Dosing skid engineering service Singapore – Best 2025

Dosing Skid Engineering Service Singapore – FLOMEK’s Precision Approach to Fluid Handling Systems

Introduction to Dosing Skid Engineering Service in Singapore

In the industrial landscape of Singapore, precision, efficiency, and compliance are paramount. Whether it’s in water treatment, chemical processing, or pharmaceutical applications, the demand for tailored, reliable fluid handling systems is growing rapidly. One such critical solution is the dosing skid engineering service Singapore, a specialized engineering service that integrates pumps, tanks, valves, piping, and instrumentation into a compact, skid-mounted unit for precise chemical dosing and injection.

FLOMEK Singapore takes the lead in offering industry-grade dosing skid engineering service Singapore that meets the rigorous demands of modern industries. These custom-designed systems are manufactured to ensure optimal dosing accuracy, safety, and operational ease.

What Is a Dosing Skid?

A dosing skid is a pre-assembled, modular unit that integrates dosing pumps, control systems, valves, and accessories into a single frame or skid. It is used to inject chemicals, additives, or other fluids into a process stream at controlled rates. The compact and modular nature of the system makes it an ideal solution for industries that require consistency, compliance, and easy maintenance.

The dosing skid engineering service Singapore delivers systems tailored to meet local industry requirements, including compliance with PUB standards, NEA regulations, and relevant ISO certifications.

Applications of Dosing Skid Systems in Singapore

Dosing skid systems are widely used across various industries in Singapore, such as:

- Water and wastewater treatment plants

- Chemical processing plants

- Power generation facilities

- Food and beverage production

- Pharmaceutical and biotechnology

- Marine and offshore industries

The dosing skid engineering service Singapore caters to all these sectors with advanced solutions that are tested and calibrated for local operational environments.

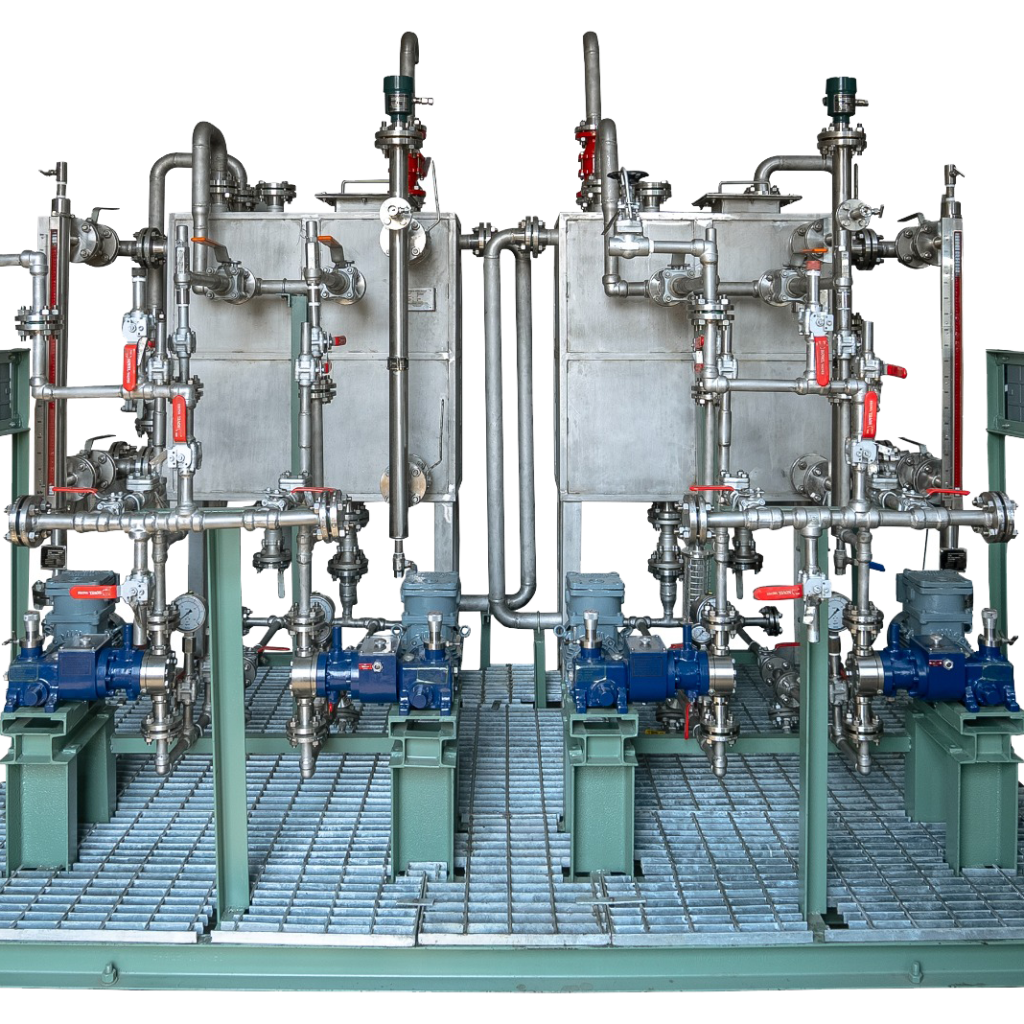

Key Components of a Dosing Skid System

Each dosing skid engineered by FLOMEK Singapore is tailored to your exact process requirements and can include:

- Dosing Pumps (Diaphragm, Peristaltic, or Plunger types)

- Chemical Storage Tanks

- Pressure Gauges and Flow Meters

- Instrumentation for Control & Automation

- Safety Relief Valves & Pressure Regulators

- Electrical Control Panels with PLC Integration

- Skid Frame – Stainless Steel, Mild Steel, or Coated Alloys

Every element in our dosing skid engineering service Singapore solution is carefully selected to enhance system durability and dosing accuracy.

Advantages of FLOMEK’s Dosing Skid Engineering Service Singapore

1. Custom Engineered Solutions

No two processes are the same. FLOMEK ensures that each dosing skid engineering service Singapore package is custom-designed according to chemical type, dosing rate, pressure requirements, and industry application.

2. Plug-and-Play Installation

The modular, pre-tested nature of the dosing skid allows for quick installation and startup, minimizing downtime and reducing commissioning efforts.

3. Precision and Accuracy

Our systems are calibrated for high-precision dosing, ensuring the right amount of chemical is delivered consistently.

4. Space-Efficient Designs

Compact footprints make it suitable for space-constrained sites, which is often a concern in Singapore’s urban industrial zones.

5. Compliance and Quality Assurance

All dosing skids are manufactured under strict quality control measures and meet Singaporean industrial compliance standards. Our dosing skid engineering service Singapore prioritizes safety and reliability.

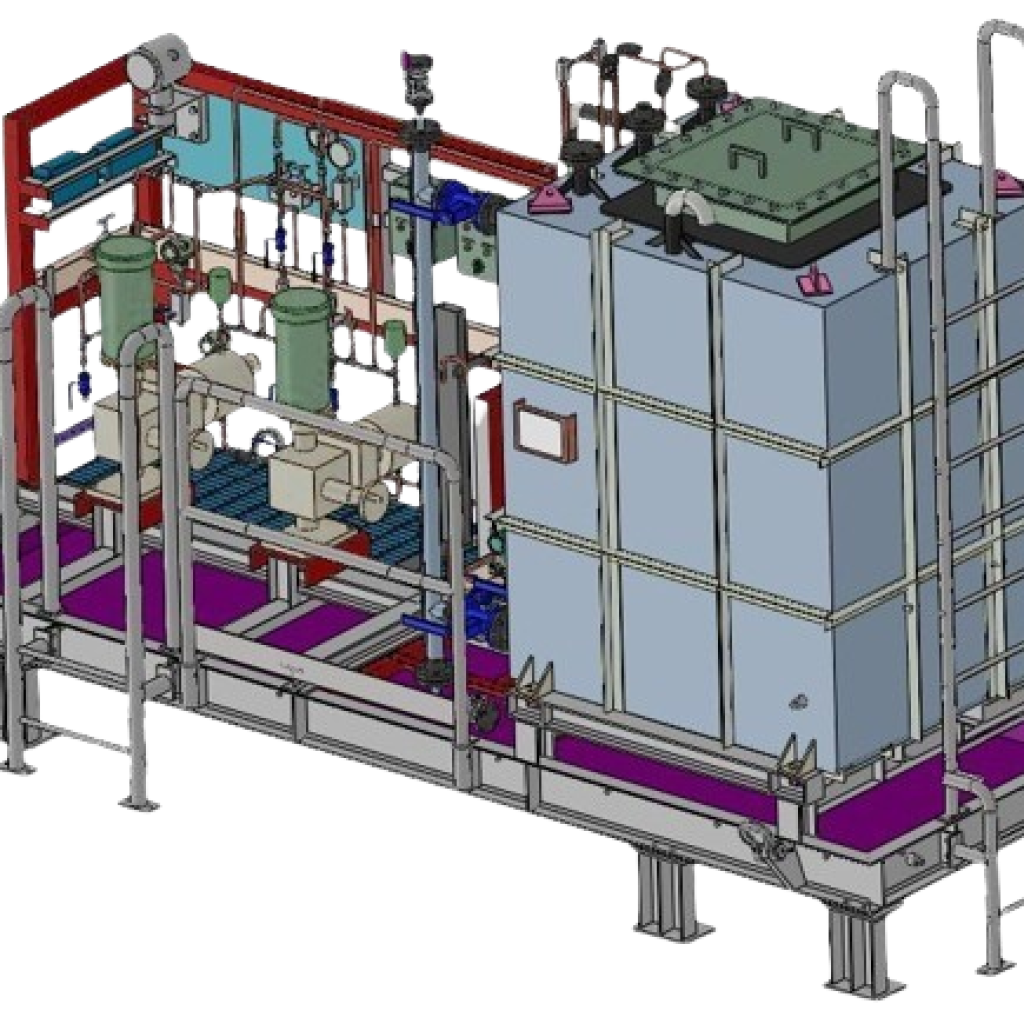

Design and Engineering Expertise

FLOMEK’s dosing skid engineering service Singapore is supported by a team of seasoned mechanical, process, and electrical engineers who bring deep domain expertise to every project. From initial concept and 3D modeling to fabrication and factory testing, every phase is controlled and optimized.

Our Engineering Services Include:

- Process Design Calculations

- P&ID and GA Drawings

- Pump Selection & Material Specification

- PLC & SCADA Integration

- Instrument Calibration

- Site Commissioning and Performance Testing

The robust in-house capabilities behind our dosing skid engineering service Singapore guarantee a seamless transition from design to deployment.

Industries We Serve with Dosing Skid Engineering Service Singapore

Water Treatment Sector

Whether it is chlorine dosing, polymer injection, or pH control, FLOMEK’s dosing skid engineering service Singapore ensures water treatment plants comply with PUB’s water quality standards.

Power and Utility Plants

In cooling towers and boilers, chemical dosing is critical to prevent corrosion and scaling. Our dosing skids ensure continuous and automated chemical feed to protect critical equipment.

Chemical Industry

FLOMEK’s dosing skid engineering service Singapore is widely used in acid/alkali neutralization, disinfectant dosing, and chemical blending processes.

Food & Beverage

Food-grade materials and hygienic design standards are incorporated to suit CIP processes, flavor dosing, and preservative additions.

Pharmaceuticals and Biotech

Precision, repeatability, and aseptic design are core elements in our dosing systems for pharmaceutical cleanroom applications.

Turnkey Dosing Skid Engineering Service Singapore

At FLOMEK, we offer end-to-end turnkey solutions:

- Feasibility Study & Engineering Consultation

- Custom Design & Approval Workflow

- Procurement of Components (locally available or imported)

- In-house Skid Fabrication and Assembly

- Testing: FAT, Hydrotest, Electrical Test, Instrument Calibration

- Packing, Logistics & On-Site Commissioning

Our fully integrated dosing skid engineering service Singapore ensures you have a one-stop solution with a single point of accountability.

Automation and Control in Dosing Skids

Modern dosing systems demand smart control. FLOMEK integrates PLC, SCADA, and HMI systems into our dosing skids to enable:

- Real-time monitoring and control

- Alarm and interlock settings

- Historical data logging

- Remote access via IoT and cloud

With our smart automation capabilities, dosing skid engineering service Singapore becomes a future-ready solution for industries moving toward digitalization.

Why FLOMEK for Dosing Skid Engineering Service Singapore?

- Local expertise with global standards

- ISO-certified fabrication workshop

- Compliance with Singapore regulations

- After-sales support and preventive maintenance

- Engineering precision and quality assurance

By choosing FLOMEK’s dosing skid engineering service Singapore, industries gain a long-term partner dedicated to operational excellence and engineering innovation.

Maintenance & Lifecycle Support

Our responsibility doesn’t end with delivery. FLOMEK provides ongoing support, including:

- Scheduled maintenance of dosing skids

- Spare parts management

- Pump recalibration and performance tuning

- Software updates for automation systems

- On-site technician visits and troubleshooting

This lifecycle support solidifies our commitment to sustainable and uninterrupted dosing operations through our dosing skid engineering service Singapore.

Environmental & Safety Considerations

FLOMEK designs dosing systems that ensure:

- Containment of hazardous chemicals

- Secondary containment trays

- Explosion-proof components for classified areas

- Compliance with NEA environmental codes

- Zero-spill connection systems

These features reinforce our position as a responsible provider of dosing skid engineering service Singapore, prioritizing people, process, and the planet.

Project Case Highlights (No specific client names mentioned)

- Skid for pH correction in a water treatment plant – integrated with PLC & online sensor feedback.

- Acid dosing skid with double containment design for a semiconductor facility.

- Food-grade dosing system for preservatives in a bottling plant.

- High-volume chemical skid with dual-pump redundancy for a marine vessel.

Each of these projects showcases our capability to deliver tailored dosing skid engineering service Singapore under complex and challenging conditions.

Advanced Material Selection for Dosing Skids in Singapore

One of the most critical factors in the reliability of a dosing system is the selection of materials. At FLOMEK, every dosing skid engineering service Singapore project is evaluated for chemical compatibility, corrosion resistance, and operating temperature/pressure profiles.

Common Material Options Include:

- SS316 / SS304 for high corrosion resistance

- HDPE or PP for handling aggressive acids and alkalis

- PTFE-lined pipes for ultra-corrosive chemicals

- FRP structures for lightweight and non-metallic installations

- Explosion-proof enclosures for hazardous zones

By carefully engineering the system materials, we extend the lifecycle of your dosing skid while maintaining operational safety. This meticulous attention to detail is what sets FLOMEK apart in dosing skid engineering service Singapore.

Instrumentation & Control Philosophy in Dosing Skid Design

Instrumentation is the heart of a modern dosing skid. FLOMEK’s engineers integrate reliable field instruments and control logic that align with the client’s process philosophy. For every dosing skid engineering service Singapore, we customize based on application sensitivity and automation level.

Instruments typically integrated include:

- Flow Meters (Electromagnetic, Coriolis, or Ultrasonic)

- Level Transmitters for tanks (Radar or Ultrasonic)

- Pressure Transmitters and Gauges

- Temperature Sensors (RTD/Thermocouple)

- Control Valves with Positioners

- Batch Controllers and Timers

All instruments are pre-wired and tested during FAT (Factory Acceptance Test), making the skid a plug-and-play system. Our comprehensive dosing skid engineering service Singapore ensures accuracy, safety, and process integration with your DCS, PLC, or SCADA system.

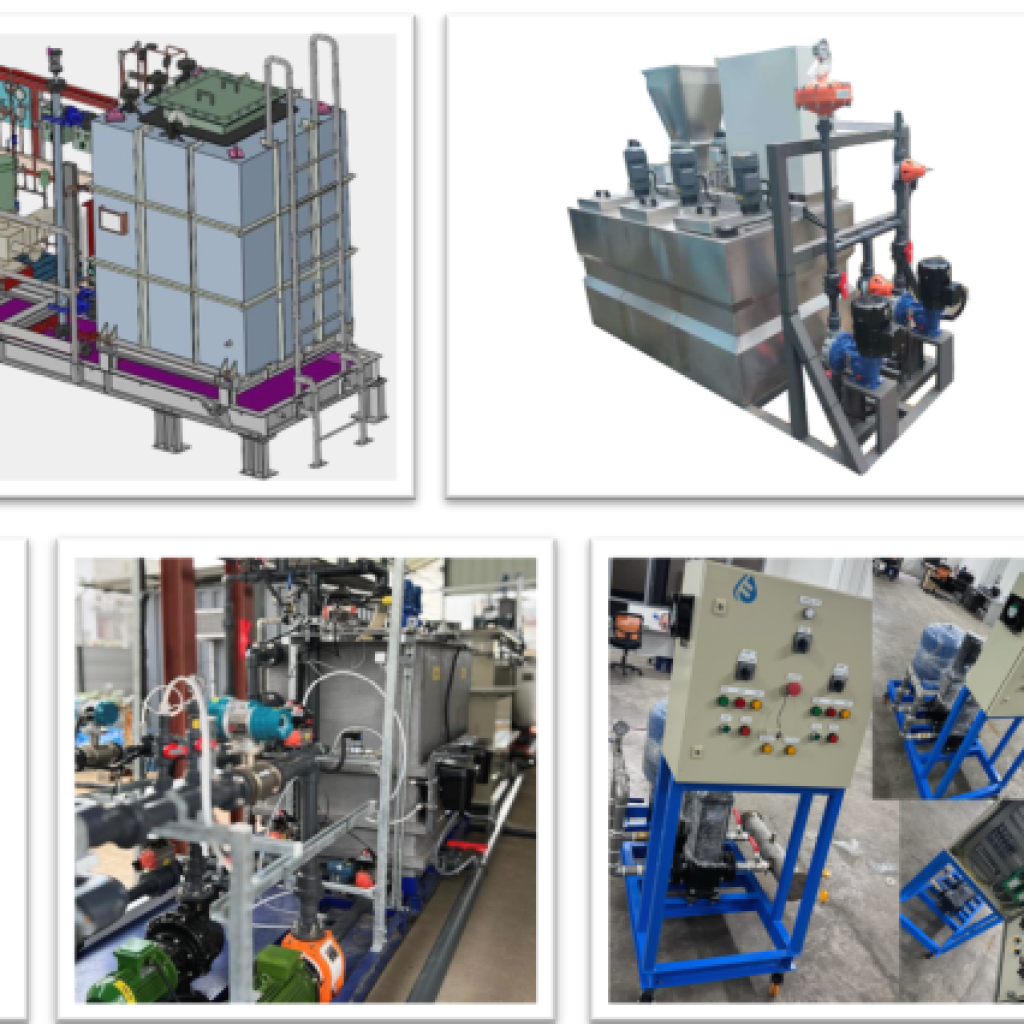

Skid Configurations Offered Under Dosing Skid Engineering Service Singapore

Depending on your process needs, space availability, and fluid handling requirements, FLOMEK offers the following skid configurations under our dosing skid engineering service Singapore:

1. Single-Pump Dosing Skid

Ideal for basic applications with minimal redundancy. A compact and cost-effective solution for startups or utility chemical dosing.

2. Duplex Pump Dosing Skid

Two pumps (1 working + 1 standby) ensure operational continuity. Essential in critical applications like chlorine dosing in drinking water or caustic injection in boilers.

3. Multipoint Dosing Skid

Designed to serve multiple dosing points from a single tank. Used in processes that require various chemical additions across stages.

4. Batch Dosing Skid

Automated skids with batch controllers, used in production plants where precision and repeatability are key.

5. Mobile Dosing Skid

FLOMEK also provides trolley-mounted or skid-mounted mobile dosing systems for temporary or field-based applications.

Each system configuration is a product of our refined dosing skid engineering service Singapore, customized for functionality, ergonomics, and long-term operability.

Compliance with Singapore Industrial Regulations

FLOMEK ensures every dosing skid engineering service Singapore project is designed and built to comply with local codes, including:

- PUB’s Water Quality Guidelines

- Workplace Safety and Health (WSH) Regulations

- NEA (National Environment Agency) Hazardous Chemical Handling

- SS638 (Formerly CP5) for Electrical Installations

- ISO 9001 and ISO 45001 Standards

We work closely with consultants and EPC firms to ensure each skid meets pre-approval and submission requirements. This proactive compliance approach distinguishes our dosing skid engineering service Singapore as industry-ready and regulation-proof.

Field Testing and Commissioning Services

Our dosing skid engineering service Singapore does not stop at manufacturing. Commissioning is a critical step where we fine-tune the system for optimal field performance.

On-site Services Include:

- Alignment of piping and pump bases

- Calibration of instruments

- Loop testing of sensors to control panel

- Functional logic verification

- Operator training and handover documents

Our skilled field engineers conduct testing in line with international best practices and site-specific safety protocols. We believe successful dosing skid engineering service Singapore means delivering a working, compliant, and dependable solution to your doorstep.

Digital Twin and 3D Modeling Services

To aid our clients in reviewing and approving the dosing skid design, we offer 3D modeling and digital twin capabilities. Each dosing skid engineering service Singapore includes CAD and digital simulation to:

- Validate ergonomics and accessibility

- Simulate pipe flow and mixing

- Visualize integration into existing plants

- Identify clash points and optimize space

This visualization and design optimization ensures zero surprises during fabrication or installation. It is an integral part of FLOMEK’s high-quality dosing skid engineering service Singapore workflow.

Dosing Skid Integration with Existing Plants

Many clients approach FLOMEK for retrofit and expansion projects. Our dosing skid engineering service Singapore is adept at delivering retrofit-friendly designs for brownfield projects. Services include:

- Site survey and 3D laser scanning

- Piping tie-in planning and valve positioning

- Electrical and PLC interface analysis

- Scheduling and shut-down planning for minimal disruption

Whether you’re upgrading a legacy system or scaling up capacity, our dosing skid engineering service Singapore is tailored to integrate flawlessly into your plant infrastructure.

Chemical Compatibility Engineering

Proper chemical handling is vital. FLOMEK’s dosing skid engineering service Singapore uses material compatibility charts, MSDS reviews, and industry data to:

- Select appropriate pump heads (PP, SS, PVDF)

- Define suitable gasket and O-ring materials (EPDM, PTFE, FKM)

- Use compatible coatings and lining materials

- Engineer pipe joints for aggressive media

We validate every part of the system to be chemically compatible for long-term, leak-free, and safe operations. Chemical dosing is critical – and FLOMEK’s dosing skid engineering service Singapore handles it with precision.

Zero-Leakage, Safe-Handling Skid Designs

Safety is paramount in dosing systems. FLOMEK’s dosing skid engineering service Singapore incorporates:

- Double containment piping systems

- Safety pressure relief valves

- Drip trays with leak sensors

- Manual isolation valves and interlocks

- Emergency shutdown systems (ESD)

- ATEX/IECEx certified components for hazardous zones

This focus on safety makes FLOMEK the trusted partner for mission-critical industries requiring dependable dosing skid engineering service Singapore.

Post-Installation Technical Support

Once your skid is commissioned, FLOMEK provides continuous technical support, including:

- Performance checks and troubleshooting

- Remote support via SCADA/PLC

- Regular health check reports

- On-site inspections and recalibrations

- Pump and instrument replacements

We also offer service contracts to ensure your dosing skid engineering service Singapore investment stays productive and efficient for years.

Client-Centric Engineering Documentation

Every dosing skid engineering service Singapore includes a full documentation package for project traceability and audit readiness:

- P&ID and electrical wiring diagrams

- Calibration certificates and ITPs

- FAT reports and hydrotest logs

- O&M manuals and maintenance schedule

- PLC logic narrative and configuration files

We engineer transparency into every project, providing clients with the documentation and tools to manage the system independently.

Partnering for Precision – FLOMEK’s Promise

FLOMEK Singapore is committed to delivering reliable, precision-engineered solutions through our advanced dosing skid engineering service Singapore. From small-scale installations to industrial multi-skid systems, we offer excellence at every step—from concept design to final commissioning.

By choosing FLOMEK’s dosing skid engineering service Singapore, you choose a future-ready solution backed by decades of engineering experience, local compliance knowledge, and industry-specific innovation.

Energy Efficiency in Dosing Skid Engineering Service Singapore

In today’s sustainability-driven market, energy efficiency is no longer optional—it’s essential. FLOMEK incorporates energy-saving features into every dosing skid engineering service Singapore to help clients reduce operational costs and environmental impact.

Energy-Efficient Features Include:

- Variable Frequency Drives (VFDs): Allow pump speed adjustments based on dosing demand, saving energy.

- Low-consumption solenoid dosing pumps: Ideal for intermittent dosing applications.

- Flow optimization control loops: Reduce energy usage during low-demand periods.

- Auto shutdown and sleep mode features in PLCs and HMIs.

- Efficient hydraulic layouts with minimized pressure drops.

By integrating these innovations into each dosing skid engineering service Singapore, FLOMEK helps organizations meet green building standards, corporate ESG goals, and cost-reduction strategies without compromising process reliability.

Customized Skid Control Panels in Singapore

Control panels form the intelligence center of any dosing skid. FLOMEK’s engineering team specializes in designing customized control panels to enhance system autonomy and safety for our dosing skid engineering service Singapore clients.

Features of FLOMEK Control Panels:

- Integrated PLCs (Siemens, Allen-Bradley, Schneider)

- Full-color HMIs with real-time alarms and trends

- Password-protected operator levels

- Remote monitoring via GSM/4G/Cloud

- Data logging with USB/SD card exports

- IoT-ready architecture for smart factories

Every control panel is designed in-house, tested, and approved before delivery, ensuring seamless system integration as part of our comprehensive dosing skid engineering service Singapore offering.

Conclusion

In an environment as dynamic and regulated as Singapore’s industrial sector, choosing the right engineering partner is essential. FLOMEK Singapore delivers precision, performance, and process integrity through its premium dosing skid engineering service Singapore.

We understand that your operations demand more than just equipment—they require integrated solutions backed by expertise, customization, and service reliability. That is why FLOMEK remains the trusted name in dosing skid engineering service Singapore for industries that value engineering excellence and long-term reliability.

Whether you’re planning a greenfield project, retrofitting existing infrastructure, or expanding process capabilities, FLOMEK’s dosing skid engineering service Singapore is your reliable partner in engineering the future of fluid dosing systems.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply