High-pressure pump Singapore – Best 2025

Introduction to High-Pressure Pump Technology

In today’s fast-paced industrial landscape, the demand for reliable and efficient pumping systems has grown significantly. Among them, the high-pressure pump Singapore market has evolved into a vital segment, catering to sectors that require robust pressure handling and superior fluid dynamics. From water treatment to petrochemical, from HVAC systems to marine applications, high-pressure pumps are essential tools ensuring stable operations under rigorous conditions.

Singapore, being a hub for advanced infrastructure, marine activity, and process industries, has seen an increasing need for specialized high-pressure pump Singapore solutions. These pumps are engineered to perform in harsh conditions while maintaining efficiency, safety, and long operational life.

What is a High-Pressure Pump?

A high-pressure pump is designed to move fluids at significantly higher pressures than standard pumps. The high-pressure pump Singapore industry defines these pumps by their ability to:

- Deliver fluids at pressures typically above 800 PSI (up to 40,000 PSI in specialized applications)

- Maintain high flow rates

- Withstand corrosive, high-temperature, or hazardous fluids

- Support process-critical applications where failure is not an option

These characteristics make high-pressure pump Singapore solutions indispensable in various industries, including oil & gas, pharmaceuticals, food processing, automotive, and desalination.

Applications of High-Pressure Pumps in Singapore

In Singapore, where industries operate with precision and environmental regulations are strict, the use of high-pressure pump Singapore systems spans across multiple applications:

1. Water Jet Cutting

Singapore’s advanced manufacturing and aerospace industries rely on water jet cutting, which requires extremely high pressure to cut materials like metal, glass, or ceramics. High-pressure pump Singapore technology ensures consistent cutting power and precision.

2. Reverse Osmosis (RO) Plants

High-pressure pumps are critical for membrane-based water purification. The high-pressure pump Singapore market includes models specifically engineered for RO systems, where they provide the pressure needed to force seawater or brackish water through semi-permeable membranes.

3. Boiler Feed Systems

Power generation plants in Singapore use high-pressure pump Singapore systems for boiler feed applications. These pumps handle high temperatures and ensure a constant water supply to maintain efficient steam generation.

4. Fire Fighting Systems

Many high-rise buildings and industrial zones in Singapore install high-pressure pump Singapore systems as part of their fire protection infrastructure. These pumps provide the necessary pressure for sprinkler and hydrant systems.

5. Hydrostatic Testing

Pipeline and pressure vessel manufacturers use high-pressure pump Singapore setups for hydrostatic testing to verify structural integrity.

Types of High-Pressure Pumps

Choosing the right type of high-pressure pump Singapore is vital for ensuring system performance and reliability. Common types include:

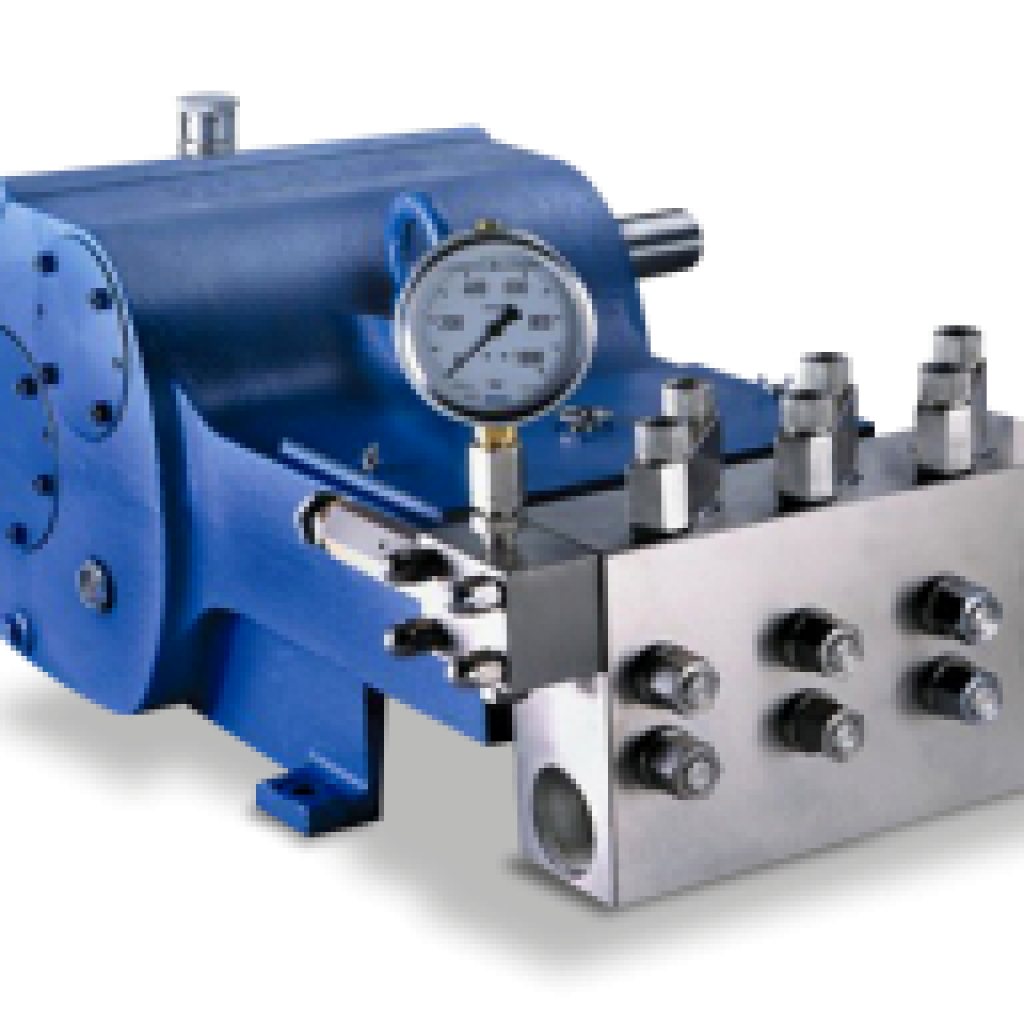

1. Triplex Plunger Pumps

Ideal for industrial cleaning, oil & gas, and water jetting. Triplex plunger pumps are valued for their smooth flow and ability to handle very high pressures with precision.

2. Multistage Centrifugal Pumps

These pumps are commonly used in water treatment and boiler feed systems. High-pressure pump Singapore providers often recommend multistage pumps for applications that require sustained pressure over long distances.

3. Hydraulic Diaphragm Pumps

Used for chemical dosing and hazardous fluid handling. The diaphragm design ensures leak-proof operation, making it a popular high-pressure pump Singapore option in the pharmaceutical and water treatment sectors.

Materials and Design Considerations

The design of high-pressure pump Singapore systems must account for fluid type, operating temperature, pressure rating, and corrosion resistance. Key material choices include:

- Stainless Steel (SS316 or Duplex) for seawater or aggressive chemicals

- Bronze or Cast Iron for general water pumping

- Titanium for highly corrosive or marine applications

The high-pressure pump Singapore industry emphasizes modular designs, service-friendly access, and advanced seal technology to minimize downtime and ensure long-term performance.

Key Benefits of High-Pressure Pump Solutions in Singapore

1. Superior Efficiency

The precision engineering of high-pressure pump Singapore units ensures high flow rates with minimum energy consumption, translating into lower operational costs.

2. Durability in Harsh Environments

Singapore’s tropical climate and industrial demands require pumps that can withstand high humidity, corrosive atmospheres, and continuous duty cycles. High-pressure pump Singapore models are built with these considerations in mind.

3. Compact and Space-Saving Designs

In urban environments like Singapore, space is a premium. Manufacturers focus on compact high-pressure pump Singapore systems that fit into tight mechanical rooms without sacrificing performance.

4. Automation and Control Integration

Most modern high-pressure pump Singapore systems can be integrated with Building Management Systems (BMS), Programmable Logic Controllers (PLCs), and Internet of Things (IoT) platforms for real-time monitoring and predictive maintenance.

Choosing the Right High-Pressure Pump in Singapore

When selecting a high-pressure pump Singapore, consider the following parameters:

- Required Flow Rate and Pressure: Ensure the pump meets both peak and average operating conditions.

- Fluid Characteristics: Viscosity, temperature, and chemical composition affect material selection.

- Duty Cycle: Continuous vs. intermittent use can impact motor sizing and cooling requirements.

- Installation Location: Indoor, outdoor, marine, or hazardous area certification may be necessary.

- Maintenance Access: Select models with easy access to seals, bearings, and motors.

For companies seeking dependable high-pressure pump Singapore solutions, careful specification matching is crucial to long-term system efficiency and reliability.

Common Challenges in High-Pressure Pump Operation

Despite their robustness, high-pressure pump Singapore systems can face operational challenges if not properly maintained:

- Cavitation due to poor suction head

- Seal Failure from chemical attack or dry running

- Overheating from improper lubrication or blocked cooling

- Vibration and Noise indicating misalignment or bearing wear

Preventive maintenance schedules and using OEM spare parts ensure your high-pressure pump Singapore systems continue to operate smoothly.

Preventive Maintenance Practices

To extend the life of your high-pressure pump Singapore, implement the following best practices:

- Weekly inspection of pressure gauges, motor amperage, and seal leakage

- Monthly lubrication of bearings and checking alignment

- Quarterly performance benchmarking against OEM parameters

- Annual service including complete dismantling, replacement of wear parts, and alignment

Energy Efficiency and Environmental Compliance

The high-pressure pump Singapore market is increasingly shifting towards energy-efficient models with smart controls. Variable Frequency Drives (VFDs) are often integrated to match pump speed with demand, reducing electricity usage and carbon footprint.

Singapore’s commitment to sustainability also mandates the use of high-pressure pump Singapore systems that meet water efficiency standards and environmental compliance guidelines.

Industry Trends in High-Pressure Pump Technology

As Singapore leads innovation in industrial automation and water reuse, the following trends are shaping the high-pressure pump Singapore industry:

- Digital Twin Technology: Real-time simulations for optimizing pump performance

- Smart Sensors: For vibration, pressure, and temperature monitoring

- Self-Priming and Self-Cooling Designs: For remote or difficult installations

- Compact Skid Packages: Pre-engineered units with integrated pump, control, piping, and safety systems

These trends demonstrate the evolution of high-pressure pump Singapore solutions toward intelligent, efficient, and resilient systems.

Why Singapore Industries Trust High-Pressure Pump Systems

Singapore’s strategic importance as a logistics and manufacturing hub demands consistent uptime. The reliance on high-pressure pump Singapore systems stems from:

- Availability of advanced technology

- Local expertise and engineering support

- Customization options

- Quick turnaround on spares and service

Whether used in desalination, fire fighting, process plants, or aerospace, the high-pressure pump Singapore offering continues to support mission-critical operations.

High-Pressure Pump System Integration in Singapore

In modern infrastructure and plant environments, a high-pressure pump Singapore solution is rarely used in isolation. Instead, these pumps are increasingly integrated into complex systems that include:

- Control panels with automation features

- PLC and SCADA systems for remote operation

- Pressure sensors and flowmeters

- Safety interlocks and alarm systems

- Skid-mounted units with pipelines, valves, and tanks

Integrating your high-pressure pump Singapore into a turnkey package reduces installation time, minimizes risk, and ensures compatibility with your facility’s existing processes. This is especially critical in industries such as semiconductor fabrication, power generation, and chemical processing where every second counts.

Safety Considerations for High-Pressure Pump Singapore Installations

With great power comes great responsibility—high-pressure pump systems operate under extreme conditions and must be designed and maintained with strict adherence to safety protocols.

Key safety measures include:

- Pressure Relief Valves (PRVs): Preventing overpressure and catastrophic failure.

- Interlocks & Emergency Stops: Ensuring immediate shutdown during anomalies.

- Vibration Monitoring Systems: Protecting against bearing or impeller failure.

- Explosion-proof Enclosures: Required in hazardous areas with flammable substances.

- Zero-leak Sealing Technologies: Especially vital in chemical or pharmaceutical applications.

The high-pressure pump market emphasizes safe and compliant solutions that meet both local and international safety standards (e.g., ISO, IEC, ASME, API).

Industry-Specific High-Pressure Pump Singapore Solutions

1. Oil & Gas Industry

In upstream, midstream, and downstream operations, high-pressure pump Singapore systems are essential for:

- Well stimulation and hydraulic fracturing

- High-pressure fluid transfer

- Pipeline testing and flushing

- Chemical injection at precise pressure and flow rates

Stainless steel and API 674-compliant high-pressure pump Singapore systems are most commonly used.

2. Marine & Shipbuilding

Singapore’s maritime industry relies on high-pressure pump packages for:

- Ballast water treatment systems

- Engine cooling and scrubber units

- Bilge and fire suppression systems

These marine-grade pumps are built to withstand harsh sea conditions and saltwater exposure.

3. Pharmaceutical & Food Processing

The hygienic design of high-pressure pump systems is critical in sanitary environments. These pumps must be:

- CIP/SIP compatible

- FDA-compliant

- Resistant to microbial growth

Diaphragm and peristaltic high-pressure pump variants are ideal for sterile fluid transfer.

4. Desalination & Water Reuse

Singapore’s national water agency promotes water sustainability through desalination and NEWater programs. High-pressure pump Singapore models used in reverse osmosis and ultrafiltration help optimize energy consumption while maintaining high throughput.

Custom-Built High-Pressure Pump Skids

To cater to diverse operational requirements, high-pressure pump Singapore providers often supply custom skid packages, which include:

- Pumps with pre-engineered baseplates

- All associated piping, valves, filters, and sensors

- Pressure vessels or buffer tanks

- Electrical and automation panels

- Anti-vibration mountings

These systems are pre-tested (FAT-tested), easy to install (plug & play), and reduce project lead times for clients in Singapore.

Energy Efficiency and Sustainability in High-Pressure Pump Systems

Modern high-pressure pump Singapore installations are not just about pressure—they’re about sustainability. With Singapore’s Green Plan 2030 in mind, industries are now shifting to:

- IE3 and IE4 premium-efficiency motors

- VFD (Variable Frequency Drive) technology to reduce energy wastage

- Smart pumping algorithms that match load demands in real-time

- Leak-proof sealing to minimize chemical or water loss

An energy-efficient high-pressure pump Singapore system can reduce operational costs by up to 30% annually, especially in water-intensive industries like textile, semiconductor, and food manufacturing.

High-Pressure Pump Commissioning & Training in Singapore

Even the best high-pressure pump Singapore system is only as good as its commissioning process. A well-structured commissioning plan includes:

- Alignment checks

- Pipe flushing & air venting

- Pre-start interlock testing

- Load testing and ramp-up

- End-user training on operation and troubleshooting

With industrial assets being high-value, training operators and engineers on proper use of high-pressure pump Singapore systems is vital to long-term reliability.

Future Innovations in High-Pressure Pump Singapore Technology

Singapore’s smart nation vision extends into industrial equipment as well. The high-pressure pump Singapore sector is adopting advanced innovations to meet future challenges:

1. AI-Powered Predictive Maintenance

Sensors installed in high-pressure pump Singapore systems now feed data into AI algorithms that predict component wear, seal degradation, or performance anomalies—before failure occurs.

2. 3D-Printed Components

Advanced impeller and casing parts for high-pressure pump Singapore models can now be 3D-printed using alloys like Inconel, titanium, and ceramic composites.

3. Hybrid Pumps

Dual-mode high-pressure pump Singapore variants combine electric and hydraulic drive systems for energy optimization and flexible deployment across industries.

Comparing High-Pressure Pump Technologies

| Pump Type | Max Pressure | Application | Common in Singapore for |

|---|---|---|---|

| Triplex Plunger Pump | 10,000+ PSI | Water jet cutting, hydrotesting | Precision manufacturing, shipyards |

| Multistage Centrifugal | 1,000–2,500 PSI | Boiler feed, high-rise supply | Power plants, skyscrapers |

| Hydraulic Diaphragm | Up to 3,000 PSI | Chemical injection, pharma dosing | Water treatment, chemical plants |

| Peristaltic High Pressure | Up to 1,500 PSI | Slurries, viscous fluids | Waste treatment, F&B sector |

Each high-pressure pump Singapore application has unique performance and material demands, so choosing the correct pump type is critical.

Lifecycle Cost of High-Pressure Pump Singapore Systems

When evaluating a high-pressure pump Singapore solution, it’s important to consider not just the initial purchase cost, but the total lifecycle cost (LCC). The LCC includes:

- Capital expenditure (CAPEX): Purchase of pump, motor, skid, accessories

- Installation cost: Mounting, piping, electrical integration

- Energy consumption: Based on hours of operation and motor efficiency

- Maintenance cost: Spares, lubrication, periodic servicing

- Downtime costs: Unplanned outages due to breakdowns or inefficiency

In many industrial applications, energy usage accounts for over 80% of the total lifecycle cost. Therefore, energy-efficient high-pressure pump Singapore systems not only support sustainability but also offer long-term financial benefits.

Environmental Compliance and Green Building Standards

Singapore is known for its commitment to environmental sustainability. Every high-pressure pump Singapore installation must comply with local environmental guidelines, including:

- PUB Water Efficiency Requirements

- NEA Emission Control Standards

- BCA Green Mark Certification

To support these regulations, manufacturers are offering high-pressure pump Singapore systems with:

- Low-leakage mechanical seals

- Energy-efficient IE3/IE4 motors

- Recyclable components

- Noise reduction enclosures

- Low-vibration designs

By choosing eco-compliant high-pressure pump Singapore solutions, companies contribute to a greener future and benefit from possible tax incentives or carbon credits.

Industry Certifications and Standards

To ensure quality and regulatory compliance, high-pressure pump Singapore products are often certified to meet international standards. Common certifications include:

- ISO 9001 – Quality Management Systems

- ISO 14001 – Environmental Management Systems

- API 674 / API 675 – Positive Displacement Pumps for Oil & Gas

- ASME B73.1 / B73.2 – Centrifugal Pumps for Chemical Process

- ATEX Certification – Explosion-proof for hazardous areas

- CE / IECEx / UL / FM Approvals – Electrical and fire safety standards

These certifications ensure that your high-pressure pump Singapore purchase is a solid investment, designed and manufactured according to global benchmarks.

Smart Monitoring and Predictive Maintenance Systems

Industry 4.0 and IoT are transforming the way high-pressure pump Singapore systems are managed. Smart pumps come with advanced sensors and analytics to:

- Monitor temperature, pressure, and vibration in real time

- Detect leaks or wear before failure occurs

- Optimize energy use based on flow demand

- Trigger automated maintenance alerts

- Log historical performance for compliance audits

With predictive maintenance, businesses can reduce unplanned downtime by up to 60% and extend pump life by several years—making smart-enabled high-pressure pump Singapore solutions a game changer.

Common Misconceptions About High-Pressure Pumps

Despite their widespread use, some myths persist about high-pressure pump Singapore systems. Let’s debunk a few:

❌ Myth 1: “High-pressure pumps are overkill for general use.”

✅ Fact: While high-pressure pumps are engineered for demanding applications, they are often the correct choice where standard pumps fail to meet pressure or head requirements, especially in vertical buildings or RO systems.

❌ Myth 2: “They consume too much energy.”

✅ Fact: Modern high-pressure pump Singapore systems come with VFDs and high-efficiency motors that optimize energy use according to demand.

❌ Myth 3: “Maintenance is too difficult.”

✅ Fact: Most systems now include user-friendly interfaces, modular spares, and smart diagnostics, making them easier to service than ever.

Custom Engineering Support for High-Pressure Pump Singapore Applications

Custom engineering is often required for unique flow conditions, exotic materials, or extreme operating environments. Leading high-pressure pump Singapore providers offer:

- Design consultation and hydraulic modeling

- 3D CAD drawings for space planning

- CFD analysis for flow optimization

- Finite Element Analysis (FEA) for structural integrity

- PE endorsement and documentation for regulatory submissions

With engineering support from concept to commissioning, tailored high-pressure pump Singapore systems outperform off-the-shelf models in efficiency and reliability.

Integration with Other Utility Systems

High-pressure pumps are not isolated units—they form a part of a broader utility network in most facilities. In Singapore, high-pressure pump Singapore installations are often integrated with:

- Compressed air systems

- Cooling water loops

- Chemical dosing lines

- Steam or condensate recovery systems

Proper integration improves overall facility efficiency and ensures better control across the entire production or utility cycle.

Considerations for Offshore and Hazardous Environments

Singapore’s position as a leader in offshore and marine engineering means that high-pressure pump Singapore systems are regularly deployed in:

- Floating Production Storage and Offloading (FPSO) units

- Oil rigs and subsea modules

- LNG bunkering facilities

For these applications, high-pressure pump Singapore units must offer:

- Saltwater corrosion resistance

- Intrinsically safe design

- Compliance with DNV/ABS standards

- Operation in explosive zones (Zone 1 & 2 classified areas)

Selecting the right high-pressure pump Singapore solution for offshore use ensures safety, uptime, and compliance with stringent industry regulations.

End-of-Life Pump Management and Recycling

With Singapore’s push for circular economy practices, even the end-of-life stage of a high-pressure pump Singapore must be planned responsibly. Leading players now offer:

- Pump refurbishment services

- Spare part reclamation

- Recycling of metals and electrical parts

- Eco-certificates for equipment decommissioning

By choosing recyclable and maintainable high-pressure pump Singapore systems, businesses align with Singapore’s Zero Waste Masterplan while maximizing ROI.

Summary: Why Singapore Relies on High-Pressure Pumps

To summarize the value and critical role of high-pressure pump Singapore systems:

- ✅ Designed for extreme pressure and performance requirements

- ✅ Essential across multiple industries: water, marine, pharma, petrochemical

- ✅ Built with advanced materials to withstand heat, corrosion, and wear

- ✅ Equipped with smart controls for real-time monitoring and efficiency

- ✅ Fully compliant with Singapore’s rigorous safety and green standards

- ✅ Offered with engineering support for turnkey skid design and integration

- ✅ Proven to lower lifecycle cost through energy savings and durability

The Future is Under Pressure – and in Good Hands

Whether you’re building a new plant, retrofitting an existing facility, or expanding your water treatment capacity, a high-pressure pump Singapore system is essential. Designed to meet strict performance, safety, and energy standards, these pumps support Singapore’s dynamic industries with unmatched reliability.

When it comes to performance, sustainability, and precision, high-pressure pump Singapore systems are more than just equipment—they’re the lifeblood of industrial operations.

Conclusion: Powering Industries with High-Pressure Pump Solutions in Singapore

As industrial processes become more demanding, the need for high-performance fluid handling solutions continues to grow. The high-pressure pump Singapore market stands as a beacon of engineering excellence, offering unmatched pressure delivery, operational safety, and system reliability.

From the skyscrapers of Marina Bay to the shipyards of Tuas, from food processing zones to pharma clean rooms, high-pressure pump Singapore systems play a vital role in keeping industries running smoothly. Choosing the right pump ensures not just operational continuity but also compliance with Singapore’s exacting standards for safety, energy efficiency, and sustainability.

Investing in the right high-pressure pump Singapore solution today means building a future of uninterrupted performance and industrial resilience.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply