Double containment dosing skid Singapore – Best 2025

Introduction to Double Containment Dosing Skid in Singapore

In today’s fast-paced industrial environments, the need for safe, reliable, and efficient chemical dosing systems is paramount. Double Containment Dosing Skid Singapore solutions are gaining momentum across industries such as water treatment, petrochemicals, pharmaceuticals, and food processing. At FLOMEK Singapore, we specialize in engineering double containment dosing skid systems that ensure maximum safety, environmental protection, and operational efficiency.

What Is a Double Containment Dosing Skid?

A double containment dosing skid is a specialized chemical injection system that includes both a primary and secondary containment layer. This design protects the environment, operators, and surrounding equipment from potential chemical leaks or spills. In the context of Double Containment Dosing Skid Singapore, the system is manufactured to meet Singapore’s stringent safety, environmental, and operational standards.

The primary containment is the actual chemical line or vessel. The secondary containment acts as a shield, capturing leaks from the primary line in case of failure. This dual protection is critical for handling hazardous chemicals, especially in high-risk environments like water and wastewater treatment plants in Singapore.

Importance of Double Containment in Singapore’s Industrial Sector

In Singapore, where environmental regulations are strict and safety protocols are non-negotiable, using a double containment dosing skid is not just preferred—it is often required. Chemical dosing systems that fail to incorporate secondary containment pose significant risks, including:

- Groundwater contamination

- Personnel health hazards

- Equipment corrosion

- Regulatory violations

- Downtime due to leak-induced maintenance

This is why Double Containment Dosing Skid Singapore solutions by FLOMEK are designed to exceed both local and international safety benchmarks.

Key Components of a Double Containment Dosing Skid

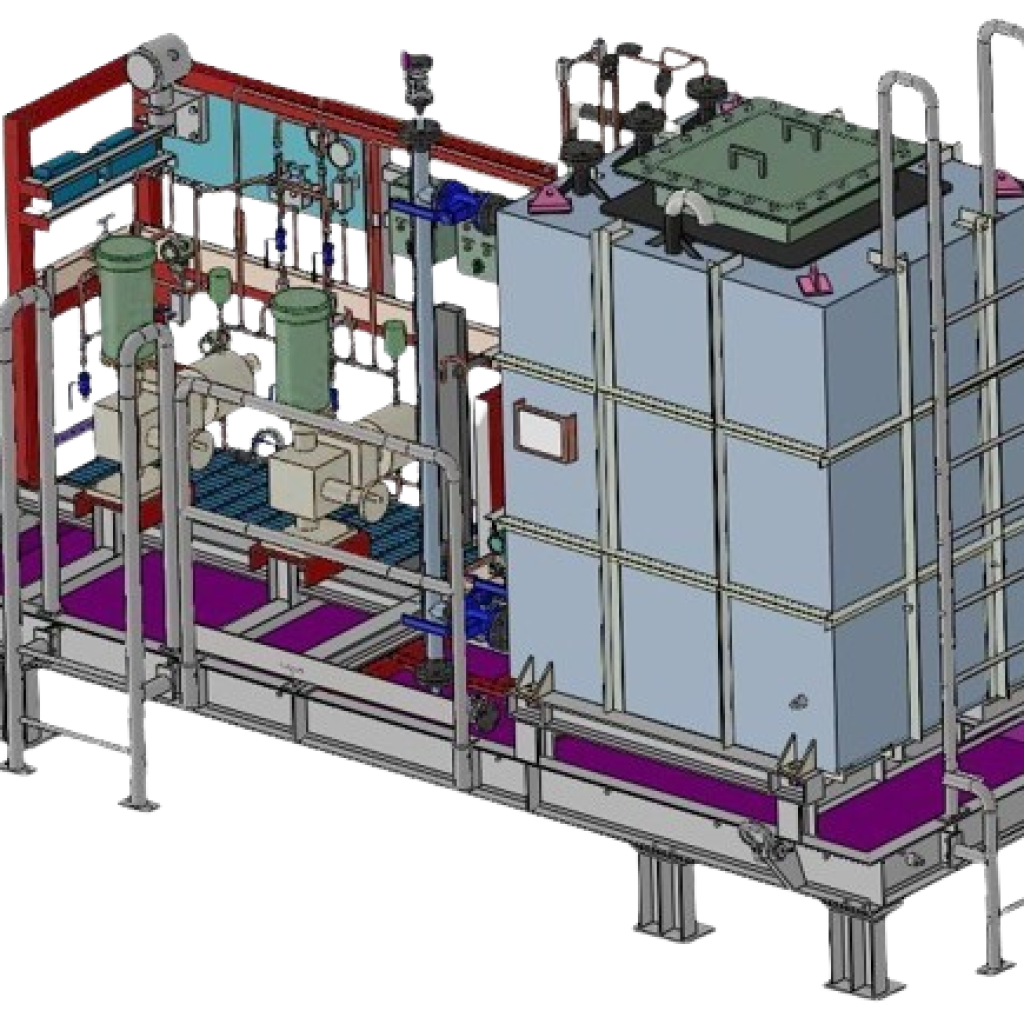

At FLOMEK Singapore, each double containment dosing skid is custom-engineered to suit your process needs. Standard components include:

- Primary chemical dosing pumps (diaphragm, peristaltic, or plunger type)

- Double containment piping systems

- Leak detection sensors

- HDPE or PP storage tanks

- Flow meters and pressure gauges

- PLC-based control systems

- Containment trays and bunds

- Skid-mounted frame for mobility and integration

We offer complete Double Containment Dosing Skid Singapore solutions with full automation and interlocks to prevent spillage and ensure system shutoff during failure.

Applications of Double Containment Dosing Skid in Singapore

Our Double Containment Dosing Skid Singapore systems are trusted across multiple industries:

1. Water & Wastewater Treatment Plants

Chemical injection of sodium hypochlorite, alum, or polymers requires utmost caution. FLOMEK’s double containment dosing skid ensures zero leakage and complete containment.

2. Power Plants

In power stations, dosing ammonia or hydrazine into boilers must be tightly controlled. Our double containment systems offer safe dosing even under pressure.

3. Oil & Gas

Handling corrosive substances like H₂S scavengers, corrosion inhibitors, and methanol needs reliable containment. Our Double Containment Dosing Skid Singapore ensures environmental safety on offshore platforms and onshore terminals.

4. Pharmaceuticals & Food Processing

Clean and contamination-free dosing is critical. Our skids use FDA-compliant materials and ensure cross-contamination prevention with double containment.

Why Choose FLOMEK for Double Containment Dosing Skid Singapore?

✅ Custom Design & Fabrication

Every Double Containment Dosing Skid Singapore solution by FLOMEK is designed in-house by expert engineers. We consider the chemical type, flow rate, working pressure, and plant layout before starting fabrication.

✅ Turnkey Installation

From design to commissioning, FLOMEK Singapore provides complete support for installation, testing, and calibration. We also offer PLC & SCADA integration for automated control and remote monitoring.

✅ Local Compliance & Safety

Our skids comply with PUB, NEA, and WSH guidelines. We understand the legal landscape in Singapore and ensure every double containment dosing skid we supply passes all inspections.

✅ Corrosion Resistance & Durability

Materials used in our Double Containment Dosing Skid Singapore solutions—such as PTFE, PVDF, and HDPE—are selected for their chemical resistance and long service life.

✅ Maintenance & After-Sales Support

FLOMEK doesn’t stop at sales—we offer preventive maintenance, on-call support, spare parts availability, and troubleshooting for every double containment dosing skid installed.

Advantages of Double Containment Dosing Skid Singapore Systems

- Environmental Protection: Leaks are captured and contained, protecting the site and the ecosystem.

- Operator Safety: Prevents exposure to harmful chemicals.

- Regulatory Compliance: Meet Singapore’s stringent environmental and industrial safety regulations.

- Cost Saving: Reduces chemical wastage and cleanup costs.

- Risk Reduction: Minimizes chances of chemical contamination and accidents.

- Easy Maintenance: Designed for accessibility and quick inspection.

- Leak Detection & Alerts: Sensors alert operators in real-time.

- Compact & Modular: Skid-based system allows portability and space-saving installation.

Technical Specifications: Double Containment Dosing Skid Singapore

| Feature | Specification |

|---|---|

| Flow Range | 0.1 LPH to 2000 LPH |

| Pressure Rating | Up to 20 bar |

| Material of Construction | PP, PVDF, SS316, HDPE |

| Containment Method | Pipe-in-pipe or tray-based |

| Leak Detection | Float switches / conductivity sensors |

| Control Options | Manual, Semi-automatic, PLC-based |

| Mounting | Skid frame with vibration damping feet |

| Power Supply | 230V/1ph/50Hz or 415V/3ph/50Hz |

All Double Containment Dosing Skid Singapore configurations are tailored to the chemical compatibility and plant operation parameters.

Installation Process of Double Containment Dosing Skid Singapore

At FLOMEK, the process is streamlined for optimal client satisfaction:

- Site Assessment – Understand plant layout, dosing points, and chemical type.

- Design & Engineering – 2D/3D layout provided before fabrication.

- Fabrication – Conducted at our ISO-certified facility.

- Testing & FAT – All components tested for flow, leakage, and automation logic.

- Delivery & Installation – Onsite delivery, positioning, and electrical/pneumatic connections.

- Commissioning & Training – Skid tested under working conditions, with operator training provided.

Smart Integration: Double Containment Dosing Skid Singapore with PLC & SCADA

FLOMEK offers PLC & SCADA integration for every double containment dosing skid. This smart integration provides:

- Live monitoring of flow, pressure, and tank levels.

- Alarm triggers for leak detection.

- Remote control and setpoint adjustments.

- Data logging and report generation.

The modern plant in Singapore demands digitalization—Double Containment Dosing Skid Singapore solutions from FLOMEK enable full Industry 4.0 integration.

How FLOMEK Ensures Quality in Every Double Containment Dosing Skid Singapore

- ISO 9001:2015 Certified manufacturing standards

- 100% hydrostatic leak testing

- Third-party material test certificates

- Digital traceability of components

- Client-specific documentation (O&M manuals, GA drawings, P&ID)

Client Testimonials

“We were struggling with chemical leaks in our previous system. Since installing FLOMEK’s Double Containment Dosing Skid Singapore, we’ve had zero incidents.” – Senior Engineer, Water Treatment Plant.

“The automation and leak detection system was exactly what our team needed. Excellent support from FLOMEK throughout.” – Facilities Manager, Pharmaceutical Plant.

Premium Double Containment Dosing Skid Singapore Solutions – Designed for Safety, Built for Reliability

Introduction: Why Double Containment Matters in Dosing Systems

Singapore’s industrial operations, particularly in sectors handling aggressive and hazardous chemicals, require robust safety solutions. One of the most critical systems used to ensure safe chemical injection is the Double Containment Dosing Skid Singapore setup.

These systems not only prevent accidental leaks but also offer operators peace of mind when dealing with potentially corrosive and harmful substances. With industries in Singapore increasingly focused on sustainable practices and workplace safety, the adoption of Double Containment Dosing Skid Singapore systems is no longer optional—it is essential.

At FLOMEK Singapore, we provide tailor-made, compact, and fully tested double containment dosing skids that meet Singapore’s demanding industry standards and environmental requirements.

What is a Double Containment Dosing Skid?

A double containment dosing skid is an advanced chemical dosing system enclosed within a dual-layer containment system. This includes:

- Primary Containment: The main fluid-carrying line or equipment.

- Secondary Containment: A backup enclosure that captures leaks from the primary line to ensure total isolation.

The purpose of installing a Double Containment Dosing Skid Singapore is to safeguard people, property, and the environment. Whether handling sodium hypochlorite, hydrochloric acid, caustic soda, or other harsh chemicals, this system provides a fail-safe mechanism that protects against unexpected equipment failure.

Why the Demand for Double Containment Dosing Skid in Singapore is Growing

Singapore’s water treatment, semiconductor, pharmaceutical, and petrochemical industries are heavily regulated. Regulatory bodies such as PUB, NEA, and WSH Council enforce stringent standards for chemical handling and disposal.

A Double Containment Dosing Skid Singapore ensures compliance with these regulations. Moreover, rising awareness about environmental risks and zero-leakage policies has made these systems a standard requirement in new installations and upgrades.

FLOMEK Singapore is at the forefront of this safety revolution, offering next-gen containment solutions for clients across the island.

Top Features of FLOMEK’s Double Containment Dosing Skid Singapore

Each Double Containment Dosing Skid Singapore we manufacture includes a unique blend of safety, automation, and modularity:

✅ Dual Pipe Construction

Double-walled piping made of HDPE, PVDF, or SS316 offers unmatched chemical compatibility and protection.

✅ Leak Detection Alarms

Integrated conductivity sensors or float-type level detectors ensure early warning for any breach in containment.

✅ Easy Maintenance Access

Quick-connect fittings and transparent containment sections make inspection simple without compromising safety.

✅ Skid-Mounted Modular Frame

Compact design allows for easy transportation, relocation, or retrofitting into existing plant infrastructure.

✅ Full Automation & Control

Optional PLC control panels with HMI/SCADA integration help monitor flow rate, pressure, tank level, and leak alerts.

Industries that Trust FLOMEK’s Double Containment Dosing Skid Singapore

- Municipal Water Treatment – Safe dosing of alum, chlorine, or flocculants with no risk of groundwater contamination.

- Pharmaceutical & Biotech – Precision dosing with high chemical purity assurance and GMP compliance.

- Petrochemical & Refinery – Handling volatile chemicals with zero spill tolerance.

- Semiconductor Manufacturing – Protecting ultra-pure water systems from contamination.

- Food & Beverage – Accurate and sanitary chemical dosing, CIP compliance, and HACCP standards.

Our Double Containment Dosing Skid Singapore solutions are already trusted by multiple government, private, and industrial clients.

Design Considerations for a Double Containment Dosing Skid Singapore

When building a Double Containment Dosing Skid Singapore, FLOMEK evaluates key performance criteria:

| Design Factor | FLOMEK’s Approach |

|---|---|

| Chemical Type | Material compatibility analysis |

| Dosing Accuracy | High-precision metering pumps with flow feedback |

| Pressure Rating | Designed for up to 20 bar applications |

| Leak Management | Dual-containment with drain and sensor system |

| Control Interface | Touchscreen HMI with alarms and logs |

| Footprint | Compact design optimized for Singapore’s limited space |

From engineering drawings to fabrication, each detail in the Double Containment Dosing Skid Singapore is designed to meet both process requirements and safety mandates.

The Engineering Behind a Safe Skid – Step-by-Step Overview

1. Process Analysis:

We begin by understanding your plant’s process requirements, chemical properties, flow rates, and pressure ranges.

2. Material Selection:

Based on the chemical resistance chart, we choose safe, durable materials like PP, PVDF, or SS316 for both primary and secondary containment.

3. 3D Modelling & Layouts:

Every Double Containment Dosing Skid Singapore is modeled using CAD software and reviewed with the client before fabrication.

4. Fabrication & Assembly:

Precision-cut pipes, calibrated pumps, and electrical control systems are mounted on a corrosion-proof skid platform.

5. FAT (Factory Acceptance Test):

We simulate real-life operations to ensure every sensor, valve, and pump operates within set parameters.

6. Site Installation & SAT (Site Acceptance Test):

Our engineers handle delivery, installation, wiring, and final commissioning with client training and documentation.

Automation Capabilities – Smart Dosing Starts Here

All Double Containment Dosing Skid Singapore systems from FLOMEK can be upgraded with automation features such as:

- Remote Monitoring: Real-time data on flow rate, pressure, and alarms.

- Flow Control Feedback Loop: Adjusts dosing rate automatically based on process demand.

- Email & SMS Alerts: Notifies operators in case of leak or system failure.

- Data Logging: Records performance for compliance reports.

This digital layer makes your Double Containment Dosing Skid Singapore not just safe—but intelligent.

Why Clients Choose FLOMEK Singapore for Double Containment Dosing Skid

✅ Local Expertise

We understand the challenges and requirements of Singapore’s industrial ecosystem.

✅ Customized Systems

No two clients are the same. Our systems are made-to-measure.

✅ Rapid Turnaround

From inquiry to commissioning, we follow a fast-track project timeline without compromising quality.

✅ Certifications & Compliance

We meet PUB, NEA, ISO, and WSH standards consistently.

✅ After-Sales Support

Preventive maintenance plans, spare parts availability, and service call-outs ensure long-term peace of mind.

Technical Specifications

| Parameter | Specification |

|---|---|

| Flow Range | 0.05 to 1000 LPH |

| Pressure Rating | Up to 20 bar |

| Pump Type | Diaphragm, plunger, peristaltic |

| Materials | PP, PVDF, PTFE, SS316 |

| Containment | Pipe-in-pipe with leak sensors |

| Control Panel | IP65 rated with touchscreen HMI |

| Power | 230V / 415V AC, 50Hz |

| Options | SCADA/PLC Integration, auto-tank refill, pH feedback |

Every Double Containment Dosing Skid Singapore we ship is backed by full documentation, testing reports, and long-term service contracts.

Environmental Compliance in Singapore: How Skid Systems Help

A key reason for using Double Containment Dosing Skid Singapore is the ability to meet or exceed local environmental compliance laws, including:

- NEA Pollution Control Measures

- WSH Chemical Safety Guidelines

- PUB Drainage & Sewerage Design Criteria

In the event of a spill, traditional systems often fail to contain the damage. FLOMEK’s double containment design ensures the chemical never reaches the floor or drainage system, preventing fines and ecological damage.

Client Feedback – Real Stories, Real Solutions

“Our older dosing system failed twice due to pipe cracks. Since upgrading to FLOMEK’s Double Containment Dosing Skid Singapore, we’ve had 24/7 dosing without a single leak.”

— Plant Manager, Industrial Wastewater Facility

“The transparent outer layer and leak sensor make it incredibly easy to monitor. We saved time, money, and reduced our downtime dramatically.”

— Facility Head, Semiconductor Plant

Future Trends: The Evolution of Double Containment Dosing Skid Singapore

- Integration with AI-based leak prediction

- Green energy-powered dosing skids

- IoT-enabled real-time diagnostics

- Portable containment skids for field deployment

FLOMEK is investing in next-gen technologies to take Double Containment Dosing Skid Singapore systems into the future.

Enhancing Operational Safety Through Double Containment Technology

In Singapore’s rapidly advancing industrial sectors, operational safety and environmental stewardship have taken center stage. Industries such as chemical processing, water treatment, semiconductor manufacturing, pharmaceuticals, and petrochemical refining all require sophisticated solutions to prevent hazardous leaks and maintain system integrity. One of the most effective ways to achieve this is through the implementation of a Double Containment Dosing Skid Singapore system.

At FLOMEK Singapore, we specialize in delivering reliable, high-performance dosing skids engineered with double containment for both safety and process integrity. Our solutions are designed to meet the unique requirements of Singapore’s industrial landscape, helping facilities stay compliant, sustainable, and efficient.

What Makes a Double Containment Dosing Skid Singapore System Essential?

Leaks in chemical dosing systems not only pose environmental risks but also jeopardize worker safety and violate regulatory norms. The Double Containment Dosing Skid Singapore system mitigates these risks by providing an additional layer of protection through dual containment design.

This secondary containment ensures that even if the primary chemical line fails, the secondary housing captures any leakage, thus preventing contamination and hazards. In Singapore, where space constraints and environmental sensitivities are high, such innovations are not just value additions—they are necessities.

Advantages of FLOMEK’s Double Containment Dosing Skid Singapore Systems

1. Zero-Leak Assurance

Our systems are engineered to ensure zero-leak operation. The double containment design functions as a built-in emergency response, ensuring chemicals are safely enclosed.

2. Comprehensive Leak Detection

Each Double Containment Dosing Skid Singapore system from FLOMEK includes integrated sensors and alert mechanisms, ensuring prompt response in case of a containment breach.

3. Chemical Compatibility

We use materials like PVDF, PTFE, and HDPE that are fully compatible with a wide range of chemicals, including acids, alkalis, and solvents.

4. Regulatory Compliance

Our solutions align with Singapore’s NEA, PUB, and WSH guidelines, ensuring total regulatory adherence from design to operation.

5. Low Maintenance, High Reliability

Designed for minimal manual intervention, our systems come with modular components that are easy to replace and upgrade.

Tailored Solutions for Your Facility

No two facilities are alike, which is why every Double Containment Dosing Skid Singapore solution is tailored to meet your plant’s specific needs. Whether it’s flow rate, pressure range, chemical type, or control logic, we design systems that match your exact process requirements.

Technical Capabilities

- Flow Rate: 0.1 LPH to 2000 LPH

- Pressure Handling: Up to 20 bar

- Pump Types: Diaphragm, peristaltic, plunger

- Skid Material: Powder-coated MS, SS304, SS316

- Containment Housing: Dual-pipe construction or bund tray with sensors

- Integration: SCADA, HMI, PLC

- Certification: ISO 9001, ISO 14001, WSH compatible

Environmental Responsibility

With growing concern over environmental impact, a Double Containment Dosing Skid Singapore helps reduce the carbon footprint and chemical waste by containing accidental spills, thus protecting surrounding ecosystems and water bodies. Our systems ensure that operations remain clean and environmentally responsible.

Real-World Use Cases in Singapore

1. Municipal Water Treatment

FLOMEK’s systems have been deployed across multiple PUB-certified water treatment plants to ensure chlorine dosing is leak-free and environmentally sound.

2. Pharmaceuticals

High-purity chemical dosing requires flawless containment. Our double containment systems have helped pharma giants eliminate contamination risks.

3. Semiconductor & Electronics

Ultra-clean environments cannot tolerate even minute chemical leaks. FLOMEK’s double containment skid ensures precision and purity.

Industries Served

- Municipal water treatment

- Oil & gas (upstream & downstream)

- Semiconductor & electronics

- Power generation

- Pulp & paper

- F&B and breweries

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply