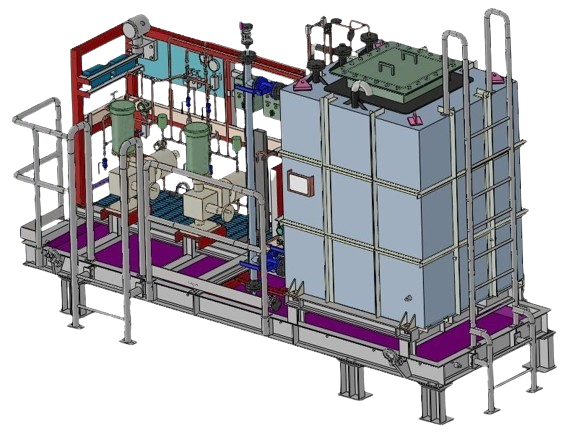

Chemical Dosing Skid

| Capacity | 100 Liter to Customer requirement |

|---|---|

| Construction | Portable prototype or civil based |

| Support | EPC | Turn key | Water & Sea water | Oil & Gas | Chemical |

| MOC Skid | MS, EN-8, SS304, SS316, SS316L, Duplex & Super Duplex Steel, (Comes with Various Lining RL, FRP, PP, PTFE) |

| Interface | Integrated both automated and semi automated |

| Design | Process I Mechanical I Electrical I Software and Hardware I Hydraulic & Fluid dynamics I Structural & Load |

| Support | Installation & Commissioning upto AMC and operation. |

Chemical Dosing Skid Packages: Precision Solutions for Industrial Applications

Introduction

In today’s industrial landscape, the importance of effective chemical dosing cannot be overstated. Chemical dosing skid packages are designed to deliver precise amounts of chemicals in various applications, ensuring optimal process efficiency and safety. At FLOMEK Singapore, we specialize in providing top-of-the-line chemical dosing skid packages that meet the unique needs of our clients across various sectors.

What is a Chemical Dosing Skid Package?

A chemical dosing skid package is a prefabricated assembly of pumps, tanks, valves, and piping designed to accurately dose chemicals into a system. These packages can be customized to accommodate a wide range of chemicals and flow rates, making them versatile solutions for various industries, including water treatment, pharmaceuticals, and food processing.

Key Components of Chemical Dosing Skid Packages

- Pumps: The heart of any dosing skid, pumps ensure that the correct volume of chemicals is delivered consistently. FLOMEK offers a range of high-quality dosing pumps suitable for various applications.

- Tanks: Chemical storage tanks are integral to dosing skids, providing a safe and efficient way to hold chemicals before they are dosed into the process.

- Valves: These control the flow of chemicals, ensuring that the right amount is delivered at the right time.

- Piping: Designed to withstand the chemical properties of the substances being used, the piping is crucial for directing chemicals from storage to application points.

- Instrumentation: Sensors and meters monitor flow rates and chemical concentrations, allowing for real-time adjustments and ensuring accurate dosing.

Advantages of Chemical Dosing Skid Packages

- Precision and Accuracy One of the primary benefits of chemical dosing skid packages is their ability to deliver precise amounts of chemicals. This is vital for applications where chemical concentrations must be controlled strictly to ensure compliance with safety and environmental regulations.

- Efficiency Chemical dosing skid packages streamline the dosing process, reducing manual labor and minimizing the risk of human error. Automated systems can be integrated for even greater efficiency, allowing for continuous operation without constant supervision.

- Customization At FLOMEK Singapore, we understand that no two applications are the same. That’s why our chemical dosing skid packages are fully customizable to meet the specific needs of our clients. Whether you need to dose multiple chemicals or require specific flow rates, we can tailor a solution just for you.

- Safety Chemical handling can be hazardous. Chemical dosing skid packages are designed with safety in mind, incorporating features such as leak detection, secondary containment, and emergency shut-off systems to protect workers and the environment.

- Cost-Effectiveness Investing in chemical dosing skid packages can lead to significant cost savings over time. By improving efficiency and accuracy, these systems reduce waste and lower the overall cost of chemical consumption.

Applications of Chemical Dosing Skid Packages

- Water Treatment In the water treatment industry, precise chemical dosing is critical for ensuring safe and clean water supply. Chemical dosing skid packages are used to add disinfectants, coagulants, and other treatment chemicals to water sources.

- Pharmaceutical Manufacturing The pharmaceutical industry demands high precision in chemical dosing to meet regulatory requirements. Chemical dosing skid packages are essential for maintaining quality and consistency in drug production.

- Food Processing In food processing, maintaining the correct chemical balance is vital for both safety and quality. Our chemical dosing skid packages can accurately dose ingredients and additives to ensure product integrity.

- Chemical Processing In chemical manufacturing, the need for precise dosing is paramount. Our chemical dosing skid packages are designed to handle a variety of chemicals, ensuring accurate dosing throughout the production process.