Pump skid repair Singapore – Best 2025

Pump Skid Repair Singapore – Professional Solutions by Experts

Introduction to Pump Skid Repair in Singapore

In the dynamic industrial environment of Singapore, the need for efficient, reliable, and well-maintained equipment is critical. One such essential component in various industries is the pump skid. These integrated systems are the backbone of fluid handling processes across water treatment plants, oil & gas refineries, pharmaceutical production, and chemical industries. Over time, these systems can degrade, resulting in inefficiency, system failures, and safety risks. That’s where Pump Skid Repair Singapore services come into play.

Pump Skid Repair Singapore is a vital service that ensures the long-term performance and safety of integrated pumping systems. Whether dealing with corrosion, motor failures, leakages, or instrumentation malfunctions, timely repairs can save your business from costly downtime and operational disruptions.

In this comprehensive guide, we will explore the full landscape of Pump Skid Repair Singapore, from common repair needs, benefits, and processes to why companies like FLOMEK Singapore are leading the way in delivering expert repair services across industries.

What is a Pump Skid?

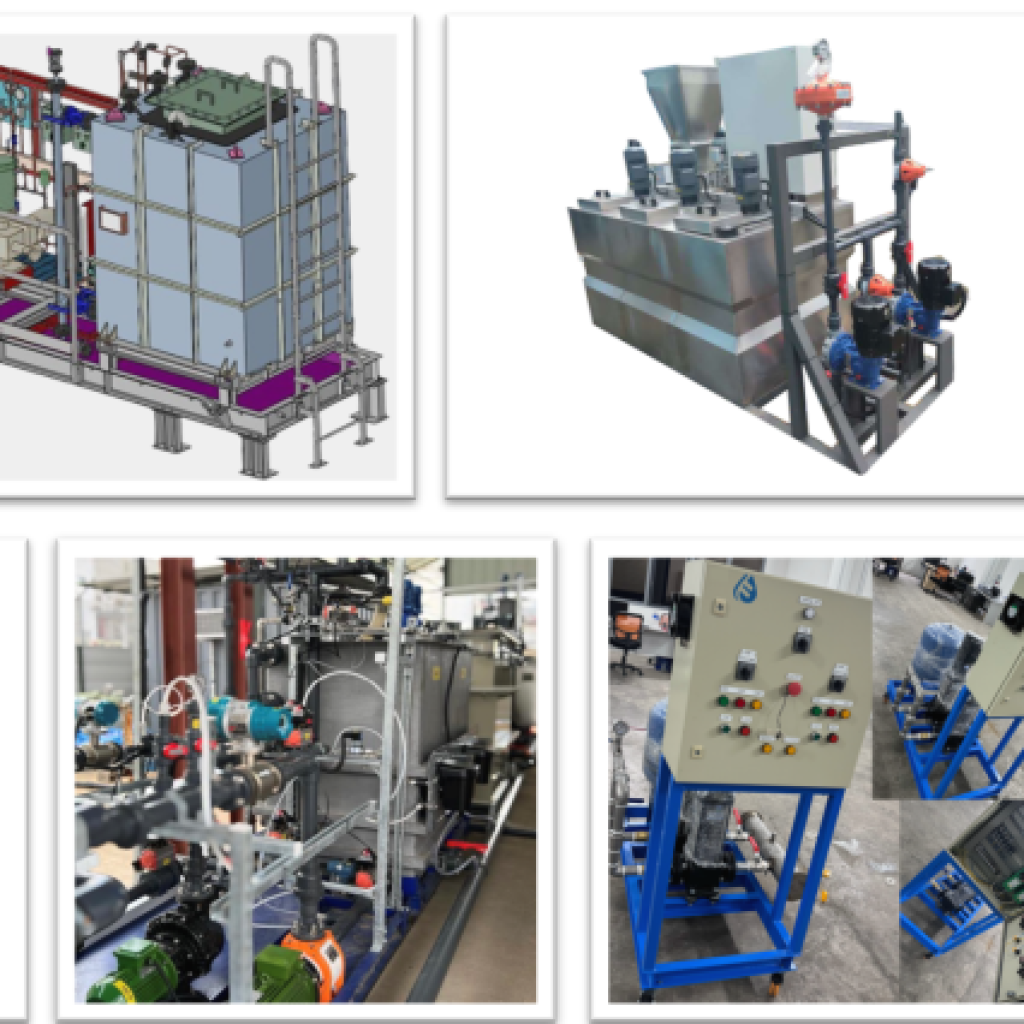

A pump skid is a pre-assembled and tested system that includes pumps, piping, valves, pressure gauges, instrumentation, and controls—all mounted on a base frame or skid. Pump skids are used in:

- Water and wastewater treatment plants

- Oil and gas facilities

- Food and beverage processing units

- Chemical dosing and injection systems

- HVAC systems

- Industrial manufacturing plants

These modular systems are designed for efficiency, mobility, and customization. However, regular usage and environmental stress cause wear and tear over time, leading to the need for professional Pump Skid Repair Singapore.

Why Pump Skid Repair is Essential

1. Prevent Unplanned Downtime

Regular maintenance can delay breakdowns, but wear is inevitable. Pump Skid Repair Singapore services address issues proactively, helping companies avoid unexpected failures.

2. Cost-Efficiency

Early detection and repair reduce the chances of complete system overhauls. Investing in Pump Skid Repair Singapore services is far more economical than replacing an entire pump skid.

3. Safety Compliance

Faulty skids can pose environmental and safety hazards. Repairing and certifying skids ensures your facility meets Singapore’s strict workplace and environmental safety regulations.

4. Enhanced Performance

A well-repaired pump skid performs close to its original efficiency. Professional Pump Skid Repair Singapore restores pump output, pressure control, and fluid accuracy.

Common Problems Requiring Pump Skid Repair

Understanding what goes wrong is key to timely repair. The most common issues seen in Pump Skid Repair Singapore include:

- Seal leakage due to worn-out mechanical seals or gaskets

- Corrosion of piping or pump housing

- Bearing failure in motors and pumps

- Vibration and misalignment causing excessive wear

- Instrumentation failure in flow meters, pressure gauges, or PLCs

- Electrical issues in motor control panels

- Clogging or sediment buildup in valves or pipelines

By engaging a skilled Pump Skid Repair Singapore provider, these issues can be diagnosed and rectified promptly.

FLOMEK – Your Expert Partner in Pump Skid Repair Singapore

FLOMEK Singapore Private Limited (FSPL) has been a trusted name in pump system design, repair, and maintenance across Singapore. With years of industry experience, we offer:

- 24/7 emergency repair services

- On-site and off-site repair options

- In-house testing and diagnostics

- Genuine spare parts

- Re-engineering & retrofit services

- Expertise in all major pump brands

- Skid rebuilding and performance enhancement

Choosing FLOMEK for your Pump Skid Repair Singapore needs ensures reliable, efficient, and cost-effective service from certified professionals.

The Repair Process: Step-by-Step

Here’s what to expect when you hire a professional Pump Skid Repair Singapore team:

1. Site Inspection & Fault Diagnosis

Technicians visit your site to inspect and assess the condition of the pump skid. A full diagnosis is conducted using modern tools like vibration analyzers, thermal imaging, and laser alignment.

2. Repair Proposal & Cost Estimate

After fault detection, the Pump Skid Repair Singapore team submits a detailed proposal with the scope of work, spare parts list, downtime estimation, and quotation.

3. Dismantling & Transport (if needed)

Depending on the complexity, repairs can be conducted on-site or in a workshop. Skids needing overhaul are safely dismantled and transported to the workshop.

4. Mechanical & Electrical Repairs

Pump refurbishment, seal replacement, impeller balancing, rewinding of motors, replacement of corroded piping, valve servicing, and panel rewiring are carried out.

5. Testing & Validation

Each repaired skid is hydro-tested, performance-tested, and validated before reinstallation to ensure it meets operational benchmarks.

6. Documentation & Reporting

Comprehensive service reports, inspection checklists, and photos are provided for your maintenance records and audit compliance.

Industries Benefiting from Pump Skid Repair Singapore

Industries that depend on Pump Skid Repair Singapore include:

- Water Treatment Plants

Ensuring clean, uninterrupted water flow is critical. - Chemical Processing

Accurate dosing and fluid transfer are essential to safety and quality. - Oil & Gas Sector

High-pressure pump skids must operate reliably under extreme conditions. - Pharmaceutical Manufacturing

Skid performance affects batch accuracy and production timelines. - Food & Beverage

Ensures hygiene, precision, and continuous processing.

Custom Pump Skid Repair Singapore Solutions

Each skid is unique. That’s why Pump Skid Repair Singapore services are customized based on:

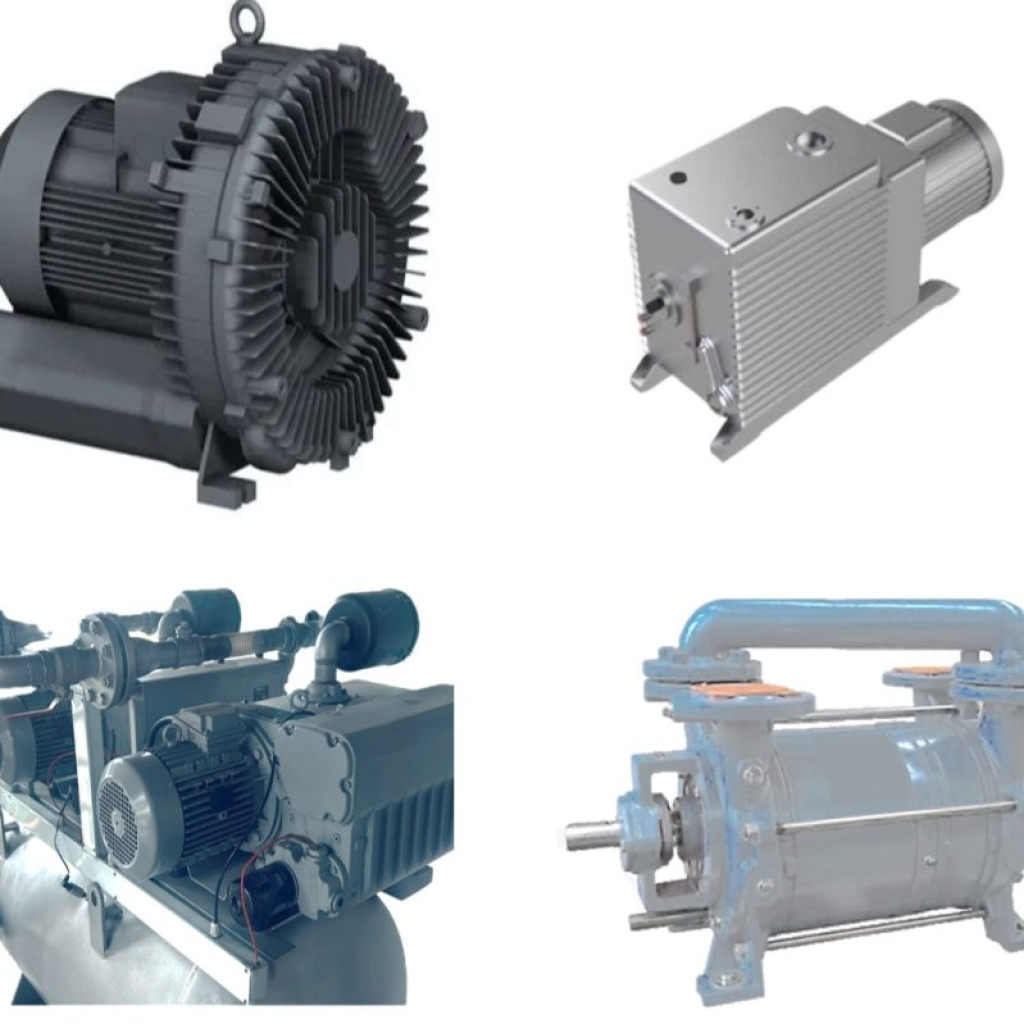

- Pump type (centrifugal, diaphragm, gear, screw, etc.)

- Application pressure and flow range

- Skid size and mounting design

- Material compatibility (SS316, PVC, FRP, etc.)

- Instrumentation and control type (manual, PLC, HMI)

FLOMEK’s Pump Skid Repair Singapore technicians analyze all factors before proposing an optimal repair solution.

Preventive Maintenance After Repair

Once a skid is repaired, preventive maintenance ensures its longevity. Post-repair support from FLOMEK includes:

- Routine inspections

- Vibration & noise monitoring

- Seal replacement schedules

- Flow and pressure calibration

- Electrical insulation testing

- Spare parts stocking

This service keeps your Pump Skid Repair Singapore investment delivering maximum ROI.

Pump Skid Refurbishment & Upgrade Services

Sometimes, repairing is not enough. Pump Skid Repair Singapore also includes:

- Retrofit of outdated pumps with energy-efficient models

- Upgrading control systems to smart PLCs

- Repainting & anti-corrosion coating

- Replacing manual valves with actuated types

- Adding instrumentation for flow/pressure monitoring

Upgrading extends equipment life and boosts performance—cost-effectively.

Why Choose FLOMEK for Pump Skid Repair Singapore?

Here’s why businesses prefer FLOMEK for Pump Skid Repair Singapore:

- Local expertise with decades of service experience

- Certified engineers and technicians

- Full compliance with PUB, NEA, SCDF, and MOM standards

- Quick turnaround with reliable results

- Competitive pricing

- Zero compromise on quality or safety

- On-call support throughout Singapore

We don’t just repair—we enhance reliability and performance.

Customer Testimonials

“FLOMEK’s Pump Skid Repair Singapore team restored our dosing skid to full capacity within two days. Excellent workmanship!”

– Engineering Manager, Water Treatment Plant, Tuas

“Their on-site repair helped us avoid shutdown. Highly recommend for Pump Skid Repair Singapore.”

– Maintenance Head, Petrochemical Plant, Jurong Island

“Professional service, transparent pricing, and reliable support from FLOMEK’s Pump Skid Repair Singapore crew.”

– Facilities Manager, Pharmaceutical Company, Woodlands

FAQs – Pump Skid Repair Singapore

Q1: How often should pump skids be serviced in Singapore?

A: At least every 6 months or after 3,000 operating hours, depending on application load.

Q2: Is Pump Skid Repair Singapore expensive?

A: It’s significantly cheaper than system replacement and helps extend equipment life.

Q3: Can you repair skids from international OEMs?

A: Yes, FLOMEK’s team handles skids from Grundfos, Wilo, Ebara, SEEPEX, Milton Roy, and more.

Q4: Do you provide repair documentation?

A: Yes, all Pump Skid Repair Singapore services come with detailed reports and test results.

Q5: Do you offer AMCs for pump skids?

A: Yes, Annual Maintenance Contracts (AMCs) are available for long-term service support.

In-Depth Guide: Pump Skid Components and How They Affect Repair Needs

Understanding the internal workings of a pump skid system is essential to appreciating the complexity and importance of Pump Skid Repair Singapore services. A pump skid is more than just a motor and pump on a frame. It’s an integrated system of mechanical and electrical components, each critical to the overall performance.

Core Components Requiring Pump Skid Repair in Singapore

1. Base Frame and Mounting Assembly

The structural steel frame or skid is the backbone of the system. Over time, this can suffer from corrosion, misalignment, or vibration cracks, all of which require specialized Pump Skid Repair Singapore techniques such as welding, re-alignment, or anti-vibration retrofitting.

2. Pumps and Motors

These are the heart of any skid system. Repairs can include motor rewinding, impeller balancing, seal replacement, shaft alignment, and bearing servicing—all central to Pump Skid Repair Singapore.

3. Piping and Valves

Piping systems often require leak detection, replacement of corroded sections, or flushing to remove scaling. Valve seat wear, leakage, or actuator failures are addressed in professional Pump Skid Repair Singapore jobs.

4. Instrumentation & Control Systems

Flow meters, pressure transmitters, and level indicators are prone to drift or failure over time. PLCs and HMIs may need firmware upgrades or reprogramming. Skilled Pump Skid Repair Singapore providers like FLOMEK handle electrical and automation troubleshooting efficiently.

How Environmental Factors in Singapore Affect Pump Skid Lifespan

Singapore’s tropical climate poses unique challenges to industrial equipment. Pump Skid Repair Singapore providers must consider these environmental stressors during repair planning:

- Humidity and condensation can corrode metallic parts and short electrical circuits.

- High ambient temperatures cause overheating and reduce motor insulation life.

- Urban pollution and dust affect air filters, cooling fans, and exposed instrument panels.

- Coastal salt air, especially in marine applications, accelerates stainless steel corrosion.

All these require climate-adapted materials, coatings, and designs during Pump Skid Repair Singapore, especially in critical industries such as marine, water treatment, and chemical processing.

On-Site vs. Workshop-Based Pump Skid Repair in Singapore

Different conditions demand different solutions. Here’s how Pump Skid Repair Singapore can be delivered based on customer requirements:

On-Site Pump Skid Repair Singapore

Ideal for minor repairs or when disassembly and transport are not feasible. Benefits include:

- Fast turnaround

- Reduced logistical costs

- Minimal system downtime

- Immediate fault isolation

FLOMEK’s mobile service units are equipped to provide on-site Pump Skid Repair Singapore with diagnostics, tools, and certified technicians.

Off-Site (Workshop-Based) Pump Skid Repair Singapore

When the repair scope involves complete overhaul, sandblasting, painting, or detailed performance testing, skids are transported to the FLOMEK repair facility. Workshop benefits include:

- Full control over repair environment

- Access to heavy-duty tools and testing rigs

- In-depth root cause analysis

- Guaranteed repair quality

Whether on-site or off-site, FLOMEK tailors Pump Skid Repair Singapore to your operational needs.

When Should You Replace Instead of Repair?

Though Pump Skid Repair Singapore is the preferred approach, there are cases when replacement might be more economical:

- The pump or motor has failed repeatedly despite servicing.

- Spare parts are obsolete or no longer available.

- Operational needs have outgrown the current skid capacity.

- Upgrading to energy-efficient technology is more cost-effective.

In such cases, FLOMEK can offer skid redesign and replacement solutions, integrating your existing process requirements into a modern, high-performance system—still under the umbrella of Pump Skid Repair Singapore expertise.

Cost Factors in Pump Skid Repair Singapore

Several elements affect pricing for Pump Skid Repair Singapore:

- Severity of Damage – Minor leaks vs. major component failure

- Part Replacement Requirements – Availability and sourcing of OEM spares

- Labor Hours – Complexity, travel, and manpower needed

- Testing & Commissioning Needs

- Transport & Handling Costs

- Emergency/Urgent Repairs – Off-hour or holiday surcharges

At FLOMEK, our pricing for Pump Skid Repair Singapore is transparent, competitive, and backed by detailed quotations and scope documentation.

Certifications & Standards for Pump Skid Repair in Singapore

When hiring a service for Pump Skid Repair Singapore, it is essential to ensure the repair contractor adheres to relevant standards and certifications, such as:

- ISO 9001:2015 Quality Management Systems

- SS 531 & SS 532 Safety Standards

- IECEx and ATEX compliance for hazardous area equipment

- PUB & NEA approvals for water treatment systems

- BCA or MOM certifications for workplace safety

FLOMEK meets or exceeds all applicable standards in every Pump Skid Repair Singapore project, ensuring compliance and peace of mind for clients.

Emergency Pump Skid Repair Services in Singapore

Downtime is money. That’s why FLOMEK offers 24/7 emergency Pump Skid Repair Singapore for industries that can’t afford delays, such as:

- Water utilities

- Power plants

- Chemical refineries

- Semiconductor factories

Our rapid-response teams arrive equipped for immediate diagnostics, temporary fixes, and action plans for permanent repair. For urgent Pump Skid Repair Singapore, FLOMEK is your best ally.

Value-Added Services Alongside Pump Skid Repair Singapore

When you engage FLOMEK, you get more than repair:

- Condition Monitoring – Regular data-driven insights on pump health

- Spare Parts Management – Planning and stocking critical parts

- Energy Audits – Suggesting upgrades or replacements for power savings

- Root Cause Failure Analysis (RCFA) – Prevent repeat problems

- Training for Plant Teams – Operational best practices after repair

All these services strengthen your investment in Pump Skid Repair Singapore and optimize plant reliability.

The Future of Pump Skid Repair – Smart Diagnostics and Remote Monitoring

As Industry 4.0 progresses, Pump Skid Repair Singapore is evolving. Today’s advanced skids come with:

- IoT-enabled sensors for predictive maintenance

- Remote monitoring dashboards

- AI-driven fault detection

- Smart alerts and mobile notifications

FLOMEK supports and repairs even the most advanced systems, bringing future-ready Pump Skid Repair Singapore services to your doorstep.

1. Signs Your Pump Skid Needs Repair

- Abnormal vibrations or noises

- Drop in system pressure or flow

- Visible leakage or rust

- Overheating motors

- Increased energy consumption

- Frequent tripping of electrical panels

📌 Use the keyword “Pump Skid Repair Singapore” as a solution in each symptom case.

2. Choosing the Right Contractor for Pump Skid Repair Singapore

- What certifications to look for

- Importance of local expertise

- In-house vs outsourced technicians

- Availability of emergency support

- Case studies of successful repair outcomes

3. Case Study: Real Pump Skid Repair Projects in Singapore

- Showcase before-and-after repair

- Highlight industries (e.g., water treatment, pharma, chemicals)

- Include flow rate, pump types, timeline, cost savings

4. Pump Skid Repair Singapore vs. Pump Skid Replacement: Which is Right for You?

- Cost-benefit comparison

- Downtime implications

- Repair ROI vs. new installation ROI

5. 10 Mistakes to Avoid in Pump Skid Maintenance

- Using untrained personnel

- Ignoring early warning signs

- Skipping vibration testing

- Delaying Pump Skid Repair Singapore when needed

6. How to Prepare Your System for a Pump Skid Repair in Singapore

- Safety steps

- Isolation procedures

- Documentation checklist

- Support staff coordination

7. Materials Used in Pump Skid Construction and Their Impact on Repair

- Stainless steel vs. FRP vs. carbon steel

- How material affects lifespan

- Surface treatments and coatings in Singapore’s climate

8. The Role of Predictive Maintenance in Reducing Pump Skid Repair Costs

- Condition monitoring tools

- Flow rate and pressure trend analysis

- Remote monitoring benefits

9. How FLOMEK Leads the Market in Pump Skid Repair Singapore

- In-house capabilities

- Brand partnerships (Grundfos, Ebara, etc.)

- Emergency service model

- Skid re-engineering capabilities

10. Frequently Asked Questions About Pump Skid Repair in Singapore

- How long does a typical repair take?

- What is the warranty for repairs?

- Do you repair both mechanical and electrical systems?

- Can you service imported skid packages?

11. Pump Skid Design Considerations to Minimize Future Repairs

- Smart layout design

- Access to valves/instruments

- Anti-vibration elements

- Efficient draining and flushing ports

12. Annual Maintenance Contracts (AMC) for Pump Skid Repair Singapore

- Benefits of enrolling in AMC

- Sample scope of work

- Predictable budgeting

- How it increases skid life by 30%+

13. Top Pump Brands Serviced in Pump Skid Repair Singapore

- Grundfos, SEEPEX, Ebara, KSB, Wilo, etc.

- Repair parts availability

- Brand-specific service nuances

14. Sustainable and Eco-Friendly Approaches in Pump Skid Repair Singapore

- Use of green coatings and paints

- Recycling components

- Energy-efficient motor upgrades

- Reducing water wastage during testing

15. Emergency Pump Skid Repair in Singapore: What to Do in a Breakdown

- 24/7 hotline numbers

- Immediate isolation steps

- Temporary bypass solutions

- How FLOMEK responds in less than 4 hours

Conclusion – Your Skid, Our Expertise

Your pump skid is essential to your plant’s productivity. Any downtime, inefficiency, or malfunction can severely affect your operations. That’s why Pump Skid Repair Singapore must be entrusted to a partner who understands both your system and your industry.

FLOMEK Singapore has the tools, knowledge, and experience to diagnose, repair, and enhance your pump skid system, giving you lasting performance and reliability.

Final Thoughts – Trust FLOMEK for Pump Skid Repair Singapore

A faulty skid can bring an entire operation to a standstill. That’s why Pump Skid Repair Singapore isn’t just a service—it’s a safeguard for productivity, safety, and profit. With the right expertise, tools, and local support, your repaired skid can serve you reliably for years.

If you’re facing issues with your pump skid or want to schedule preventive maintenance, contact FLOMEK today—the trusted name in Pump Skid Repair Singapore.

Contact Information:

- Website: https://flomek.com

- Email: sales@flomek.com

- Phone: +65 1234 5678

- Address: 123 Industrial Avenue, Singapore 567890

Get in touch with us today to discuss your project or request a quote. Let Flomek help you find the perfect pump solution to keep your operations flowing smoothly. Pump manufacture in yishun

Also Read – Best pump services Pump manufacture in yishun

Copyright © Flomek 2024, All Right Reserved.Designed and Developed by ❤️ Krigo Softwares

Leave A Reply