Chemical dosing panel with skid Singapore – Best 2025

Introduction to Chemical dosing panel with skid Singapore

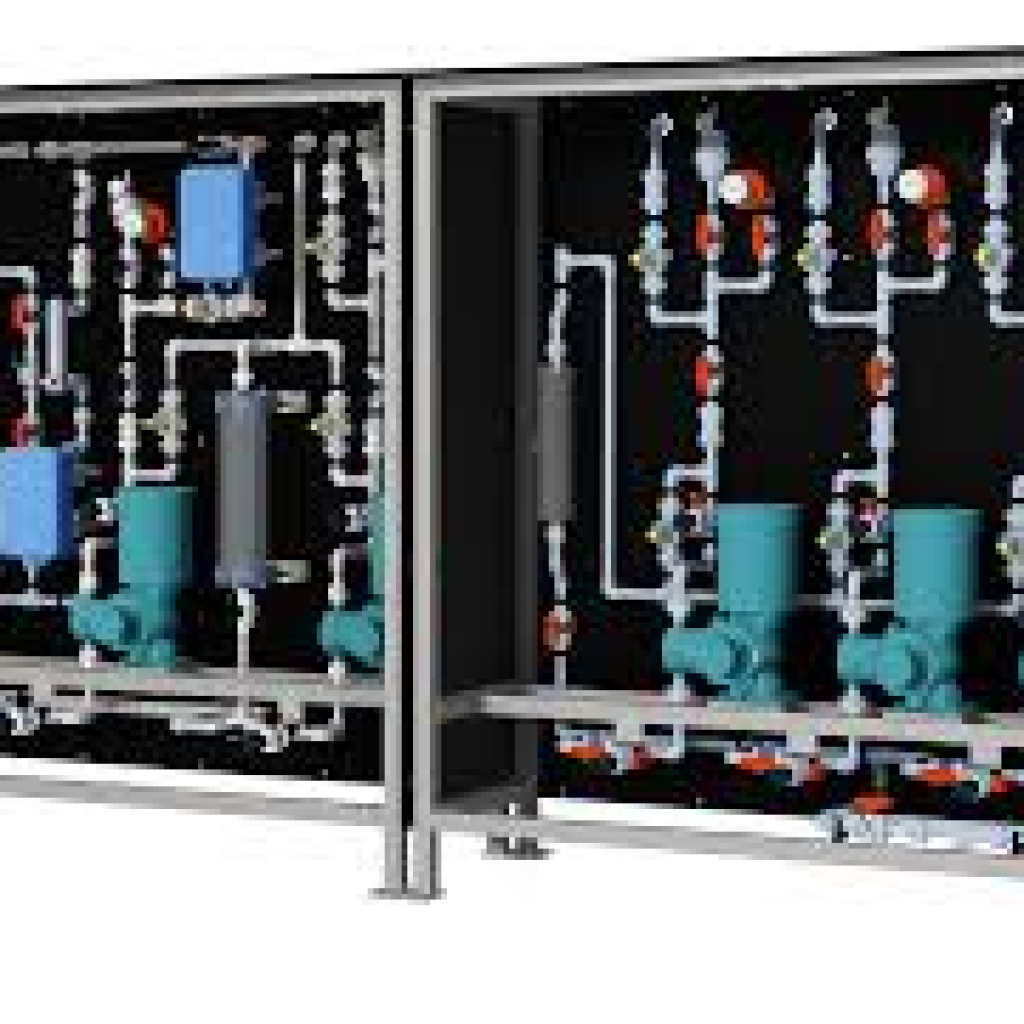

In the fast-evolving industrial landscape of Singapore, precision and efficiency in chemical dosing are critical. The Chemical dosing panel with skid Singapore is a turnkey solution designed to automate and control the dosing of chemicals with maximum accuracy and safety. These systems are engineered to handle a wide range of chemical types and volumes, ensuring optimal performance across multiple industries.

Flomek specializes in delivering advanced Chemical dosing panel with skid Singapore systems that integrate high-quality dosing pumps, control panels, and skid-mounted platforms. This comprehensive solution guarantees streamlined installation, reduced setup times, and robust operational reliability.

Importance of Chemical dosing panel with skid Singapore in industrial applications

The significance of a reliable Chemical dosing panel with skid Singapore cannot be overstated in industries such as water treatment, pharmaceuticals, food processing, and petrochemicals. Accurate chemical dosing ensures product quality, environmental compliance, and operational efficiency. Manual dosing methods are prone to errors, inefficiencies, and safety risks, which can be drastically minimized by deploying an automated Chemical dosing panel with skid Singapore.

Components and features of Chemical dosing panel with skid Singapore

A typical Chemical dosing panel with skid Singapore system includes the following key components:

- Precision dosing pumps capable of handling varying chemical viscosities

- Control panel with PLC or microcontroller for automation and monitoring

- Skid-mounted structural frame for easy transport and installation

- Chemical storage tanks integrated with safety features

- Valves, sensors, and piping designed for chemical compatibility

- User-friendly interface for operational control and diagnostics

Flomek’s Chemical dosing panel with skid Singapore solutions feature modular designs allowing customization based on client-specific requirements, ensuring both scalability and ease of maintenance.

Advantages of using Chemical dosing panel with skid Singapore

The benefits of implementing a Chemical dosing panel with skid Singapore include:

- Enhanced dosing precision reducing chemical wastage

- Compact, skid-mounted design reducing installation space and time

- Improved safety with integrated monitoring and emergency shutdowns

- Reduced labor costs due to automation

- Compliance with Singapore’s stringent environmental and safety standards

- Easy scalability for future capacity expansions

Applications Across Various Industries in Singapore

The versatility of a Chemical dosing panel with skid Singapore makes it indispensable across a broad spectrum of industries in Singapore. Each sector has specific chemical dosing requirements that must be met with precision and reliability.

Water and Wastewater Treatment

In water treatment plants, a Chemical dosing panel with skid Singapore is critical for adding disinfectants, pH adjusters, and coagulants. Precise dosing ensures safe potable water supply and compliance with PUB’s environmental regulations. Flomek’s systems are engineered to handle aggressive chemicals like chlorine and sulfuric acid safely and efficiently.

Food and Beverage Industry

The food sector demands stringent hygiene and chemical control. A Chemical dosing panel with skid Singapore automates the addition of cleaning agents, sanitizers, and additives with zero contamination risk. This automation improves product consistency and reduces human error, critical for maintaining Singapore’s high food safety standards.

Petrochemical and Chemical Manufacturing

Handling corrosive and hazardous substances requires a robust Chemical dosing panel with skid Singapore designed to withstand harsh environments. Flomek customizes skid-mounted dosing systems to safely inject catalysts, solvents, and reagents, ensuring process integrity and worker safety.

Pharmaceutical Production

The pharmaceutical industry demands the highest precision in chemical dosing. Flomek’s Chemical dosing panel with skid Singapore solutions incorporate advanced control algorithms and redundancy features to guarantee consistent formulation and meet strict regulatory requirements.

How Flomek Designs and Customizes Chemical dosing panel with skid Singapore

Flomek takes a client-centric approach when designing a Chemical dosing panel with skid Singapore. Every project begins with a thorough needs assessment, including chemical characteristics, flow rates, environmental conditions, and space constraints.

Tailored Engineering Solutions

Flomek’s engineering team leverages modular design principles, allowing customization of pumps, control systems, and skid frames. Material selection is carefully matched to the chemical media to prevent corrosion and extend equipment life.

Automation and Control Integration

Each Chemical dosing panel with skid Singapore is integrated with programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to enable real-time monitoring, data logging, and remote control. This integration ensures operators maintain full control while minimizing manual intervention.

Quality Assurance and Testing

Prior to delivery, Flomek rigorously tests each Chemical dosing panel with skid Singapore under simulated operating conditions. This testing phase validates system performance, safety interlocks, and compliance with Singapore’s standards.

Installation and Maintenance Best Practices

Proper installation and ongoing maintenance are critical to maximizing the lifespan and efficiency of a Chemical dosing panel with skid Singapore.

Installation

Flomek provides turnkey installation services, ensuring the Chemical dosing panel with skid Singapore is set up according to best engineering practices. Skid-mounted design simplifies installation by allowing the system to be delivered as a preassembled unit, reducing on-site labor and potential errors.

Maintenance

Regular preventive maintenance is vital. Key practices include:

- Periodic calibration of dosing pumps

- Inspection of seals and valves for wear

- Cleaning chemical tanks to prevent contamination

- Software updates for control systems

- Training operators on emergency shutdown procedures

Flomek offers comprehensive maintenance contracts tailored to the operating environment, guaranteeing system reliability over the years.

Compliance with Singaporean Regulations and Standards

Singapore’s industrial sector is highly regulated to ensure safety and environmental protection. A Chemical dosing panel with skid Singapore from Flomek is engineered to meet or exceed these regulatory requirements.

Workplace Safety and Health Act (WSHA)

Flomek designs dosing panels with built-in safety interlocks, emergency stops, and clear labeling, ensuring compliance with WSHA standards to protect workers.

Environmental Protection and Management Act (EPMA)

Accurate chemical dosing minimizes environmental discharges. Flomek’s systems are designed for leak detection and spill containment, aligning with EPMA guidelines.

PUB Water Quality Regulations

For water treatment applications, Flomek ensures that the Chemical dosing panel with skid Singapore meets PUB’s stringent water quality control measures through precise dosing and automated monitoring.

Case Studies and Client Success Stories with Chemical dosing panel with skid Singapore

Flomek’s portfolio includes numerous successful implementations of the Chemical dosing panel with skid Singapore, showcasing its reliability and effectiveness across various industries.

Water Treatment Plant Upgrade in Jurong

A leading water treatment facility in Jurong faced challenges with inconsistent chemical dosing that affected water quality compliance. Flomek supplied a customized Chemical dosing panel with skid Singapore integrated with advanced sensors and automation. Post-installation, the plant reported a 30% reduction in chemical consumption and improved process stability, fully meeting PUB regulations.

Pharmaceutical Manufacturing in Tuas

A pharmaceutical company in Tuas required a dosing system capable of handling corrosive cleaning agents with high precision. Flomek delivered a skid-mounted panel with corrosion-resistant materials and redundant dosing pumps. The system improved dosing accuracy by 25% and minimized downtime, ensuring continuous production and regulatory compliance.

Food Processing Facility in Woodlands

A food processing plant in Woodlands automated their sanitizer dosing with Flomek’s Chemical dosing panel with skid Singapore. The compact skid design allowed quick installation without disrupting ongoing operations. Enhanced automation reduced labor costs and improved hygiene standards, contributing to the facility’s certification renewal.

Key Design Considerations for Chemical dosing panel with skid Singapore

When engineering a Chemical dosing panel with skid Singapore, several critical design factors must be addressed to ensure performance, safety, and longevity.

Material Compatibility

Selecting the right materials for pumps, valves, piping, and skid frames is crucial, especially when handling aggressive chemicals. Flomek uses corrosion-resistant alloys and specialty plastics tailored for the specific chemicals in your process.

System Footprint and Layout

A compact skid-mounted design optimizes limited plant space common in Singapore’s urban industrial zones. Flomek engineers create layouts that integrate seamlessly with existing infrastructure while allowing easy access for maintenance.

Automation Level

Depending on the client’s requirements, the automation level can range from manual control panels to fully integrated PLC systems with remote monitoring. Flomek’s flexible designs ensure the Chemical dosing panel with skid Singapore matches operational preferences and budget.

Safety Features

Built-in leak detection, emergency shutdown mechanisms, and explosion-proof components protect personnel and equipment, complying fully with Singapore’s Workplace Safety and Health regulations.

Troubleshooting Common Issues in Chemical dosing panel with skid Singapore

Even the best-designed systems can experience operational challenges. Understanding common issues and their solutions helps maintain system reliability.

Flow Rate Inconsistencies

Caused by worn pump diaphragms or clogged valves, inconsistent dosing can be corrected by scheduled maintenance and filter replacements. Regular calibration keeps dosing accuracy within tolerance.

Control Panel Failures

Software glitches or electrical faults in the control panel may disrupt dosing. Flomek provides diagnostic tools and remote support to quickly identify and fix such problems, minimizing downtime.

Chemical Leakage

Leakage risks increase with aging seals or improper fittings. Regular inspection and replacement of worn parts are essential to maintaining system integrity and workplace safety.

Environmental Benefits of Using Chemical dosing panel with skid Singapore

Implementing an efficient Chemical dosing panel with skid Singapore positively impacts environmental sustainability.

- Reduced Chemical Waste: Accurate dosing prevents overuse, lowering chemical discharge into the environment.

- Energy Savings: Automated control reduces pump run times and energy consumption.

- Minimized Human Exposure: Closed skid systems reduce operator contact with hazardous substances, promoting workplace health.

By adopting Flomek’s Chemical dosing panel with skid Singapore, companies align with Singapore’s green initiatives and contribute to cleaner production practices.

Integrating Remote Monitoring with Chemical dosing panel with skid Singapore

The integration of remote monitoring solutions elevates the functionality of a Chemical dosing panel with skid Singapore.

Real-Time Data Access

Operators can monitor chemical flow rates, tank levels, and system health remotely via secure web portals or mobile apps, enabling proactive management.

Predictive Maintenance

Data analytics identify trends indicating impending equipment failures, allowing maintenance before breakdowns occur. This minimizes unexpected downtime and repair costs.

Compliance Reporting

Automated generation of dosing logs and system status reports simplifies compliance with Singapore’s regulatory audits.

Flomek’s Commitment to Customer Support for Chemical dosing panel with skid Singapore

Flomek provides extensive customer support tailored to the operational needs of your Chemical dosing panel with skid Singapore.

- Installation Assistance: Expert on-site teams guide system commissioning and operator training.

- Maintenance Programs: Customized service contracts ensure regular system checks and timely upgrades.

- Technical Support: 24/7 helpdesk and remote diagnostics reduce response times for troubleshooting.

- Spare Parts Availability: Ready inventory ensures minimal wait times for critical components.

Advanced Automation Features in Chemical dosing panel with skid Singapore

Modern Chemical dosing panel with skid Singapore systems increasingly integrate advanced automation technologies to improve accuracy and efficiency.

Programmable Logic Controllers (PLC)

PLC-based control systems enable precise scheduling, flow adjustment, and system diagnostics in real time. Flomek’s Chemical dosing panel with skid Singapore solutions include customizable PLC programming to suit specific process demands.

Touchscreen Human-Machine Interfaces (HMI)

User-friendly HMIs provide operators with intuitive control over dosing parameters, alarms, and performance metrics. HMIs in Flomek’s Chemical dosing panel with skid Singapore facilitate quick adjustments and reduce human error.

Automated Alarms and Safety Interlocks

Critical safety functions such as leak detection, pump failure alarms, and emergency stop circuits are fully automated, ensuring that the Chemical dosing panel with skid Singapore operates within safe limits at all times.

The Role of Skid-Mounted Systems in Space Optimization

Space constraints are a significant challenge in many Singapore industrial facilities. The skid-mounted design of the Chemical dosing panel with skid Singapore addresses this by offering a compact, integrated solution.

- Pre-assembled units reduce installation time and complexity.

- Modular skid frames allow easy transport and relocation.

- Efficient piping and wiring layouts minimize footprint without compromising functionality.

Flomek’s skid-mounted dosing panels are engineered to fit into tight spaces while maintaining accessibility for maintenance and inspection.

Customization Options for Chemical dosing panel with skid Singapore

Flomek offers a wide range of customization choices to tailor the Chemical dosing panel with skid Singapore exactly to client requirements.

Pump Types and Capacities

Depending on chemical properties and dosing volumes, clients can select diaphragm pumps, peristaltic pumps, or solenoid pumps integrated within the skid. Flomek engineers design systems to handle flow rates from a few milliliters per minute up to several liters per hour.

Material Selection

To ensure compatibility and longevity, materials such as stainless steel, PVC, PTFE, or FRP are chosen based on the chemical’s corrosiveness and temperature. The skid frame itself can be fabricated from carbon steel with protective coatings or stainless steel.

Control System Flexibility

From basic on/off controls to complex PLC-driven automation with SCADA integration, Flomek customizes the control architecture of the Chemical dosing panel with skid Singapore to match operational sophistication and monitoring needs.

Benefits of Skid-Mounted Chemical dosing panel with skid Singapore for Maintenance

Maintenance efficiency is critical for minimizing downtime in industrial operations.

- Easy Access: Skid-mounted panels provide centralized and accessible arrangement of pumps, valves, and instrumentation.

- Pre-tested Systems: Factory assembly and testing reduce startup issues and maintenance surprises.

- Modular Components: Individual components are replaceable without dismantling the entire skid.

- Simplified Troubleshooting: Centralized control panels offer clear diagnostics aiding faster repairs.

Flomek’s Chemical dosing panel with skid Singapore design philosophy prioritizes maintenance simplicity to maximize operational availability.

Integration of Safety Standards in Chemical dosing panel with skid Singapore

Safety is a paramount concern when dealing with chemicals.

- Explosion-Proof Enclosures: For volatile chemicals, Flomek equips panels with ATEX-certified enclosures meeting Singapore’s hazardous zone classifications.

- Emergency Shutoff Valves: Automated valves prevent chemical flow during abnormal conditions.

- Overpressure and Leak Sensors: Early detection systems alert operators to prevent accidents.

- Comprehensive Documentation: Detailed manuals and compliance certificates accompany every Chemical dosing panel with skid Singapore, supporting safe operation and audits.

By incorporating these features, Flomek ensures your chemical dosing process meets and exceeds local and international safety standards.

Cost Efficiency of Chemical dosing panel with skid Singapore

While initial investment is an important consideration, the total cost of ownership makes the Chemical dosing panel with skid Singapore an economical choice.

- Lower Installation Costs: Pre-fabricated skid units cut site labor and commissioning time.

- Reduced Chemical Waste: Precise dosing minimizes excess chemical purchase and disposal costs.

- Energy Savings: Efficient pump and control system design lowers electricity consumption.

- Extended Equipment Life: Durable materials and preventive maintenance reduce replacement frequency.

Choosing Flomek’s Chemical dosing panel with skid Singapore means better budget control and ROI over the equipment lifecycle.

Supporting Singapore’s Industrial Growth with Chemical dosing panel with skid Singapore

As Singapore continues to expand its industrial base, demand for reliable and efficient chemical dosing grows.

Flomek’s Chemical dosing panel with skid Singapore solutions support this growth by enabling industries to:

- Scale operations quickly with modular skid systems.

- Meet strict environmental regulations through precise dosing.

- Improve productivity and reduce labor costs with automation.

- Enhance safety and reduce workplace hazards.

By partnering with Flomek, companies contribute to Singapore’s vision of a smart, sustainable, and resilient industrial economy.

Comparing Chemical dosing panel with skid Singapore to Traditional Systems

Traditional chemical dosing systems often involve separate components installed individually on-site, leading to longer installation times and higher risks of misalignment or leaks.

In contrast, a Chemical dosing panel with skid Singapore offers:

- Factory-assembled and tested units ensuring quality control.

- Reduced site labor costs and faster commissioning.

- Integrated safety features and streamlined wiring.

- Enhanced portability and scalability for future upgrades.

This makes the Chemical dosing panel with skid Singapore an optimal choice for modern, efficient chemical dosing applications.

Training and Skill Development for Operators of Chemical dosing panel with skid Singapore

Proper training of personnel ensures safe and efficient operation of the Chemical dosing panel with skid Singapore.

Flomek provides comprehensive training programs covering:

- System operation and control panel use.

- Routine maintenance and troubleshooting techniques.

- Safety protocols and emergency procedures.

- Understanding sensor data and automated alerts.

Empowered operators maximize uptime and reduce operational risks associated with chemical dosing.

Innovations Driving the Future of Chemical dosing panel with skid Singapore

Research and development continue to push the capabilities of Chemical dosing panel with skid Singapore systems.

- Integration with Industry 4.0 platforms enables seamless data exchange with enterprise systems.

- AI-powered dosing algorithms optimize chemical usage based on historical and real-time process data.

- Enhanced materials improve durability and chemical resistance in increasingly demanding environments.

- Wireless monitoring and control reduce wiring complexity and enhance installation flexibility.

Flomek remains at the forefront of these advancements, delivering state-of-the-art Chemical dosing panel with skid Singapore solutions to its clients.

Future Trends in Chemical dosing panel with skid Singapore Technology

The future of Chemical dosing panel with skid Singapore technology is driven by innovation in automation, sustainability, and digital integration.

Smart Dosing with AI and IoT

Next-generation systems are incorporating AI algorithms and IoT sensors to optimize dosing based on real-time process data. This reduces chemical waste and improves process adaptability, key for Singapore’s smart industry initiatives.

Energy-Efficient Designs

There is a growing emphasis on energy conservation. Future Chemical dosing panel with skid Singapore models will utilize variable speed drives and energy recovery technologies to minimize power consumption without compromising performance.

Modular and Scalable Solutions

To meet evolving industrial demands, modular skid-mounted panels allow rapid upgrades and capacity scaling, enabling Singapore’s industries to stay agile and competitive.

Why Choose Flomek for Your Chemical dosing panel with skid Singapore Needs?

Flomek stands out as a trusted provider of Chemical dosing panel with skid Singapore solutions due to its comprehensive expertise and client-focused approach.

- Custom Engineering: Tailored designs to match your exact chemical, flow, and space requirements.

- Turnkey Solutions: End-to-end project management from design through installation and commissioning.

- Quality Assurance: Rigorous testing to ensure reliability and compliance.

- Local Support: Dedicated Singapore-based service and maintenance teams for rapid response.

- Innovation: Integration of the latest automation and monitoring technologies.

By partnering with Flomek, you ensure a seamless experience and a dosing system that delivers long-term value and peace of mind.

Conclusion: Maximizing Efficiency with Chemical dosing panel with skid Singapore

Choosing the right Chemical dosing panel with skid Singapore is critical for industrial efficiency, safety, and regulatory compliance. Flomek’s turnkey skid-mounted dosing panels combine precision engineering, automation, and durability to meet Singapore’s stringent industry standards.

Investing in a Flomek Chemical dosing panel with skid Singapore guarantees improved chemical usage, reduced operational costs, and enhanced process control—driving your business towards a sustainable and competitive future.

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply