Custom-built chemical skid Singapore – Best 2025

Custom-built Chemical Skid Singapore – Tailored Engineering by FLOMEK Singapore

In today’s highly specialized industrial landscape, having the right equipment for chemical processing is not a luxury — it is a necessity. Custom-built chemical skid Singapore solutions are now the backbone of safe, efficient, and reliable chemical dosing and injection processes across various industries. At FLOMEK Singapore, we are leading the industry by delivering custom-built chemical skid Singapore packages that meet the unique needs of our clients with unmatched precision and durability.

Why Custom-built Chemical Skids Matter in Singapore’s Industry

Singapore is a hub for petrochemical, pharmaceutical, water treatment, and marine sectors, all of which require precise handling of chemicals. A custom-built chemical skid Singapore system ensures chemical processes are compact, efficient, scalable, and safe. These systems are fabricated to meet specific requirements rather than using off-the-shelf generic designs, which may not suit your operational conditions.

Key Industries That Rely on Custom-built Chemical Skids in Singapore

- Oil & Gas

- Pharmaceutical & Biotech

- Water & Wastewater Treatment

- Petrochemicals

- Power Plants

- Marine & Offshore

- Food & Beverage Processing

For each of these industries, a custom-built chemical skid Singapore solution provides the level of control, safety, and customization required to handle aggressive, corrosive, or temperature-sensitive chemicals.

FLOMEK Singapore: Experts in Custom-built Chemical Skid Singapore Solutions

As a premier engineering solutions provider, FLOMEK Singapore specializes in the design, fabrication, and commissioning of custom-built chemical skid Singapore systems. Our experience in rotating equipment, skid engineering, and process plant services uniquely positions us as a one-stop partner for all chemical injection and dosing needs.

Each custom-built chemical skid Singapore package we deliver is engineered from scratch, taking into account:

- Specific chemical properties

- Flow rates & pressure requirements

- Piping layout and material compatibility

- Electrical & automation integration

- Pump configuration (diaphragm, centrifugal, metering)

- System footprint and installation constraints

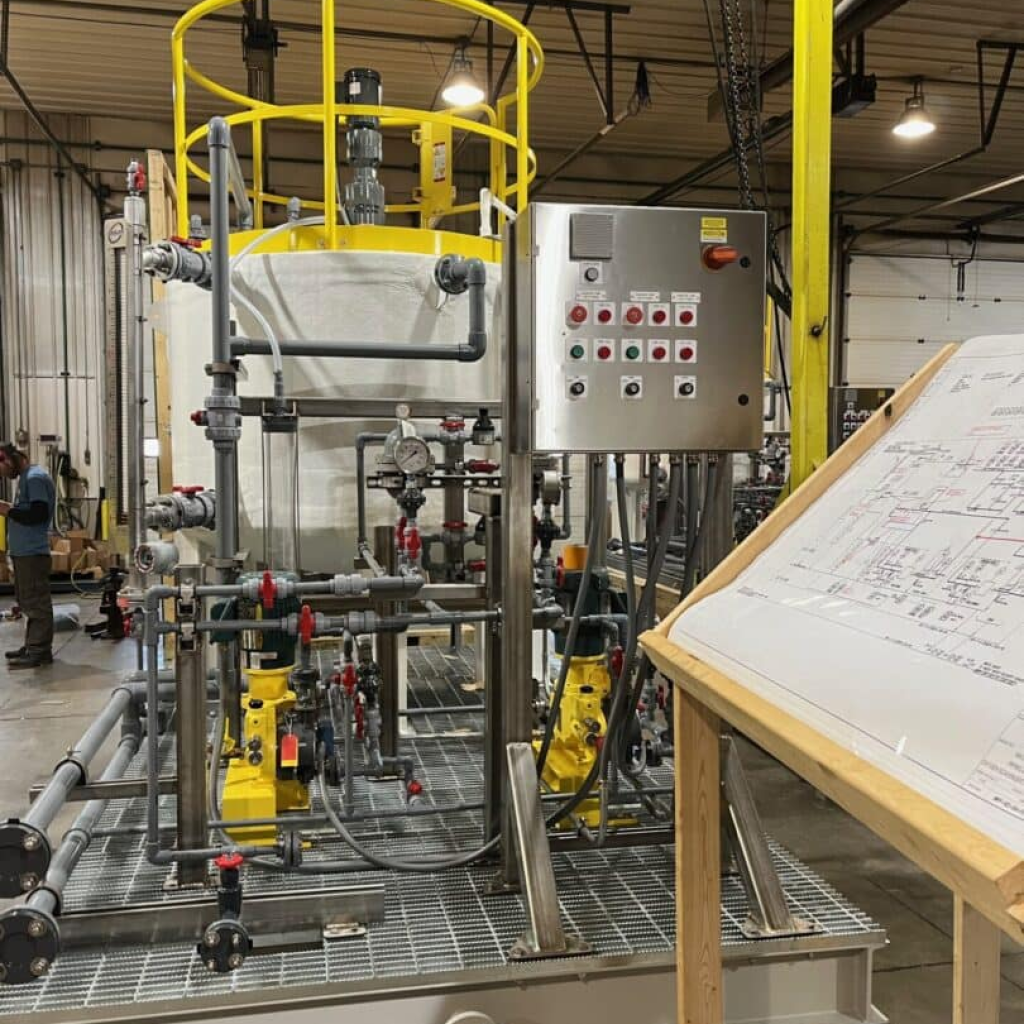

Components of a Custom-built Chemical Skid Singapore Package

A well-designed custom-built chemical skid Singapore package includes more than just pumps and pipes. It is a compact and integrated unit comprising:

- Chemical storage tanks

- Dosing or injection pumps (accurately selected)

- Flow meters and pressure regulators

- Control valves and safety devices

- Instrumentation and automation controls (PLC/SCADA)

- Base frame/skid with lifting hooks and forklift slots

- Piping system with leak-proof joints

- Electrical panels with interlocks and indicators

All these components are selected and engineered based on the customer’s process data, ensuring that the custom-built chemical skid Singapore unit operates with maximum efficiency, minimal downtime, and optimum safety.

Advantages of Choosing a Custom-built Chemical Skid Singapore

Choosing a custom-built chemical skid Singapore system from FLOMEK comes with multiple operational and economic benefits:

1. Tailored for Process Accuracy

Generic systems can lead to underdosing or overdosing — both of which affect product quality and safety. A custom-built chemical skid Singapore is engineered to match your exact process parameters.

2. Compact Design and Mobility

FLOMEK’s custom-built chemical skid Singapore units are compact, modular, and easy to relocate or integrate into existing pipelines.

3. Enhanced Chemical Compatibility

Each material (SS316, PVDF, PTFE, FRP) is carefully selected for chemical compatibility, making the custom-built chemical skid Singapore resistant to corrosion and chemical attacks.

4. Reduced Installation Time

All piping, testing, and electrical integration are completed before delivery. The custom-built chemical skid Singapore is plug-and-play ready, reducing site work.

5. Easy Maintenance

FLOMEK’s skid systems are designed for easy access and minimal downtime during preventive maintenance.

Types of Custom-built Chemical Skid Singapore Systems by FLOMEK

We engineer a wide range of custom-built chemical skid Singapore solutions:

• Chemical Dosing Skid

For accurate and continuous injection of chemicals like chlorine, alum, polymers, or acids in water treatment plants.

• Corrosion Inhibitor Skid

Designed for oil & gas pipelines to prevent internal corrosion using precise chemical dosage.

• Biocide Injection Skid

Used in cooling towers or HVAC systems to control microbial growth.

• Anti-scalant & pH Correction Skid

Common in RO Plants and wastewater systems, these custom-built chemical skid Singapore units help maintain water quality.

• Multi-chemical Skids

FLOMEK also designs dual or triple chemical injection systems in one skid frame, saving space and increasing versatility.

Quality & Compliance in Every Custom-built Chemical Skid Singapore

FLOMEK Singapore ensures that every custom-built chemical skid Singapore complies with:

- ASME standards for pressure components

- ISO 9001 quality protocols

- ATEX / IECEx requirements for explosive zones

- Singapore Environmental and Safety Regulations

- Client-specific QHSE protocols

Before dispatch, each custom-built chemical skid Singapore undergoes:

- Hydrostatic testing

- Electrical continuity and insulation test

- Functional FAT (Factory Acceptance Test)

- Leak detection and alignment check

This ensures every custom-built chemical skid Singapore solution is field-ready, certified, and safe to install.

Engineering Workflow at FLOMEK Singapore for Custom-built Chemical Skid

1. Requirement Gathering

Our engineering team starts by collecting detailed inputs from the client — fluid characteristics, flow rate, temperature, pressure, and layout restrictions.

2. 3D Modelling & Simulation

We use advanced CAD tools to create 3D models of the custom-built chemical skid Singapore, including fluid simulation for flow assurance.

3. Component Selection

Every valve, gauge, and pump is selected with strict compatibility to chemical and process needs.

4. Fabrication & Assembly

Skids are manufactured in our workshop with a quality-focused process and skilled workforce.

5. Testing & Documentation

Full documentation, test certificates, calibration reports, and O&M manuals are provided with every custom-built chemical skid Singapore.

6. Delivery, Installation & Commissioning

FLOMEK provides optional installation and commissioning services at the site, ensuring that your custom-built chemical skid Singapore operates as designed from day one.

Why FLOMEK is Your Best Partner for Custom-built Chemical Skid Singapore

At FLOMEK Singapore, our goal is not just to deliver products, but to deliver solutions. With in-depth industry knowledge, process expertise, and world-class fabrication facilities, we offer:

- In-house Design & Fabrication

- Custom PLC/HMI Programming for Control Panels

- Experience in Hazardous Zone Equipment

- Fast Turnaround & On-Time Delivery

- After-sales Maintenance & Technical Support

When you choose FLOMEK for your custom-built chemical skid Singapore requirements, you choose reliability, safety, and technical excellence.

Sustainability in Chemical Skid Design

Modern industries are increasingly focusing on sustainability and energy efficiency. FLOMEK ensures all custom-built chemical skid Singapore designs are:

- Energy efficient through VFD-integrated pump systems

- Designed to minimize chemical wastage

- Built with corrosion-resistant materials for longer life

- Easy to integrate with SCADA for better monitoring and automation

This makes our custom-built chemical skid Singapore solutions future-ready and compliant with sustainability goals.

Applications of Custom-built Chemical Skid Singapore

• Water Disinfection

• Cooling Tower Treatment

• Boiler Feed Systems

• Industrial Effluent Treatment

• Desalination & Reverse Osmosis Pre-treatment

• Fire Water Systems (Anti-freeze or Biocide Injection)

• Flocculation & Coagulation Dosing

No matter the application, FLOMEK’s custom-built chemical skid Singapore systems offer the flexibility to adapt and scale with your plant’s evolving needs.

Future Trends in Custom-built Chemical Skid Singapore Systems

As technology evolves, custom-built chemical skid Singapore packages will incorporate:

- Remote monitoring & IIoT integration

- Predictive maintenance alerts via sensors

- Self-cleaning dosing lines

- AI-driven dosing algorithms

FLOMEK is already investing in next-generation innovations to make our custom-built chemical skid Singapore offerings smarter, safer, and more efficient.

The Engineering Behind Custom-built Chemical Skid Singapore Packages

Designing and manufacturing a custom-built chemical skid Singapore unit is a highly engineered process that requires deep understanding of fluid dynamics, chemical properties, safety standards, and system automation. FLOMEK Singapore employs a detailed engineering approach to ensure every custom-built chemical skid Singapore solution performs flawlessly in its operating environment.

1. Detailed Process Engineering

Before fabrication, the FLOMEK engineering team analyzes process data including:

- Fluid density and viscosity

- Required flow rates and dosing precision

- Temperature and pressure ratings

- pH, corrosiveness, and reactivity of the chemicals

- Site layout and space constraints

Using this data, we simulate fluid behavior in the proposed piping system to avoid common issues such as cavitation, turbulence, or dead legs in the design.

2. Modular Design Flexibility

Every custom-built chemical skid Singapore system by FLOMEK is designed to be modular. This means clients can:

- Expand or upgrade the skid in the future

- Integrate additional pumps or tanks

- Connect with existing PLC or DCS systems

- Replace components easily with minimal downtime

Modularity also makes transport and installation faster, reducing site disruption.

Automation & Control in Custom-built Chemical Skid Singapore Systems

Advanced automation is a key advantage of using a custom-built chemical skid Singapore over traditional systems. FLOMEK offers integration of:

- Programmable Logic Controllers (PLC)

- Touchscreen HMIs (Human-Machine Interfaces)

- IoT-enabled sensors for remote monitoring

- Level, pressure, and flow sensors with digital output

- SCADA system compatibility

This makes the custom-built chemical skid Singapore smart, reliable, and ready for Industry 4.0.

Safety Systems in FLOMEK’s Custom-built Chemical Skid Singapore

Working with hazardous chemicals requires built-in safety features. Each FLOMEK custom-built chemical skid Singapore includes multiple protective mechanisms:

- Emergency shutdown interlocks

- Spill containment trays

- Pressure relief valves and rupture discs

- Flame-proof enclosures for hazardous zones

- Lockout-Tagout (LOTO) compliance panels

- Safety labels, color-coded pipes, and MSDS integration

Our designs ensure that every custom-built chemical skid Singapore we manufacture adheres to both local and international safety standards.

Custom-built Chemical Skid Singapore vs. Off-the-Shelf Dosing Systems

Here’s why a custom-built chemical skid Singapore provides significantly higher value over generic skid systems:

| Feature | Off-the-Shelf System | Custom-built Chemical Skid Singapore |

|---|---|---|

| Design Fit | Generalized | Precise to your process |

| Chemical Compatibility | Limited | Full compatibility |

| Flow Control Accuracy | Moderate | High accuracy with calibration |

| Space Optimization | Often bulky | Compact, site-specific footprint |

| Safety Features | Basic | Tailored to hazards & industry |

| Automation | Limited or none | Full PLC/HMI/SCADA ready |

| Scalability | Fixed design | Expandable and modular |

| Maintenance Access | Restricted | Ergonomic & service-friendly |

This comparison illustrates why many industries are moving toward custom-built chemical skid solutions from reliable manufacturers like FLOMEK.

Control Strategies in Custom-built Chemical Skid Singapore

Chemical dosing must be accurate, responsive, and often synchronized with upstream or downstream process data. FLOMEK offers intelligent dosing systems in every custom-built chemical skid Singapore unit with:

- Flow-Proportional Dosing – Based on a signal from a flow meter or sensor

- pH-Based Feedback Loop Dosing – Maintains target pH via inline pH probes

- Batch Mode Dosing – Based on preset volume or timer for chemical injection

- Redundant Logic – For safety, alerts, or automated pump switchover

- Remote Monitoring – Integration with centralized SCADA or cloud-based control systems

This makes your custom-built chemical skid Singapore an active part of your plant’s intelligent process network.

Environmental Considerations in Skid Design

Environmental safety is a major consideration in modern chemical handling. A custom-built chemical skid Singapore by FLOMEK incorporates multiple features to minimize environmental impact:

- Bund Walls & Spill Trays – Secondary containment in case of leakage

- Closed-loop Calibration Cylinders – Prevent chemical spillage during calibration

- Dry-run Protection Sensors – Prevent pump damage and chemical wastage

- Exhaust Vents or Scrubbers – For odorous or volatile chemical applications

- Drip-free connections and Quick Couplers – Minimize handling risks during maintenance

By building sustainability into your custom-built chemical skid Singapore, FLOMEK helps clients stay compliant with Singapore’s environmental codes and green certifications.

Real-world Use Cases of Custom-built Chemical Skid Singapore Systems

Below are examples of how FLOMEK’s custom-built chemical skid solutions are used across sectors:

A. Pharmaceutical Sector

A pharmaceutical company needed precise dosing of CIP chemicals. FLOMEK delivered a custom-built chemical skid package with:

- Metering pumps with 0.5% accuracy

- Sterile piping design

- CIP/SIP compliant construction

- Cleanroom-grade instrumentation

B. Petrochemical Industry

For corrosion inhibition in a refinery pipeline, our team engineered a custom-built chemical skid with:

- Explosion-proof motor enclosures

- Flow switches for emergency cut-off

- Real-time flow rate display via HMI

- Remote monitoring via Modbus protocol

C. Municipal Water Treatment

In collaboration with a utility contractor, FLOMEK built a custom-built chemical skid for alum dosing. It featured:

- Duty/standby pump configuration

- Diaphragm dosing pumps with pulsation dampeners

- FRP tank with level transmitter

- UV-protected enclosure for outdoor installation

Service, Support & Maintenance for Custom-built Chemical Skid Singapore Packages

Beyond delivery, FLOMEK Singapore offers continued value through:

• Site Commissioning

We ensure seamless installation of your custom-built chemical skid, calibrating instruments and ensuring PLC logic matches site needs.

• Operator Training

Your team receives training on startup, shutdown, cleaning, and emergency procedures.

• Preventive Maintenance

We provide periodic health checks for your custom-built chemical skid, including:

- Vibration analysis

- Seal inspection

- Flow calibration

- Control panel diagnostics

• Spares & Retrofit Kits

FLOMEK offers genuine spare parts and retrofit kits for all our custom-built chemical skid units.

Design Configurations for Custom-built Chemical Skid Singapore Systems

We offer a variety of layout configurations based on space availability and process needs:

1. Single Pump Skid

Ideal for low-flow dosing applications.

2. Dual Pump Skid (Duty/Standby)

Ensures continuous dosing even during maintenance of one pump.

3. Multi-chemical Skid

Multiple tanks and pumps on a shared skid for simultaneous dosing of different chemicals.

4. Stacked Skid Design

Vertically aligned tanks and pumps for limited floor space installations.

The FLOMEK Commitment to Excellence in Custom-built Chemical Skid Singapore

FLOMEK’s commitment to excellence in every custom-built chemical skid project ensures:

- No two skids are the same – Every package is engineered for your application.

- Design-to-delivery under one roof – In-house engineering, fabrication, and testing.

- Certified workmanship – Welders, panel builders, and QC staff are certified to global standards.

- Sustainability-focused – Designed to minimize chemical loss, improve energy usage, and reduce environmental impact.

- Compliance guaranteed – We ensure every custom-built chemical skid complies with MOM, NEA, and other local regulations.

Custom-built Chemical Skid Singapore: Driving Operational Efficiency Through Innovation

In an era where operational precision, safety, and automation are critical to industrial success, investing in a custom-built chemical skid solution provides more than just a tool—it delivers strategic value. From water utilities and process industries to marine sectors and energy producers, companies are increasingly opting for customized skids that streamline dosing, reduce waste, and ensure compliance.

Tailor-Made for Singapore’s Industrial Demands

Singapore’s industrial infrastructure is space-conscious, efficiency-focused, and heavily regulated. Off-the-shelf systems often fall short of meeting site-specific safety codes or integration needs. This makes a custom-built chemical skid not only a practical choice but a necessary one for sustainable, compliant operations.

Common Chemicals Handled in Custom-built Chemical Skid Singapore Packages

Understanding the chemical properties being processed is critical to material selection, pump sizing, and safety controls. FLOMEK Singapore has developed custom-built chemical skid systems for a wide range of chemicals, including:

- Sodium Hypochlorite (NaOCl) – Used in water disinfection

- Sulfuric Acid (H₂SO₄) – Common in pH adjustment and cleaning

- Ferric Chloride / Ferric Sulfate – Used in coagulation in wastewater treatment

- Polyacrylamide (PAM) – A flocculant requiring precise and slow dosing

- Ammonia / Ammonium Hydroxide – Dosed in power and semiconductor plants

- Citric Acid / Caustic Soda – For CIP systems in F&B and pharma industries

- Antiscalants & Corrosion Inhibitors – Common in RO systems and oil pipelines

Each of these chemicals demands a different engineering approach. A custom-built chemical skid package from FLOMEK ensures proper compatibility, control, and safety.

Material Selection for Custom-built Chemical Skid Singapore Projects

The longevity and safety of a custom-built chemical skid largely depend on selecting the right materials. FLOMEK engineers evaluate chemical reactivity, temperature, and pressure to choose the best options:

| Component | Available Materials | Considerations |

|---|---|---|

| Piping | SS316, PVC, CPVC, FRP, PP, PVDF | Corrosion resistance, chemical type |

| Tanks | HDPE, LLDPE, SS316, FRP | UV resistance, chemical compatibility |

| Valves | PTFE-lined, Alloy-20, Hastelloy | Resistance to acids, bases, solvents |

| Gaskets & Seals | EPDM, Viton, PTFE | Pressure/temperature range, chemical type |

Each custom-built chemical skid from FLOMEK is verified through chemical compatibility tables and past performance data, ensuring a long-lasting, leak-free system.

Final Thoughts: Choosing FLOMEK for Custom-built Chemical Skid Singapore

As Singapore moves towards becoming a green and smart manufacturing hub, having a custom-built chemical skid that is safe, automated, modular, and efficient is no longer optional—it is essential.

FLOMEK Singapore is proud to be a trusted partner to industries seeking precision dosing and chemical handling solutions. With every custom-built chemical skid , we combine decades of engineering experience, innovation, and quality to deliver systems that last — and perform.

Conclusion

A custom-built chemical skid solution is not just about fitting pumps on a frame. It’s about engineering reliability, safety, precision, and compliance into a compact package that powers your critical chemical processes.

At FLOMEK Singapore, every custom-built chemical skid is a testament to our engineering excellence and commitment to client success. With decades of experience, a dedicated team, and a customer-first mindset, FLOMEK is proud to be your preferred partner for custom-built chemical skid systems — engineered for performance and built to last.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply