Chemical dosing solutions Singapore – Best 2025

Chemical Dosing Solutions Singapore

Introduction to Chemical Dosing Solutions in Singapore

In the fast-evolving industrial and municipal landscape of Singapore, Chemical Dosing Solutions Singapore has become a cornerstone for precision, safety, and operational efficiency. Whether in water treatment, power generation, pharmaceuticals, or manufacturing, the need for accurate chemical dosing is non-negotiable. As industries grow increasingly complex, the demand for reliable and customizable chemical dosing solutions in Singapore rises sharply.

With Singapore being a hub for advanced manufacturing and sustainable urban solutions, businesses are now actively seeking tailored chemical dosing solutions Singapore offers for a wide range of applications. These solutions are vital for maintaining water quality, ensuring regulatory compliance, and minimizing chemical wastage.

What Are Chemical Dosing Solutions?

Chemical dosing solutions refer to the automated or semi-automated systems designed to inject chemicals into a process or medium in precise amounts. These systems ensure that the correct quantity of chemicals—such as coagulants, disinfectants, pH adjusters, and anti-scalants—is introduced at the right time and place.

In the context of Chemical Dosing Solutions Singapore, these systems are engineered with robust technologies to meet the stringent standards and environmental regulations imposed by local authorities and global best practices.

Importance of Chemical Dosing in Singaporean Industries

Singapore is globally recognized for its focus on clean technology and water innovation. Chemical dosing solutions Singapore plays a pivotal role in maintaining this reputation. Here’s how these solutions impact various sectors:

1. Water & Wastewater Treatment

Water security is of national importance in Singapore. In both public utilities and private facilities, chemical dosing solutions Singapore ensures safe drinking water and compliant wastewater discharge. Dosing chlorine, alum, or lime must be accurate to prevent health hazards and ecological harm.

2. Oil & Gas and Petrochemical Sectors

Corrosion inhibitors, demulsifiers, and other additives must be precisely dosed to ensure safety and process optimization. Chemical dosing solutions Singapore supports this with corrosion-resistant systems and real-time monitoring.

3. Food & Beverage Manufacturing

Consistency and hygiene are vital. Whether dosing cleaning agents or preservatives, chemical dosing solutions Singapore guarantees product integrity and meets HACCP standards.

4. Power Plants

In power generation, especially in combined cycle and thermal plants, chemicals are used to control scaling and corrosion. Chemical dosing solutions Singapore maintains the longevity and efficiency of plant components.

5. Pharmaceuticals and Life Sciences

Precision in dosing sterile solutions and reagents is paramount. Chemical dosing solutions Singapore ensures accuracy, traceability, and compliance with GMP standards.

Key Features of Modern Chemical Dosing Solutions Singapore

Choosing the right chemical dosing solutions Singapore involves evaluating a combination of features that promote efficiency, reliability, and safety. Modern systems typically include:

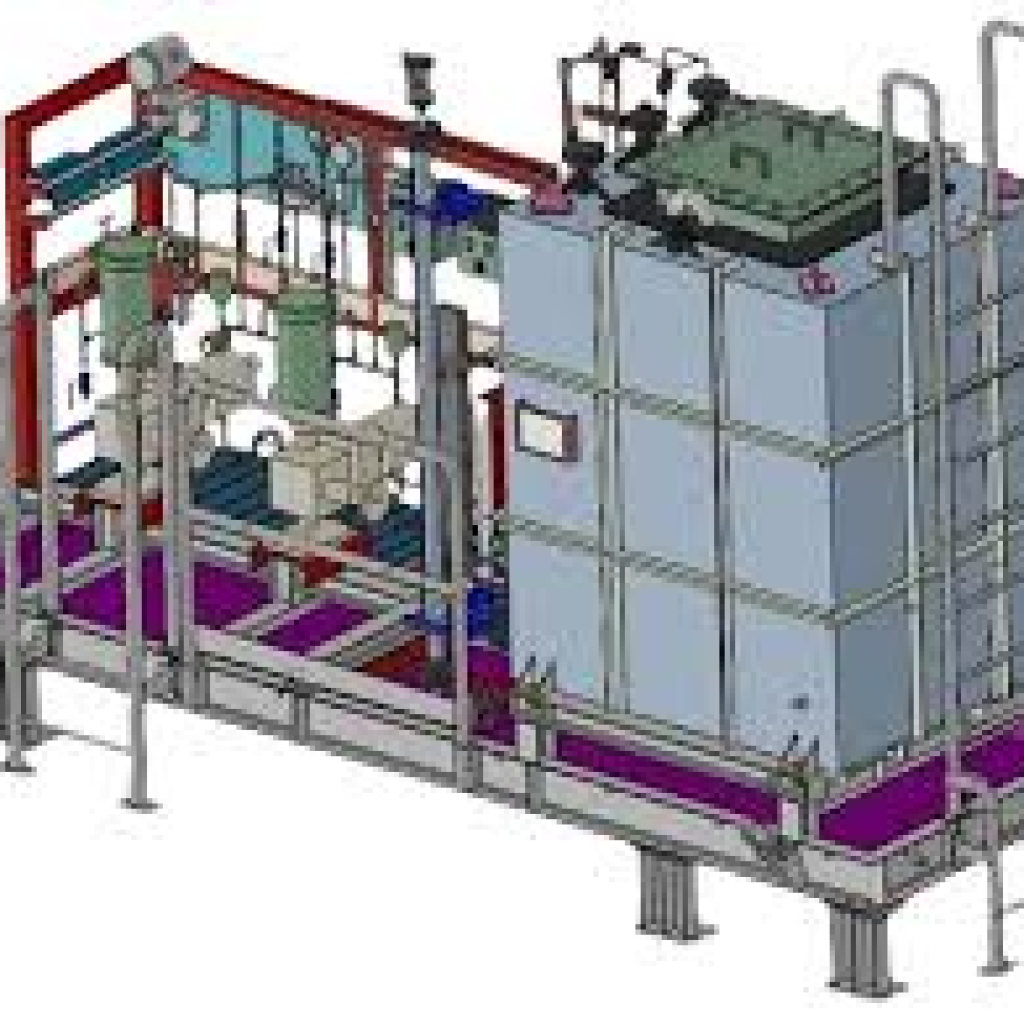

1. Customizable Dosing Skids

These pre-engineered packages can be tailored to specific flow rates, pressures, and chemical compatibilities. Chemical dosing solutions Singapore often include integrated tanks, pumps, and controls.

2. Advanced Metering Pumps

High-precision metering pumps are at the heart of chemical dosing solutions Singapore. These can be diaphragm or plunger type, driven by motor or solenoid for optimal performance.

3. Automated Controls & PLC Integration

Automation through PLC (Programmable Logic Controller) enables real-time feedback and remote monitoring. This is critical for industries where dosage fluctuation can cause costly shutdowns.

4. Chemical Storage and Handling Safety

Compliance with Singapore’s Workplace Safety and Health (WSH) regulations means chemical dosing solutions Singapore include safe containment, alarms, and spill protection systems.

5. Flow, pH, and ORP Sensors

Integrated sensors ensure feedback-controlled dosing, increasing the system’s responsiveness. Chemical dosing solutions Singapore often feature inline and bypass configurations for minimal disruption.

Applications of Chemical Dosing Solutions Singapore

A. Disinfection & Sterilization

In water treatment plants and industrial cooling towers, dosing sodium hypochlorite or other disinfectants is crucial. With chemical dosing solutions Singapore, precise chlorine dosing prevents microbial growth while avoiding harmful overdosing.

B. pH Control

Industries need tight pH ranges for optimal reactions. Whether using acid or alkali, chemical dosing solutions Singapore automatically adjust the dosage based on real-time pH measurements.

C. Coagulation & Flocculation

To remove suspended solids in water and wastewater, accurate dosing of coagulants like ferric chloride is required. Chemical dosing solutions Singapore achieves optimal turbidity reduction with minimal chemical use.

D. Anti-Scalant & Corrosion Inhibition

In RO systems, cooling towers, and boilers, chemical dosing helps maintain system efficiency and lifespan. Chemical dosing solutions Singapore ensures balanced chemical application for scale and rust prevention.

E. Nutrient Dosing in Biological Treatment

For biological treatment processes such as activated sludge, nutrients like phosphates and nitrates must be dosed in controlled amounts. Chemical dosing solutions Singapore supports accurate biological load control.

Advantages of Using Chemical Dosing Solutions Singapore

- Improved Accuracy and Control

Chemical wastage is minimized with smart dosing. This leads to cost savings and environmental compliance. - Enhanced Process Reliability

With automated systems, chemical dosing solutions Singapore ensures uninterrupted dosing, even during system fluctuations. - Regulatory Compliance

Singapore’s NEA and PUB have strict water and chemical safety guidelines. These systems help meet all local requirements. - Safety for Operators

With enclosed skid designs and leak-detection systems, chemical dosing solutions Singapore prioritizes workplace safety. - Long-Term Cost Savings

Automation reduces manual labor, chemical overuse, and downtime—delivering long-term financial benefits.

Choosing the Right Chemical Dosing Solutions Singapore

To select the most suitable chemical dosing solutions Singapore, consider the following:

- Type of Chemical: Compatibility of materials (PVC, SS316, PE) with the chemical to be dosed.

- Required Flow Rate and Pressure: Systems must match process requirements.

- Control Requirements: Need for manual vs. automated control with SCADA or PLC.

- Environmental Conditions: For outdoor installations, UV-resistant and weatherproof solutions are recommended.

- Maintenance and Support Needs: Opt for solutions with local technical support and ease of spare part availability.

Technological Advancements in Chemical Dosing Solutions Singapore

In line with Industry 4.0, chemical dosing solutions Singapore now come equipped with:

- IoT Integration: Remote control and real-time alerts via mobile or cloud-based dashboards.

- AI-Powered Dosing Algorithms: Systems that learn and self-adjust for optimal performance.

- Green Dosing Technologies: Eco-friendly dosing solutions that reduce carbon footprint and energy consumption.

These advancements position chemical dosing solutions Singapore at the forefront of sustainable industrial automation.

Maintenance and Calibration of Chemical Dosing Systems

While modern chemical dosing solutions Singapore are designed for reliability, regular maintenance is vital. Recommended actions include:

- Monthly Inspection of valves, fittings, and pump seals.

- Quarterly Calibration of dosing pumps and sensors.

- Annual Replacement of wear parts like diaphragms and tubing.

- Routine Flushing of lines to prevent crystallization and clogging.

Proactive maintenance ensures that your chemical dosing solutions Singapore remain accurate and efficient over time.

Case Applications in Singapore’s Industrial Context

Though we are not listing specific companies, many sectors across Singapore—from water utilities to semiconductor manufacturers—rely on chemical dosing solutions Singapore to keep their operations compliant and efficient. Their needs typically involve:

- Multi-chemical dosing from central control rooms

- Containerized mobile dosing units for offshore or remote sites

- Fully skid-mounted units for plug-and-play deployment

Sustainable Practices with Chemical Dosing

Sustainability is a key national goal. Modern chemical dosing solutions Singapore enable:

- Reduction in Chemical Overuse

- Decreased Waste Generation

- Energy-Efficient Operation

- Remote Diagnostics to Reduce Site Visits

These align perfectly with Singapore’s Smart Nation and Green Plan initiatives.

Industries Benefiting from Chemical Dosing Solutions Singapore

| Industry | Application |

|---|---|

| Water Utilities | Disinfection, pH control, flocculation |

| Semiconductor | Ultrapure water conditioning |

| Oil & Gas | Injection of corrosion inhibitors |

| Power Generation | Scale prevention in boilers |

| Manufacturing | Process water conditioning |

| Marine & Offshore | Mobile dosing containers |

In each of these sectors, chemical dosing solutions Singapore provide unmatched precision, durability, and regulatory assurance.

Design Considerations for Chemical Dosing Solutions Singapore

Creating effective chemical dosing solutions Singapore goes beyond just choosing pumps and tanks. It requires careful planning, engineering know-how, and compliance with Singapore’s environmental and safety regulations. The design phase must address:

1. Chemical Compatibility

All materials used must be resistant to the specific chemicals in use. For example, sodium hypochlorite requires HDPE or PP tanks, while acidic chemicals may need PVDF piping. When building chemical dosing solutions Singapore, engineers focus on long-lasting materials that meet SPH, NEA, and PUB standards.

2. Footprint Optimization

Space is a premium in Singapore’s industrial zones. Compact skid-mounted or containerized chemical dosing solutions Singapore are increasingly preferred. These units are pre-assembled and require minimal installation space and time.

3. Redundancy and Backup Systems

To ensure uninterrupted operations, especially in 24/7 plants like water treatment or manufacturing, chemical dosing solutions Singapore often include dual-pump systems with auto-changeover controls.

4. Ease of Maintenance

Designs must allow easy access for technicians to replace parts, calibrate sensors, and perform safety inspections. Smart layout and modular designs are vital for maintaining chemical dosing solutions Singapore efficiently.

Integration with Existing Infrastructure

Integrating chemical dosing solutions Singapore into existing industrial systems presents both opportunities and challenges. Successful integration depends on:

a. Process Compatibility

New dosing equipment must seamlessly interact with the flow rates, pressures, and temperature ranges of current systems. Chemical dosing solutions Singapore are custom-built to ensure chemical injection points align with operational flows.

b. Control System Synchronization

PLC-based control panels used in chemical dosing solutions Singapore can be integrated into existing SCADA or DCS platforms. This integration allows centralized monitoring and enhanced process analytics.

c. Data Logging & Reporting

In industries with regulatory reporting requirements, chemical usage must be tracked. Modern chemical dosing solutions Singapore include built-in data logging for trend analysis, chemical inventory management, and regulatory audits.

Common Challenges in Chemical Dosing Solutions Singapore

1. Chemical Precipitation or Crystallization

This is common when dosing alkaline chemicals or phosphates. Stagnant lines or temperature fluctuations can cause deposits. Reliable chemical dosing solutions Singapore incorporate agitation, line flushing, and trace heating to counteract this.

2. Pump Pulsation & Inaccurate Flow

Dosing pumps with poor design can cause inconsistent flow, affecting dosing accuracy. To address this, top-tier chemical dosing solutions Singapore feature dampeners and pulse-free technology.

3. Leakage and Spillage Risks

Leaks are hazardous and lead to compliance issues. High-grade mechanical seals, double containment systems, and leak detection alarms are standard in advanced chemical dosing solutions Singapore.

4. Operator Training Gaps

Even well-designed systems fail without proper training. That’s why most chemical dosing solutions Singapore come with detailed SOPs, safety manuals, and HAZOP documentation.

Human Resource & Operational Readiness

Implementing chemical dosing solutions Singapore also requires investment in human capability. Skilled operators, engineers, and safety personnel must understand:

- System logic and dosing principles

- Calibration techniques

- Chemical handling protocols

- Emergency procedures

Proper onboarding and upskilling ensure smooth operation and maximize the value of the chemical dosing solutions Singapore deployed.

Regulatory Landscape for Chemical Dosing in Singapore

Singapore has a robust framework of health, safety, and environmental protection regulations. Every chemical handling or dosing operation must adhere to guidelines from:

- National Environment Agency (NEA)

- Public Utilities Board (PUB)

- Workplace Safety and Health Council (WSHC)

- Building and Construction Authority (BCA)

Compliance with these rules is baked into the engineering of chemical dosing solutions Singapore. This includes bund wall containment, Material Safety Data Sheet (MSDS) adherence, and routine inspections as part of operations.

Emerging Trends in Chemical Dosing Solutions Singapore

The future of chemical dosing solutions Singapore lies in digital transformation and sustainable engineering. Some current and upcoming trends include:

1. AI-Driven Predictive Control

Advanced analytics combined with AI enables the system to predict chemical needs based on historical and environmental data. This improves efficiency and reduces over-dosing risks.

2. Sustainable and Green Design

Eco-design principles are now being applied to chemical dosing solutions Singapore, including the use of solar-powered control panels, non-toxic construction materials, and low-energy pumps.

3. Mobile Dosing Skids

For industries like offshore oil & gas or temporary wastewater treatment setups, mobile containerized dosing systems are becoming a game-changer. These modular chemical dosing solutions Singapore are easily transportable and quick to deploy.

4. Remote Troubleshooting and Digital Twins

With the help of IoT sensors and cloud-based platforms, technicians can perform diagnostics without being on-site. In the future, chemical dosing solutions will leverage digital twins for simulation and remote configuration.

Custom Solutions for Specialized Industries

Every industry has unique challenges, and chemical dosing solutions are increasingly being tailored accordingly:

- Semiconductor & Electronics: Ultrapure chemical dosing with extreme accuracy

- Breweries & Beverages: Clean-in-place (CIP) chemical dosing for hygiene

- Construction Sites: pH neutralization and sediment dosing for temporary discharge treatment

- Marine & Offshore: Compact, corrosion-resistant dosing systems for saline environments

These use-case-specific solutions reinforce the value of choosing highly adaptable chemical dosing solutions.

Investing in the Future with Chemical Dosing Solutions Singapore

In conclusion, chemical dosing solutions are no longer just auxiliary systems—they are vital infrastructure that ensures quality, compliance, efficiency, and safety across sectors. From ultrapure water systems in high-tech industries to bulk disinfection in municipal plants, chemical dosing technology must be reliable, responsive, and future-proof.

Organizations that invest in high-performance chemical dosing solutions position themselves for long-term operational success, improved sustainability, and reduced compliance risks. As demand for advanced water treatment, pollution control, and process efficiency grows, the importance of deploying smart, scalable, and robust chemical dosing solutions will only increase.

If you aim to keep pace with evolving industry standards while securing safe and efficient chemical control, chemical dosing solutions is the strategic investment that delivers tangible, measurable outcomes.

Innovation and Digitalization in Chemical Dosing Solutions Singapore

As Singapore drives forward with its Smart Nation initiative, the demand for smart chemical dosing solutions is accelerating. Digitalization is transforming how industries operate and monitor their dosing processes. Cutting-edge chemical dosing solutions now offer real-time monitoring, auto-calibration, and integration with AI systems for predictive analytics.

Smart Sensors and IoT Connectivity

Smart sensors are now being embedded into chemical dosing systems to track pH, conductivity, ORP, turbidity, and flow. These sensors send real-time data to cloud platforms or SCADA systems. Such features make chemical dosing solutions not only more efficient but also safer and more compliant.

Predictive Maintenance and Reduced Downtime

Predictive analytics tools can now detect anomalies before equipment failure. For instance, pump vibration or pressure variations can indicate wear-and-tear or clogging. By installing intelligent chemical dosing solutions, operators can schedule maintenance activities proactively, thereby minimizing system downtimes and chemical waste.

Centralized Control Systems

Modern chemical dosing solutions come with centralized dashboards. Whether you’re running a water treatment plant or a food processing facility, centralized control allows operators to manage multiple dosing systems simultaneously. The ability to remotely control and adjust dosages contributes significantly to operational efficiency.

Conclusion

As Singapore continues to drive innovation and sustainability, Chemical Dosing Singapore becomes an essential enabler of industrial success. From water treatment to pharmaceuticals, the need for dependable, accurate, and compliant dosing solutions has never been more pressing.

By investing in advanced chemical dosing Singapore, industries can not only meet operational targets but also align with national sustainability objectives, regulatory standards, and future-ready automation goals.

Whether you’re designing a new plant, upgrading your system, or solving a process challenge, choosing the right chemical dosing Singapore can dramatically improve safety, efficiency, and ROI.

The Role of Skid-Based Systems in Chemical Dosing Solutions Singapore

One of the most effective innovations in recent years is the adoption of skid-mounted chemical dosing systems. These modular systems are self-contained and fabricated off-site, allowing for fast and efficient installation.

Benefits of Skid-Based Chemical Dosing Solutions

- Plug-and-play capability

- Reduced installation time

- Pre-tested for performance and leaks

- Modular for scalability

- Compact design to fit tight spaces in Singapore’s industrial zones

These skids are the backbone of reliable chemical dosing solutions Singapore, particularly for contractors and engineers working under tight project timelines.

Environmental Sustainability and Chemical Dosing

Singapore’s environmental policies are some of the most stringent in Asia. In this context, chemical dosing solutions Singapore contribute to several sustainability goals.

Eco-Efficient Chemical Consumption

Accurate dosing reduces chemical overuse, lowering environmental impact. With automation, operators avoid overfeeding and underfeeding, which often lead to chemical waste and pollution.

Energy-Efficient Pump Designs

Modern metering pumps in chemical dosing solutions Singapore are now designed to consume minimal power. Diaphragm and solenoid pumps with low energy consumption profiles are increasingly used in green buildings and industrial parks.

Minimizing Packaging Waste

Bulk chemical storage and transfer systems are integrated into chemical dosing solutions Singapore to minimize the use of small chemical containers, reducing plastic waste and carbon footprint.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply