Flomek booster pump service – Singapore’s No 1 Best Pump service & supplier

Flomek Booster Pump Service – Reliable Pressure Solutions for Industrial and Commercial Applications

Introduction to Flomek Booster Pump Service

Flomek booster pump service is a specialized solution designed to ensure consistent water pressure, operational reliability, and long-term efficiency for industrial, commercial, and infrastructure applications. In modern facilities, uninterrupted water pressure is essential for smooth operations, safety compliance, and energy efficiency. Flomek booster pump service is engineered to meet these demands through precision servicing, expert diagnostics, and professional maintenance practices.

Flomek booster pump service supports systems used in high-rise buildings, water treatment plants, manufacturing facilities, HVAC systems, fire protection networks, and process industries. By combining engineering expertise with advanced service methodologies, Flomek booster pump service ensures optimal pump performance under varying load conditions.

A well-maintained booster pump system minimizes downtime, reduces energy consumption, and extends equipment lifespan. Flomek booster pump service is focused on preventive maintenance, corrective repairs, system optimization, and performance restoration, making it a trusted solution for pressure boosting requirements.

Understanding Booster Pump Systems

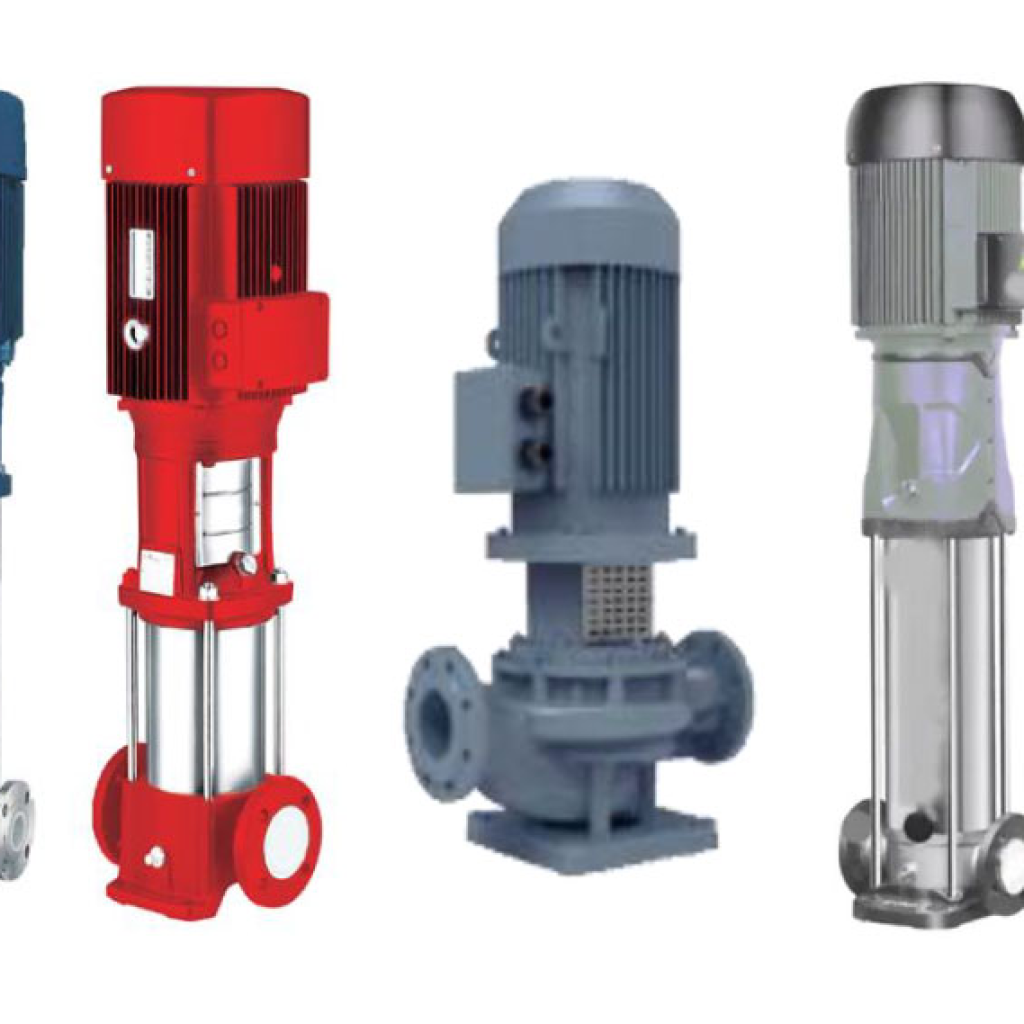

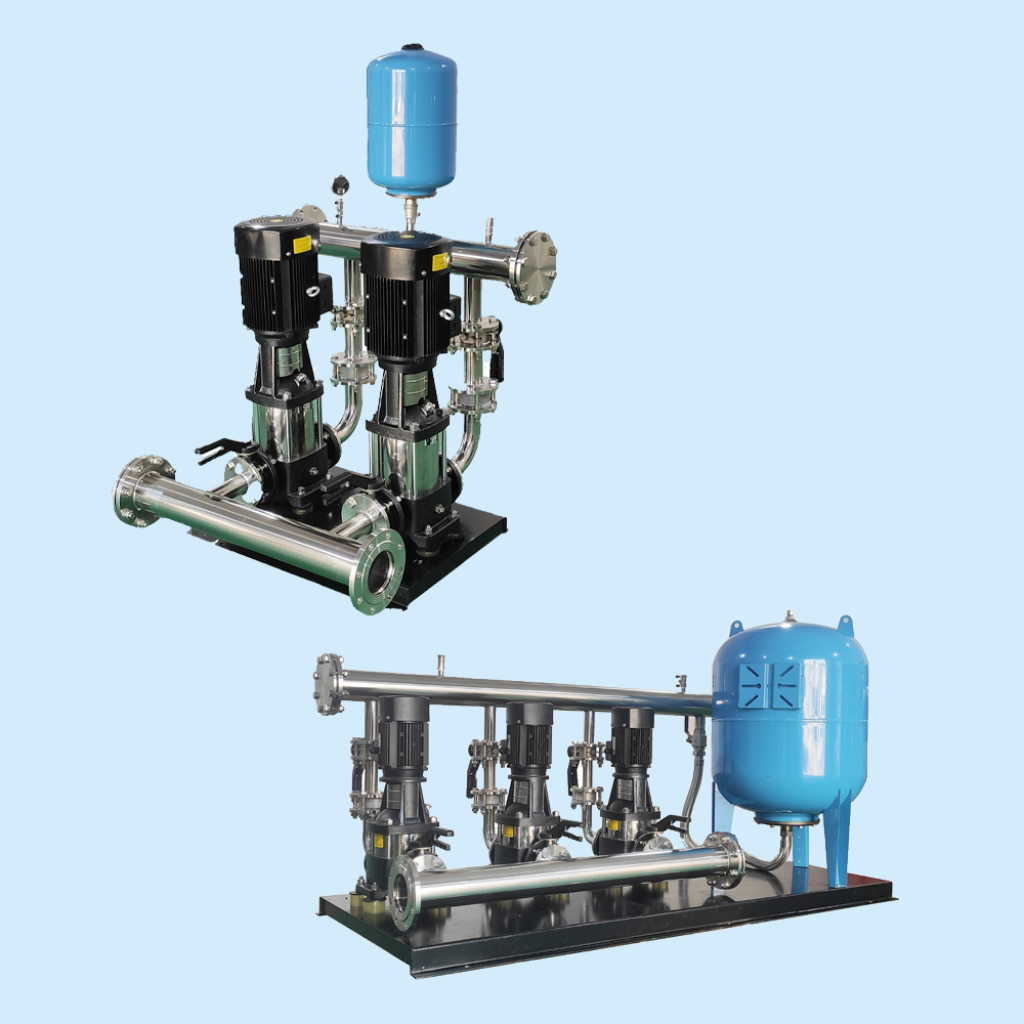

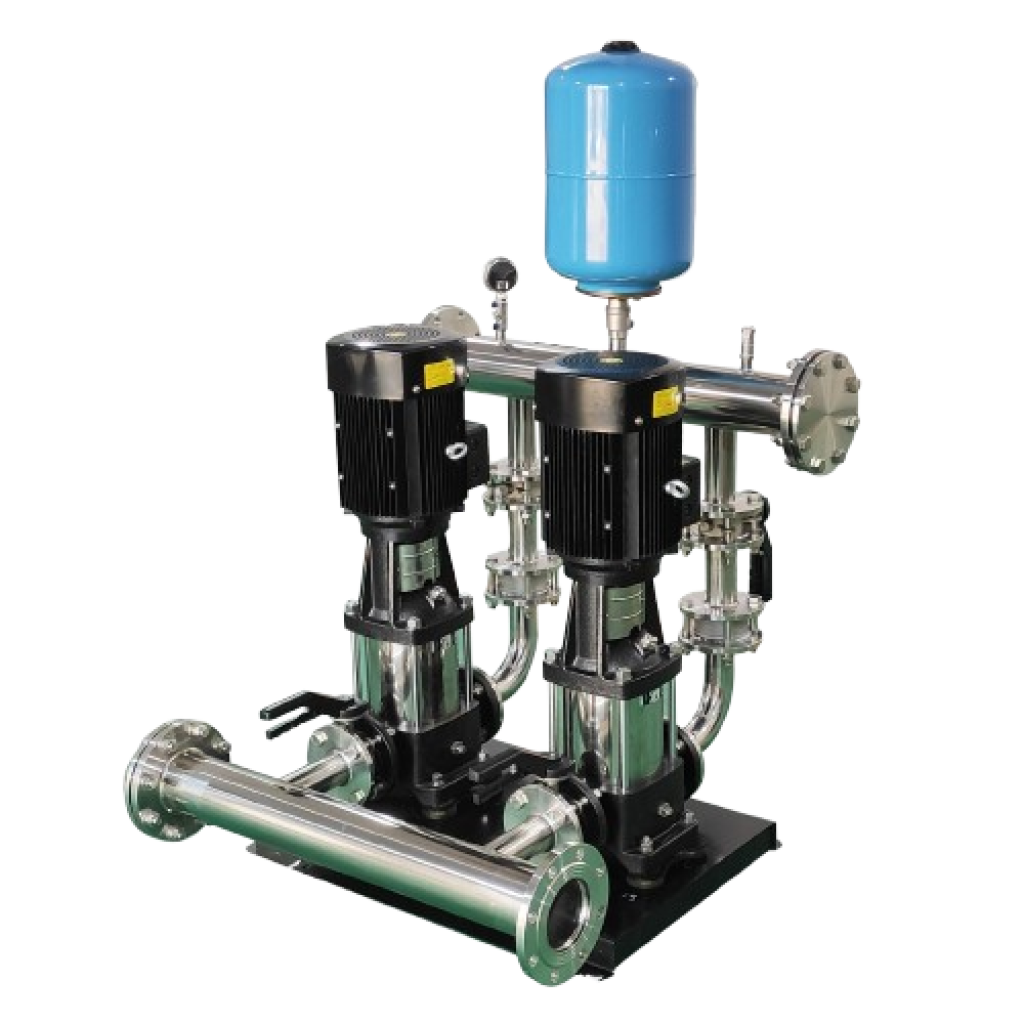

Booster pump systems are designed to increase water pressure when incoming supply pressure is insufficient to meet operational requirements. These systems typically include centrifugal pumps, motors, pressure vessels, control panels, sensors, valves, and piping networks. Flomek booster pump service covers all these components to ensure seamless operation.

Flomek booster pump service addresses common challenges such as pressure fluctuations, uneven flow distribution, excessive energy usage, cavitation, seal failures, bearing wear, and control system issues. Proper servicing ensures that booster pump systems deliver consistent pressure across all demand points.

By implementing Flomek booster pump service, facilities can avoid premature pump failures, reduce operational costs, and maintain compliance with industry standards.

Importance of Professional Booster Pump Servicing

Professional servicing is critical for maintaining system efficiency and reliability. Flomek booster pump service follows structured maintenance procedures aligned with industrial best practices. Routine servicing helps identify early signs of wear, misalignment, vibration, and hydraulic inefficiencies.

Flomek booster pump service ensures:

- Stable discharge pressure

- Reduced mechanical stress

- Optimized motor performance

- Extended seal and bearing life

- Improved system reliability

Without professional servicing, booster pump systems are prone to frequent breakdowns and inefficient operation. Flomek booster pump service eliminates these risks through systematic inspection and corrective action.

Scope of Flomek Booster Pump Service

Flomek booster pump service includes a comprehensive range of activities designed to maintain and restore system performance.

System Inspection and Assessment

Flomek booster pump service begins with a detailed inspection of pumps, motors, couplings, base frames, and piping. Performance parameters such as pressure, flow rate, vibration, and temperature are evaluated.

Preventive Maintenance

Preventive maintenance is a core component of Flomek booster pump service. Scheduled inspections and servicing help prevent unexpected failures and reduce long-term maintenance costs.

Mechanical Servicing

Flomek booster pump service includes bearing replacement, mechanical seal servicing, shaft alignment, impeller inspection, and coupling maintenance.

Electrical and Control Checks

Control panels, pressure sensors, variable speed drives, and safety interlocks are inspected and calibrated as part of Flomek booster pump service.

Performance Optimization

System tuning and hydraulic balancing are performed to ensure energy-efficient operation. Flomek booster pump service helps reduce power consumption while maintaining required pressure levels.

Applications of Flomek Booster Pump Service

Flomek booster pump service is suitable for a wide range of applications:

High-Rise Buildings

Maintaining uniform water pressure across multiple floors requires reliable booster pump systems. Flomek booster pump service ensures consistent supply and system stability.

Water Treatment Facilities

Booster pumps play a critical role in filtration, distribution, and process operations. Flomek booster pump service supports uninterrupted plant operation.

Industrial Manufacturing

Manufacturing processes often depend on precise water pressure. Flomek booster pump service ensures reliable performance under continuous duty cycles.

HVAC Systems

Chilled water and cooling systems rely on stable pressure. Flomek booster pump service helps maintain efficient HVAC operation.

Fire Protection Systems

Reliable pressure is essential for fire safety systems. Flomek booster pump service ensures readiness and compliance.

Advantages of Choosing Flomek Booster Pump Service

Flomek booster pump service offers several operational and financial advantages:

- Reduced unplanned downtime

- Extended equipment lifespan

- Improved energy efficiency

- Lower maintenance costs

- Enhanced system reliability

By adopting Flomek booster pump service, facilities can focus on core operations while ensuring dependable pressure boosting performance.

Engineering Expertise Behind Flomek Booster Pump Service

Flomek booster pump service is supported by experienced engineers and technicians with in-depth knowledge of pump hydraulics, mechanical systems, and electrical controls. Each service activity is carried out using standardized procedures and precision tools.

Flomek booster pump service emphasizes root cause analysis to address recurring issues and improve long-term system performance. This engineering-driven approach differentiates Flomek booster pump service from basic maintenance practices.

Preventive Maintenance Strategy

Preventive maintenance is essential for maximizing system uptime. Flomek booster pump service includes structured maintenance schedules tailored to operating conditions and system criticality.

Preventive activities include:

- Lubrication checks

- Vibration analysis

- Alignment verification

- Seal condition monitoring

- Pressure and flow verification

Through preventive maintenance, Flomek booster pump service reduces the risk of catastrophic failures and costly repairs.

Energy Efficiency and Cost Optimization

Energy consumption is a major operating cost for booster pump systems. Flomek booster pump service focuses on optimizing pump performance to reduce energy usage.

By correcting hydraulic inefficiencies, eliminating leaks, and optimizing control settings, Flomek booster pump service helps facilities achieve measurable energy savings.

Reliability and Operational Continuity

Operational continuity is critical in industrial and commercial environments. Flomek booster pump service is designed to ensure uninterrupted performance even under demanding conditions.

By maintaining redundancy systems and ensuring proper pump sequencing, Flomek booster pump service enhances overall system reliability.

Quality and Safety Standards

Flomek booster pump service adheres to stringent quality and safety standards. All servicing activities follow approved procedures to ensure safe handling of equipment and compliance with operational guidelines.

Safety checks are integrated into every stage of Flomek booster pump service to protect both personnel and equipment.

Customized Service Solutions

Every facility has unique operating requirements. Flomek booster pump service offers customized solutions based on system design, duty cycles, and application demands.

Customized service plans ensure that Flomek booster pump service delivers maximum value and performance for each installation.

Long-Term Asset Protection

Booster pump systems represent a significant capital investment. Flomek booster pump service protects this investment by ensuring optimal operating conditions and preventing premature failures.

With regular Flomek booster pump service, facilities can extend equipment life and reduce replacement costs.

Role of Flomek Booster Pump Service in Sustainable Operations

Sustainability is increasingly important in industrial operations. Flomek booster pump service supports sustainable practices by improving energy efficiency and reducing resource waste.

Efficient pump operation contributes to lower carbon emissions and responsible resource utilization.

Integrated System Approach

Flomek booster pumps service considers the entire pumping system rather than individual components. This integrated approach ensures balanced operation and improved system performance.

By addressing piping, controls, and hydraulics together, Flomek booster pumps service delivers comprehensive results.

Advanced Diagnostics in Flomek Booster Pumps Service

Flomek booster pumps service incorporates advanced diagnostic techniques to evaluate system health and operational efficiency. Modern booster pump systems operate under variable demand conditions, making accurate diagnostics essential. Flomek booster pumps service utilizes pressure trend analysis, vibration monitoring, and operational data evaluation to identify inefficiencies before they escalate into failures.

Through systematic diagnostics, Flomek booster pumps service identifies hidden issues such as hydraulic imbalance, internal leakage, worn impellers, bearing fatigue, and control instability. Early detection allows corrective measures to be implemented with minimal disruption to operations.

Flomek booster pumps service ensures diagnostic findings are translated into actionable maintenance strategies, improving system reliability and performance consistency.

Hydraulic Performance Optimization

Hydraulic efficiency is a critical factor in booster pump operation. Flomek booster pumps service focuses on restoring and maintaining hydraulic performance by ensuring pumps operate close to their best efficiency point.

Improper system design, throttled valves, fouled impellers, or incorrect pump sequencing can reduce efficiency. Flomek booster pumps service evaluates system curves, demand profiles, and operational parameters to optimize performance.

By implementing hydraulic optimization measures, Flomek booster pumps service reduces unnecessary energy losses and enhances pressure stability across the system.

Mechanical Integrity and Component Reliability

Mechanical reliability is the backbone of any booster pump system. Flomek booster pumps service ensures all mechanical components function within designed tolerances.

Key mechanical service activities include:

- Shaft inspection and alignment verification

- Bearing condition assessment and replacement

- Mechanical seal inspection and leakage prevention

- Coupling inspection and vibration reduction

Flomek booster pumps service prioritizes precision workmanship to prevent recurring mechanical issues and extend service intervals.

Electrical System Health and Control Stability

Electrical and control systems are integral to booster pump operation. Flomek booster pumps service includes comprehensive inspection of motors, starters, control panels, and automation systems.

Flomek booster pumps service verifies:

- Motor insulation condition

- Current and voltage balance

- Control logic stability

- Sensor calibration accuracy

Stable electrical performance ensures smooth pump operation and prevents unexpected shutdowns. Flomek booster pumps service integrates electrical health checks into every maintenance program.

Pressure Management and Flow Regulation

Pressure management is the primary function of booster pump systems. Flomek booster pumps service ensures pressure levels are maintained accurately under varying demand conditions.

Improper pressure control can result in pipe stress, leakage, and inefficient water usage. Flomek booster pumps service calibrates pressure sensors, adjusts control parameters, and verifies pump staging logic to maintain optimal pressure levels.

Through precise pressure management, Flomek booster pumps service supports operational stability and infrastructure protection.

Redundancy and Standby System Readiness

Many booster pump systems are designed with redundancy to ensure uninterrupted operation. Flomek booster pumps service verifies that standby pumps, automatic changeover systems, and safety interlocks function correctly.

Routine testing of standby configurations is an essential part of Flomek booster pumps service. Ensuring all pumps are operational prevents failure during peak demand or emergency conditions.

Commissioning Support within Flomek Booster Pumps Service

Flomek booster pumps service also supports commissioning activities for new and upgraded systems. Proper commissioning ensures systems operate as intended from the start.

Commissioning support includes:

- Performance verification

- Control logic validation

- Pressure and flow testing

- Safety system checks

Flomek booster pumps service ensures commissioning is carried out systematically to prevent early-stage failures.

Troubleshooting and Root Cause Analysis

Recurring issues in booster pump systems often indicate underlying design or operational problems. Flomek booster pumps service emphasizes structured troubleshooting and root cause analysis.

Rather than addressing symptoms alone, Flomek booster pumps service investigates the fundamental causes of failures such as cavitation, misapplication, or control instability. This approach ensures long-term reliability and reduces repeat breakdowns.

Maintenance Planning and Lifecycle Management

Effective maintenance planning is essential for cost control and asset longevity. Flomek booster pumps service supports lifecycle management by developing structured maintenance schedules aligned with operating conditions.

Lifecycle-focused Flomek booster pumps service helps organizations:

- Forecast maintenance costs

- Plan component replacements

- Reduce emergency repairs

- Extend equipment life

This strategic approach transforms maintenance from reactive to proactive.

Adaptability to Changing Operating Conditions

Operating conditions evolve over time due to expansion, demand changes, or process modifications. Flomek booster pumps service evaluates system adaptability and recommends adjustments to maintain performance.

Whether flow demand increases or pressure requirements change, Flomek booster pumps service ensures systems remain efficient and reliable under new conditions.

Compliance and Operational Best Practices

Compliance with operational guidelines and industry best practices is essential for safe and reliable pumping systems. Flomek booster pumps service aligns maintenance activities with recognized engineering standards.

By maintaining compliance, Flomek booster pumps service reduces operational risk and ensures consistent system performance.

Risk Reduction Through Proactive Servicing

Unexpected pump failures can disrupt operations and lead to significant losses. Flomek booster pumps service minimizes risk through proactive servicing and condition monitoring.

Risk-based maintenance strategies implemented under Flomek booster pumps service prioritize critical equipment and reduce vulnerability to failures.

Integration with Facility Maintenance Programs

Flomek booster pumps service integrates seamlessly with broader facility maintenance programs. Coordination with mechanical, electrical, and operations teams ensures efficient execution and minimal disruption.

Integrated maintenance enhances communication, improves planning accuracy, and strengthens system reliability.

System Reliability Engineering with Flomek Booster Pumps Service

System reliability is a core objective of Flomek booster pumps service. Booster pump systems often operate continuously and are expected to perform under fluctuating demand conditions. Flomek booster pumps service is designed to stabilize performance by addressing mechanical, hydraulic, and control-related reliability factors.

Through structured inspections and performance verification, Flomek booster pumps service identifies weak points in the system that could lead to failure. These include improper pump sequencing, uneven load sharing, excessive vibration, and pressure instability. Addressing these factors improves overall system resilience.

Flomek booster pumps service ensures reliability is built into everyday operation rather than achieved through emergency intervention.

Continuous Operation Support through Flomek Booster Pumps Service

Many facilities rely on round-the-clock operation. Flomek booster pumps service supports continuous operation by ensuring pumps, motors, and controls remain within safe operating limits.

Continuous-duty applications require careful attention to heat dissipation, lubrication quality, seal integrity, and electrical stability. Flomek booster pumps service monitors these parameters to prevent degradation over time.

By supporting continuous operation, Flomek booster pumps service reduces unplanned shutdowns and maintains operational continuity.

Vibration Control and Noise Reduction

Excessive vibration is a common cause of premature pump failure. Flomek booster pumps services includes vibration assessment and corrective alignment procedures to reduce mechanical stress.

Improper alignment, worn bearings, unbalanced impellers, and piping strain are common contributors to vibration. Flomek booster pump service addresses these issues methodically to stabilize operation.

Noise reduction is an added benefit of vibration control. Flomek booster pumps services improves workplace conditions while protecting mechanical components.

Long-Term Performance Assurance

Sustained performance requires consistent attention to system health. Flomek booster pump service provides long-term performance assurance through regular evaluation, optimization, and corrective action.

By maintaining performance benchmarks, Flomek booster pump service ensures booster pump systems continue to meet operational requirements year after year.

Strategic Value of Flomek Booster Pump Service

Beyond routine maintenance, Flomek booster pump service delivers strategic value by improving operational efficiency, reducing lifecycle costs, and enhancing system resilience.

Facilities that adopt Flomek booster pump service benefit from improved uptime, predictable maintenance costs, and enhanced operational confidence.

Final Perspective

Flomek booster pump service represents a comprehensive, engineering-driven approach to booster pump maintenance, optimization, and reliability. By combining mechanical expertise, electrical diagnostics, hydraulic optimization, and lifecycle planning, Flomek booster pump service ensures dependable pressure boosting across diverse applications.

Organizations seeking consistent performance, reduced risk, and long-term operational efficiency continue to rely on Flomek booster pump service as a critical component of their infrastructure strategy.

Conclusion

Flomek booster pump service is a complete, professional solution for maintaining, optimizing, and protecting booster pump systems across industrial and commercial applications. Through expert servicing, preventive maintenance, and performance optimization, Flomek booster pump service ensures reliable pressure delivery, reduced operational costs, and long-term system efficiency.

Organizations that prioritize system reliability, energy efficiency, and asset protection benefit significantly from Flomek booster pump service. With a strong focus on engineering excellence and operational reliability, Flomek booster pump service remains a dependable choice for pressure boosting solutions.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply