Dosing skid manufacturer Singapore – Best 2025

Introduction to Dosing Skid Manufacturer Singapore

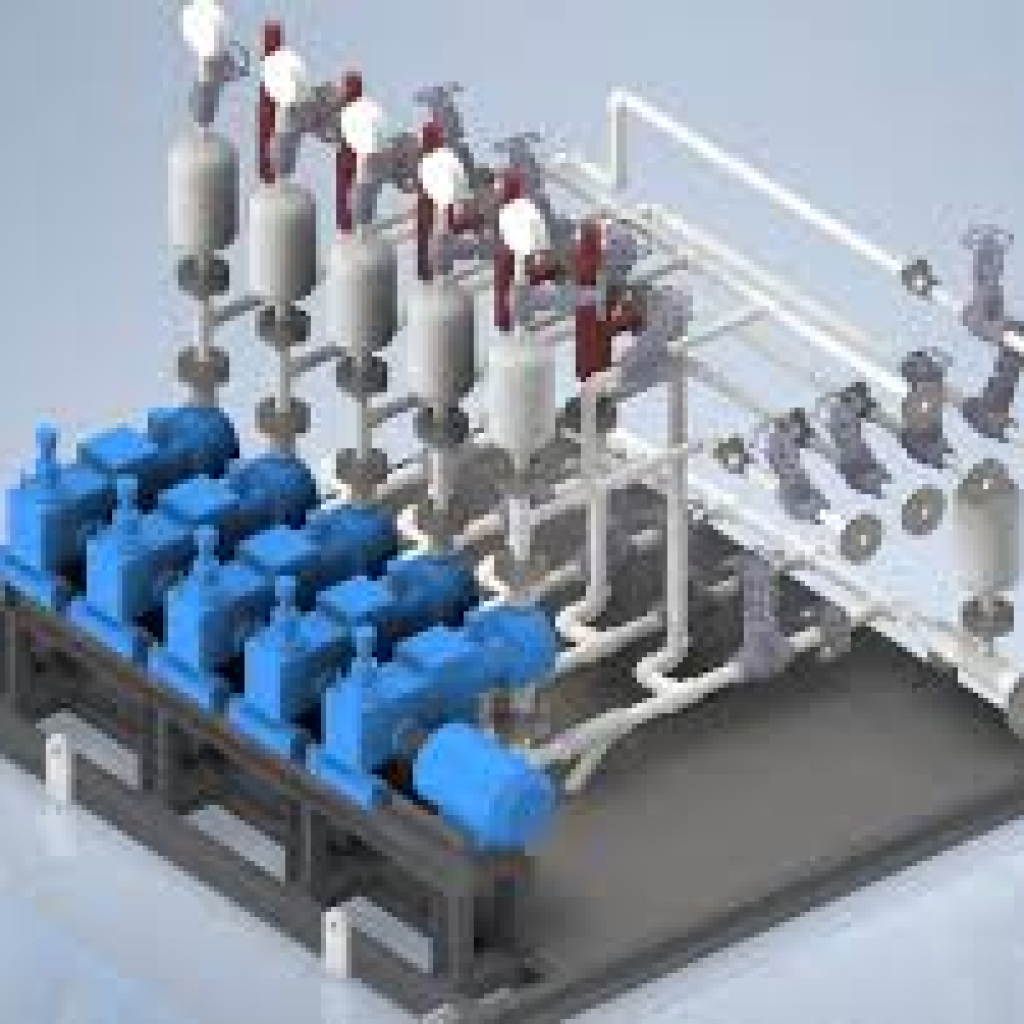

When it comes to precision chemical dosing and efficient fluid handling, selecting a reputable dosing skid manufacturer Singapore is paramount. A dosing skid is a pre-assembled and integrated system designed to accurately inject chemicals, additives, or fluids into a process stream. These systems are essential in industries such as water treatment, chemical processing, pharmaceuticals, and food & beverage production.

As Singapore continues to position itself as a global hub for industrial innovation and manufacturing, the demand for advanced dosing skid solutions is rapidly growing. A reliable dosing skid manufacturer Singapore offers tailored, high-quality skid systems that meet the stringent requirements of local and international industries.

Understanding the Role of a Dosing Skid Manufacturer in Singapore

A professional dosing skid manufacturer Singapore plays a crucial role in designing, fabricating, and delivering custom dosing skid packages. These manufacturers specialize in integrating pumps, piping, instrumentation, and control systems into compact and modular units. Their expertise ensures that each dosing skid is engineered to provide accurate dosing rates, ease of maintenance, and operational safety.

Singapore-based dosing skid manufacturers understand the local market’s unique needs and regulatory environment, enabling them to deliver compliant and efficient solutions. Whether it is a chemical dosing skid for water treatment or a pharmaceutical dosing skid requiring sterile conditions, the dosing skid manufacturer Singapore delivers reliable products tailored to your application.

Types of Dosing Skids Manufactured by Dosing Skid Manufacturer Singapore

The versatility of dosing skid systems is reflected in the range of types offered by a leading dosing skid manufacturer Singapore:

1. Chemical Dosing Skids

Chemical dosing skids are used to inject precise quantities of chemicals into water streams, process lines, or reactors. These are widely used in wastewater treatment plants, cooling towers, and industrial processes to ensure proper chemical balance and regulatory compliance.

2. Water Treatment Dosing Skids

In water and wastewater treatment, dosing skids provide accurate dosing of chlorine, acids, alkalis, and other treatment chemicals. A trusted dosing skid manufacturer Singapore designs these systems to withstand harsh chemicals and continuous operation.

3. Pharmaceutical Dosing Skids

Pharmaceutical applications require high-precision dosing systems that comply with stringent hygiene and safety standards. Manufacturers in Singapore offer dosing skids with advanced control features and materials suitable for sterile environments.

4. Customized Dosing Skid Solutions

Every industrial process is unique, and a quality dosing skid manufacturer Singapore provides customized skid solutions designed to meet specific flow rates, chemical types, and process conditions. Customization includes skid size, material selection, and integration with existing control systems.

Core Components of Dosing Skids from a Dosing Skid Manufacturer Singapore

Understanding the critical components of dosing skids helps appreciate the expertise involved in manufacturing these systems:

- Dosing Pumps: The heart of the dosing skid, responsible for accurate chemical injection. Common pump types include diaphragm pumps, peristaltic pumps, and metering pumps.

- Piping and Tubing: Designed with chemical-resistant materials like PVC, PVDF, or stainless steel to ensure durability and prevent corrosion.

- Control Systems: Modern dosing skids feature programmable logic controllers (PLCs) or microprocessor-based controllers for precise dosing control and automation.

- Safety Devices: Pressure relief valves, alarms, and flow meters are incorporated for safe and reliable operation.

A professional dosing skid manufacturer Singapore sources premium components to ensure reliability and longevity.

Advantages of Choosing a Local Dosing Skid Manufacturer Singapore

Selecting a local dosing skid manufacturer Singapore offers several distinct advantages:

- Shorter Delivery Time: Proximity allows for faster fabrication, testing, and delivery.

- Local Compliance: Familiarity with Singapore’s regulatory standards guarantees compliant skid designs.

- Customization: Close collaboration enables tailor-made solutions suited to your process.

- After-Sales Support: On-site service, maintenance, and troubleshooting are more accessible.

- Cost Efficiency: Reduced logistics and import duties help lower overall costs.

Technological Innovations by Dosing Skid Manufacturer Singapore

Singapore’s leading dosing skid manufacturers integrate cutting-edge technology to improve performance and user experience:

- Automation and PLC Integration: Enables real-time monitoring, automated dosing schedules, and remote operation.

- Remote Monitoring: Using IoT and cloud connectivity for preventive maintenance and process optimization.

- Smart Dosing Systems: Advanced sensors adjust dosing rates based on process feedback for optimal chemical usage.

Applications of Dosing Skids Manufactured in Singapore

Dosing skids manufactured in Singapore find applications across diverse industries:

- Water & Wastewater Treatment: For disinfectant dosing and pH control.

- Chemical Processing: Precise addition of catalysts, inhibitors, or reactants.

- Food & Beverage: Adding preservatives or flavorings with high accuracy.

- Pharmaceuticals: Sterile chemical dosing in drug manufacturing processes.

How to Choose the Right Dosing Skid Manufacturer Singapore

Choosing the right manufacturer involves evaluating:

- Experience: Years in dosing skid design and manufacturing.

- Quality Standards: Certifications and adherence to international standards.

- Customization Capabilities: Ability to tailor skids per your requirements.

- After-Sales Support: Maintenance, repair, and technical assistance availability.

- Customer Reviews: Feedback and case studies indicating reliability.

Maintenance and Support by Dosing Skid Manufacturer Singapore

Reliable dosing skid manufacturers provide comprehensive maintenance plans and after-sales service, which include:

- Scheduled inspections

- Calibration of dosing pumps

- Replacement of worn parts

- Emergency repair services

Proper maintenance ensures longevity and consistent dosing performance.

Why Trust a Dosing Skid Manufacturer Singapore?

Singapore-based dosing skid manufacturers stand out due to:

- Highly Skilled Workforce: Engineers and technicians trained in the latest technologies.

- Robust Infrastructure: State-of-the-art fabrication facilities.

- Strict Quality Control: Ensuring every dosing skid meets client specifications and safety requirements.

The Role of a Dosing Skid Manufacturer Singapore in Industrial Automation

In today’s fast-evolving industrial landscape, automation plays a pivotal role in enhancing productivity and precision. A reliable dosing skid manufacturer Singapore integrates automation technology within dosing skid systems to streamline operations. Through programmable logic controllers (PLCs), human-machine interfaces (HMIs), and advanced sensors, dosing skids can perform automated dosing with minimal human intervention, ensuring consistent chemical feed rates and improving safety standards.

By collaborating with a seasoned dosing skid manufacturer Singapore, companies can upgrade their existing chemical dosing infrastructure to smart, automated systems that not only reduce operational errors but also allow remote monitoring and data logging for compliance purposes.

Materials and Engineering Excellence from a Dosing Skid Manufacturer Singapore

The quality and longevity of a dosing skid largely depend on the materials and engineering precision applied during manufacturing. The best dosing skid manufacturer Singapore emphasizes the use of corrosion-resistant materials such as stainless steel (SS316), high-density polyethylene (HDPE), or specialty plastics like PVDF for piping and skid frames to withstand harsh chemicals and outdoor environmental conditions.

Besides materials, engineering excellence means designing skid layouts that optimize space, facilitate ease of maintenance, and comply with safety regulations. The layout includes clear labeling, ergonomic valve placement, and adequate safety shields around moving parts. Such attention to detail can only be achieved by an experienced dosing skid manufacturer Singapore with a proven track record.

Customization Services Offered by Dosing Skid Manufacturer Singapore

One of the most significant advantages of working with a dosing skid manufacturer Singapore is their ability to offer tailored solutions. Unlike off-the-shelf products, customized dosing skids are built to suit specific client requirements such as:

- Flow rate capacity (from milliliters per hour to several hundred liters per hour)

- Chemical compatibility and safety standards

- Integration with existing plant automation systems

- Modular designs for easy expansion

- Specific skid footprint to fit limited spaces

This flexibility ensures your dosing skid performs optimally within your process parameters, enhancing efficiency and reducing downtime.

Quality Assurance and Testing by a Dosing Skid Manufacturer Singapore

Quality assurance is paramount when it comes to dosing skid manufacturing. A reputed dosing skid manufacturer Singapore implements rigorous testing protocols, including hydrostatic pressure tests, leak tests, electrical safety checks, and performance validation. The manufacturer ensures that every dosing skid leaving their facility operates flawlessly under specified conditions.

Furthermore, they provide detailed documentation and certifications for quality compliance, which is essential for industries like pharmaceuticals or water treatment where regulatory audits are common.

Environmental Compliance and Sustainability in Dosing Skid Manufacturing

Singapore is known for its strong commitment to environmental sustainability. Leading dosing skid manufacturer Singapore companies align their production processes with green manufacturing principles. This includes:

- Minimizing waste during fabrication

- Using eco-friendly materials where possible

- Designing dosing skids that optimize chemical usage, reducing environmental impact

- Ensuring that skid components are recyclable or reusable

Choosing a sustainable dosing skid manufacturer Singapore not only supports environmental stewardship but can also improve your corporate social responsibility profile.

Industry Standards Followed by Dosing Skid Manufacturer Singapore

To maintain international competitiveness and ensure safety, dosing skid manufacturers in Singapore strictly follow industry standards such as:

- ISO 9001 for Quality Management Systems

- API (American Petroleum Institute) standards for chemical processing equipment

- ASME (American Society of Mechanical Engineers) codes for pressure vessels and piping

- Local Singapore Environmental and Safety regulations

Compliance with these standards is a key consideration when selecting your dosing skid manufacturer Singapore.

Training and Technical Support from Dosing Skid Manufacturer Singapore

A professional dosing skid manufacturer Singapore doesn’t just deliver the equipment; they also provide comprehensive training for your operational and maintenance teams. Proper training ensures that your staff can operate the dosing skid safely and efficiently, reducing operational risks.

Technical support also includes:

- Troubleshooting assistance

- Spare parts availability

- Upgrades and retrofits

- Emergency repair services

Choosing a manufacturer who offers robust support services can save you significant downtime and operational costs.

Cost Considerations When Choosing a Dosing Skid Manufacturer Singapore

When evaluating pricing, it’s important to consider the total cost of ownership rather than just the upfront price. A reputed dosing skid manufacturer Singapore provides:

- Transparent cost estimates without hidden charges

- Long-term durability reducing replacement costs

- Efficient designs minimizing chemical waste and energy consumption

- Maintenance packages to prevent costly breakdowns

Investing in a quality dosing skid from a trusted Singapore manufacturer will ultimately deliver superior value.

Future Trends in Dosing Skid Manufacturing in Singapore

The dosing skid manufacturer Singapore industry is continuously evolving. Key trends shaping the future include:

- Increased use of IoT for predictive maintenance

- Integration of AI algorithms for optimized dosing schedules

- Development of compact, modular skids for easy relocation

- Use of advanced materials for greater chemical resistance and lightweight structures

Staying ahead of these trends ensures your dosing skid system remains efficient and future-proof.

Innovations in Control Systems by Dosing Skid Manufacturer Singapore

The modern dosing skid manufacturer Singapore places a strong emphasis on advanced control systems to enhance precision and operational efficiency. Integration of digital controllers, programmable logic controllers (PLC), and remote monitoring systems allows real-time adjustments and data logging. These innovations reduce chemical wastage, optimize dosing accuracy, and help clients comply with strict environmental regulations.

With the increasing adoption of Industry 4.0, the dosing skid manufacturer Singapore often equips their systems with IoT connectivity, enabling remote diagnostics and predictive maintenance — minimizing downtime and service costs.

Safety Protocols Embedded by Dosing Skid Manufacturer Singapore

Safety is a critical concern in dosing skid fabrication and operation. Leading dosing skid manufacturer Singapore companies design their systems with multiple layers of safety features such as:

- Emergency shutoff valves

- Leak detection sensors

- Pressure relief devices

- Explosion-proof electrical components for hazardous areas

These safety protocols not only protect personnel but also safeguard expensive equipment and the environment from chemical spills and accidents.

The Economic Impact of Partnering with a Local Dosing Skid Manufacturer Singapore

Choosing a local dosing skid manufacturer Singapore contributes positively to Singapore’s economy while benefiting your project budget. Local manufacturing eliminates costly import duties and reduces shipping delays. Moreover, local manufacturers can offer flexible payment terms, onsite consultation, and faster turnaround times compared to overseas suppliers.

Additionally, investing in a Singapore-based dosing skid manufacturer Singapore means supporting local jobs, innovation, and sustainable industrial growth within the country.

Material Selection Strategies by a Dosing Skid Manufacturer Singapore

Material selection is vital for the durability and functionality of dosing skids. A trusted dosing skid manufacturer Singapore carefully evaluates the chemical properties of the fluids being dosed and environmental conditions to choose appropriate materials. Common selections include:

- Stainless Steel (SS316/SS304): For excellent corrosion resistance and mechanical strength.

- PVC and CPVC: Cost-effective for moderate chemical resistance.

- PVDF and PTFE: For aggressive chemicals requiring high chemical inertness.

- Carbon Steel with Protective Coatings: For structural components with less chemical contact.

This strategic selection process ensures longevity and safety of the dosing skid system.

Environmental Applications: How Dosing Skid Manufacturer Singapore Supports Green Initiatives

Singapore’s commitment to sustainability drives many industries to adopt greener technologies. A progressive dosing skid manufacturer Singapore contributes by designing eco-friendly systems that minimize chemical consumption and waste. Their dosing skids ensure accurate chemical dosing that prevents overdosing, reducing harmful discharge into the environment.

In water treatment plants, these dosing skids help maintain water quality and reduce pollutant levels efficiently, supporting Singapore’s environmental protection goals.

The Importance of Precision in Chemical Dosing: Expertise of Dosing Skid Manufacturer Singapore

Chemical dosing requires exact volumes to avoid process inefficiencies or safety hazards. The expertise of a reliable dosing skid manufacturer Singapore lies in engineering systems with high-accuracy pumps and flow meters that achieve consistent dosing, even at low flow rates.

By ensuring precision, the dosing skid helps maintain product quality, optimizes chemical usage, and lowers operating costs, proving invaluable in pharmaceutical, food & beverage, and industrial processes.

Challenges Faced by Dosing Skid Manufacturer Singapore and Their Solutions

Despite advancements, dosing skid manufacturing faces challenges such as:

- Corrosive Chemical Handling: Overcome by selecting advanced materials and coatings.

- Compact Space Constraints: Solved by modular and customizable skid designs.

- Complex Process Integration: Addressed through flexible control system options and communication protocols.

- Maintenance Accessibility: Achieved via ergonomic skid layouts and easily replaceable components.

The top dosing skid manufacturer Singapore continuously innovates to resolve these challenges efficiently.

Comparing Local vs. International Dosing Skid Manufacturers: Why Singapore Leads

While international suppliers may offer competitive pricing, partnering with a local dosing skid manufacturer Singapore provides distinct benefits:

- Better understanding of local regulations and client needs

- Faster delivery and installation support

- Easier communication and project management due to proximity

- Compliance with Singapore’s strict environmental and safety standards

This combination ensures projects are executed smoothly with high-quality outcomes.

Dosing Skid Manufacturer Singapore and Industry 4.0: Smart Skid Solutions

The digital transformation era has reached dosing skid manufacturing in Singapore. Leading manufacturers now provide “smart dosing skid” solutions that include:

- Integrated sensors for flow, pressure, and chemical concentration

- Cloud-based data storage and analytics

- Remote control and alarm notifications via mobile apps

- Predictive maintenance alerts to avoid unexpected failures

Such smart skids improve plant efficiency, reduce labor costs, and support data-driven decision-making.

How a Dosing Skid Manufacturer Singapore Ensures Compliance with Health and Safety Standards

Health and safety regulations in Singapore are stringent, especially for chemical handling equipment. The dosing skid manufacturer Singapore ensures all skids comply with:

- Workplace Safety and Health (WSH) guidelines

- Singapore Standard SS 620 (chemical handling)

- Fire safety codes

- Electrical safety standards (e.g., IECEx for hazardous locations)

These compliance measures ensure safe operation and legal conformity, minimizing risks for operators and owners.

Testimonials and Client Experiences with Dosing Skid Manufacturer Singapore

Many industrial clients in Singapore praise their local dosing skid manufacturer Singapore for:

- Timely project delivery

- Excellent customization and design expertise

- Responsive after-sales support

- High reliability and performance of dosing skid systems

Such testimonials underscore the value and trust built by Singapore manufacturers in the industrial community.

Why Regular Upgrades with Your Dosing Skid Manufacturer Singapore Matter

Technology and process demands evolve. A proactive dosing skid manufacturer Singapore offers upgrade packages for existing skid systems, including:

- Replacing outdated control units with latest PLC models

- Adding remote monitoring capabilities

- Upgrading pump technologies for better efficiency

- Incorporating new safety devices as per updated regulations

These upgrades extend the life and improve the safety and efficiency of your dosing skid investment.

Conclusion: Partner with a Leading Dosing Skid Manufacturer Singapore for Optimal Solutions

In summary, choosing a dosing skid manufacturer Singapore ensures access to expertly engineered, durable, and compliant dosing skid systems. Their in-depth local knowledge, innovative technologies, and comprehensive support services provide unmatched value to businesses across multiple sectors.

For tailored chemical dosing solutions that meet your process demands and regulatory requirements, connect with a trusted dosing skid manufacturer Singapore today.

Frequently Asked Questions (FAQs) about Dosing Skid Manufacturer Singapore

Q1: How long does it take to get a dosing skid manufactured in Singapore?

Lead times vary based on complexity but typically range from 4 to 12 weeks with a reliable dosing skid manufacturer Singapore.

Q2: Can dosing skids be customized for hazardous chemical dosing?

Yes, expert dosing skid manufacturer Singapore companies design skids with explosion-proof components and safety interlocks for hazardous applications.

Q3: Do dosing skid manufacturers in Singapore provide installation services?

Most reputable dosing skid manufacturer Singapore firms offer end-to-end services, including installation and commissioning.

Q4: What certifications should I look for in a dosing skid manufacturer?

ISO 9001 certification and compliance with local safety and environmental regulations are essential.

Contact Your Trusted Dosing Skid Manufacturer Singapore Today

Finding the right dosing skid manufacturer Singapore ensures your chemical dosing processes run smoothly, efficiently, and safely. With Singapore’s reputation for high manufacturing standards, advanced technology, and excellent support services, partnering with a local manufacturer is the smart choice.

Contact a leading dosing skid manufacturer Singapore now to discuss your requirements, get a personalized quote, and benefit from top-notch design and engineering services.

Conclusion

Selecting a reputable dosing skid manufacturer Singapore is key to ensuring efficient, reliable, and compliant chemical dosing solutions for your operations. Whether you require standard or customized dosing skid systems, Singapore manufacturers deliver quality and innovation backed by strong local expertise and service support.

Contact your trusted dosing skid manufacturer Singapore today to discuss your project requirements and get a tailored quote.

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply