Chemical Dosing skid package singapore – 2024 BEST

Chemical Dosing Skid Package in Singapore: Comprehensive Guide

In industries ranging from water treatment to oil and gas, precision chemical dosing is vital for ensuring safety, efficiency, and compliance with regulatory standards. A chemical dosing skid package Singapore offers a fully integrated, turnkey solution designed for precise chemical injection. These systems are engineered to handle a wide range of chemicals, ensuring smooth and reliable operation while minimizing downtime and reducing risks.

This article will explore the importance of chemical dosing skid packages in Singapore, how they work, their advantages, and why industries rely on them for critical operations.

What is a Chemical Dosing Skid Package?

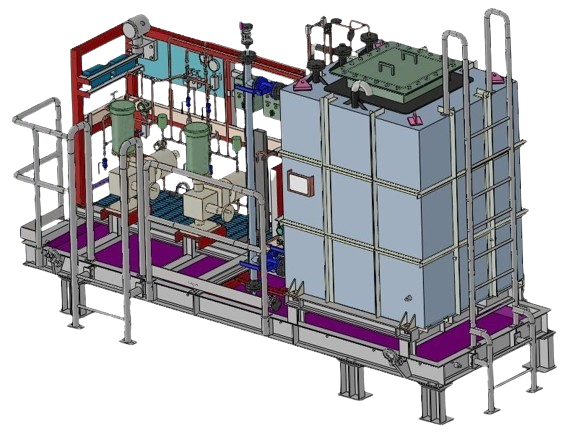

A chemical dosing skid package Singapore is a modular, pre-assembled system designed to store, measure, and inject chemicals into various industrial processes. These systems typically include:

- Chemical storage tanks

- Dosing pumps

- Flow meters

- Control systems

- Safety mechanisms

Each unit is customized to the specific needs of the application, ensuring accurate chemical dosing for a wide variety of processes such as water treatment, petrochemical operations, or manufacturing.

Importance of Chemical Dosing in Singapore

Singapore, being a global industrial hub, hosts a variety of industries that require precise chemical handling. From wastewater treatment plants to large-scale refineries, chemical dosing skid packages are critical for maintaining operational efficiency and adhering to environmental regulations.

Whether for pH adjustment, disinfection, or corrosion control, a chemical dosing skid package Singapore provides an essential solution that ensures the right amount of chemicals is injected at the right time.

How Does a Chemical Dosing Skid Package Work?

A chemical dosing skid package Singapore operates through the following steps:

- Storage: Chemicals are stored in tanks made from corrosion-resistant materials like polyethylene or stainless steel.

- Measurement: Flow meters or sensors measure the exact quantity of chemicals needed.

- Pump Operation: Dosing pumps, such as diaphragm or peristaltic pumps, ensure the accurate delivery of chemicals into the system.

- Control Systems: An automated control system regulates the timing, quantity, and frequency of the chemical injection.

- Safety Mechanisms: Safety valves and alarms prevent over-dosing and ensure the system shuts down in case of any irregularities.

This ensures that every process requiring chemical injection is carried out precisely, reducing waste, operational errors, and environmental risks.

Why Choose a Chemical Dosing Skid Package in Singapore?

The demand for reliable and efficient chemical dosing systems in Singapore continues to grow due to several factors:

1. Regulatory Compliance

Industries such as oil & gas, pharmaceuticals, and water treatment are governed by strict regulations that demand precise chemical dosing to avoid contamination or harm to the environment. A chemical dosing skid package Singapore ensures compliance with local regulations.

2. Cost-Effective

By delivering the exact amount of chemicals required for a process, these systems minimize wastage, ultimately leading to significant cost savings. The modular nature of a chemical dosing skid package reduces installation time and costs, as the system comes pre-assembled.

3. Scalability

Whether your plant is large or small, a chemical dosing skid package Singapore can be customized to fit your operational needs. These systems can be expanded as your process requirements grow.

4. Customization

Each industry has unique chemical dosing needs. A chemical dosing skid package Singapore can be fully customized, whether it’s selecting the right pumps or configuring the controls.

Applications of Chemical Dosing Skid Packages in Singapore

A chemical dosing skid package Singapore can be found in a wide range of industries, each requiring precise chemical handling for different processes. Here are some common applications:

1. Water Treatment

One of the most common uses for a chemical dosing skid package Singapore is in water and wastewater treatment plants. Chemicals such as chlorine, ferric chloride, and sodium hypochlorite are dosed for disinfection, coagulation, and pH control.

2. Oil and Gas Industry

In the oil and gas sector, a chemical dosing skid package Singapore is used for injecting corrosion inhibitors, scale inhibitors, and demulsifiers into pipelines, ensuring the smooth and safe transport of oil and gas.

3. Manufacturing

Industries such as paper manufacturing and textiles often require chemical dosing for bleaching, dyeing, and other processing steps. A chemical dosing skid package Singapore ensures precise dosing for consistent quality and minimal waste.

4. Food & Beverage

A chemical dosing skid package Singapore is crucial in the food and beverage industry for sanitizing equipment, water purification, and ensuring the correct pH levels during production processes.

Key Components of a Chemical Dosing Skid Package

Every chemical dosing skid package Singapore is built with several essential components that ensure the system operates efficiently and safely. These components are often tailored to the needs of specific applications:

- Dosing Pumps

- The core of any chemical dosing system, dosing pumps ensure the precise delivery of chemicals. Types include diaphragm pumps, peristaltic pumps, and piston pumps.

- Storage Tanks

- Made from materials that resist corrosion and contamination, these tanks store the chemicals before dosing.

- Flow Meters

- Flow meters monitor the flow rate of chemicals being dosed into the system, ensuring accuracy.

- Control Panels

- The control system allows operators to manage dosing parameters, including timing and flow rates, automatically.

- Safety Systems

- Alarm systems, pressure relief valves, and shutdown mechanisms are essential for preventing accidents and ensuring safety during operation.

Benefits of Using a Chemical Dosing Skid Package in Singapore

- Precision A chemical dosing skid package Singapore ensures precise delivery of chemicals, minimizing risks of overdosing or underdosing, which can lead to costly consequences.

- Automation Most chemical dosing skid packages are fully automated, reducing the need for manual monitoring and minimizing human error.

- Environmental Protection Proper chemical dosing protects the environment by ensuring no harmful chemicals are released in excessive quantities. This is especially important in water treatment plants and industrial processes that discharge into waterways.

- Compact and Modular Design A chemical dosing skid package Singapore is compact and easy to install, requiring minimal space and infrastructure changes. Its modular design allows for easy integration into existing systems.

Maintenance and Servicing of Chemical Dosing Skid Packages in Singapore

Regular maintenance of a chemical dosing skid package Singapore is essential for ensuring the long-term reliability and performance of the system. Here’s what maintenance typically involves:

- Inspection of Components

- Regularly inspecting pumps, valves, and control systems ensures that all components are in optimal working condition.

- Calibration

- Flow meters and sensors need to be calibrated periodically to maintain dosing accuracy.

- Replacement of Worn Parts

- Parts such as pump diaphragms or tubing may wear out over time and need replacement to avoid downtime.

- Cleaning

- Chemical buildup can affect system performance, so periodic cleaning of tanks and pipelines is necessary.

Selecting the Right Chemical Dosing Skid Package in Singapore

Choosing the right chemical dosing skid package Singapore depends on your specific needs and the nature of your processes. Here are some factors to consider:

- Chemical Compatibility Ensure the materials used in the skid package are compatible with the chemicals being dosed to avoid corrosion or damage.

- Flow Rate The dosing pump and system must be capable of delivering the required flow rate for your process.

- Automation Level Determine the degree of automation required for your system, from manual operation to fully automated, PLC-controlled systems.

- Safety Requirements Consider safety features such as alarms, pressure relief systems, and emergency shut-off mechanisms to safeguard your operations.

The Evolution of Chemical Dosing Skid Packages in Singapore

In the rapidly growing industrial landscape of Singapore, technology has always played a pivotal role in improving efficiency and safety. Over the past few decades, chemical dosing skid packages Singapore have evolved from simple manual systems to highly sophisticated, automated solutions. This evolution has been driven by advancements in control systems, sensor technology, and material science, making modern chemical dosing systems more reliable and cost-effective.

Cutting-Edge Technologies in Chemical Dosing Skid Packages

Today’s chemical dosing skid packages Singapore are equipped with cutting-edge technologies that enhance accuracy, safety, and ease of operation. These include:

- Advanced Control Systems Modern chemical dosing skid packages come with programmable logic controllers (PLCs) and human-machine interfaces (HMIs), allowing operators to control and monitor the system remotely. These automated systems ensure accurate dosing while minimizing human error.

- IoT Integration Many of Singapore’s latest chemical dosing skid packages incorporate IoT (Internet of Things) technologies, enabling real-time data monitoring and predictive maintenance. Sensors embedded in the system monitor parameters like flow rate, temperature, and chemical levels, sending alerts to operators if any irregularities occur.

- Smart Pumps Dosing pumps with variable frequency drives (VFDs) or intelligent pump control algorithms allow the precise adjustment of flow rates based on real-time system needs. This enhances energy efficiency and minimizes chemical wastage.

- Safety Protocols and Redundancies Enhanced safety features, such as double containment systems, leak detection sensors, and redundant pumps, ensure that even in the case of equipment failure, the chemical dosing skid package Singapore continues to operate safely without jeopardizing the entire system.

Environmental Sustainability and Chemical Dosing Skid Packages

In today’s environmentally conscious world, businesses are increasingly focusing on sustainable practices. The use of a chemical dosing skid package Singapore plays a critical role in helping industries minimize their environmental impact. By precisely controlling the amount of chemicals used, these systems help reduce chemical wastage, limit over-dosing, and prevent harmful chemicals from being released into the environment.

1. Minimizing Waste

By using advanced flow meters and sensors, a chemical dosing skid package Singapore ensures that the exact quantity of chemicals required is injected into the process, significantly reducing unnecessary waste and chemical spillage.

2. Energy Efficiency

Many modern dosing pumps are designed to optimize energy consumption. By using energy-efficient pumps and control systems, the overall energy footprint of the plant can be reduced, contributing to lower operational costs and a smaller environmental impact.

3. Reducing Pollution

By ensuring precise dosing, these systems reduce the risk of over-dosing chemicals that may contaminate water bodies or harm the local ecosystem, making chemical dosing skid packages an essential part of Singapore’s commitment to sustainability.

Modular Design for Flexibility and Customization

One of the major benefits of a chemical dosing skid package Singapore is its modular design. These skid packages are built in a way that allows businesses to customize the system according to their specific process requirements. Whether it’s adding additional pumps, integrating new control systems, or scaling up for future growth, the flexibility of a chemical dosing skid package makes it an ideal solution for both small and large-scale industrial applications.

1. Tailored Solutions

A chemical dosing skid package Singapore can be tailored to meet the unique demands of various industries. For example, in the water treatment industry, the system can be customized to handle multiple chemical dosing streams, while in oil and gas, the skid can be engineered to withstand harsh environments and corrosive chemicals.

2. Ease of Expansion

As your business grows, so do your operational needs. The modular design of a chemical dosing skid package Singapore allows for easy expansion without the need for costly overhauls or system replacements.

Best Practices for Optimizing Chemical Dosing Skid Performance

To ensure the optimal performance of your chemical dosing skid package Singapore, it’s important to implement best practices in operation and maintenance:

1. Routine Maintenance

Regular inspection and maintenance of the skid package components, such as dosing pumps, flow meters, and valves, will ensure the system runs smoothly and avoids unexpected breakdowns.

2. System Calibration

Flow meters and sensors should be regularly calibrated to maintain accurate dosing rates. Calibration prevents under-dosing or over-dosing, which can impact the efficiency of your processes.

3. Staff Training

Operators should be well-trained on how to use the chemical dosing skid package efficiently. Proper training helps in detecting issues early and ensures safe handling of chemicals.

4. Data Monitoring

Take advantage of IoT-enabled systems to continuously monitor your skid package performance. Real-time data analysis allows you to spot inefficiencies, track chemical usage, and predict when maintenance will be required.

Singapore’s Market for Chemical Dosing Skid Packages

The market for chemical dosing skid package Singapore is rapidly expanding, driven by increased industrial activity and the need for precision in chemical handling. Some of the key sectors propelling the growth of this market include:

1. Water and Wastewater Treatment

Singapore places significant emphasis on water management, and chemical dosing skid packages play a critical role in ensuring that water treatment plants operate efficiently. With growing demands for clean water and stringent environmental regulations, the use of these systems is on the rise.

2. Pharmaceutical Industry

The pharmaceutical industry requires exact dosages of chemicals during production, and a chemical dosing skid package Singapore ensures that the required precision is achieved. These packages are crucial for maintaining quality standards in the production of drugs and other pharmaceutical products.

3. Oil and Gas Sector

In Singapore’s oil and gas industry, chemical dosing skid packages are vital for injecting chemicals that prevent corrosion, scale formation, and hydrate blockages in pipelines. The harsh conditions of the oil and gas sector demand robust and reliable skid systems, making them a valuable investment for operators.

Future Trends in Chemical Dosing Skid Technology

As technology continues to advance, we can expect even more innovative features to be integrated into chemical dosing skid packages Singapore. Some of the future trends include:

1. Artificial Intelligence (AI) Integration

AI could be integrated into chemical dosing skid packages to optimize dosing parameters based on real-time data. AI algorithms can analyze historical performance data to predict the best dosing rates for different conditions, ensuring maximum efficiency.

2. Increased Automation

While modern skid packages already feature high levels of automation, the future will likely bring even more autonomous operations, with systems capable of self-diagnosing and self-correcting issues without operator intervention.

3. Sustainability Focus

With increasing attention on environmental sustainability, future chemical dosing systems may be designed to further reduce chemical waste, improve energy efficiency, and integrate more environmentally friendly materials.

Conclusion

In conclusion, a chemical dosing skid package Singapore is an indispensable tool for industries requiring precise chemical handling. With its modular design, advanced control systems, and ability to improve both efficiency and environmental compliance, these systems offer numerous benefits. As industries continue to grow in Singapore, the demand for reliable, cost-effective, and sustainable chemical dosing solutions will only increase.

Investing in the right chemical dosing skid package Singapore not only ensures operational efficiency but also helps businesses stay ahead in an increasingly competitive industrial landscape, where precision and compliance are key.

A chemical dosing skid package Singapore is an essential solution for various industries that require accurate, reliable, and safe chemical dosing systems. From water treatment plants to oil refineries, these packages are designed to provide precise chemical handling while ensuring regulatory compliance and environmental protection.

Investing in a chemical dosing skid package Singapore offers businesses the advantages of scalability, customization, and efficiency, making it an indispensable asset for industrial operations in Singapore.

By choosing the right chemical dosing skid package, businesses can not only ensure the efficiency of their processes but also guarantee long-term cost savings and adherence to stringent regulatory standards.

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly.

Also Read – Best pump services

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply