Turnkey projects – Best 2025

Turnkey Projects: A Complete Guide to Streamlined Project Execution

Introduction to Turnkey Projects

Turnkey projects have become a cornerstone in modern business practices, offering clients an all-in-one solution for complex initiatives. In essence, a turnkey project refers to a project wherein a single contractor or company handles all aspects of execution—ranging from design and engineering to procurement, installation, testing, and commissioning. Upon completion, the client simply “turns the key” to start operations. This approach ensures minimized risk, streamlined timelines, and consolidated responsibility.

In industries like construction, oil & gas, water treatment, manufacturing, pharmaceuticals, and energy, turnkey projects offer a structured and efficient solution for clients who want to reduce coordination hassles and ensure predictable outcomes.

What Are Turnkey Projects?

Turnkey projects are contractual arrangements in which a company is hired to plan, design, construct, and commission a facility or system and then hand it over to the client in a ready-to-use condition. The term “turnkey” signifies that the client only needs to “turn the key” to begin operations.

Key Characteristics of Turnkey Projects:

- Single-Point Responsibility: One entity is accountable for all deliverables.

- Time-Bound Delivery: Projects are typically completed on a fixed timeline.

- Budget-Centric: Costs are agreed upon in advance, minimizing budget overruns.

- Operational Readiness: Facilities are delivered fully operational.

- Minimized Client Involvement: Reduced need for micromanagement from clients.

Advantages of Turnkey Projects

1. Simplified Management

With turnkey projects, the client deals with one contractor or project developer, making communication simpler and clearer. There’s no need to coordinate with multiple vendors, subcontractors, or consultants.

2. Time Efficiency

Turnkey projects are designed to be executed efficiently, following pre-set deadlines. This ensures fast delivery, which is critical in time-sensitive operations such as manufacturing or commercial real estate.

3. Cost Predictability

Budgets are pre-defined, and the scope is fixed. This eliminates cost creep and ensures that the project stays within financial limits—one of the most significant benefits of turnkey projects.

4. Quality Control

The responsibility for quality lies with a single provider. Therefore, turnkey project contractors are highly incentivized to maintain standards to avoid penalties or reputational damage.

5. Reduced Risk for Clients

Risk is transferred to the contractor. The client does not bear the technical, financial, or operational risks during the project lifecycle—making turnkey projects ideal for clients looking for a hassle-free experience.

Industries That Benefit from Turnkey Projects

1. Construction & Real Estate

In the building and construction sector, turnkey projects involve the end-to-end development of residential, commercial, or industrial properties, ready for immediate use upon handover.

2. Water Treatment & Utilities

Companies like FLOMEK Singapore execute turnkey projects for water treatment plants, delivering fully operational facilities including design, fabrication, installation, and commissioning.

3. Oil & Gas

From drilling platforms to refinery units, turnkey projects ensure that oil & gas infrastructure is completed and operational with minimal client intervention.

4. Pharmaceutical & Food Processing

For highly regulated industries, turnkey project execution ensures compliance, proper validation, and quick time-to-market for new facilities.

5. Manufacturing & Industrial Plants

Setting up a new manufacturing plant under a turnkey project reduces time, improves coordination, and allows businesses to focus on production immediately after handover.

Turnkey Projects Lifecycle: Step-by-Step

1. Project Initiation

The client defines project goals, timeline, and expected deliverables. The turnkey project provider presents a comprehensive proposal including design concepts, timelines, and cost estimates.

2. Detailed Engineering and Design

The provider undertakes detailed designs using advanced software and engineering standards. The design includes layouts, equipment specifications, piping diagrams, and more.

3. Procurement and Manufacturing

Materials, machinery, and equipment are sourced by the contractor. In many turnkey projects, in-house fabrication or procurement from certified vendors ensures quality control.

4. Installation & Construction

Civil work, mechanical installation, piping, cabling, and system assembly are carried out according to the approved design. Safety and compliance protocols are strictly enforced.

5. Testing & Commissioning

Before handover, the entire system or plant is tested under real operating conditions. Fine-tuning, performance testing, and validation are part of this stage.

6. Handover & Training

Upon successful validation, the project is handed over to the client along with operational manuals, documentation, and training for staff to begin operations.

Choosing the Right Turnkey Project Partner

A reliable turnkey project partner brings expertise, resources, and a proven track record. Here’s what to look for:

1. Experience & Expertise

Ensure your partner has handled similar turnkey projects in your industry. Review case studies and client testimonials.

2. Integrated Services

A true turnkey project provider offers design, engineering, fabrication, installation, and commissioning under one roof.

3. Technical Support

Post-handover support, AMC contracts, and troubleshooting assistance should be part of the package.

4. Compliance & Safety

Ensure the company follows industry best practices and regulatory compliance in all turnkey projects.

Challenges in Turnkey Projects and How to Overcome Them

1. Scope Creep

If the project scope isn’t clearly defined, it can lead to cost overruns. Solution: Create detailed specifications at the beginning of the turnkey project.

2. Communication Gaps

Delays or misunderstandings can arise due to miscommunication. Solution: Have regular meetings and progress reports throughout the turnkey project lifecycle.

3. Budget Overruns

Poor planning or unexpected issues can inflate costs. Solution: Choose a turnkey project provider with accurate forecasting tools and budget control mechanisms.

The Future of Turnkey Project

1. Digitalization & Automation

Integration of IoT, AI, and real-time analytics is transforming turnkey project into smart, connected systems that offer operational insights from day one.

2. Modular Turnkey Solutions

Companies are now offering modular turnkey project—pre-fabricated systems that are easy to install and scale, especially in water treatment and chemical dosing plants.

3. Green & Sustainable Projects

Eco-friendly materials, energy-efficient systems, and water-saving technologies are becoming standard in modern turnkey project.

Why Choose FLOMEK Singapore for Turnkey Projects?

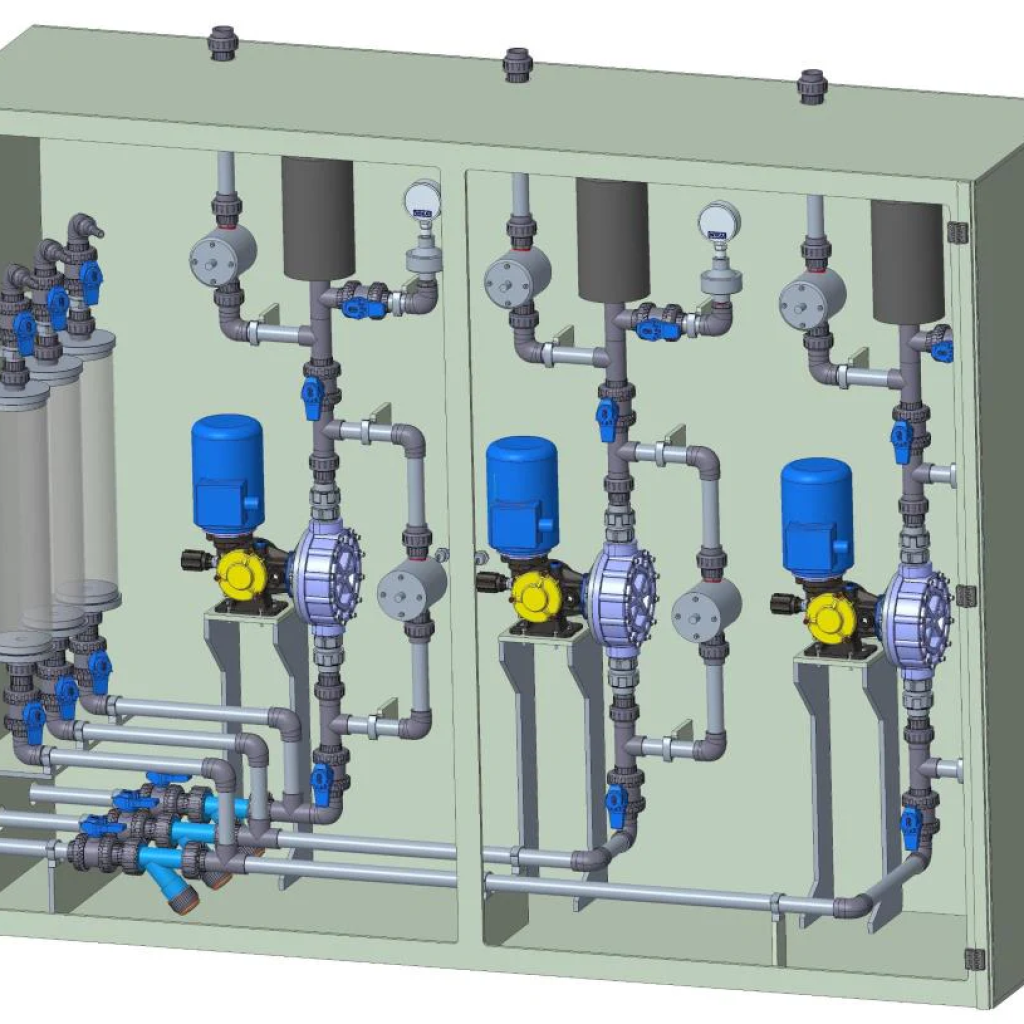

At FLOMEK Singapore, we specialize in executing complex turnkey project with precision and reliability. Whether it’s a water treatment plant, a chemical dosing skid, or an industrial pump system, our team ensures complete delivery from design to commissioning.

Our Turnkey Project Capabilities:

- Design and Engineering by certified professionals

- Custom Skid Fabrication in-house

- High-Performance Pump & Process Equipment

- Automation and PLC Integration

- On-Site Installation & Commissioning

- Ongoing Service & Maintenance

By choosing FLOMEK, clients benefit from proven experience, a skilled engineering team, and commitment to quality—all essential in the execution of successful turnkey project.

Conclusion

In today’s competitive landscape, turnkey project offer an unmatched advantage by combining efficiency, quality, and simplicity into one comprehensive solution. From industrial plants to infrastructure development, turnkey project reduce risk, streamline delivery, and ensure operational readiness from day one.

Businesses seeking reliable, cost-effective, and expert-driven project execution should consider turnkey project as the go-to model. With the right partner—like FLOMEK Singapore—your next project could be operational faster, smoother, and with complete peace of mind.

Frequently Asked Questions (FAQs)

Q1. What is a turnkey project?

A turnkey project is a contractual model where a single contractor delivers a complete, ready-to-operate facility or system to the client.

Q2. What industries use turnkey projects?

Industries like construction, water treatment, oil & gas, pharmaceuticals, and manufacturing frequently use turnkey project.

Q3. What are the benefits of turnkey project?

Key benefits include time savings, cost control, single-point accountability, and reduced client risk.

Q4. How does a turnkey project differ from an EPC project?

While both are similar, turnkey project usually imply complete operational readiness, while EPC (Engineering, Procurement, Construction) might require further setup post-handover.

Q5. Why choose FLOMEK Singapore for turnkey project execution?

FLOMEK Singapore offers integrated engineering, fabrication, and commissioning solutions with years of experience in turnkey project, especially in water, chemical, and process industries.

Detailed Components of Turnkey Project

To better understand turnkey project, it’s important to break down their key components. Each component plays a critical role in ensuring that the final delivery is successful, cost-efficient, and operationally sound.

1. Project Planning and Feasibility Study

Every turnkey project begins with an in-depth feasibility analysis. This includes:

- Site analysis

- Regulatory approvals

- Cost-benefit projections

- Risk assessments

The goal is to determine whether the turnkey project is technically and financially viable.

2. Engineering Design and Architecture

A well-executed turnkey project depends on robust engineering design. This includes:

- Process design

- Piping and instrumentation diagrams (P&ID)

- Electrical, mechanical, and civil engineering layouts

- Structural calculations and stress analysis

3. Procurement Management

Materials and components are selected, sourced, and managed entirely by the turnkey project provider. Procurement ensures quality compliance and timely delivery of:

- Pumps, valves, compressors

- Electrical panels, PLC systems

- Piping, skids, and structural supports

4. Fabrication and Modular Construction

Many turnkey project today involve modular fabrication. This reduces on-site work and enhances control. Skid-based solutions, for example, allow for:

- Pre-assembled units

- Factory testing

- Quick on-site installation

5. Installation and Site Integration

Once all components are ready, on-site installation begins. For industrial turnkey project, this may involve:

- Foundation and civil works

- Mechanical erection

- Electrical wiring

- Instrumentation and automation setup

6. Testing, Validation, and Commissioning

No turnkey project is complete without system testing. Activities include:

- Leak testing

- Flow tests

- Load and performance trials

- PLC/HMI configuration

7. Documentation and Regulatory Compliance

Turnkey project contractors provide all necessary documentation for regulatory compliance, which includes:

- As-built drawings

- Operation and Maintenance (O&M) manuals

- Compliance certificates

- Safety checklists

Types of Turnkey Project

Depending on the industry and purpose, turnkey project can be categorized into the following types:

1. Industrial Turnkey Project

These include the setup of manufacturing plants, warehouses, and packaging lines. Everything from machinery installation to safety systems is included.

2. Infrastructure Turnkey Project

These involve the construction of roads, bridges, railways, and public buildings. Government bodies often prefer turnkey project for such developments due to single-point accountability.

3. Water and Wastewater Turnkey Projects

From water treatment plants to sewage pumping stations, turnkey project ensure that the systems are tested and ready for municipal or industrial operation.

4. Energy Sector Turnkey Project

These include solar farms, thermal power plants, and renewable energy facilities. Clients benefit from fully functional systems ready to generate and distribute power.

5. Commercial Turnkey Project

Shopping malls, office spaces, and hotels often rely on turnkey project delivery for streamlined construction and fit-out.

Turnkey Project vs. Traditional Projects

| Feature | Turnkey Project | Traditional Projects |

|---|---|---|

| Management | Single vendor handles all aspects | Multiple vendors and subcontractors |

| Risk | Mostly on contractor | Shared or client-heavy |

| Cost Control | High, with fixed-price contracts | Medium, often has overruns |

| Timeline | Defined with milestones | Flexible, prone to delays |

| Client Involvement | Minimal | High |

In traditional project models, the client must coordinate with architects, consultants, engineers, and multiple contractors. With turnkey project, this coordination burden is eliminated.

Role of Technology in Turnkey Project

Modern turnkey projects rely heavily on technology for enhanced accuracy, safety, and performance.

1. BIM (Building Information Modelling)

Used in construction-related turnkey project to simulate project execution in 3D, BIM reduces errors and improves collaboration.

2. PLC and SCADA Integration

For industrial turnkey projects, programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems ensure automation, monitoring, and control.

3. IoT-Enabled Systems

Smart sensors and remote monitoring tools are increasingly used in water and energy turnkey projects to ensure real-time performance tracking.

4. AI-Based Predictive Maintenance

In post-commissioning support, AI tools help turnkey project providers offer predictive maintenance for equipment, reducing downtime and costs.

Global Trends in Turnkey Projects

1. Demand for Smart Infrastructure

Cities across the globe are investing in smart roads, smart water, and smart energy. These initiatives are powered by turnkey projects with integrated technologies.

2. Rise of Green Buildings and LEED Certification

Sustainable construction practices are a key focus. Turnkey projects are increasingly aligned with green building codes, carbon-neutral designs, and LEED certifications.

3. Expansion in Developing Economies

Emerging markets in Asia, Africa, and Latin America are adopting turnkey projects for rapid industrialization, urbanization, and infrastructure development.

Post-Project Support in Turnkey Projects

Reliable turnkey project partners offer robust post-handover support, including:

- Annual Maintenance Contracts (AMC)

- On-Site Troubleshooting Services

- Remote Monitoring

- Replacement Parts Supply

- Performance Upgrades

FLOMEK Singapore, for example, offers comprehensive support contracts for all their executed turnkey projects, ensuring that clients experience continued operational excellence.

Common Mistakes in Turnkey Projects and How to Avoid Them

1. Inadequate Requirement Definition

Failing to clearly define requirements can result in costly change requests. Ensure you communicate expectations clearly in the turnkey project scope.

2. Ignoring Regulatory Approvals

Missing out on necessary permits can halt the project. Your turnkey project provider should handle this proactively.

3. Overlooking Site Conditions

Surprises like soil instability or utility access issues can affect delivery. Always request a thorough site survey as part of your turnkey project plan.

4. Choosing Low-Cost Over Quality

While price matters, low-cost vendors may compromise on quality. Always select a turnkey project contractor with proven credentials.

How FLOMEK Singapore Delivers High-Quality Turnkey Projects

FLOMEK Singapore is a leading name in executing advanced turnkey projects for industrial clients. With decades of engineering experience, our team ensures:

- Complete design & build services

- Skid-mounted systems tailored for each application

- PLC & SCADA integration for smart control

- ISO-compliant quality standards

- On-time and on-budget delivery

Whether it’s a chemical dosing system, a water filtration plant, or a complex process skid, FLOMEK ensures each turnkey project meets stringent quality and performance benchmarks.

Environmental and Sustainability Considerations in Turnkey Projects

Sustainability has become a major consideration across all industries. Clients today demand not just efficient and cost-effective turnkey projects, but also environmentally responsible solutions.

1. Energy-Efficient Designs

Modern turnkey projects incorporate:

- Low-energy equipment

- Heat recovery systems

- Smart lighting and power optimization

These innovations reduce carbon footprints and improve long-term operational savings.

2. Waste Reduction

Turnkey project teams often utilize modular and prefabricated components to reduce on-site construction waste. Efficient waste management protocols, recycling plans, and use of eco-friendly materials are now standard in sustainable turnkey projects.

3. Water Management

In water-intensive industries, turnkey projects often integrate water recycling systems, rainwater harvesting, and effluent treatment solutions to align with green building norms.

4. LEED Certification and Green Ratings

Leading turnkey project providers help clients achieve environmental certifications such as:

- LEED (Leadership in Energy and Environmental Design)

- Green Mark Certification (in Singapore)

- ISO 14001 Environmental Management

These factors contribute to long-term sustainability and improved ESG (Environmental, Social, Governance) ratings for clients.

Client Checklist Before Starting a Turnkey Project

Before embarking on a turnkey project, it’s essential for clients to prepare effectively. Here’s a pre-project checklist:

✅ Define Clear Objectives

Establish your core project goals—capacity, output, compliance needs, and expected ROI. A well-defined outcome simplifies the execution of turnkey projects.

✅ Allocate a Realistic Budget

Even though turnkey projects offer fixed pricing, it’s wise to include contingency funds for unforeseen approvals, delays, or additional scopes.

✅ Conduct Site Assessments

Soil tests, topography surveys, and utility availability reports are crucial before breaking ground. Your turnkey project partner can assist with this phase.

✅ Legal and Regulatory Readiness

Check if the turnkey project needs:

- Government permits

- Environmental clearances

- Import/export licenses

A competent partner will help navigate local and international compliance.

✅ Choose a Proven Contractor

Partner with a company like FLOMEK Singapore that has experience handling complex turnkey projects in your industry.

Global Success Stories in Turnkey Projects

🚧 Infrastructure: Metro Rail Project in India

A leading engineering firm completed a 100-km metro rail line using the turnkey project model—covering station design, civil construction, signaling systems, and electrification.

🏭 Manufacturing: Car Assembly Plant in Eastern Europe

An automotive giant set up a fully operational manufacturing unit through a turnkey project. The contractor delivered the entire assembly line, testing equipment, and automation within 14 months.

💧 Water: Desalination Plant in the Middle East

This massive turnkey project converted seawater into potable water for over 1 million people, using advanced RO (Reverse Osmosis) and energy recovery technologies.

🏢 Commercial: High-Rise Green Building in Singapore

Using a turnkey project approach, a high-rise was built to Green Mark Platinum standards—complete with solar panels, smart HVAC systems, and vertical gardens.

These real-world examples show the power of turnkey projects in delivering exceptional results across diverse domains.

Turnkey Project Contract Structures Explained

A strong contract is the foundation of a successful turnkey project. Here’s how contracts are typically structured:

1. Lump-Sum Turnkey (LSTK)

This is the most common model. The client pays a fixed amount for the entire turnkey project, regardless of the actual cost incurred by the contractor.

Benefits:

- Predictable cost

- Minimum client risk

- Fixed completion date

2. Engineering, Procurement, Construction (EPC)

While similar to turnkey, EPC may involve post-delivery operations handled separately. Some clients prefer EPC over pure turnkey projects to retain flexibility.

3. BOT (Build-Operate-Transfer)

This model is often used in public infrastructure. The turnkey project provider operates the facility for a set period before transferring ownership back to the client or government.

4. BOOT (Build-Own-Operate-Transfer)

Similar to BOT but includes ownership by the contractor during the operational phase. Common in energy and utilities turnkey projects.

Role of Project Management in Turnkey Projects

Strong project management ensures the smooth execution of all phases of turnkey projects.

🔹 Project Scheduling and Gantt Charts

A master schedule is created that maps every phase—from design to handover. Tracking tools ensure every milestone of the turnkey project is monitored.

🔹 Resource Allocation

From skilled engineers to specialized machinery, turnkey projects require precise resource planning to avoid bottlenecks.

🔹 Risk Assessment and Mitigation

Professional turnkey project teams anticipate risks such as material delays, regulatory issues, or labor strikes—and prepare action plans in advance.

🔹 Client Reporting and Updates

Weekly or bi-weekly updates, site reports, dashboards, and stakeholder meetings keep the client fully informed throughout the turnkey project.

Customization in Turnkey Projects

While turnkey projects are designed for fast deployment, they also allow room for customization.

Examples:

- Pharmaceutical Industry: Specific cleanroom classifications, HEPA filtration, and GMP compliance

- Chemical Plants: Tailored dosing skid sizes, explosion-proof panels

- Food & Beverage: Stainless steel construction for hygiene, CIP (Clean-In-Place) systems

With partners like FLOMEK, you can request customized P&IDs, control logic, or even IoT integration tailored to your operational workflows—all within the scope of a turnkey project.

Turnkey Projects in Singapore: A Growing Trend

Singapore’s demand for turnkey projects is increasing in:

- Urban infrastructure: MRT expansions, public housing

- Water sector: NEWater facilities, desalination

- Green energy: Rooftop solar and EV infrastructure

- Healthcare: Turnkey clinics and hospitals

Government support, high regulatory standards, and a tech-savvy workforce make Singapore an ideal environment for successful turnkey projects.

Final Insights: Why Turnkey Projects Are the Future

- Speed: Faster delivery timelines compared to traditional project methods.

- Simplicity: One vendor, one contract, one responsibility.

- Scalability: Suitable for small modular units or large-scale plants.

- Control: Predictable cost, timeline, and performance metrics.

- Trust: Established providers like FLOMEK Singapore bring credibility and proven success.

In a competitive market, investing in turnkey projects gives companies the agility to launch faster, comply better, and scale smoother—with zero guesswork.

The business world is rapidly moving toward streamlined, efficient, and low-risk project execution models—and turnkey projects are at the heart of this transformation. By offering end-to-end solutions, single-point accountability, and operational readiness, turnkey projects deliver value across industries.

Whether you’re in water treatment, infrastructure, manufacturing, or energy, partnering with an experienced and reliable provider like FLOMEK Singapore ensures that your turnkey project is delivered to the highest standards.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply