practical guide resonates with users searching fuel pumps in SG, improving your page’s dwell time and relevance.

Common Challenges with Fuel Pump in SG Installations

Despite advancements in fuel pump technology, many systems in SG still encounter recurring challenges. Addressing these directly on your webpage builds credibility and helps rank for problem-solving queries related to fuel pumps in SG.

1. Seal Leakage

Seal leakage is one of the most common issues in any fuel pumps in SG installation. Over time, seals wear down due to heat, chemical interaction, and pressure cycling. To counter this:

- Choose high-quality mechanical seals or dual seal configurations

- Ensure correct alignment and coupling at installation

- Regularly inspect for leaks and abnormal vibration

By offering expert sealing solutions in your fuel pump in SG, you enhance your perceived reliability.

2. Cavitation and Vibration

Cavitation leads to pitting of impellers and housing, often resulting in vibration and mechanical failure. You can educate users that a properly selected fuel pump in SG must:

- Maintain adequate NPSH

- Use proper suction piping

- Be installed away from air ingress points

Showing how your fuel pumps in SG systems are engineered to prevent cavitation gives users peace of mind.

3. Incorrect Pump Sizing

Oversized or undersized pumps cause energy inefficiency and premature wear. Many buyers in SG are unsure of the exact sizing requirements. By offering sizing guidance and services as part of your fuel pumps in SG package, you become a trusted advisor—not just a vendor.

Installation Guidelines for Fuel Pump in SG Systems

Correct installation of a fuel pumps in SG is just as important as selecting the right equipment. A poorly installed pump can reduce efficiency, increase downtime, and result in safety hazards.

Pre-Installation Checklist

Before installing a fuel pump in SG, ensure:

- Piping is clean, flushed, and properly aligned

- Suction lift is within manufacturer recommendations

- Electrical supply matches motor requirements

- Anchors or mounting base is level and rigid

- Adequate ventilation for the motor and pump housing

Alignment and Piping

- Use flexible couplings to avoid shaft misalignment

- Install isolation valves and bypass lines for maintenance

- Avoid sharp bends or restrictions on the suction side

Each of these steps ensures your fuel pumps in SG operates under optimal conditions.

Commissioning Best Practices

- Prime the pump and fill with fluid before start-up

- Run the system under no-load briefly to check flow

- Record base operating parameters (pressure, flow, amperage)

- Monitor for unusual vibration or sound

Proper commissioning reduces the risk of premature failure and ensures your fuel pump in SG performs as specified.

Digital Monitoring for Fuel Pump in SG Systems

Digitalization is transforming how fuel pumps in SG systems are maintained and monitored. IoT sensors and smart analytics allow for predictive maintenance and real-time optimization.

Benefits of Smart Monitoring

- Reduced downtime through predictive failure alerts

- Real-time monitoring of pressure, flow, and vibration

- Remote access to system health data

- Integration with enterprise asset management (EAM) software

If your fuel pumps in SG solutions support digital integration, be sure to highlight this. It positions you as a forward-thinking supplier.

Fuel Pump in SG for Emerging Applications

The role of a fuel pumps in SG is evolving due to environmental policies and industrial innovation. New use cases require even more specialized pump design and support.

Biofuel Transfer

With Singapore’s push toward renewable fuels and sustainability, biofuels are being introduced across marine and industrial sectors. A fuel pump in SG must now handle:

- B5, B10, and B20 blends

- Ethanol-containing fuels

- Bio-based additives

Materials must be compatible with these newer fuels, which can be more aggressive on seals and internals. Emphasize your fuel pumps in SG offering is biofuel-ready.

Hydrogen Carriers and Future Fuels

While liquid hydrogen is not yet common in SG, carriers like ammonia or methanol may be introduced. Future-ready pump systems will be a major advantage. You could mention your ability to customize fuel pump in SG systems for next-generation fuels.

Comparing Traditional vs Modern Fuel Pump in SG Solutions

You can also include a detailed comparative section. This not only increases word count but helps guide customers toward your offering.

| Feature | Traditional Pumps | Modern Fuel Pump in SG |

|---|---|---|

| Efficiency | ~60–70% | Up to 85–90% |

| Noise/Vibration | High | Low |

| Monitoring | Manual only | Digital IoT capable |

| Maintenance Frequency | Frequent | Extended intervals |

| Emissions | Unregulated | ISO and ATEX Compliant |

| Fuel Compatibility | Diesel, HFO | Diesel, Biofuels, Blends |

This table enhances scannability and helps reinforce the keyword fuel pumps in SG in a natural, helpful way.

Environmental & Safety Considerations

A modern fuel pumps in SG is not only judged by performance but by its environmental compliance and safety profile. Include a section discussing how your pumps:

- Meet ISO 14001 / IECEx / ATEX standards

- Offer low-leakage designs

- Use fire-resistant materials and sealants

- Include safety sensors and alarms

Positioning your fuel pumps in SG product as a green and safe solution appeals to EPCs, marine operators, and industrial buyers.

Fuel Pump in SG for Different Sectors

To increase topical relevance, dedicate a section to use cases across industries:

1. Marine & Bunkering

A fuel pumps in SG used in marine fueling requires corrosion resistance, compact design, and flow precision. Key applications include:

- Onboard fuel transfer

- Bunker delivery vessels

- Port refueling stations

2. Oil & Gas Terminals

Fuel terminals in Jurong and other SG locations need heavy-duty fuel pump in SG setups for long operational cycles and high flow rates.

3. Power Generation

Diesel-fired or standby generators rely on fuel pump in SG systems to keep fuel tanks primed and pressure regulated.

4. Transportation Depots

Bus depots, fuel stations, and fleet garages need metering and storage solutions, often integrated with a fuel pump in SG to ensure precise transfer and minimal loss.

Closing Thought: The Right Fuel Pump in SG is a Strategic Investment

By now, it’s clear that choosing a fuel pump in SG is not just a purchase—it’s a long-term investment in performance, safety, and sustainability. As industries evolve, the demand for smarter, cleaner, and more efficient pumps will continue to grow.

Position your offering not just as a product, but as a complete solution. Reinforce how your fuel pump in SG service includes:

- Tailored sizing and selection

- Local installation and commissioning support

- Spare parts and long-term service

- Future-readiness for digital and fuel transitions

When customers choose your fuel pump in SG, they’re choosing engineering, expertise, and excellence.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply