Chemical dosing package Singapore – Best 2025

Comprehensive Guide to Chemical Dosing Package Singapore: Your Ultimate Solution for Precise Chemical Injection

Introduction to Chemical Dosing Package Singapore

When it comes to industrial water treatment, manufacturing, and various process applications, accuracy and reliability in chemical dosing are paramount. A Chemical dosing package Singapore is designed to meet these critical demands by providing a fully integrated system that ensures precise and efficient chemical injection into water or process lines.

In this extensive guide, we will explore everything you need to know about chemical dosing packages available in Singapore, covering the technology, components, applications, advantages, and how to select the best supplier for your needs.

What is a Chemical Dosing Package?

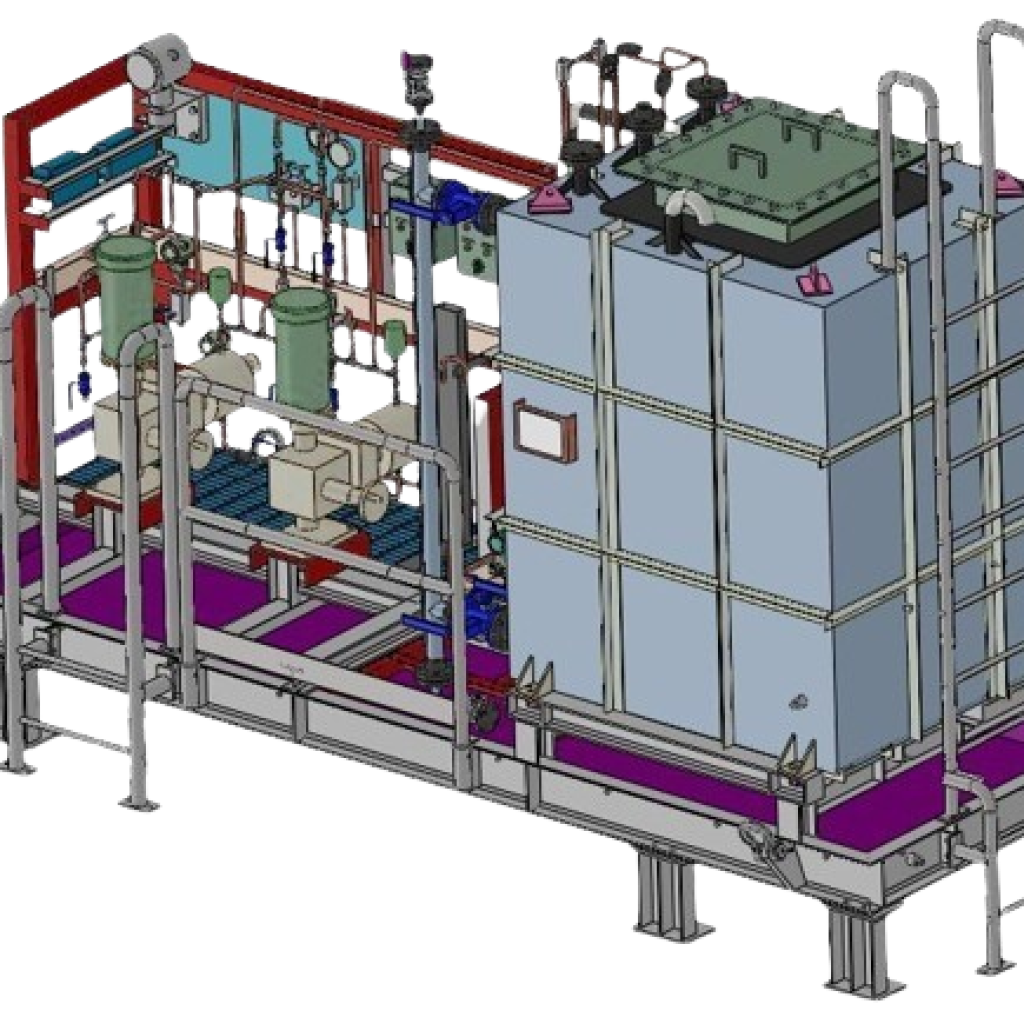

A chemical dosing package is a pre-engineered and skid-mounted system comprising all necessary components to accurately dose chemicals into a process. These packages are engineered to simplify installation, improve operational efficiency, and ensure safety and compliance.

Key Components of a Chemical Dosing Package Singapore:

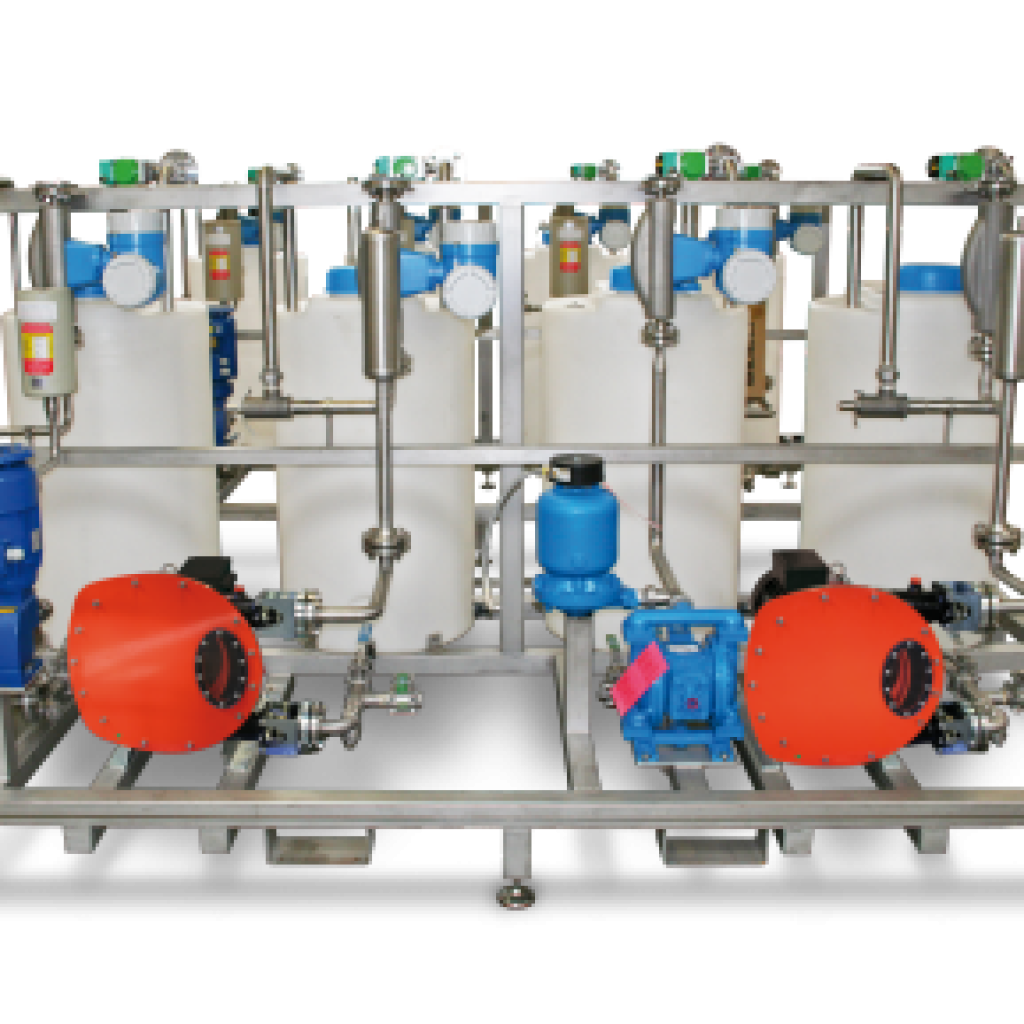

- Chemical dosing pumps: Metering pumps such as diaphragm pumps or peristaltic pumps.

- Piping and valves: High-quality materials to handle corrosive chemicals.

- Flow meters and control valves: For accurate flow measurement and control.

- Instrumentation: Sensors, controllers, and PLC systems for automated operation.

- Chemical storage tanks: For safe chemical storage.

- Safety equipment: Leak detection, spill containment, and alarms.

Why Choose a Chemical Dosing Package in Singapore?

Singapore is a hub for industrial, municipal, and commercial water treatment, making it an ideal market for advanced chemical dosing packages. The Chemical dosing package Singapore solutions are designed to meet stringent quality standards, local regulations, and operational demands.

Advantages of Chemical Dosing Package Singapore:

- Precision and Accuracy: High-performance dosing pumps deliver exact chemical volumes.

- Integrated Systems: Skid-mounted packages reduce installation time and minimize errors.

- Safety Compliance: Packages conform to Singapore’s environmental and safety regulations.

- Customization: Tailored solutions for various industries and chemical types.

- Technical Support: Local suppliers offer maintenance, repairs, and consultancy.

- Compact and Modular: Designed for space efficiency and easy scalability.

Applications of Chemical Dosing Packages in Singapore

The versatility of chemical dosing packages makes them indispensable in numerous sectors across Singapore, such as:

1. Water and Wastewater Treatment

- pH control

- Chlorination and disinfection

- Coagulation and flocculation

- Corrosion inhibition

2. Industrial Process Control

- Cooling tower treatment

- Boiler feed water treatment

- Chemical injection in manufacturing processes

3. Food & Beverage Industry

- Precise dosing of preservatives and sanitizers

- Compliance with hygiene standards

4. Pharmaceutical Industry

- Accurate chemical dosing for manufacturing

- Maintaining product consistency and quality

How Does a Chemical Dosing Package Work?

The heart of the Chemical dosing package Singapore is the metering pump that draws chemical from a storage tank and injects it into the process stream at a controlled rate. The entire system is designed to monitor, control, and optimize the dosing process to prevent overdosing or underdosing, which could cause operational or safety issues.

Automation and control systems integrated into the package allow for real-time monitoring, adjustment, and fault detection, ensuring reliability and efficiency.

Types of Chemical Dosing Pumps in Chemical Dosing Packages

In Singapore, various types of pumps are used in chemical dosing packages, selected based on the chemical properties and application requirements:

- Diaphragm Pumps: Ideal for corrosive and hazardous chemicals, offering leak-free operation.

- Peristaltic Pumps: Suitable for viscous or slurry chemicals; easy maintenance.

- Piston Pumps: High-pressure applications requiring precise control.

- Solenoid Pumps: Compact and economical for low flow rates.

Factors to Consider When Choosing a Chemical Dosing Package Singapore

Selecting the right chemical dosing package is crucial for operational success. Here are key factors to consider:

1. Chemical Compatibility

Ensure all wetted parts are compatible with the chemical being dosed to prevent corrosion or degradation.

2. Flow Rate and Pressure

Determine the required dosing volume and injection pressure to select appropriate pumps and valves.

3. Automation Level

Decide on manual, semi-automatic, or fully automated control based on process needs.

4. Space and Installation Constraints

Choose compact, skid-mounted packages if space is limited.

5. Maintenance and Service

Opt for suppliers offering local support, spare parts availability, and training.

Benefits of Skid-Mounted Chemical Dosing Packages in Singapore

Skid-mounted chemical dosing packages are highly favored in Singapore due to their ease of installation and operational efficiency.

- Plug-and-play: Minimizes downtime during installation.

- Reduced Civil Work: Less piping and electrical work needed.

- Quality Control: Factory-tested systems reduce commissioning issues.

- Mobility: Easy to relocate or expand.

Leading Suppliers of Chemical Dosing Package Singapore

Singapore hosts numerous reputable suppliers specializing in chemical dosing packages, offering customized solutions to meet diverse industrial needs.

Why Work with a Local Supplier?

- Faster lead times and delivery.

- Better understanding of local regulations and standards.

- On-site support and maintenance.

- Expertise in customized system design.

Maintenance Tips for Chemical Dosing Package Singapore

Regular maintenance is vital to ensure longevity and consistent performance:

- Routine inspection of pumps and valves.

- Calibration of flow meters and instruments.

- Checking chemical storage tanks for leaks or contamination.

- Cleaning and replacing worn-out parts promptly.

- Monitoring control systems and software updates.

Cost Factors of Chemical Dosing Package Singapore

Several factors affect the overall cost:

- Complexity and size of the package.

- Type and capacity of dosing pumps.

- Automation and instrumentation level.

- Material of construction.

- Installation and commissioning costs.

Future Trends in Chemical Dosing Packages in Singapore

Singapore is a technology-driven market embracing innovation such as:

- Smart Dosing Systems: Integration with IoT and remote monitoring.

- Energy-efficient pumps: To reduce operational costs.

- Environmentally Friendly Materials: Sustainable and corrosion-resistant materials.

- Modular Systems: For easier upgrades and flexibility.

Understanding the integral components helps in appreciating the sophistication and functionality of a Chemical dosing package Singapore.

1. Chemical Dosing Pumps

The core element that delivers the exact volume of chemical required into the process stream.

- Diaphragm Pumps: Popular in Singapore’s chemical dosing packages due to their leak-proof design and ability to handle aggressive chemicals safely.

- Peristaltic Pumps: Offer gentle pumping action ideal for shear-sensitive chemicals.

- Piston Pumps: Deliver high-pressure chemical injection in complex processes.

- Solenoid Pumps: Best for compact and low-flow applications, providing cost-effectiveness.

2. Control Panel and Automation

Advanced control panels equipped with PLCs (Programmable Logic Controllers) allow:

- Automatic dosing based on process parameters.

- Remote monitoring and data logging.

- Integration with SCADA systems for large plant management.

- Alarms and safety interlocks to prevent mishaps.

3. Flow Meters and Sensors

Precise measurement of chemical flow ensures accurate dosing and process stability. Common flow meters include:

- Magnetic flow meters

- Coriolis flow meters

- Ultrasonic flow meters

Sensors for pH, conductivity, or oxidation-reduction potential (ORP) help regulate dosing rates dynamically.

4. Chemical Storage and Handling Systems

Storage tanks are designed from materials like polyethylene or stainless steel, selected based on chemical compatibility.

- Secondary containment systems prevent leaks and environmental contamination.

- Safe chemical transfer pumps reduce manual handling risks.

5. Piping and Valves

Chemical-resistant piping and precision valves ensure the chemical reaches the injection point without leakage or degradation.

- Materials include PVDF, PTFE, or stainless steel.

- Check valves and pressure relief valves enhance safety.

Industry-Specific Uses of Chemical Dosing Package Singapore

Municipal Water Treatment

Municipalities in Singapore rely heavily on chemical dosing packages to treat drinking water and wastewater. Key chemicals include chlorine for disinfection, coagulants to remove suspended solids, and pH adjusters.

- Chlorine Dosing: Ensures safe potable water by eliminating pathogens.

- Flocculant Dosing: Helps in sedimentation and filtration by aggregating particles.

Industrial Manufacturing

Chemical dosing packages are vital for controlling corrosion, scaling, and microbial growth in cooling towers, boilers, and process lines.

- Corrosion Inhibitors: Protect expensive equipment and pipelines.

- Scale Inhibitors: Prevent mineral buildup that reduces heat transfer efficiency.

Food and Beverage Processing

Strict hygiene regulations in Singapore require precise chemical dosing for sanitizers and preservatives to maintain product safety and compliance.

Pharmaceutical Production

Maintaining exact chemical concentrations ensures product consistency and regulatory compliance, making chemical dosing packages indispensable.

Selecting the Right Chemical Dosing Package Supplier in Singapore

Choosing a supplier is a critical decision. Here are some tips to find the best Chemical dosing package Singapore provider:

1. Experience and Expertise

Look for companies with proven track records in designing and supplying dosing systems for your industry.

2. Customization Capability

A supplier who can tailor the package to your process specifics will provide better long-term value.

3. After-Sales Support

Ensure availability of maintenance services, spare parts, and technical support in Singapore.

4. Compliance and Certification

Verify the supplier meets local regulatory standards such as PUB Singapore’s water regulations.

5. Technology and Innovation

Modern suppliers provide smart dosing systems with IoT capabilities and predictive maintenance.

Installation and Commissioning of Chemical Dosing Package Singapore

Proper installation and commissioning are essential for optimal performance.

- Site preparation and foundation requirements.

- Integration with existing plant control systems.

- Calibration of pumps and instrumentation.

- Operator training and handover documentation.

Local Singapore suppliers usually provide turnkey solutions that include these critical steps, reducing project risk.

Troubleshooting Common Issues with Chemical Dosing Packages

Even the best systems may encounter operational challenges. Here are common issues and fixes:

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent dosing flow | Air in pump suction | Bleed the air out; check fittings |

| Pump not starting | Electrical fault or control error | Inspect power supply; reset control |

| Chemical leakage | Damaged seals or piping | Replace seals; inspect connections |

| Overdosing or underdosing | Faulty flow meter or controller | Calibrate instruments; check sensors |

Environmental and Safety Considerations for Chemical Dosing Package Singapore

Singapore emphasizes strict environmental compliance to prevent chemical hazards.

- Use of secondary containment to avoid spills.

- Proper ventilation in chemical dosing rooms.

- Safety interlocks and emergency shutdown systems.

- Training personnel on chemical handling and emergency procedures.

Adopting these ensures not only regulatory compliance but also workplace safety.

Cost vs. Value: Investing in Chemical Dosing Package Singapore

While initial costs can vary, investing in a high-quality Chemical dosing package Singapore pays off in:

- Reduced chemical wastage and operational costs.

- Lower maintenance expenses due to robust design.

- Avoidance of downtime and process disruptions.

- Compliance with environmental standards, avoiding fines.

Latest Innovations in Chemical Dosing Package Singapore

Singapore’s chemical dosing solutions are evolving rapidly with:

- Digital Twin Technology: Virtual simulation of dosing systems for optimization.

- Remote Diagnostics: Enables proactive maintenance via cloud-based monitoring.

- Energy-Efficient Pumps: Reducing carbon footprint and power bills.

- Eco-Friendly Materials: Enhanced durability and sustainability.

FAQs about Chemical Dosing Package Singapore

Q1: What industries benefit the most from chemical dosing packages?

Answer: Water treatment, manufacturing, food & beverage, and pharmaceutical industries are primary users in Singapore.

Q2: How often should the chemical dosing package be maintained?

Answer: Regular maintenance is recommended quarterly, with daily operator checks for optimal performance.

Q3: Can chemical dosing packages be customized?

Answer: Yes, most suppliers in Singapore offer tailored solutions based on specific process needs.

Q4: What chemicals are commonly dosed using these packages?

Answer: Chlorine, acids, alkalis, coagulants, corrosion inhibitors, and biocides are typical.

Q5: How do I ensure safety when using chemical dosing packages?

Answer: Use packages with safety interlocks, secondary containment, and ensure proper training for personnel.

Summary: Why a Chemical Dosing Package Singapore is Essential for Your Business

To summarize, a Chemical dosing package Singapore offers:

- Precision chemical injection.

- Compact and integrated skid design.

- Compliance with Singapore’s strict safety and environmental regulations.

- Customizable solutions for diverse industrial needs.

- Reliable operation backed by local supplier support.

By choosing the right system, you enhance operational efficiency, protect your equipment, and ensure regulatory compliance.

Innovations in Chemical Dosing Package Singapore: Smart Systems and IoT Integration

In recent years, the Chemical dosing package Singapore industry has seen a significant shift towards smart and connected technologies. Modern chemical dosing packages are now equipped with IoT-enabled sensors and controllers, enabling real-time data collection and remote monitoring. This innovation allows process managers to monitor dosing accuracy, detect faults instantly, and optimize chemical usage remotely from anywhere in Singapore or globally.

These smart chemical dosing packages offer benefits such as:

- Predictive maintenance to prevent downtime.

- Automated dosing adjustments based on real-time process data.

- Enhanced reporting for regulatory compliance.

- Integration with plant-wide SCADA and automation systems.

By adopting these smart technologies, Singapore industries can reduce operational costs and improve process reliability while ensuring their chemical dosing packages remain at the forefront of innovation.

Customization Options for Chemical Dosing Package Singapore: Tailoring to Your Industry Needs

No two chemical dosing requirements are exactly the same. A reputable Chemical dosing package Singapore supplier offers extensive customization to meet unique industrial process parameters.

Customization options include:

- Selection of dosing pumps based on chemical properties and flow rate.

- Material of construction choices such as PVDF, SS316, or PTFE for corrosion resistance.

- Integration of advanced control panels with PLC programming tailored to process logic.

- Modular skid designs for space constraints or future expansion.

- Multiple chemical feed points and dual dosing systems for complex treatment processes.

These customizations ensure that the chemical dosing package fits perfectly within your process environment, maximizing performance and safety.

Importance of Accurate Chemical Dosing in Singapore’s Water Treatment Plants

Water treatment plants in Singapore rely heavily on precise chemical dosing to maintain water quality, protect infrastructure, and comply with national water standards. A high-quality Chemical dosing package Singapore enables accurate delivery of disinfectants, pH adjusters, and coagulants to optimize treatment efficiency.

Proper dosing minimizes chemical waste and environmental impact, reduces operational costs, and prevents issues like scaling, corrosion, or biological contamination. Singapore’s PUB regulations demand stringent control and monitoring of chemical dosing, making advanced dosing packages indispensable.

How Chemical Dosing Package Singapore Supports Sustainability Goals

Sustainability is a growing priority for Singapore’s industries and municipalities. Efficient chemical dosing plays a crucial role in reducing chemical consumption and minimizing environmental footprints.

The Chemical dosing package Singapore systems designed with energy-efficient pumps, leak-proof components, and automated controls help achieve these sustainability goals by:

- Reducing overdosing and chemical waste.

- Enhancing process water reuse through precise treatment.

- Lowering energy consumption with optimized pump operation.

- Using eco-friendly materials that reduce environmental hazards.

By choosing sustainable chemical dosing packages, companies in Singapore can align their operations with national green initiatives and global environmental standards.

Training and Support Services for Chemical Dosing Package Singapore Users

Investing in a chemical dosing package is only part of the solution. Proper operation and maintenance require skilled personnel. Leading Chemical dosing package Singapore providers offer comprehensive training programs and ongoing technical support tailored to customer needs.

Training includes:

- Safe chemical handling and dosing procedures.

- Routine maintenance and troubleshooting.

- Understanding control panel operations and alarm systems.

- Compliance with Singapore’s workplace safety standards.

Technical support ensures that any operational issues are promptly resolved, minimizing downtime and protecting your investment.

Case Study: Successful Implementation of Chemical Dosing Package Singapore in Industrial Cooling Towers

One industrial client in Singapore recently upgraded their cooling tower water treatment system with a state-of-the-art Chemical dosing package Singapore. The customized skid-mounted package included corrosion inhibitors, biocide dosing pumps, and fully automated PLC controls integrated into the plant’s SCADA system.

Results included:

- 20% reduction in chemical consumption.

- Improved water quality and reduced downtime.

- Enhanced compliance with environmental discharge regulations.

- Simplified maintenance and operator control.

This case highlights the critical role chemical dosing packages play in maintaining industrial efficiency and regulatory adherence in Singapore.

Regulatory Compliance and Quality Standards for Chemical Dosing Package Singapore

All chemical dosing equipment used in Singapore must meet strict regulatory requirements to ensure safety and environmental protection.

Key compliance considerations for Chemical dosing package Singapore include:

- Certification to ISO 9001 quality standards.

- Adherence to Singapore’s PUB water treatment regulations.

- Use of materials that meet environmental safety norms.

- Installation following workplace safety guidelines.

- Proper documentation for audit and inspection purposes.

Choosing a compliant chemical dosing package guarantees that your operations remain safe, legal, and sustainable.

Integration of Chemical Dosing Package Singapore with Other Process Equipment

A modern industrial or municipal plant typically involves multiple interconnected systems. The Chemical dosing package Singapore can be seamlessly integrated with other process equipment such as:

- Filtration units

- Reverse osmosis (RO) systems

- pH neutralization tanks

- Online analyzers and sensors

Such integration enhances overall process control, efficiency, and automation, delivering a holistic water treatment or chemical injection solution.

Challenges in Implementing Chemical Dosing Package Singapore and How to Overcome Them

Despite their advantages, installing and operating chemical dosing packages can face challenges such as:

- Space limitations in plant layouts.

- Compatibility issues with highly corrosive or viscous chemicals.

- Complexity in integrating with legacy control systems.

- Ensuring operator training and safety adherence.

Overcoming these challenges requires partnering with experienced Singapore-based suppliers who offer tailored design solutions, on-site support, and comprehensive training programs.

Conclusion: Your Trusted Partner for Chemical Dosing Package Singapore

Investing in a reliable Chemical dosing package Singapore is essential for precise chemical injection, operational safety, and efficiency. By selecting a trusted supplier with proven expertise and quality systems, you ensure seamless integration and long-term success in your industrial or municipal applications.

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply