Custom chemical dosing skid Singapore – Best 2025

Custom Chemical Dosing Skid Singapore – Precision-Engineered by FLOMEK

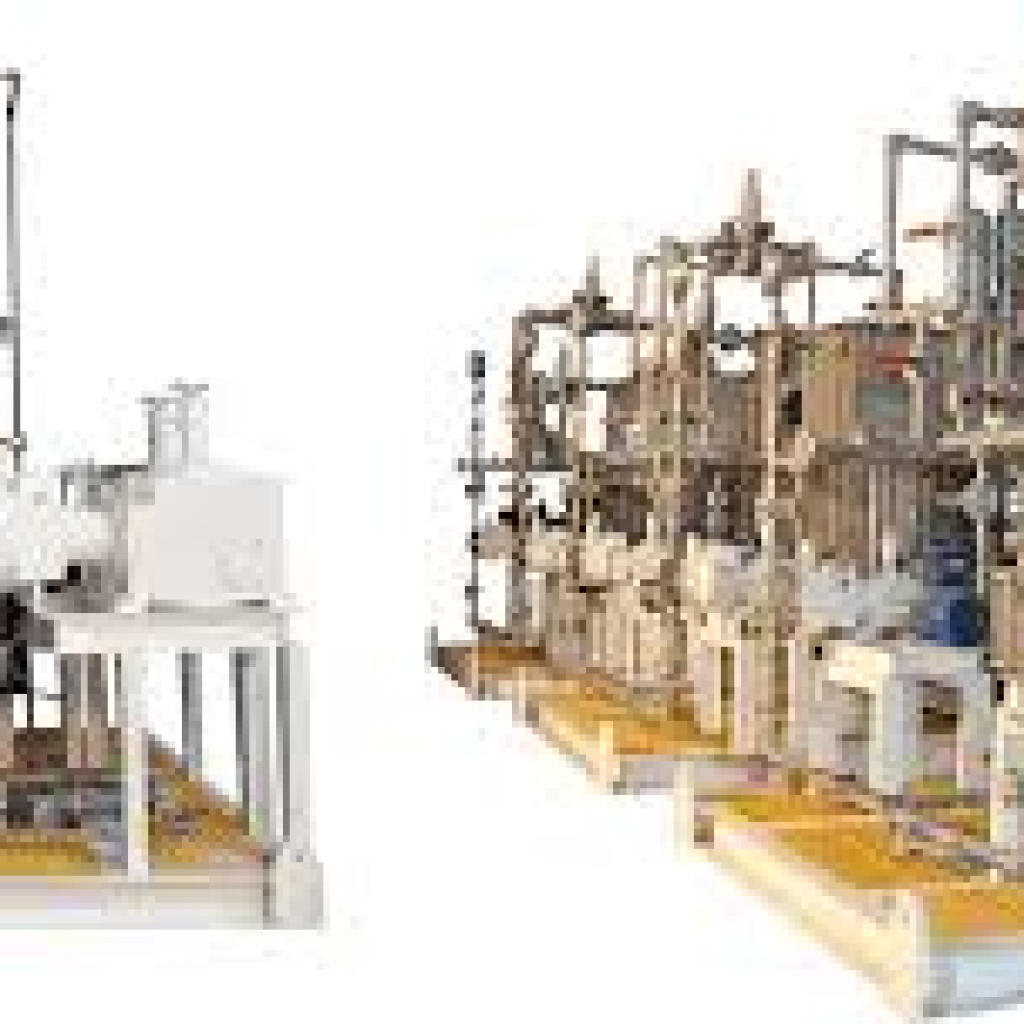

In Singapore’s fast-paced industrial environment, the demand for precision, safety, and reliability in fluid handling systems has never been higher. Among the most critical equipment in chemical processing and water treatment is the custom chemical dosing skid — a compact, integrated solution that ensures the accurate and safe delivery of chemicals in various processes.

If you’re searching for a custom chemical dosing skid in Singapore, FLOMEK Singapore stands as one of the most trusted names in the market. With extensive engineering experience, local manufacturing capabilities, and deep knowledge of industry regulations, FLOMEK delivers turnkey chemical skid systems that meet and exceed client expectations.

✅ What Is a Custom Chemical Dosing Skid?

A chemical dosing skid is a prefabricated modular system designed to store, dose, and deliver precise quantities of chemicals into pipelines or process equipment. These skids are “custom” when engineered specifically for a client’s operational requirements — including the type Custom chemical dosing skid Singapore of chemical, dosing rate, flow control, pressure needs, and automation level.

In Singapore, where industries like water treatment, pharmaceuticals, oil & gas, and petrochemicals are held to stringent standards, custom chemical dosing skids ensure compliance while optimizing process efficiency.

✅ Why Choose a Custom Chemical Dosing Skid in Singapore?

Standard systems may not always address specific operational or safety concerns, especially in complex or regulated applications. Here’s why Singapore industries are opting for custom chemical dosing skids from FLOMEK:

1. Precision Engineering

Singapore’s water and wastewater treatment plants require ultra-accurate chemical dosing to comply with PUB and NEA guidelines. FLOMEK’s skids are engineered with Custom chemical dosing skid Singapore dosing accuracies within ±1%, supporting exact pH correction, disinfection, and chemical balancing.

2. Compact Footprint

With limited space in urban industrial facilities, FLOMEK designs custom skids that are space-efficient without compromising functionality. Floor-mounted, wall-mounted, or containerized options are available.

3. Compliance with Singapore Standards

From NEA’s hazardous chemical handling guidelines to WSHA (Workplace Safety and Health Act) and SCDF requirements, all FLOMEK custom chemical dosing skids are engineered to comply with local laws and certifications.

4. Local Engineering & Support

With a full-fledged local team, FLOMEK ensures quicker delivery, faster servicing, Custom chemical dosing skid Singapore and immediate response in case of breakdowns — a distinct advantage for Singapore-based clients.

✅ Applications Across Singapore’s Industrial Landscape

FLOMEK’s custom chemical dosing skids are used across a variety of sectors:

➤ Water & Wastewater Treatment Plants

From chlorine and alum dosing to pH balancing, FLOMEK skids play a crucial role in public and private water systems across Singapore.

➤ Oil & Gas

Precise chemical injection in upstream and downstream operations, Custom chemical dosing skid Singapore including corrosion inhibitors, antifoaming agents, and demulsifiers.

➤ Pharmaceutical & Life Sciences

Highly sterile and accurate dosing systems for ultrapure water systems and batch manufacturing.

➤ Semiconductor Manufacturing

FLOMEK designs dosing skids for corrosive and ultra-clean chemicals used in wafer production.

➤ Food & Beverage

Safe chemical dosing for CIP (Cleaning in Place), pH control, and food-safe chemical delivery.

✅ Key Features of FLOMEK’s Custom Dosing Skids

Every custom chemical dosing skid in Singapore fabricated by FLOMEK includes:

| Feature | Description |

|---|---|

| Dosing Pump | Diaphragm, peristaltic, or Custom chemical dosing skid Singapore plunger pumps based on fluid characteristics |

| Tank & Piping | Corrosion-resistant SS316, HDPE, or PVDF tanks with level sensors |

| Control Panel | PLC-based system for local or SCADA control |

| Flow Meters | Ultrasonic, magnetic, or mechanical depending on application |

| Safety Features | Pressure relief valves, rupture discs, bund containment |

| Skid Frame | SS304/316 or powder-coated steel base, vibration-free mounting |

✅ Integrated Control Systems – Automation Ready

With the rise of Industry 4.0, automation Custom chemical dosing skid Singapore is no longer optional. FLOMEK’s custom chemical dosing skid Singapore systems integrate seamlessly with:

- SCADA / DCS systems

- PLC controllers (Allen-Bradley, Siemens, Schneider, etc.)

- Remote monitoring and IIoT sensors

- Emergency stop, SMS/email alert modules

This makes your chemical dosing system smart, responsive, and easy to maintain.

✅ Designed for Safety and Sustainability

Chemical dosing involves hazardous substances. FLOMEK prioritizes safety by including:

- Double-wall tanks

- ATEX/IECEx certified components for explosive zones

- Leak detection systems

- Eye-wash stations integrated into the skid (optional)

- Chemical containment trays

Moreover, with the Singapore Custom chemical dosing skid Singapore Green Plan 2030, FLOMEK skids are designed to minimize chemical waste and energy use, contributing to sustainable operations.

✅ Why FLOMEK Is Singapore’s Top Choice for Custom Skid Design

FLOMEK Singapore has earned its reputation as a leading manufacturer of custom chemical dosing skids by consistently delivering systems that are:

- Engineered to the highest standards

- Easy to install and maintain

- Fully documented for audits and regulatory submissions

- Supported by an experienced local team

FLOMEK also offers full-cycle support — from design, 3D modeling, and fabrication to installation, testing, commissioning, and post-sales service.

✅ Trusted by Leading Industries in Singapore

FLOMEK’s systems are already deployed at:

- PUB Water Reclamation Plants

- Petrochemical hubs in Jurong Island

- Food factories in Tuas

- Semiconductor parks in Woodlands and Kallang

Each project reinforces our commitment to delivering reliable custom chemical dosing skid solutions in Singapore.

Engineering the Future: Smart Custom Chemical Dosing Skid Singapore Solutions by FLOMEK

In modern-day Singapore, process plants, water treatment systems, and chemical industries must manage complex Custom chemical dosing skid Singapore challenges — from chemical compatibility and safety regulations to space limitations and automation needs. The solution? A custom chemical dosing skid Singapore clients can trust for high precision, safety, and seamless integration.

FLOMEK Singapore is redefining how custom dosing systems are built. With a relentless commitment to innovation, compliance, and efficiency, FLOMEK offers engineered-to-order chemical dosing skids tailored to the unique requirements of Singapore’s high-demand industries.

✅ Design-Driven Solutions for Complex Dosing Challenges

One-size-fits-all simply doesn’t work for chemical dosing. FLOMEK approaches each project with a design-first philosophy, using the following principles:

1. Chemical Compatibility Analysis

FLOMEK performs a detailed assessment of the chemicals being dosed — whether it’s hydrochloric acid, sodium hypochlorite, ferric chloride, polymers, Custom chemical dosing skid Singapore or flocculants — and selects materials like:

- PVDF and PTFE for corrosive acids

- HDPE or PP tanks for alkaline compounds

- SS316L for cleanroom environments

This ensures long-term integrity and zero cross-contamination.

2. Dynamic Flow Control

Many applications in Singapore require variable flow dosing — from ultra-low microdosing to batch-volume injections. FLOMEK designs systems with:

- Variable frequency drives (VFDs) for pump speed control

- Servo or stepper motor dosing systems

- Feedback loops using inline sensors

This ensures real-time precision even during process fluctuations.

3. Redundancy and Fail-Safe Mechanisms

No plant can afford chemical underdosing or overdosing. FLOMEK integrates:

- Dual pump configurations (duty/standby)

- Automated switchover systems

- Pressure sensors and emergency cutoffs

- UPS-based control systems for blackout scenarios

✅ Regulatory Compliance – Built for Singapore Standards

In Singapore, working with chemicals means facing one of the most rigorous regulatory environments in Southeast Asia. FLOMEK ensures every custom chemical dosing skid Singapore clients receive adheres to these key standards:

⚖️ NEA Guidelines

- Proper bunding for chemical containment

- Double-wall piping Custom chemical dosing skid Singapore and venting

- Clear chemical labeling and safety signage

🧯 SCDF Fire Safety Requirements

- Use of explosion-proof motors (Ex d rated) in hazardous zones

- Integration with fire suppression systems

- Compliance with Fire Safety Certificate (FSC) protocols

🔧 PUB Water Quality and Dosing Requirements

- Inline chemical concentration monitoring

- Alarm thresholds for under/overdosing

- Emergency neutralization tanks

📋 HAZOP and Risk Assessment

FLOMEK supports clients with HAZOP documentation Custom chemical dosing skid Singapore and process hazard analysis (PHA) reports as part of custom project delivery.

✅ Real-World Customization Scenarios in Singapore

Let’s explore how custom-designed skids serve different industries across Singapore:

➤ Case: Jurong Island – Petrochemical Skid Package

Challenge:

Corrosion inhibitors needed for multiple points in a high-pressure crude oil system.

FLOMEK Solution:

- Multi-channel dosing skid with six separate pumps

- Corrosion-resistant PVDF and SS316 piping

- Integrated remote monitoring via Modbus to DCS

- Weatherproof outdoor-rated enclosure with ATEX certification

Impact:

Reduced downtime by 37% and enabled centralized chemical management across 3 kilometers of pipeline.

➤ Case: PUB Water Reclamation Plant

Challenge:

Precise alum and polymer dosing to treat varying influent quality at high flow rates.

FLOMEK Solution:

- Dual-compartment chemical storage tank (1,000L)

- Magnetic drive dosing pumps with pulsing flow control

- PLC interface with SCADA link to PUB central operations

Impact:

Dosing error reduced to under 0.5%, ensuring Custom chemical dosing skid Singapore continuous compliance with PUB effluent standards.

➤ Case: Tuas Industrial Food Factory

Challenge:

CIP system needed pH adjustment skid for neutralization before discharge.

FLOMEK Solution:

- Compact floor-mounted skid with Custom chemical dosing skid Singapore integrated neutralization tank

- Dosing based on real-time pH sensor feedback

- Chemical-resistant plastic enclosure to suit food hygiene area

Impact:

Helped client avoid NEA non-compliance penalties while automating CIP waste treatment.

✅ PLC & SCADA Integration – Automating Dosing Intelligence

FLOMEK’s custom chemical dosing skids in Singapore are not just mechanical solutions — they’re also smart systems. By integrating PLC, SCADA, and IIoT, we offer:

- Live monitoring of chemical consumption

- Auto-adjustment based on flow Custom chemical dosing skid Singapore meters or water quality

- SMS/email alerts for fault conditions

- Historical data logs for audits and preventive maintenance

Compatible with leading automation systems:

- Siemens

- Allen-Bradley (Rockwell)

- Schneider Electric

- Omron

- Delta

✅ Compact, Modular, and Scalable

Whether you’re working in a rooftop treatment plant in CBD or an offshore vessel docked in Keppel Bay, space is at a premium. FLOMEK’s skid packages are:

- Modular for easy future upgrades

- Skid-mounted or containerized for plug-and-play use

- Stackable with minimal footprint

- Built with pre-wired, pre-piped configurations Custom chemical dosing skid Singapore to minimize site work

This means reduced site installation time and zero compromise on operational safety.

✅ Services Included with Every FLOMEK Skid Project

Here’s what every FLOMEK custom chemical dosing skid Singapore client receives:

| Service | Description |

|---|---|

| Site Study & Consultation | On-site engineering visit and data gathering |

| 3D Design & Simulation | Full CAD drawings and flow modeling |

| Factory Acceptance Testing (FAT) | Skid tested under actual load conditions before delivery |

| Onsite Commissioning | Local team for installation and commissioning |

| Training & Handover | Operator and maintenance staff training |

| After-Sales Service | Maintenance, spares, emergency response |

✅ Ready for Your Industry Needs?

From standard acid dosing systems to fully containerized mobile chemical injection stations, FLOMEK has delivered over 150 skid packages across Singapore to date — all engineered to suit exact process, space, safety, and automation needs.

✅ Ready to Transform Your Process?

Don’t settle for generic chemical solutions. Work with the leading custom chemical dosing skid manufacturer in Singapore. FLOMEK combines engineering excellence with deep local expertise to deliver systems that work from day one — and keep working for years to come.

1. Introduction to Custom Chemical Dosing Skids in Singapore

- What is a chemical dosing skid?

- Why customization is critical in Custom chemical dosing skid Singapore dosing applications

- Growth of chemical dosing technology in Singapore

- Keywords: Custom chemical dosing skid Singapore, chemical dosing solutions, customized skids

2. Why Choose a Custom Chemical Dosing Skid in Singapore? (700 words)

- Tailored solutions for local industry needs

- Singapore’s strict environmental & safety regulations

- Comparison: Custom vs standard dosing skids

- FLOMEK’s advantage in local customization

3. Core Components of a Custom Chemical Dosing Skid

- Chemical dosing pumps

- Storage tanks

- Flow meters & pressure Custom chemical dosing skid Singapore gauges

- Mixing units

- PLC & automation integration

- Safety valves, injection quills

- Control panels & enclosures

- Keywords repeated: Custom chemical dosing skid Singapore, dosing pumps, PLC system

4. Industries Using Custom Chemical Dosing Skids in Singapore

- Water treatment (municipal and industrial)

- Wastewater treatment plants

- Oil & Gas industry

- Petrochemical plants

- Pharmaceutical & Biotech sectors

- Food & Beverage

- Keywords: Singapore chemical skid, dosing skid Singapore, chemical treatment system

5. Design & Engineering Considerations

- Material compatibility (SS316, PVDF, HDPE, FRP)

- Flow rate, chemical concentration, pH

- Space constraints (compact skids for small facilities)

- Mobile skids vs fixed systems

- Hazard classification (ATEX zones, explosion-proof design)

- Redundancy and safety backups

- Keywords: Custom design chemical skid Singapore, dosing skid safety design

6. Automation & Control System Integration

- Smart skids: Integration with SCADA/PLC

- Real-time monitoring and remote access

- Alarm & emergency shutdown systems

- Data logging and Custom chemical dosing skid Singapore preventive maintenance alerts

- Cloud integration (IIoT readiness)

- Keywords: automated chemical dosing system Singapore, PLC integration dosing skid

7. FLOMEK’s Role as a Custom Skid Manufacturer in Singapore

- In-house design & fabrication team

- Local workshop for fast delivery

- Project references and case studies

- Certifications and compliance (ISO, NEA, PUB)

- Client testimonials from Custom chemical dosing skid Singapore Singapore industries

- Keywords repeated: Custom chemical dosing skid Singapore by FLOMEK, Singapore skid manufacturer, dosing solution provider Singapore

8. Testing, Commissioning & FAT/SAT Services

- Full functional testing

- Factory Acceptance Test (FAT)

- Site Acceptance Custom chemical dosing skid Singapore Test (SAT)

- Documentation and training for operators

- Keywords: custom chemical dosing skid FAT SAT Singapore, commissioning chemical skid

9. Maintenance & After-Sales Support

- Scheduled maintenance programs

- Dosing pump service & calibration

- Spare parts availability

- Troubleshooting & Custom chemical dosing skid Singapore emergency support

- Keywords: Chemical dosing skid maintenance Singapore, pump service, after-sales support FLOMEK

10. Costing & ROI of a Custom Chemical Dosing Skid in Singapore

- Breakdown of Custom chemical dosing skid Singapore cost factors

- Long-term savings vs off-the-shelf units

- How customization Custom chemical dosing skid Singapore improves ROI

- FLOMEK’s competitive pricing & value engineering

11. Case Study: FLOMEK Custom Skid for Singapore Water Plant

- Client background

- Requirements & challenges

- Custom design Custom chemical dosing skid Singapore approach

- Commissioning results

- Long-term performance metrics

- Keywords: Singapore water plant skid, custom chemical dosing solution, FLOMEK Singapore case study

13. Modular Skid vs Containerized Skid System

- Advantages of modular approach

- Containerized chemical dosing stations

- Deployment and mobility benefits

14. Sustainable Dosing: Eco-Friendly Skid Design

- Efficient dosing = minimal waste

- Energy-efficient pump systems

- Reuse of Custom chemical dosing skid Singapore wash water

- Green materials and low-carbon fabrication

15. Why FLOMEK Is the Best Choice for Custom Chemical Dosing Skid in Singapore

- Experienced engineering team

- Local references across sectors

- Full lifecycle support (design to maintenance)

- Rapid response in emergencies

- Strong partnerships with top pump brands (Grundfos, SEKO, etc.)

16. FAQs on Custom Chemical Dosing Skid Singapore

- How long does it take to deliver a custom skid?

- Can I customize based on chemical type?

- What are the space requirements?

- How often should it be maintained?

17. Get in Touch – FLOMEK Custom Chemical Dosing Skid Experts in Singapore

- CTA with contact info

- Free consultation offer

- Site visit scheduling

Ensuring Safety and Compliance in Custom Chemical Dosing Skids in Singapore

In Singapore’s industrial landscape, the integration of custom chemical dosing skids is pivotal for maintaining operational efficiency and adhering to stringent safety standards. Companies like FLOMEK Singapore specialize in designing and manufacturing these systems, ensuring they meet the specific needs of various industries while complying with local regulations.

✅ Adherence to Singapore’s Regulatory Framework

Singapore’s regulatory bodies, including the National Environment Agency (NEA) and the Singapore Civil Defence Force (SCDF), impose strict guidelines on the handling and storage of hazardous chemicals. FLOMEK’s custom chemical dosing skids are engineered to align with these regulations:

- NEA Guidelines: Emphasize safe storage, handling, and disposal of chemicals, particularly chlorine-containing substances used in water treatment.

- SCDF Fire Safety Code: Mandates fire safety measures in buildings storing hazardous materials, ensuring that dosing skids are equipped with appropriate fire suppression systems.

By integrating these regulatory requirements into the design and operation of dosing skids, FLOMEK ensures that clients maintain compliance and operate safely.

✅ Advanced Technologies in Chemical Dosing Skids

Modern chemical dosing skids incorporate advanced technologies to enhance precision, safety, and efficiency:

1. Smart Control Systems

- Programmable Logic Controllers (PLCs): Allow for automated control of dosing processes, reducing human error and ensuring consistent chemical delivery.

- Human-Machine Interfaces (HMIs): Provide real-time monitoring and control, enabling operators to adjust parameters as needed.

2. Remote Monitoring and Diagnostics

- Internet of Things (IoT) Integration: Facilitates remote monitoring of system performance, allowing for predictive maintenance and minimizing downtime.

- Data Logging: Enables tracking of chemical usage and system performance over time, aiding in compliance reporting and process optimization.

3. Safety Features

- Leak Detection Systems: Monitor for chemical leaks, triggering alarms and automatic shutdowns to prevent accidents.

- Secondary Containment: Includes bunded areas to contain spills, protecting personnel and the environment.

These technologies not only improve operational efficiency but also enhance safety and compliance with Singapore’s stringent regulations.

✅ Industry-Specific Applications of Custom Chemical Dosing Skids

FLOMEK’s custom chemical dosing skids are tailored to meet the unique requirements of various industries in Singapore:

1. Water and Wastewater Treatment

- Application: Precise dosing of disinfectants, coagulants, and pH adjusters to ensure water quality.

- Compliance: Adheres to NEA and PUB standards for water treatment processes.

2. Oil and Gas Industry

- Application: Injection of corrosion inhibitors and demulsifiers to protect pipelines and equipment.

- Compliance: Designed to meet SCDF fire safety codes and hazardous area classifications.

3. Pharmaceutical Manufacturing

- Application: Accurate dosing of active pharmaceutical ingredients (APIs) and cleaning agents.

- Compliance: Ensures adherence to Good Manufacturing Practices (GMP) and NEA guidelines.

4. Food and Beverage Processing

- Application: Controlled dosing of sanitizers and additives to maintain product quality and safety.

- Compliance: Meets NEA food safety standards and SCDF fire safety requirements.

By customizing dosing skids to the specific needs of each industry, FLOMEK ensures optimal performance and regulatory compliance.

✅ Customization and Scalability

FLOMEK’s approach to custom chemical dosing skids emphasizes flexibility and scalability:

- Modular Design: Allows for easy expansion or modification to accommodate changing process requirements.

- Material Selection: Offers a range of materials, such as stainless steel or high-density polyethylene (HDPE), based on chemical compatibility and environmental conditions.

- Space Optimization: Designs skids to fit within space constraints, a critical consideration in Singapore’s dense industrial environments.

This customization ensures that clients receive a solution tailored to their specific operational needs.

✅ Maintenance and Support Services

To ensure the longevity and reliability of chemical dosing skids, FLOMEK provides comprehensive maintenance and support services:

- Preventive Maintenance Programs: Regular inspections and servicing to prevent equipment failures.

- Training: Educates client personnel on safe operation and maintenance procedures.

- Spare Parts Availability: Ensures quick replacement of components to minimize downtime.

These services contribute to sustained operational efficiency and compliance with safety regulations.

✅ Conclusion

In Singapore’s regulated industrial sectors, custom chemical dosing skids play a crucial role in ensuring process efficiency and safety. FLOMEK Singapore’s expertise in designing and manufacturing these systems, coupled with their commitment to compliance and innovation, makes them a trusted partner for industries ranging from water treatment to pharmaceuticals.

For more information or to discuss your specific requirements, contact FLOMEK Singapore today.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply